Dinel RFLS-28 1B Series User manual

Read the instructions published in this manual carefully before using the level meter for the rst time.

Keep the manual in a safe place. The manufacturer reserves the right to implement changes without prior notice.

high-frequency level sensor

RFLS–28

INSTRUCTION MANUAL

1. Basic description.......................................................................................................................5

2. Sensor variants..........................................................................................................................5

3. Dimensional drawing ...............................................................................................................6

4. Installation and putting into operation..................................................................................7

5. Electrical connection.................................................................................................................8

5.1. Type RFLS-28N-_-_-P-_ electrical connection .............................................................8

5.2. Type RFLS-28N-_-_-PD-_ electrical connection...........................................................9

6. Settings elements .................................................................................................................. 11

7. Status indication .................................................................................................................... 12

8. Settings.................................................................................................................................... 13

8.1. Settings using the magnetic pen - RFLS-28_-_-_-P/PD-_ ........................................ 15

8.2. Settings RFLS-28_-_-_-PD-_ using the SSU-1212-AD unit ....................................... 16

8.3. Settings “medium window” mode – media resolution function .......................... 20

9. Mechanical mounting ........................................................................................................... 22

10. Sensor variant with the “PD” output with diagnostics ...................................................... 26

11. Order code.............................................................................................................................. 27

12. Accessories ............................................................................................................................. 28

13. Resilience of O-rings.............................................................................................................. 29

14. Safety, protection, and compatibility .................................................................................. 30

15. Functional safety.................................................................................................................... 30

16. Use, operation, and maintenance ....................................................................................... 30

17. Putting out of operation or disposal ................................................................................... 31

18. General conditions and warranty ........................................................................................ 31

19. Product marking .................................................................................................................... 32

20. Technical parameters............................................................................................................ 33

21. Packing, shipping, and storage............................................................................................. 35

RFLS–28 © Dinel, s.r.o.

4

To ensure the maximum safety of control processes, we have dened the following safety instruc-

tions and information. Each instruction is labelled with the appropriate pictogram.

This symbol informs you about particularly important instructions for installation and opera-

tion of the equipment or dangerous situations that may occur during installation and opera-

tion. Not observing these instructions may cause disturbance, damage, or destruction of the

equipment or may cause injury.

This symbol indicates particularly important device characteristics.

This symbol indicates helpful additional information.

All operations described in this instruction manual must only be carried out by trained

personnelorbyanaccreditedperson.Warrantyandpostwarrantyservicemustbeexclusively

carried out by the manufacturer.

Improper use, installation, or adjustment of the sensor can lead to application failures

(overlling tanks or damage to system components).

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, or for expenses incurred at the time of installation or during the period

of use of the level sensors.

5

© Dinel, s.r.o. RFLS–28

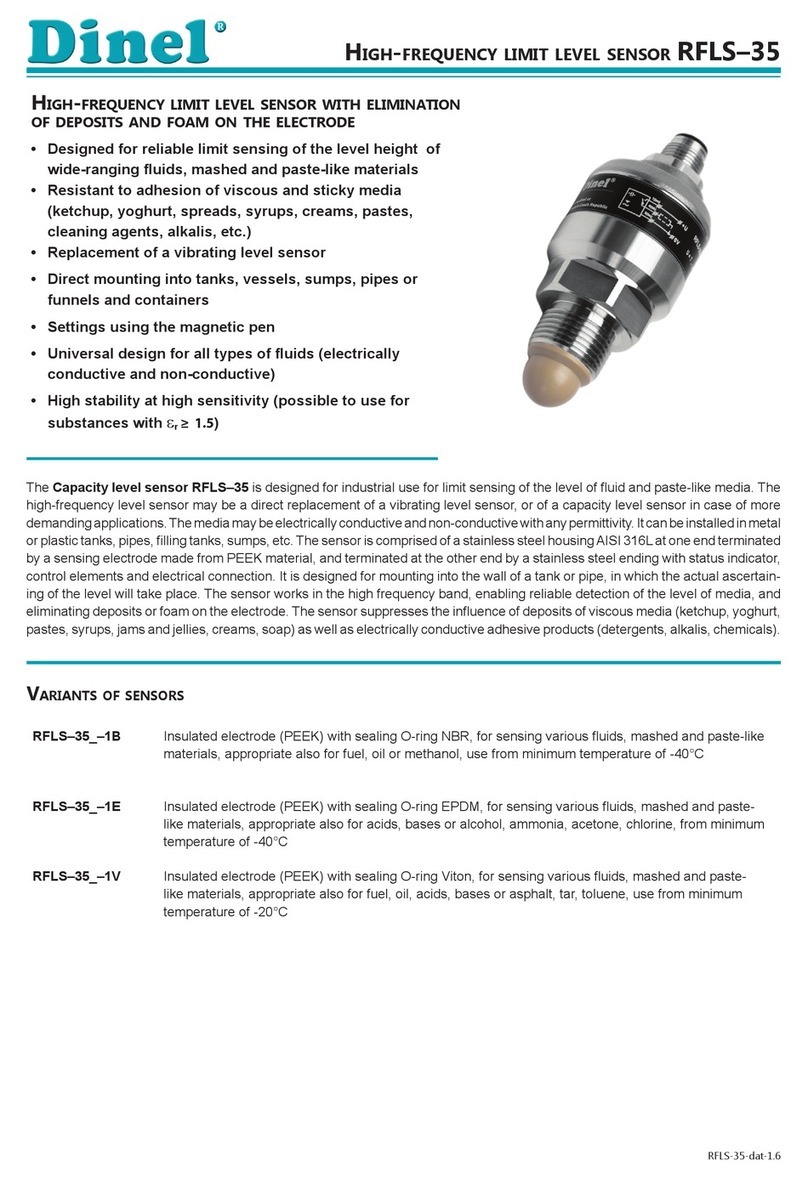

The RFLS–28 high-frequency level sensor is designed for industrial use for limit sensing of liquid

and paste media. The high-frequency level sensor may be a direct replacement for a vibrating level

sensor, or for a capacitive level sensor in the case of more demanding applications. The media may

be electrically conductive or non-conductive with any permittivity. The sensor can be installed in

metal or plastic tanks, lling tanks, sumps, etc.

The RG variant can be installed using the TN-28 extension tube or in a similar way.

The sensor works on the high frequency band, enabling reliable detection of the level of media, and

eliminating deposits or foam on the electrode. The sensor suppresses the inuence of deposits of

viscous media (ketchup, yoghurt, mayonnaise, pâtés, syrups, jams, creams, soap) as well as elec-

trically conductive adhesive products (detergents, lyes, chemicals).

The sensor can be set up by applying a magnetic pen to sensitive spots (variants RFLS-28_-_-_-P/

PD-_) or using the programming wire (variant RFLS-28_-_-_-PD-_). For remote parametrization

using the programmable wire, the special SSU-1212-AD unit is used.

The sensors can be set to perform:

• simple sensing of the presence of the medium (medium/air)

• distinction of the interface between two media (medium/medium), e.g. water/oil

• selective distinction of a specic medium (medium window function), the function can distin-

guish e.g. oil from water and air, or detect only beer foam and ignore beer and air, etc.

The sensor is made from a stainless steel housing at one end terminated by a sensing electrode,

and terminated at the other end and by an enclosure with a status indicator, control elements, and

electrical connection. The setting elements are on the sides of the sensor. The sensors are manu-

factured for use in non-explosive areas only.

VARIANTS

name minimum

temperature type

RFLS–28_–1B from -40°C NBR O-ring, for sensing various liquids, mashed and paste

materials, also appropriate for oil

RFLS–28_–10B from -40°C with protective crown, NBR O-ring, for sensing various liquids,

mashed and paste materials, also appropriate for oil

RFLS–28_–1E from -40°C EPDM O-ring, for sensing various liquids, mashed and paste

materials, also appropriate for acids or bases

RFLS–28_–10E from -40°C With protective crown, EPDM O-ring, for sensing various liquids,

mashed and paste materials, also appropriate for acids or bases

RFLS–28_–1V from -20°C FPM (Viton) O-ring, for sensing various liquids, mashed and paste

materials, also appropriate for oil, acids, bases, or asphalt and tar

RFLS–28_–10V from -20°C

with protective crown, FPM (Viton) O-ring, for sensing various

liquids, mashed and paste materials, also appropriate for oil,

acids, bases, or asphalt and tar

RFLS–28 © Dinel, s.r.o.

6

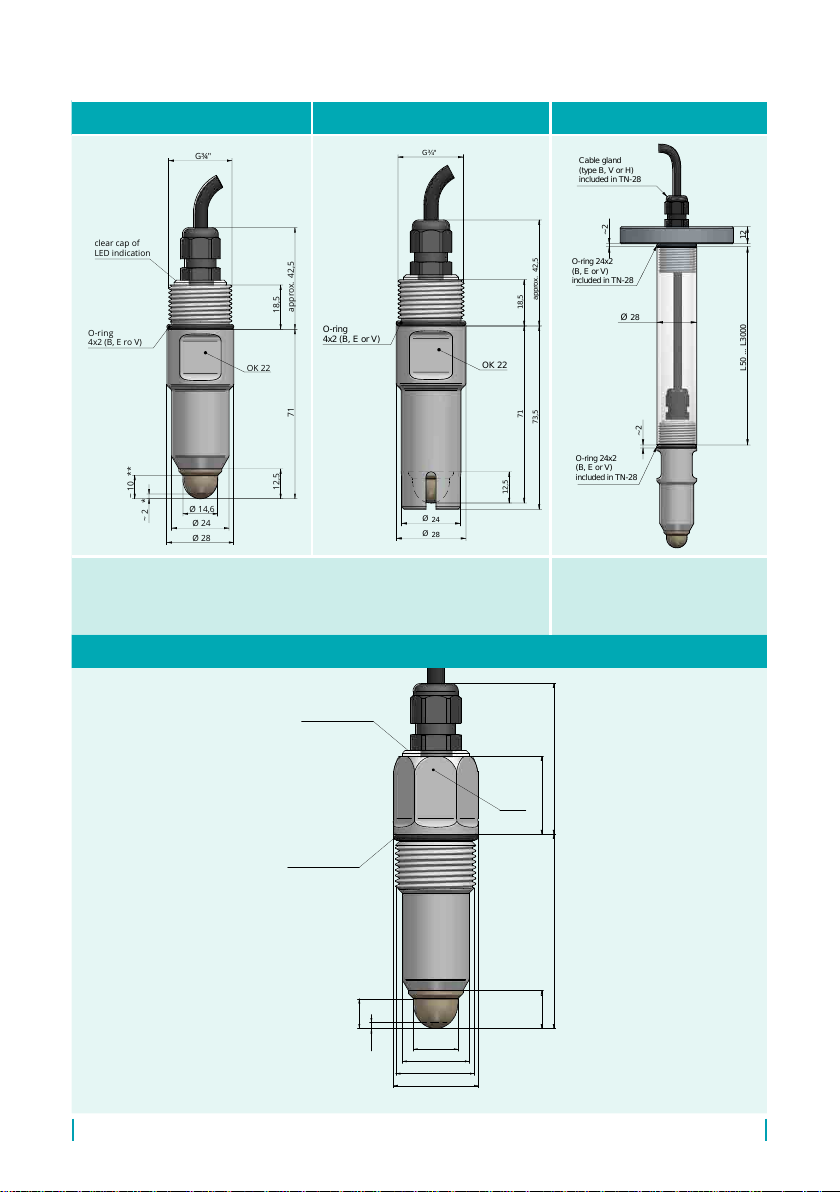

RFLS–28_–1_–RG–_–_ RFLS–28_–10_–RG–_–_ Extension tube TN-28-P***

OK 22

O-ring

4x2 (B, E ro V)

G¾"

42,5approx.

18,5

12,5

14,6

Ø

24

Ø

28

Ø

10~ **

2~ *

71

clear cap of

LED indication

G¾"

71 18,5

42,5approx.

73,5

OK 22

O-ring

4x2 (B, E or V)

24

28

12,5

Ø

Ø

L50 ... L3000

28

~ 2

12

O-ring 24x2

(B, E or V)

included in TN-28

O-ring 24x2

(B, E or V)

included in TN-28

Cable gland

(type B, V or H)

included in TN-28

~ 2

Ø

The switching point is the same for both sensor variants.

* Typical switching point position for water (factory default).

** Typical switching point position for oil.

*** Extension tube variants:

P - ange (in gure),

Z - thread G1“, Cl - Tri-Clamp

see the accessories data sheet for

the TN-28 extension tube

RFLS-28_-1_-FG–_–_

O-ring 24x2

(B, E or V)

2~ *

10~ **

G ¾"

OK 24

clear cap of

LED indication

28

Ø

22

Ø

14,6

Ø

12,5 64 49,5

approx.

25,5

7

© Dinel, s.r.o. RFLS–28

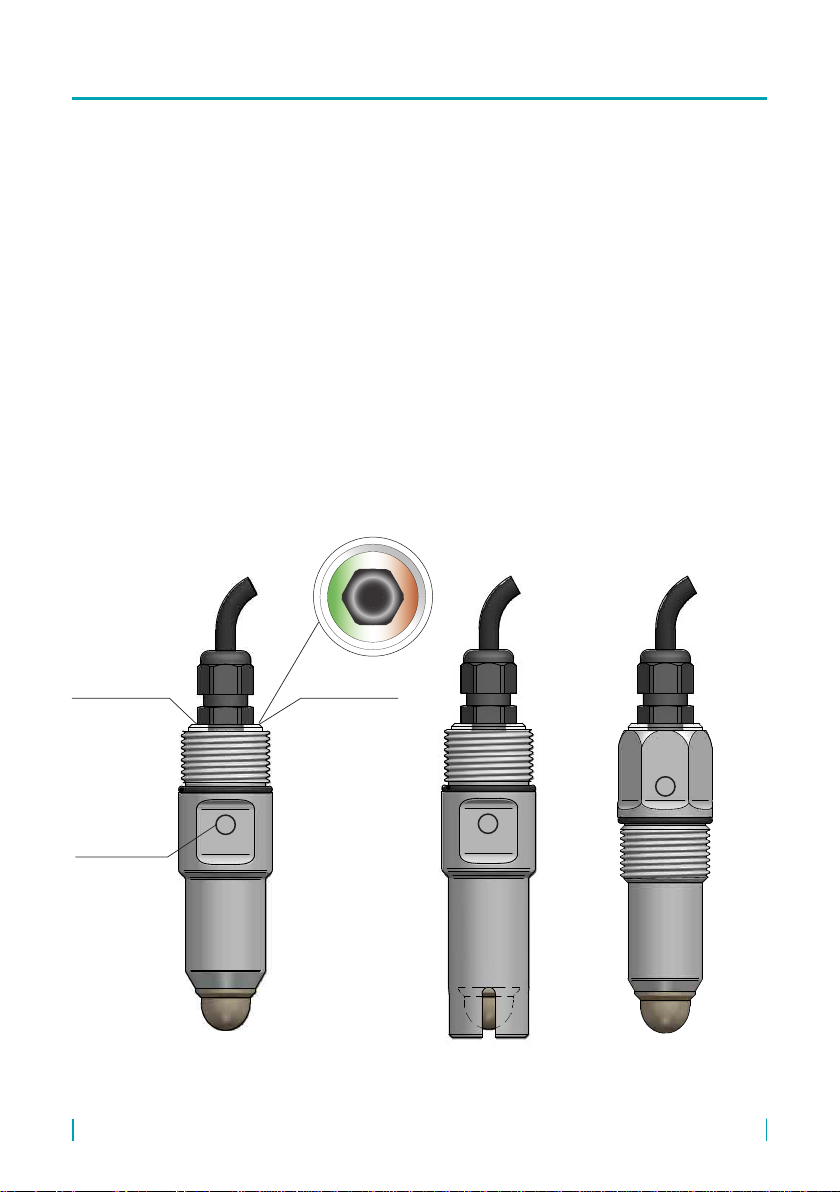

Variant “B” with a stand-

ard cable gland

20

53

43

ø 17

20

53

43

ø 17

20

53

43

ø 17

20

53

43

ø 17

20

53

43

ø 17

20

53

43

ø 17

Variant “V” with plastic cable

gland with spiral relief – in the

case of increased mechanical wear

on the cable.

Spiral relief

clear cap

LED indication

clear cap

LED indication

Spiral relief

Variant “H” with cable

gland for protective hoses

– for use in an outdoor area

or in an area with high hu-

midity.

protective hose

(ø 13 mm)

protective hose

(ø 13 mm)

Please follow the next 3 steps:

• For , see chapter 9

• For , see chapter

• For , see chapter

RFLS–28 © Dinel, s.r.o.

8

The electrical connection can only be made when de-energised!

The power supply must be designed as a stabilised source of low safe voltage with galvanic

isolation. If a switched power supply is used, its design must effectively suppress common

mode interference. If the switched power supply is equipped with a PE protective terminal,

it must be strictly earthed!

If the level meter (sensor) is to be installed in an outdoor environment more than 20 m from

an outdoor switchboard or an enclosed building, the electrical supply to the level meter

(sensor) must be supplemented with suitable overvoltage protection.

In the case of strong environmental electromagnetic interference, common routing of the

signal cable with the power cable or if the length is more than 30 m, we recommend using

a shielded cable and grounding the shielding on the power source side.

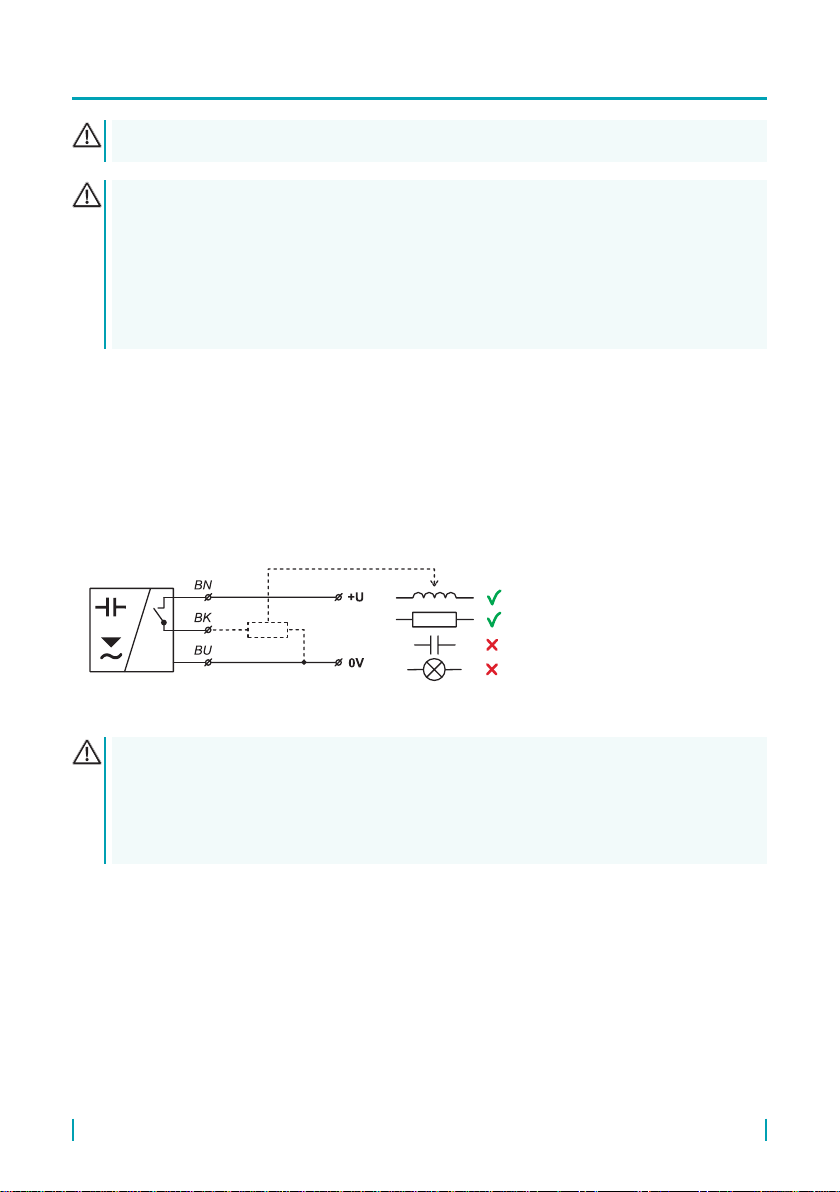

RFLS-28_-_-P sensors are permanently connected to evaluation units by a PVC cable.

Sensors with PNP output can only be loaded with a resistive or inductive load. The capacitative

loads and low resistance loads (bulb) are evaluated by the sensor as a short circuit.

Connection diagrams are listed in the gure below.

5.1. Type RFLS-28N-_-_-P-_ electrical connection

Legend:

BK – black

BN – brown

BU – blue

Fig. 1: Connection of the RFLS-28_-_-P-_ sensor with PNP output

9

© Dinel, s.r.o. RFLS–28

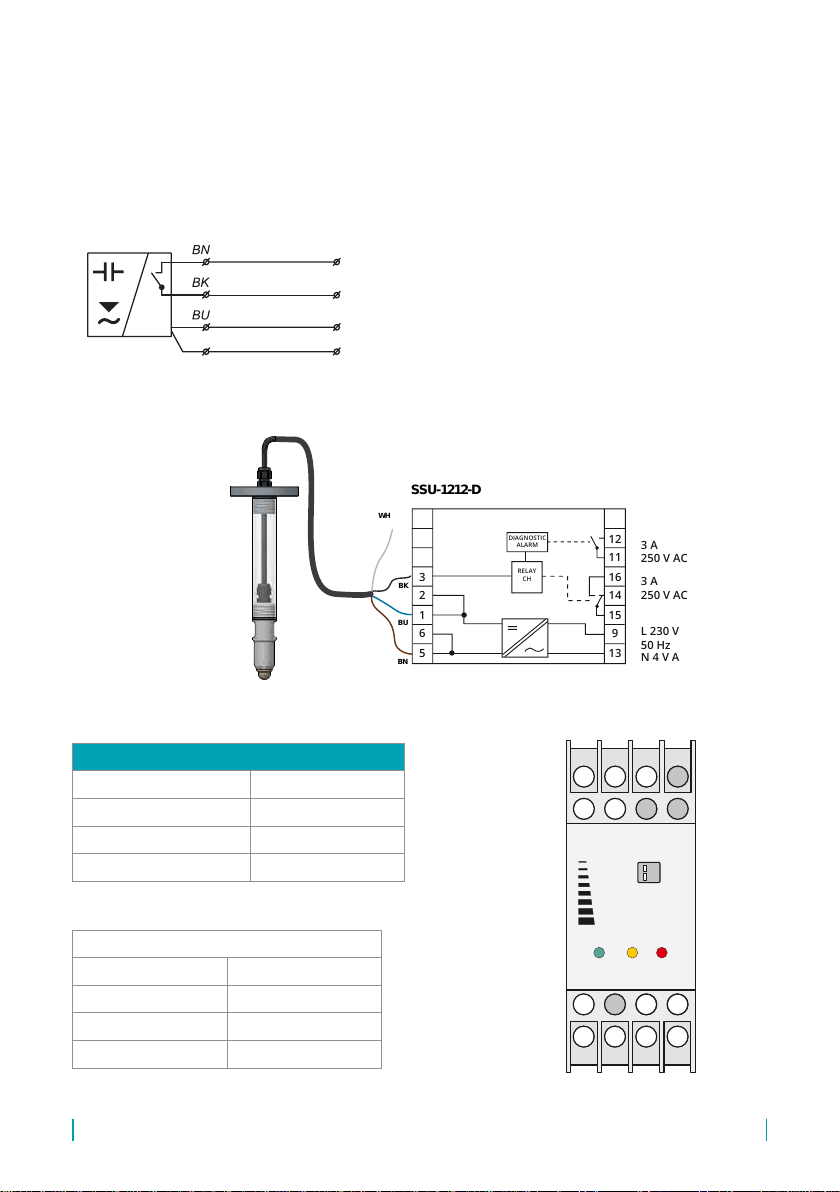

The SSU-1212-D power supply and switching unit is intended for the evaluation of the state of the

connected sensor and its transformation to a power contact. In addition, the unit is able to evaluate

diagnostic messages generated by the connected sensor. The programming wire P is not con-

nected to the unit and its end must be properly insulated.

5.2. Type RFLS-28N-_-_-PD-_ electrical connection

5.2.1. Connection to the SSU-1212-D unit – diagnostic function only

Legend:

BK – black

BN – brown

BU – blue

WH – white

P

OUT

+U

0V

WH

Fig. 2: Connection of the RFLS-28_-_-PD-_ sensor with PNP output and diagnostic function

Fig. 3: Connection of the sensor to the SSU-1212-D unit

BK

SSU-1212-D

WH

BU

BN 5

6

1

2

3

N 4 V A

L 230 V

50 Hz

3 A

250 V AC

3 A

250 V AC

13

9

15

14

16

11

12

RELAY

CH

DIAGNOSTIC

ALARM

2

6

1

5

3

7

4

8

10

14

9

13

11

15

12

16

Dinel

BLK OFF ON

ALARM

POWER

PN

OUT

SSU-1212-D

RFLS-28_-_-_-PD-_

BK

SSU-1212-D

WH

BU

BN 5

6

1

2

3

N 4 V A

L 230 V

50 Hz

3 A

250 V AC

3 A

250 V AC

13

9

15

14

16

11

12

RELAY

CH

DIAGNOSTIC

ALARM

2

6

1

5

3

7

4

8

10

14

9

13

11

15

12

16

Dinel

BLK OFF ON

ALARM

POWER

PN

OUT

SSU-1212-D

Legend

BK black

WH white

BU blue

BN brown

PNP output type sensor connection

+U sensors terminal No. 5 or 6

Q output of the sensor terminal No. 3

0 V of the sensor terminal No. 1 or 2

programming wire P not connected

RFLS–28 © Dinel, s.r.o.

10

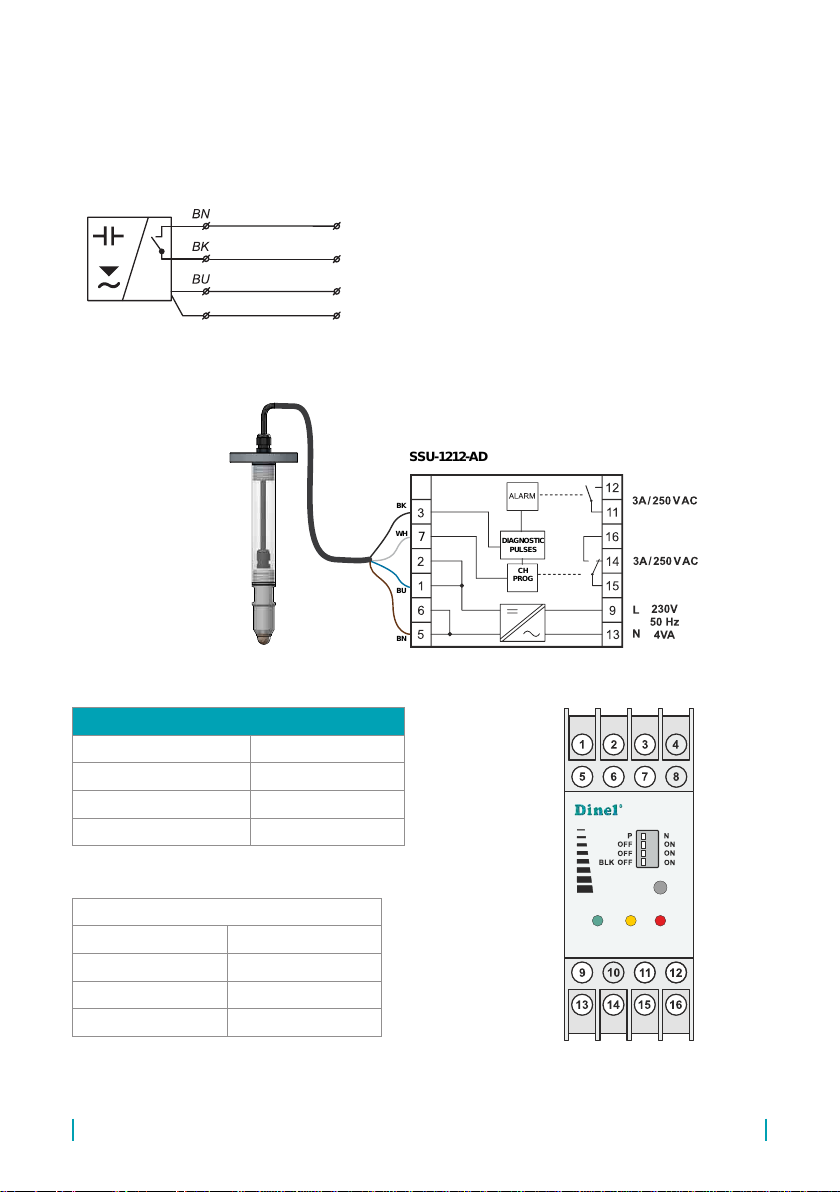

The SSU-1212-AD power supply and switching unit is intended for the evaluation of the state of the

connected sensor and its transformation to a power contact. In addition, the unit is able to evaluate

diagnostic messages generated by the connected sensor and set it remotely.

5.2.2. Connection to the SSU-1212-AD unit – diagnostic function + remote settings

Legend:

BK – black

BN – brown

BU – blue

WH – white

P

OUT

+U

0V

WH

Fig. 2: Connection of the RFLS-28_-_-PD-_ sensor with PNP output and diagnostic function

Fig. 3: Connection of the sensor to the SSU-1212-AD unit

SET CH

SET

SETTING

POWER

SSU-1212-AD

OUT ALARM

7DIAGNOSTIC

PULSES

CH

PROG

BK

SSU-1212-AD

WH

BU

BN

RFLS-28_-_-_-PD-_

SET CH

SET

SETTING

POWER

SSU-1212-AD

OUT ALARM

7DIAGNOSTIC

PULSES

CH

PROG

BK

SSU-1212-AD

WH

BU

BN

Legend

BK black

WH white

BU blue

BN brown

PNP output type sensor connection

+U sensors terminal No. 5 or 6

Q output of the sensor terminal No. 3

0 V of the sensor terminal No. 1 or 2

programming wire P terminal No. 7

11

© Dinel, s.r.o. RFLS–28

The settings elements are used to set the sensitivity and behaviour of the sensor. The RFLS-28

sensor can always be set using a magnetic pen by touching the ON or OFF magnetically sensitive

spots on the sensor. The RFLS-28N-_-_- PD-_ variant is also tted with a setting wire for remote

parametrisation of the sensor. Remote parametrisation enables all the same sensor options to be

set as when setting with the magnetic pen.

With the RFLS-28N-RG-_- P -_ variant with no option of remote parametrisation, settings needs to

be performed before the sensor is installed in the tank, because setting is unavailable after instal-

lation in the tank.

• Quick settings – the user does not know precisely what medium the sensor should be set to,

but just wants to start up the sensor (usually upon receiving it) and check to see if the sensor

is generally functional.

• Basic settings – the user has the medium available and can perform ooding and drainage

on the sensor.

• Medium window settings – the user has the medium available and can perform ooding and

drainage on the sensor.

Orange LEDGreen LED

Sensitive spot

for the magnetic

pen

Fig. 4: Positions of the settings and indication elements on the sensor

M

ON

M

ON

M

ON

RFLS–28 © Dinel, s.r.o.

12

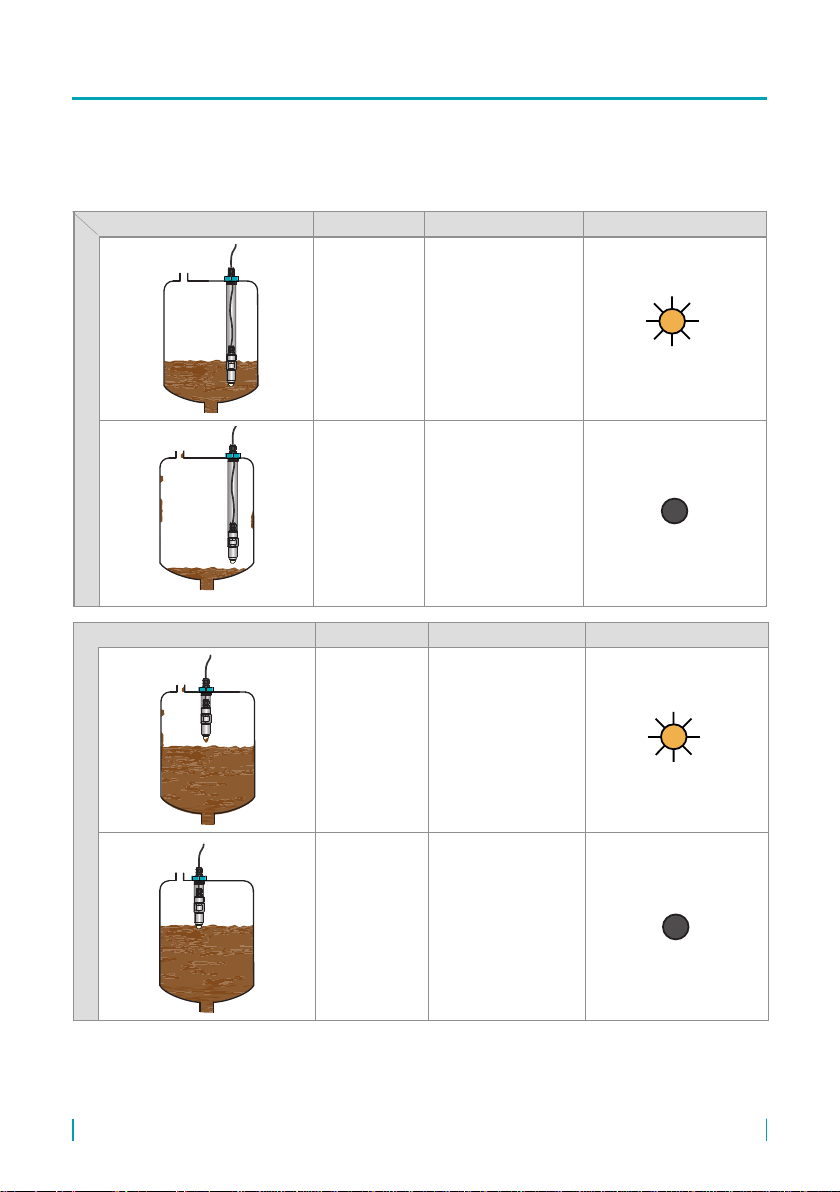

Function indication on the sensor indication on the unit

standard operation

sensor open

standard operation

sensor closed

incorrect setting

setting up

magnetic pen

application the status is unchanged

settings

PD version only

sensor malfunction

status open

sensor malfunction

status closed

0,4

0,4

0,2

0,2

0,1

0,1

0,4

0,4

0,4

0,2

0,2

1

1

0,10,1 0,10,1 0,1

0,1

0,1

0,4

0,4

0,4

0,2

0,4

0,4

0,2

0,2

sec.

sec.

sec.

sec.

sec.

sec. sec.

sec.

sec.

13

© Dinel, s.r.o. RFLS–28

For safety reasons, for scanning min. level, we recommend setting “O-mode” (sensor closes when submerged).

A faulty sensor or wiring will take eect here in the same way as level emergency conditions by opening the sensor.

Analogously, for the max. level, we recommend setting “C-mode” (sensor opens when submerged).

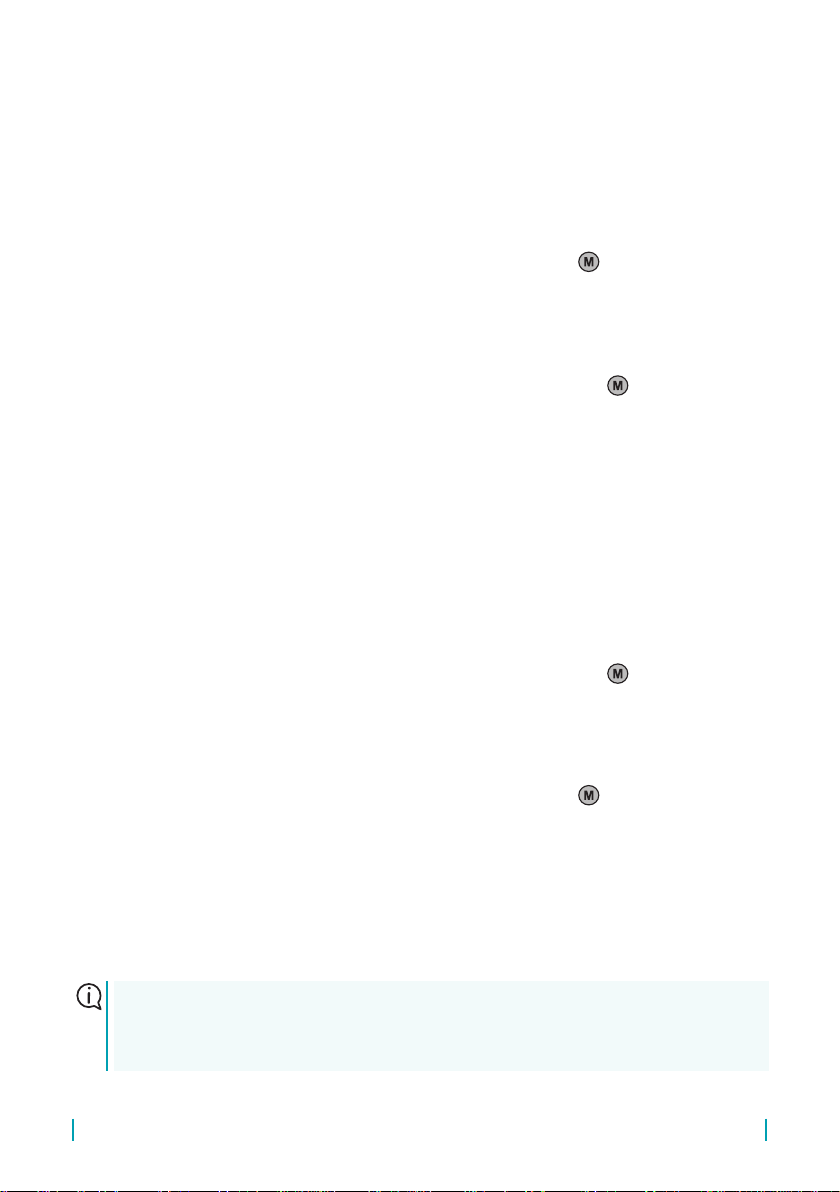

level state mode output state Orange LED

maximum level sensing

CCLOSED

(illuminated)

COPEN

(not illuminated)

level state mode output state Orange LED

minimum level sensing

OCLOSED

(illuminated)

OOPEN

(not illuminated)

The sensor can be set to normally closed “O-mode” or to normally open “C-mode” switch types.

RFLS–28 © Dinel, s.r.o.

14

For safety reasons, for scanning min. level, we recommend setting “O-mode” (sensor closes when submerged).A

faulty sensor or wiring will take eect here in the same way as level emergency conditions by opening the sensor.

Analogously, for the max. level, we recommend setting “C-mode” (sensor opens when submerged).

level state mode output state Orange LED

maximum level sensing

CCLOSED

(illuminated)

COPEN

(not illuminated)

level state mode output state Orange LED

minimum level sensing

OCLOSED

(illuminated)

OOPEN

(not illuminated)

The sensor can be set to normally closed “O-mode” or to normally open “C-mode” switch types.

15

© Dinel, s.r.o. RFLS–28

Unless otherwise agreed, “O-mode” is set on all sensors straight from the factory.

When using the “quick settings” function, the sensor does not eliminate the presence of

deposits and foam on the electrode. The manufacturer recommends performing the basic

settings as soon as possible.

This mode is only suitable for verifying the sensor before commissioning if the measured medium

is not available.

1. The sensor is turned with the measuring electrode into the free space.

2. Apply the magnetic pen for at least 5 to 10 seconds to the ON sensitive spot on the sensor

(at rst, both LEDs light up. After approx. 3 seconds, the orange LED ashes 3 times, and after

another approx. 2 seconds the orange LED ashes again 3 times. You can now remove the

magnetic pen).

The sensor is now set to O-mode (closes when submerged).

1. The sensor is turned with the measuring electrode into the free space.

2. Apply the magnetic pen for at least 5 to 10 seconds to the OFF sensitive spot on the

sensor (at rst, both LEDs light up. After approx. 3 seconds, the orange LED ashes 3 times,

and after another approx. 2 seconds the orange LED ashes again 3 times. You can now

remove the magnetic pen).

The sensor is now set to C-mode (opens when submerged).

Settings needs to be performed prior to installing the sensor in the TN-28 extension tube.

With the RFLS-28N-RG-_- P -_ variant with no option of remote parametrisation, settings needs to

be performed before the sensor is installed in the tank, because setting is unavailable after instal-

lation in the tank.

While setting up the RFLS-28 sensor, it is important to monitor both LEDs. Therefore, settings must

be performed before installing the sensor in the extension tube.

• Install the electrical connection – see Chapter 5

• In the case of simple sensing of non-adhering media, you can use the Quick settings speci-

ed in chap. 8.1.1. Otherwise, it is necessary to perform the Basic settings - with the

medium present.

• Prepare the measured medium in an auxiliary vessel.

• If you want to sense the presence of the medium (medium/air) or detect the interface of two

dierent media (medium/medium), such as water/oil, follow the instructions provided in chap.

8.1.2. Basic settings.

• If you want to selectively detect a specic medium, follow the instructions provided in chap.

8.1.3. setting up “medium window” mode.

RFLS–28 © Dinel, s.r.o.

16

For safety reasons, we recommend setting “O-mode” for level sensing (the sensor closes when

submerged). A faulty sensor or wiring will take effect here in the same way as level emergency

conditions by opening the sensor. Analogously, for the maximum level, it is recommended to set

“C-mode” (the sensor opens when submerged).

For setting the sensitivity and switching mode, where it is possible to submerge the sensor in or

remove it from the medium. When using this setting, the sensor eliminates the presence of deposits

and foam on the electrode.

1. Immerse the sensor electrode in the medium to be measured (in the case of the detection of a

two-media interface, place the electrode in the lower medium).

2. Apply the magnetic pen for 2 to 4 seconds to the ON sensitive spot of the sensor (until both

LEDs are illuminated) and then remove the magnetic pen. The settings are conrmed by three

ashes of the orange LED.

3. Take the sensor out of the medium (in the case of the detection of a two-media interface, place

the electrode in the upper medium). Leave any deposits on the electrode.

4. Apply the magnetic pen for 2 to 4 seconds to the OFF sensitive spot of the sensor (until

both LEDs are illuminated) and then remove the magnetic pen. The settings are conrmed by

three ashes of the orange LED.

5. Check the status of the indicators:

• If the orange LED is not illuminated and the green LED is ashing, the sensor is correctly set.

• If the orange and green LEDs are ashing alternately, the sensor did not recognise the limits

for closing and opening. In this case, nd out whether the minimum and maximum levels

have been set too close to one another.

1. Immerse the sensor electrode in the medium to be measured (in the case of the detection of a

two-media interface, place the electrode in the lower medium).

2. Apply the magnetic pen for 2 to 4 seconds to the OFF sensitive spot of the sensor (until

both LEDs are illuminated) and then remove the magnetic pen. The settings are conrmed by

three ashes of the orange LED.

3. Pull the sensor out of the medium. (when detecting a two-media interface, place the electrode

in the upper medium). Leave any deposits on the electrode.

4. Apply the magnetic pen for 2 to 4 seconds to the ON sensitive spot of the sensor (until both

LEDs are illuminated) and then remove the magnetic pen. The settings are conrmed by three

ashes of the orange LED.

5. Check the status of the indicators:

• If the orange LED is illuminated and the green LED is ashing, the sensor is correctly set.

• If the orange and green LEDs are ashing alternately, the sensor did not recognise the limits

for closing and opening. In this case, nd out whether the minimum and maximum levels

have been set too close to one another and repeat the set-up if necessary.

17

© Dinel, s.r.o. RFLS–28

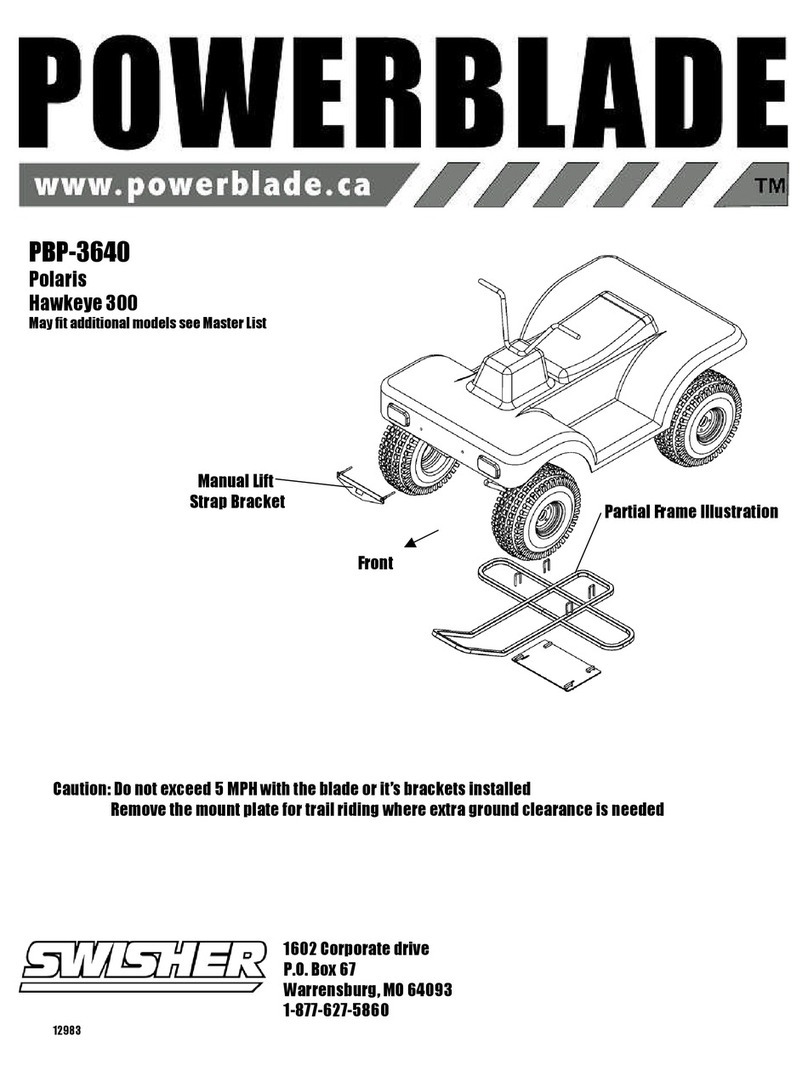

The sensor can also be used to distinguish a specic medium from others – using the "medium

window" function. E.g. the sensor can distinguish oil from water and air, detect only beer foam and

ignore beer and air, etc. To set the sensitivity and switching mode for the required medium. With

this setting, the sensor does not react to being submerged in a medium with a dierent permittivity.

Orange LED

not illuminated

Orange LED

not illuminated Orange LED

lit

1. Immerse the sensor electrode in the medium to be measured.

2. Apply the magnetic pen for at least 10 seconds to the ON sensitive spot of the sensor (at

rst both LEDs are illuminated. After approx. 3 seconds, the orange LED ashes 3 times. After

another approx. 2 seconds the orange LED ashes again 3 times, and after approx. 5 seconds

the orange LED ashes 3 times again. You can now remove the magnetic pen).

The sensor is now set to O-mode (closes when submerged in the required medium).

3. Check the status of the indicators:

• If the orange LED is illuminated and the green LED is ashing, the sensor is correctly set.

Fig. 5: “Medium window” mode – only detection of the required medium:

(e.g.: only beer foam, beer and air are ignored)

Orange LED

not illuminated

Orange LED

lit

Orange LED

not illuminated

RFLS–28 © Dinel, s.r.o.

18

1. Immerse the sensor electrode in the medium to be measured.

2. Apply the magnetic pen for at least 10 seconds to the OFF sensitive spot of the sensor (at

rst both LEDs are illuminated. After approx. 3 seconds, the orange LED ashes 3 times. After

another approx. 2 seconds the orange LED ashes again 3 times, and after approx. 5 seconds

the orange LED ashes 3 times again. You can now remove the magnetic pen).

The sensor is now set to C-mode (opens when submerged in the required medium).

3. Check the status of the indicators:

• If the orange LED is not illuminated and the green LED is ashing, the sensor is correctly set.

With the variant provided with the remote parametrisation option (RFLS-28_-_-_-PD-_), it is pos-

sible to set the sensor using the programming wire and/or the special SSU-1212-AD evaluation

unit. This unit is equipped with a contact (terminal No. 7) to connect the programming wire allowing

all setting options of the sensor to be performed. This concerns the quick settings as per para-

graph 8.1.1., the basic settings as per paragraph 9.4, and setting “medium window” mode as per

paragraph 8.1.3.

The unit has one input for the connection of the operating sensor (marked as IN, terminal No. 3).

The operating sensor enables the control of the operating relay (terminals 14, 15, 16). The unit is

tted with a diagnostic function monitoring the correct operation of the connected sensor, and the

remote parametrisation function for the connected sensor using the W programming wire. The pro-

gramming wire is connected to the terminal marked P (terminal No. 7).

This mode is only suitable for verifying the sensor before commissioning if the measured medium

is not available.

1. The sensor is turned with the measuring electrode into the free space.

2. Switch the SET CH switch to the ON position and the SET switch to the OFF position

3. Press the SETTING button for 5–10 seconds. The setting is conrmed in the following manner.

After approximately 3 seconds, the orange LED ashes three times. After another approximate-

ly 2 seconds, the orange LED ashes three times again. Now, release the SETTING button. The

sensor is now set to O-mode (closes when submerged).

4. Check the status of the ALARM indicator. If the red LED is not ashing, the sensor is set cor-

rectly. If it is ashing, the sensor is set incorrectly. Repeat the setting.

5. Switch the SET CH switch to the OFF position.

Setting using the programming wire can be performed even after the installation of the RFLS-

28 sensor with the TN-28 extension tube in the tank.

1212

19

© Dinel, s.r.o. RFLS–28

A function suitable for setting the sensor to simple sensing or resolution of the interface of two me-

dia. For setting the sensitivity and switching mode, where it is possible to submerge the sensor in or

remove it from the medium. When using this setting, the sensor eliminates the presence of deposits

and foam on the electrode.

1. Immerse the sensor electrode in the medium to be measured (in the case of the detection of a

two-media interface, place the electrode in the lower medium).

2. Switch the SET CH and SET switches to the ON position.

3. Press the SETTING button for approx. 2 seconds. The setting is conrmed by three ashes of

the orange LED.

4. Take the sensor out of the medium (in the case of the detection of a two-media interface, place

the electrode in the upper medium). Leave any deposits on the electrode.

5. Switch the SET switch to the OFF position.

6. Press the SETTING button for approx. 2 seconds. The setting is conrmed by three ashes of

the orange LED.

7. Check the status of the ALARM indicator. If the red LED is not ashing, the sensor is set cor-

rectly. If it is ashing, the sensor is set incorrectly. Repeat the setting.

8. Switch the SET CH switch to the OFF position.

1. The sensor is turned with the measuring electrode into the free space.

2. Switch the SET CH and SET switches to the ON position

3. Press the SETTING button for 5–10 seconds. The setting is conrmed in the following manner.

After approximately 3 seconds, the orange LED ashes three times. After another approxi-

mately 2 seconds, the orange LED ashes three times again. Now it is possible to release the

SETTING button. The sensor is now set to C-mode (closes when submerged in the required

medium).

4. Check the status of the ALARM indicator. If the red LED is not ashing, the sensor is set cor-

rectly. If it is ashing, the sensor is set incorrectly. Repeat the setting.

5. Switch the SET CH switch to the OFF position.

RFLS–28 © Dinel, s.r.o.

20

1. Immerse the sensor electrode in the medium to be measured (in the case of the detection of a

two-media interface, place the electrode in the lower medium).

2. Switch the SET CH switch to the ON position and the SET switch to the OFF position.

3. Press the SETTING button for approx. 2 seconds. The setting is conrmed by three ashes of

the orange LED.

4. Take the sensor out of the medium (in the case of the detection of a two-media interface, place

the electrode in the upper medium). Leave any deposits on the electrode.

5. Switch the SET switch to the ON position.

6. Press the SETTING button for approx. 2 seconds. The setting is conrmed by three ashes of

the orange LED.

7. Check the status of the ALARM indicator. If the red LED is not ashing, the sensor is set cor-

rectly. If it is ashing, the sensor is set incorrectly. Repeat the setting.

8. Switch the SET CH switch to the OFF position.

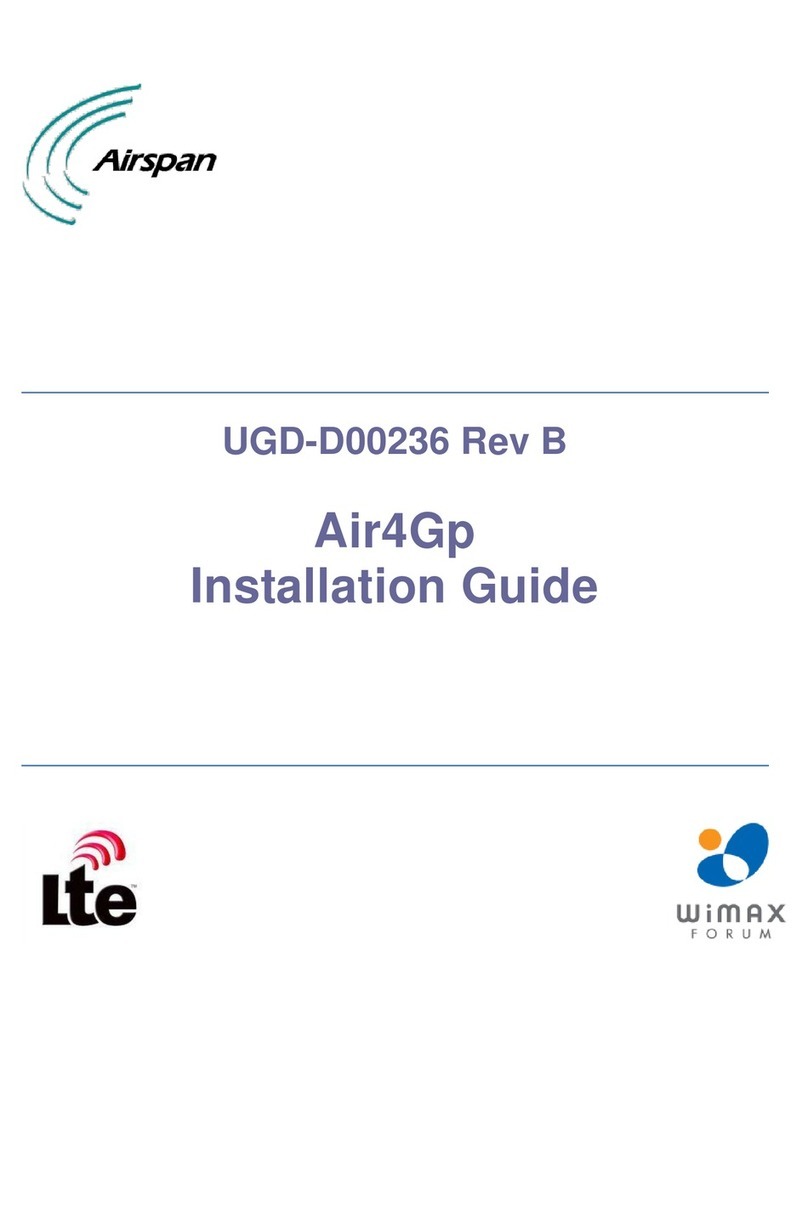

The sensor can be used to distinguish a specic medium from others. E.g. the sensor can distin-

guish oil from water and air, detect only beer foam and ignore beer and air, etc. With this mode, the

sensor does not react to being submerged in a medium with a dierent permittivity.

Orange LED

not illuminated

Orange LED

not illuminated Orange LED

lit

Fig. 6: “Medium window” mode – only detection of the required medium:

(e.g.: only beer foam, beer and air are ignored)

Orange LED

not illuminated

Orange LED

lit

Orange LED

not illuminated

This manual suits for next models

6

Table of contents

Other Dinel Accessories manuals

Popular Accessories manuals by other brands

Swisher

Swisher PowerBlade PBP-3640 Assembly instructions

Airspan

Airspan Air4Gp installation guide

Whale

Whale INSTANT MATCH SDP134T Installation guidelines

Honeywell

Honeywell T7147 Product data

Interlogix

Interlogix International Shock Sensor installation instructions

Vega

Vega VEGAPULS 63 operating instructions

Clockaudio

Clockaudio CDT100 user manual

BERKSHIRE PRODUCTS

BERKSHIRE PRODUCTS 2010 user manual

Siko

Siko LE100/1 Translation of the original installation instructions

Siko

Siko MSA213K installation instructions

Digital Dowsing

Digital Dowsing Xcam SLS quick start guide

Pepperl+Fuchs

Pepperl+Fuchs U-P R4 Series manual