Dinel DLS -27 10 Series User manual

Read carefully the instructions published in this manual before the first use of the level meters. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

INSTRUCTION MANUAL

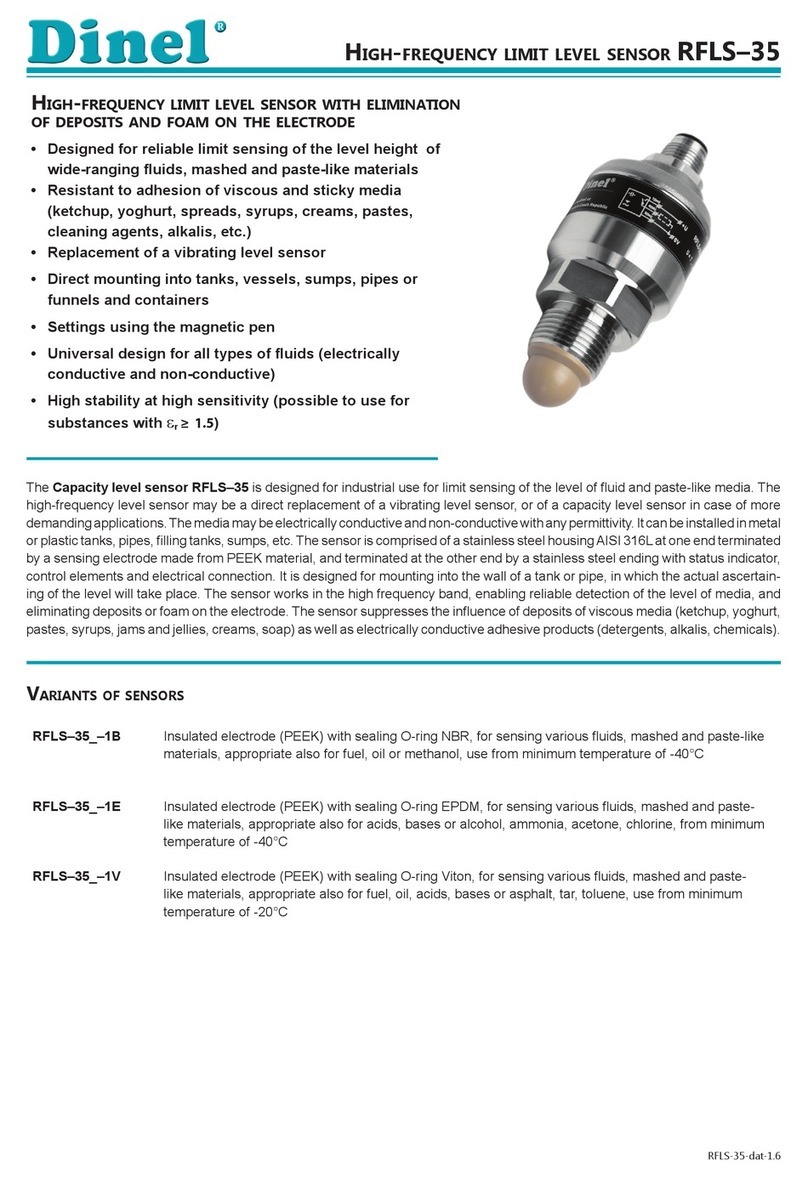

CAPACITIVE LEVEL SENSORS DLS–27

CONTENT

1. Brief ............................................................................................................................................5

2. Features of variants....................................................................................................................5

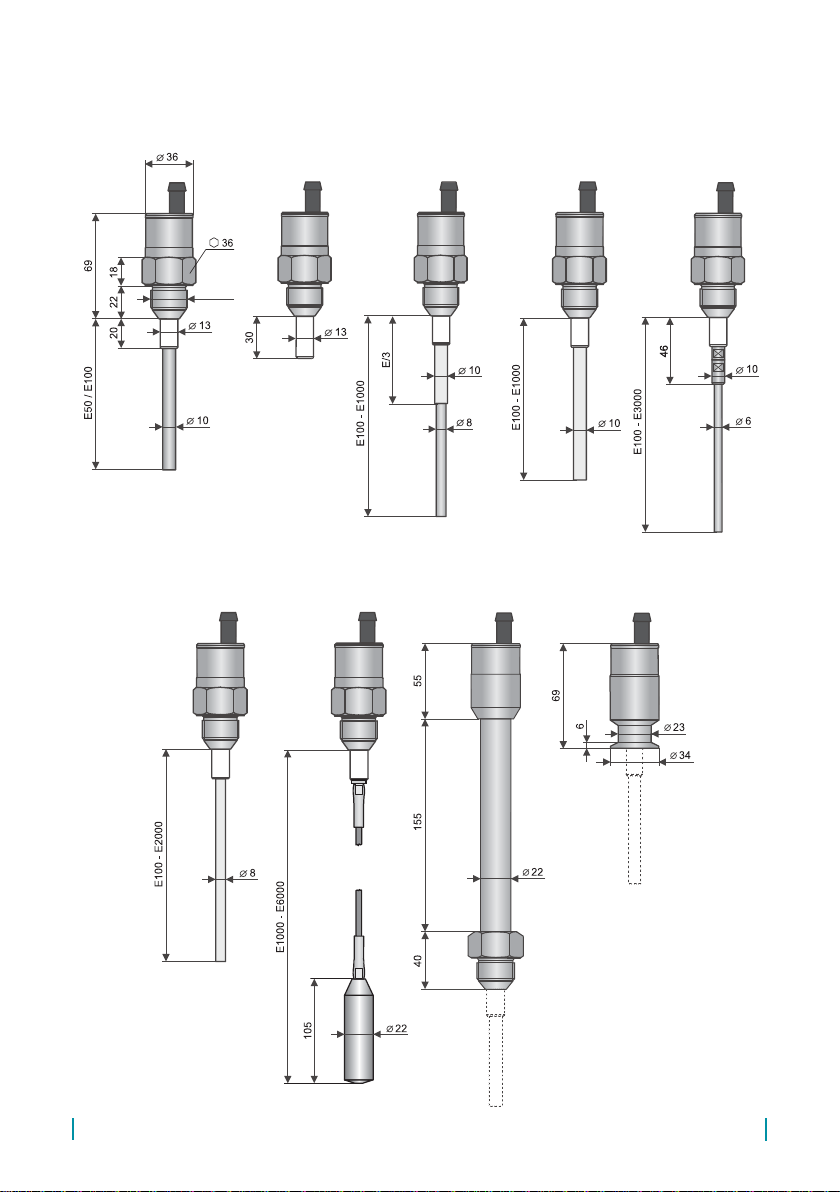

3. Dimensional drawings ................................................................................................................6

4. Mounting recommendation.........................................................................................................7

5. Range of application...................................................................................................................11

6. Electrical connection...................................................................................................................12

7. Sensor setting.............................................................................................................................13

8. Status signalization.....................................................................................................................14

9. Accessories ................................................................................................................................15

10. Order code................................................................................................................................16

11. Correct specification examples.................................................................................................16

12. Safety, protections, compatibility and explosion proof..............................................................17

13. Use, manipulation and maintenance ........................................................................................17

14. Special conditions for safe use.................................................................................................17

15. Marking of labels ......................................................................................................................18

16. Specifications ...........................................................................................................................20

17. FAQ (Frequently asked questions)...........................................................................................22

DLS–27 © Dinel, s.r.o.

4

All operations described in this instruction manual have to be carried out by trained

personnel or by an accredited person only. Installation, commissioning, operation and

maintenance of the capacitive level sensors has to be carried out in accordance with this

instruction manual; the provisions of regulations in force regarding the installation of

electrical equipment have to be adhered to.

Improper use, installation or set-up of the sensor can lead to crashes in the application,

(overfilling of the tank or damage of system components).

The manufacturer is not responsible for improper use, loss of work caused by either

direct or indirect damage, and for expenses incurred at the time of installation or during

the period of use of the level sensors.

SAFETY

PACKING, TRANSPORTATION AND STORAGE

Equipment DLS–27 is packed in a polythene bag and the whole consignment is placed in a card-

board box. The cardboard box is suitably filled to prevent mechanical damage during transport. Let

the device packed up till the use to prevent possible damage.

Sensor variants DLS–27_-20, 21, 22, 30 with the electrodes longer than 100 mm are fitted with

protective caps at the ends of the electrodes to prevent damage of the electrodes, box rupture or

injury of handling persons. Before commissioning, remove the caps.

Transport to the customer is realized by forwarding company. Upon receipt, please check whether

the shipment is complete and corresponds to the extent of the order, or whether during the transport

did not occurred the damage of the packaging or the equipment. The device apparently damaged

during transport do not use and contact the manufacturer to resolve the situation.

If the device is transported further, then only wrapped in the original packaging and protected

against shocks and weather. Store the device in its original packaging in a dry place, sheltered from

the weather, with humidity up to 85% without the effects of chemically active substances. Storage

temperature range is from -10 °C to +50 °C.

USED SYMBOLS

To ensure maximum safety of control processes, we have defined the following safety instructions

and information. Each instruction is labeled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and op-

eration of equipment or dangerous situations that may occur during the installation and

operation. Not observing these instructions may cause disturbance, damage or destruction

of equipment or may cause injury

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

5

© Dinel, s.r.o. DLS–27

FEATURES OF VARIANTS2.

DLS–27_–10 Uncoated short bar electrode for sensing non-adhesive bulk-solid (powder)

materials (sand, sugar) and electrically non-conductive liquids (oils, diesel,

petrol), horizontal mounting. Electrode length 50 mm or 100mm.

DLS–27_–11 Fully coated short bar electrode (PTFE – Polytetrafluoroethylene) for

sensing electrically conductive liquids (water). Assembly into a side wall of

vessel or into a pipe. Electrode length 30 mm.

DLS–27_–20 Semi-coated rod electrode (FEP – Tetrafluoroethylene-Perfluoro-Propylene)

for sensing light-bulk solid or powder materials (plastic granulates, flour,

cement) and non-conductive liquids (plant oils), horizontal, slant or vertical

mounting. Electrode length from 0.1m to 1m.

DLS–27_–21 Fully coated rod electrode (FEP)

for sensing electrically conductive liquids (water solutions, water), adhesive

and aggressive materials, horizontal or vertical mounting.

Electrode length from 0.1m to 1m.

DLS–27_–22 Fully coated rod electrode (PFA – Perfluoroalkoxy) for sensing electrically

conductive liquids (water solutions, water), adhesive and aggressive

materials, horizontal or vertical mounting. Electrode length from 0.1m to 1m.

DLS–27_–30 Dismountable rod uncoated electrode for sensing bulk-solid (powder)

materials and conductive or non-conductive liquids. Mounting from the top

(vertically) or slant from the side. Electrode length from 0.1m to 3m.

DLS–27_–31 Fully coated rod electrode for sensing aggressive electrically conductive

liquids (water, solutions of chemicals), vertical mounting.

Electrode length from 0.1m to 2m.

DLS–27_–40 Uncoated stainless steel rope electrode and weight for general purpose in

deeper silos (bulk-solid and powder materials sensing – sand, gravel,

cement) or hoppers (liquids sensing), vertical mounting.

Electrode length from 1m to 6m.

BRIEF1.

Capacitive level sensors (switches) DLS®are designed for limit level sensing of liquids, bulky solid

and powder materials in vessels, containers, silos, tanks, reservoirs, etc. Sensors are made in

several modifications of sensing electrodes – short and long rods or rope. The electrodes can be

coated what has important sense in case of adhesive, aggressive or electrically conductive media

sensing. The process coupling at the housing can be with thread M27x2, M30x1.5, G3/4” or with

Tri-clamp coupling. Electric connection is provided by means of permanent cable lead (variant B)

or by means of connector (variant C). Output performances – transistor outputs with open collector

(NPN, PNP) or NAMUR output.

There are next performances available: N– For normal atmospheres; Xd – For use in flammable

dust atmospheres; Xi – Explosion proof – intrinsically safe for hazardous (explosive) areas and

XiM – Explosion proof – intrinsically safe for use in mines with methane or flammable dust pres-

ence danger (see technical specifications). There are high temperature performance NT, XiT, XiMT

available.

DLS–27 © Dinel, s.r.o.

6

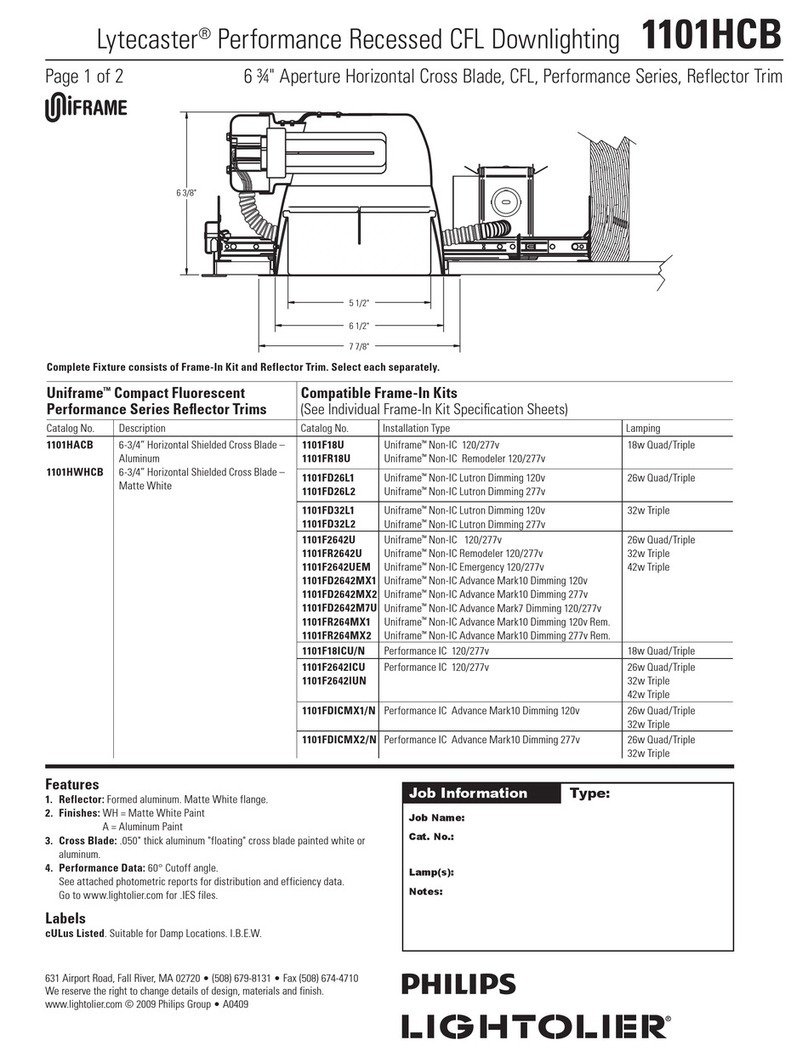

DIMENSIONAL DRAWINGS3.

DLS–27_–10

DLS–27_–11

DLS–27_–20

DLS–27_–21, 22

DLS–27_–30

DLS–27_–31 DLS–27_–40 High temperatures

variants Tri-clamp process

coupling

Thead *

* Type of threads: G 3/4''

M27x2

M30x1,5

7

© Dinel, s.r.o. DLS–27

MOUNTING RECOMMENDATION4.

DLS level sensors can be fixed in a vertical, horizontal or bevelled position into the shell of the ves-

sel, the storage tank for the fixation console in the pit, by screwing into the welding flange, using a

fixing nut or TriClamp® process connection.

Basic application recommendations are mentioned below.

If the sensors are fitted with protective caps at the ends of the electrodes, remove the

caps before commissioning.

In the case of vertical mounting it is recommended to

keep the mentioned distances applied to the length of the

electrode (the longer one).

All vertically mounted sensors

20

E

20kt

40

E

40dt

50

E

10ct

E–Electrode length in mm

Duringassemblyinto the metaltank or the storage tank,it is notnecessary to separately ground the

base of the level sensor. In the case of installation in concrete tanks or silos, it is recommended to

install a level sensor on the auxiliary metal construction (console, cap, etc.) and to then connect it

using a permanently dipped metal item or with steel reinforcement in the concrete (armouring).

In the case of the reading of an aggressive medium, we recommend that the producer be consulted.

Vertical mountingFig. 1:

Variants “C”

with connector Variants “D”

with cable outlets

Variants “B”

with cable outlets

DLS–27 © Dinel, s.r.o.

8

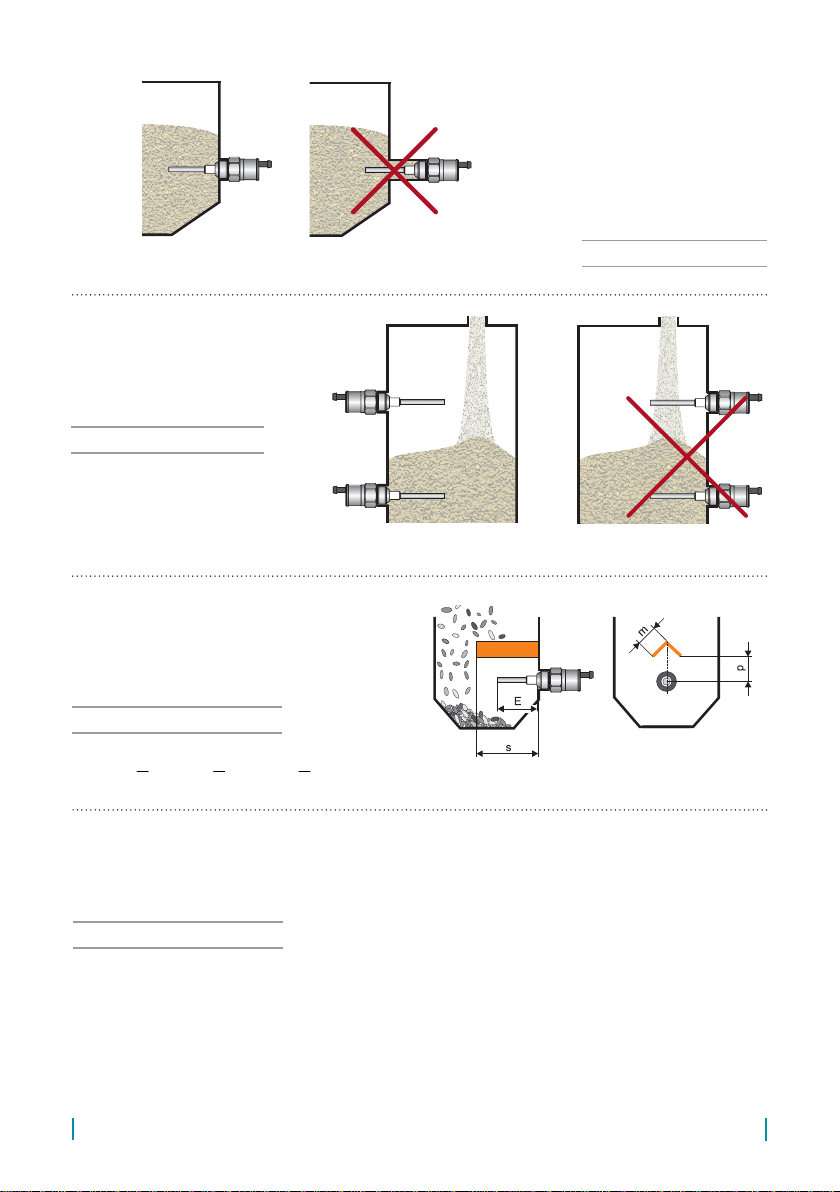

Side wall mountingFig. 3:

E

3

4

s|E

4

3

p|E

3

2

m|

E– Electrode length in mm

Protective roof mountingFig. 4:

Protective roof mounting is recom-

mended when vertical movement of mate-

rial could damage the sensing electrode

(abrasive materials, blocks creating solid

materials, etc.)

For DLS–27_–10 and DLS–27_–20

Long fitting tubes in side wall mountingFig. 2:

In the case of side wall mount-

ing it is necessary to avoid long fit-

ting tubes, where could the rests

of sensed media cumulate – see

the right figure. We recommend to

mount the sensor so that the whole

sensing electrode is inside the con-

tainer (vessel).

All from side mounted sensor

In the case of side wall mount-

ing it is necessary to place the

sensor aside the falling material

(liquid or solid).

All from side mounted sensors

In the case of slant wall mounting it is necessary to eliminate long fittings and reduce the media

sedimentation. The wrong example is in the middle figure. Left figure – appropriate mounting on the

auxiliary vertical plate. In some cases is allowed the variant shown on the right figure – but only for

DLS–27_–10 type, and only for not blocking materials.

For DLS–27_–10 and DLS–27_–20

9

© Dinel, s.r.o. DLS–27

In the case of vertical installation for non-con-

ductive fluids sensing is useful to bend the end

of electrode to right angle. We can gain by it the

good sensitivity at the end of electrode for vari-

ous fluids. When the supposed media is water

the bending has no sense (the sensor react just

when the level touches the end of electrode).

When the environmental conditions (wind, rain,

snow) are present, we recommend to use types

with insulated electrode (21 or 31).

For DLS–27_–30

h = 50 ... 200 mm

Conductive probe

CNP–18

Electrically connect

Auxiliary

electrode

Vertical installation for non-conductiveFig. 7:

fluids

E2 = E1+50

E1, E2 –Electrode length in mm

Auxiliary electrode in non-conductive tanksFig. 6:

In the case of the application of the sensor in an electrically non-conductive (e.g. plastic) vessel

in the vertical position, then for the correct function, it is recommended to connect the housing of

the level sensor with an auxiliary electrode. The auxiliary electrode can consist of a bar which is

permanently dipped into the medium (e.g. conductive probe CNP–18), or can have the form of a

metal flat plate located (sealed) from the side on the wall into the area for the expected switching of

the level sensor. The area of the plate auxiliary electrode is a minimum 200 cm2. For non-conductive

liquids, the only variation possible is with the plate auxiliary electrode and in this case it is necessary

to place the level sensor to prevent the movement of electrodes and the axis is at the distance of

lmax =E1/10, lmin = 20mm.

!

Slant wall mountingFig. 5:

DLS–27_–10

For DLS–27_–20, 21, 22, 30, 31

DLS–27 © Dinel, s.r.o.

10

20

E

40bt

Mounting in a bypass measuring tube. We

recommend to keep the tube diameter.

For: DLS–27_–20, 21, 22, 30, 31

Bypass measuring tubeFig. 8:

In the case of vertical mounting in outer are-

as or in the case of high mechanical exertion

we recommend to install protective hose on

the cable.

All sensors with cable outlets

Cable PVC hose ϕ15/10mm

Hose clip

Protective hose installFig. 9:

In the case of mounting in the pipe it is nec-

essary to provide the minimum distance of

the inner walls from the electrode at 5 mm.

In some cases (sticky fluids, low permittiv-

ity liquids) it is better to mount the sensor to

pipe bend.

For DLS–27_–10, 11, 21, 22

In the case of vertical mounting it is possible

to use hysteresis setting for simple two

state regulation (pump control). The height

of the controlled level is done by sensitivity

setting, the gap between the min. and max.

is defined by hysteresis.

For DLS–27_–20, 21, 22, 30, 31

E

3

1

E

10

1

ay|

E–Electrode

length in mm

Mounting in the pipeFig. 10:

Two state regulation by hysteresisFig. 11:

setting

E–Electrode length in mm

11

© Dinel, s.r.o. DLS–27

RANGE OF APPLICATION5.

DLS–27_–10

Is produced in two versions – with 50 mm or 100 mm length electrode. Short version (E50) is suitable

for clean non-conductive liquids level sensing (oils, diesel, petrol, etc.). Longer version (E100) is de-

signed for non-adhesive bulk-solid or non-adhesive powder materials (plastic granulates, sand, sugar,

grains, etc.) and other non-conductive liquids (lubricants, plant oils). Sensor is specified to be mount-

ed directly into a vessel or container wall (horizontal position) by means of welding flange or stainless

steel fixing nut. In case of level sensing of low-permittivity media in non-conductive containers it is

recommended to mount the sensor on auxiliary metal-plate electrode with min. 200 cm2area.

DLS–27_–11

Is specified for limit level sensing of electrically non-adhesive conductive liquids (water and water

solutions). It is possible to use it for detection of boundary between different permittivity liquids (e.g.

water – oil). Sensor is mounted directly into the side wall of the vessel or in a pipe (horizontal posi-

tion) by means of normal or stainless steel welding flange.

DLS–27_–20

Is designed for limit level detection of light-bulk solid materials (plastic granulates) or powder ma-

terials (flour, cement, limestone powder, detergents, etc.) and for materials with variable humidity

(feeding mixtures, wood sawdust, etc.). It is possible to use it for non-conductive fluids with up to 2%

of water (plant oils, liquid propane, etc.). The sensor with electrode longer than 300 mm is recom-

mended to mount in vertical position only. Sensor is mounted directly into a vessel or container wall

in horizontal (up to E300), slant or vertical position by means of welding flange or stainless steel

fixing nut. We should minimize the hollow spaces between the electrode and the wall where the

material can sediment (see application notes). In case of level sensing in non-conductive containers

it is recommended to mount the sensor on auxiliary metal plate electrode with min. 400 cm2area.

DLS–27_–21, 22

Is specified for conductive liquids level sensing (water, water solutions, mud, etc.). It is designed

for horizontal (up to E300) or vertical installation directly in the wall of a vessel. It reacts on partial

or full immersion of the electrode (dependent on adjusted sensitivity). The less is the sensitivity the

better is resistance to an adhered rests of media. Sensor is mountable directly into wall of a vessel

in horizontal or vertical position by means of welding flange.

In the case of vertical mounting it is necessary

to avoid long fitting tubes, where could the

vapours condense or some rests sediment.

right figure – wrong, left figure – appropri-

ate. The similar situation is when the sensing

electrode goes through the concrete ceiling of

the silo. The hole diameter should be at least

50mm (acc. to the thickness of the ceiling).

All vertically mounted sensors

Long fitting tubes in vertical mountingFig. 12:

DLS–27 © Dinel, s.r.o.

12

ELECTRICAL CONNECTION6.

Sensor with NPN or PNP output is allowed to lead only by resistive or inductive lead. Positive sup-

ply voltage (+U) is connected to the brown conductor BN (1), negative (0V) to the blue conductor

BU (3) and the leads (only NPN or PNP type of output) to the black conductor BK (4). The capacity

loads and low resistance loads (bulb) is evaluated by the sensor as short circuit.

Version Xd is manufacture only with fixing cable (variants “D” with cable outlets). The end of this

cable must be in terminal box with protection class IP6x.

For “B” and “D” variants with the fixed cable, the individual colour cores of the connecting cable are

connected to the respective terminals of the related equipment (supply unit) see Fig. 13 to 15.

For “C” variant with the connector, the cable can be supplied with the sensor (length 2 or 5 m), fitted

with the pressed connector socket or dismountable connector socket without the cable (see acces-

sories). In this case the cable is connected to the inside pins of the socket according to Fig. 16.

The sensor with related equipment is interconnected by a suitable three-core (N and Xd variations)

or two-core (Xi, XiT, XiM, XiMT variations) cable. The length of the cable for the Xi, XiT, XiM, XiMT

variations must be selected with respect to the maximum permitted parameters (usually inductance

and capacity) of the outside intrinsically safe circuit of supply units (NSSU, NDSU, NLCU). If using

a dismountable connector socket, the outside diameter of the cable is a maximum of 6 mm.

DLS–27_–30

Is designed for universal use in vertical position for limit level detection of liquids (conductive and

non-conductive) and bulk-solid and powder materials. It is not recommended to install the sensor

into closed vessels where intensive condensation occurs. Electrically conductive liquids are sensed

just by touch of the end of electrode. To react to non-conductive liquid or solid material it is neces-

sary 5 ÷ 20% dip into a medium dependently on the permittivity of sensed medium and set sensi-

tivity. Sensor is mounted directly into a tank, vessel, container or basin in slant or vertical position

by means of welding flange or stainless steel fixing nut. In case of level sensing of low-permittivity

media in non-conductive containers it is recommended to mount the sensor on auxiliary metal-plate

electrode with min. 500 cm2area.

DLS–27_–31

Is designed for limit level detection of conductive liquids (water and solutions of chemicals). It is

possible to install the sensor into closed vessels, tanks, basins, etc. The sensor reacts to liquid level

after 2 ÷ 20% dip into a liquid dependently on the permittivity of sensed medium and set sensitivity.

Sensor is mounted directly into a vessel, tank or open basins in vertical position by means of weld-

ing flange or fixing nut. When installed into an open basin it is necessary to ground the housing of

sensor or to connect it with sensed liquid. For this purpose it is possible to use any metallic ever

immersed object (pipe, etc.).

DLS–27_–40

Is specified for versatile use for limit level detection of liquids (conductive and non-conductive) and

bulk-solid and powder materials in depths down to 6m. It is not recommended to install the sensor

into closed vessels where intensive condensation occurs. Electrically conductive liquids are sensed

just by touch of the end of electrode. To react to non-conductive liquid or solid material it is neces-

sary 5 ÷ 20% immersion into a material. Sensor is mounted directly into a vessel, tank or open ba-

sins in vertical position by means of welding flange or fixing nut. When installed into an open basin

it is necessary to ground the housing of sensor or to connect it with sensed liquid. For this purpose

it is possible to use any metallic ever immersed object (pipe, etc.).

13

© Dinel, s.r.o. DLS–27

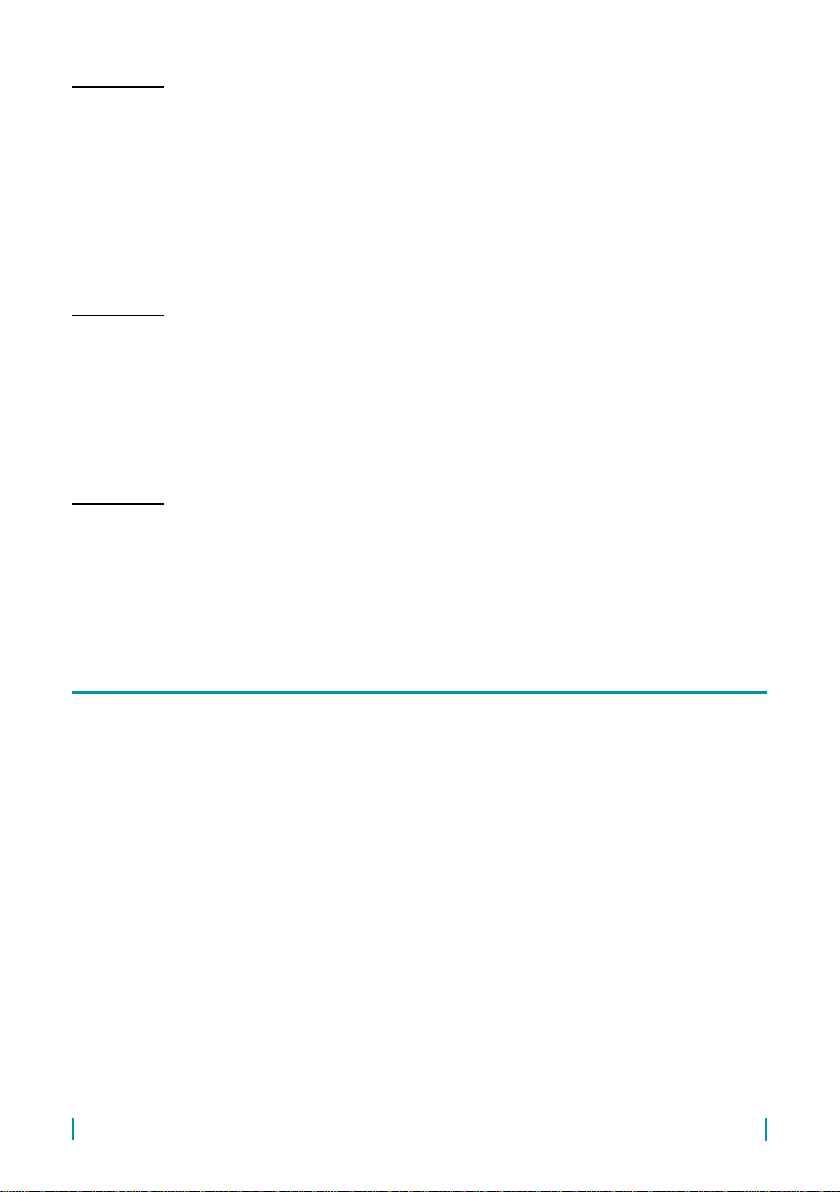

NPN type sensors connectionFig. 13:

(version “N”, “NT”, “Xd”)

Legend:

(1, 3...) – Numbers of terminals inside of the

connector socket

BK – Black

BN – Brown

BU – Blue

output (BK)

0V (BU)

+U (BN)

PNP type sensors connectionFig. 14:

(version “N”, “NT”, “Xd”)

NAMUR type sensors connectionFig. 15:

(version “Xi”, “XiM”, “XiT”, “XiMT”)

Inside of the connector socketFig. 16:

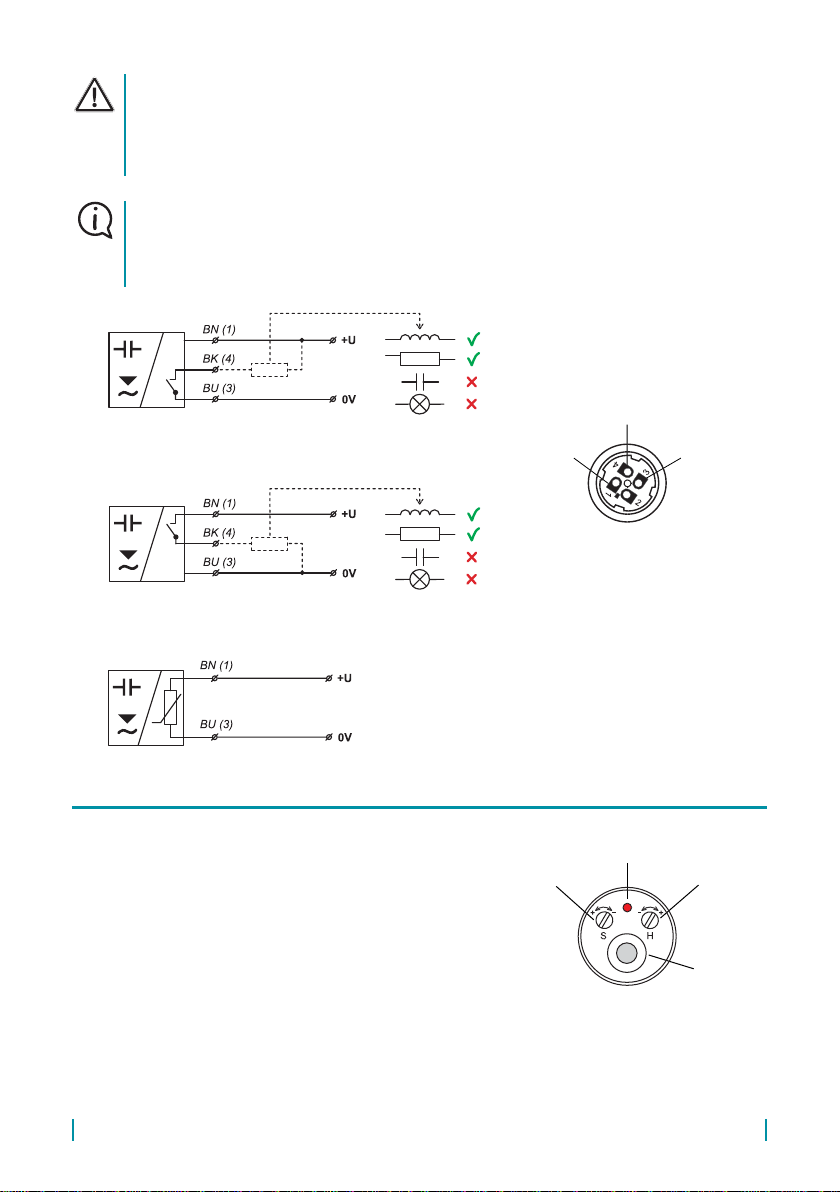

SENSOR SETTING7.

The sensitivity and hysteresis of the level sensor are set by

trimmers “S” and “H” located under the left cover screw on

the rear side.

The basic sensitivity and hysteresis is factory adjusted and

is suitable for most applications.

The sensitivity is set by trimmer “S” located under the left

cover screw on the rear side. Clockwise turning makes the

sensitivity lower, reverse direction turning makes the sensi-

tivity higher.

If the sensed medium is at your disposal before setting into service it is useful to provide individual

setting as follows. In this way it is possible to achieve resistance against sediments.

LED

Hysteresis

Cable outlet

or connector

Top view of level sensorFig. 17:

Sensitivity

Electrical connection must be done in de-energized state! For switching supply sources,

it is necessary to check that the input is galvanically separated from the network side

and that they are fitted with a filter suppressing the conforming interference (terminals

+ and – oscillate together towards the ground potential), or the interference is removed

in another manner.

It is recommended to lead the cable separately from power distribution leads and strong sources of

EMI (pulse converters, electric motors etc.).

Incaseofstrongambientelectromagneticinterference,parallelingofconductorswithpowerdistribu-

tion, or for the distribution to distance over 30 m, we recommend to use shielded cable.

DLS–27 © Dinel, s.r.o.

14

Activate the sensor by inundation (immersion) the electrode into the medium. With this activation,1.

the sensor will change its status (LED lights ON or OFF).

Lower the sensitivity (by clockwise turning) until the sensors stop to react to this activation (dipping2.

into medium). The LED is in the same status as before the activation.

Turn from ½ to 1 rotation left from the threshold point (when the sensor just stops its reaction to3.

immersion). The sensor again changes the status and reacts again to the activation (flooding).

Check the setting.4.

If the medium is not available in advance, it is possible to use the basic setting from the producer and

after some time of operation (after sedimentation of dirt) to make any correction. However, it is always

necessary to know what the permittivity of the material is and to adapt the setting on the sensor. In the

“Sensitivity characteristics” table it is stated for each type, where the change of capacity corresponds

to the 1 rotation. A definite guide can be the fact that the flooding of the electrode in the length of

100 mm into the material with relative permeability r= 2 will cause a change in the capacity about

1.5 to 2 pF (according to the type of electrode).

The hysteresis (position of the minimum and maximum level) can be changed by turning trimmer “H”

located under the right cover screw on the rear side. Clockwise turning makes the hysteresis higher,

reverse direction turning makes it lower. The lower the hysteresis is, the higher sensitivity is possible

to obtain, but the resistance against various disturbances get worse. For usual applications is optimal

hysteresis from ¼ to ¾ rotation of sensitivity trimmer.

After setting, it is necessary to properly tighten cover screws.

SENSITIVITY CHARACTERISTICS

Type of sensor Treshold

sensitivity Hysteresis Sensitivity adjusting range Temperature

stability Rel. permittivity

of material

DLS–27_–10 0.1pF 0.1pF ... 2pF Min. 8pF (1 rot. = 1pF) ± 0.004pF/K Min. 1.4

DLS–27_–11 0.2pF 0.2pF ... 4pF Min. 20pF (1 rot. = 2pF) ± 0.007pF/K Min. 5.0

DLS–27_–20 0.1pF 0.2pF ... 3pF Min. 15pF (1 rot. = 1.5pF) ± 0.006pF/K Min. 1.3

DLS–27_–21 0.3pF 0.3pF ... 6pF Min. 30pF (1 rot. = 3pF) ± 0.01pF/K Min. 4.0

DLS–27_–22 0.3pF 0.3pF ... 6pF Min. 30pF (1 rot. = 3pF) ± 0.01pF/K Min. 4.0

DLS–27_–30 0.2pF 0.2pF ... 4pF Min. 20pF (1 rot. = 2pF) ± 0.01pF/K Min. 1.6

DLS–27_–31 0.3pF 0.2pF ... 5pF Min. 25pF (1 rot. = 2.5pF) ± 0.01pF/K Min. 5.0

DLS–27_–40 0.3pF 0.2pF ... 6pF Min. 20pF (1 rot. = 2pF) ± 0.01pF/K Min. 2.0

STATUS SIGNALIZATION8.

In the following table are the types of inputs and the respective statuses (ON/ OFF) in the case of a

maximum and minimum level sensing. The signalling of the status of the sensor is indicated by the

red LED located on the upper area of the sensor beside the setting trimmers of the hysteresis (“H”)

and the sensitivity (“S”).

For minimumlevelsensingwerecommend sensorwith normallyopen output – NO,PO, RO. Itisfor

failuresafetyreasons–eventualfailureofsensorbehavessimilarlyasanexceedingofthelimitstate.

Analogically for maximum level sensing we recommend normally closed outputs – NC, PC, RC.

15

© Dinel, s.r.o. DLS–27

Level state Type of output Output state LED

Minimum level sensing

DLS–27N_–__–_–NO–_

DLS–27Xd –__–D–NO–_

DLS–27N_–__–_–PO–_

DLS–27Xd –__–D–PO–_

CLOSED

(Shine)

DLS–27Xi–__–_–RO–_ HIGHER

CURRENT

DLS–27N_–__–_–NO–_

DLS–27Xd –__–D–NO–_

DLS–27N_–__–_–PO–_

DLS–27Xd –__–D–PO–_

OPEN

(Dark)

DLS–27Xi–__–_–RO–_ LOWER

CURRENT

Maximum level sensing

DLS–27N_–__–_–NC–_

DLS–27Xd –__–D–NC–_

DLS–27N_–__–_–PC–_

DLS–27Xd –__–D–PC–_

CLOSED

(Shine)

DLS–27Xi–__–_–RC–_ HIGHER

CURRENT

DLS–27N_–__–_–NC–_

DLS–27Xd –__–D–NC–_

DLS–27N_–__–_–PC–_

DLS–27Xd –__–D–PC–_

OPEN

(Dark)

DLS–27Xi–__–_–RC–_ LOWER

CURRENT

ACCESSORIES9.

Standard

(included in the level sensors price)

1 pcs. Seal (asbestos free)•

1 pcs. Screwdriver for adjustment•

(each 5 pcs.)

Optional

(for extra charge)

Extra cables (over the standard length 2m)•

Connector socket (type ELWIKA or ELKA)•

Normal steel welding flange ON–27x2•

Stainless steel welding flange NN–G3/4“•

Stainless steel fixing nut UM–27x2•

Other seals (PTFE, Al, etc.)•

DLS–27 © Dinel, s.r.o.

16

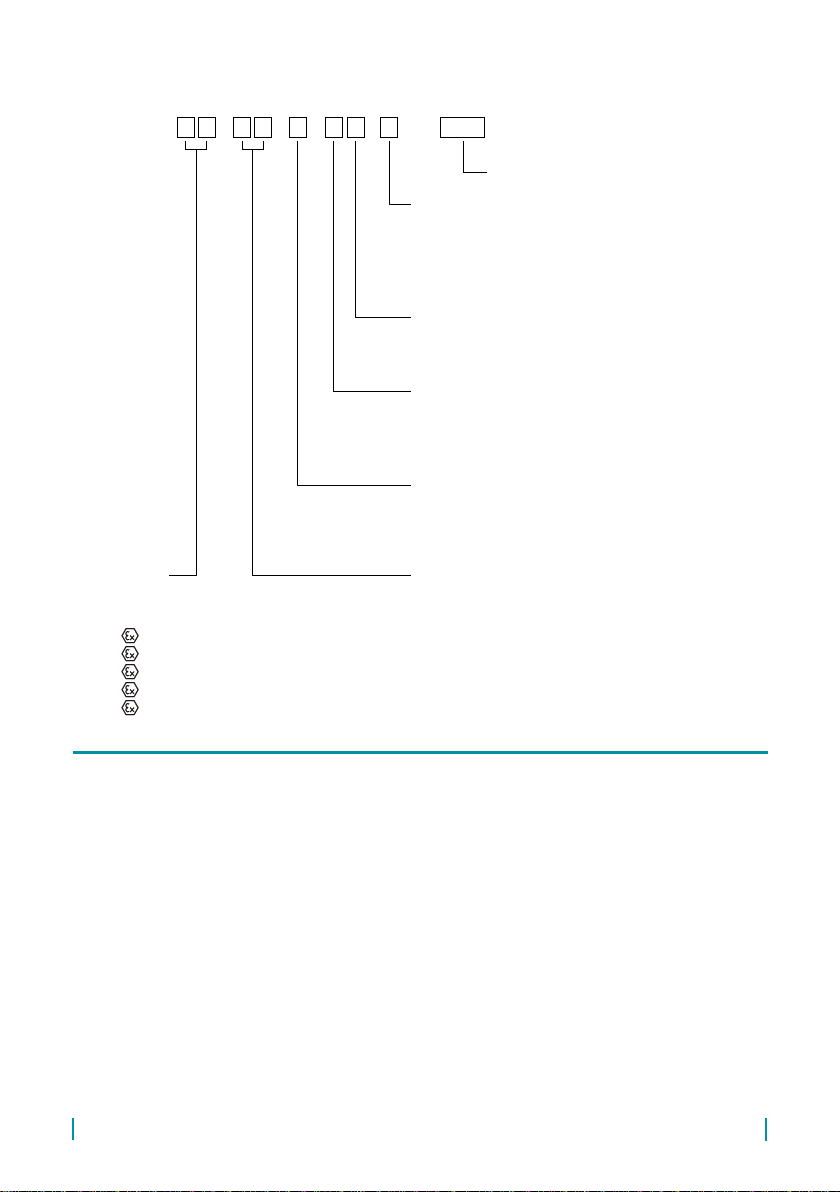

DLS – 27

Type and electrode performance:

10 – Bar, uncoated, lengths 50 or 100mm

11 – Bar, short, fully insulated 30mm

20 – Rod, partly coated, lengths 0.1 ... 1m

21 – Rod, fully coated (FEP), lengths 0.1 ... 1m

22 – Rod, fully coated (PFA), lengths 0.1 ... 1m

30 – Rod, uncoated (dismountable), lengths 0.1 ... 3m

31 – Rod, fully coated, lengths 0.1 ... 3m

40 – Rope, uncoated rope and weight, lengths 1 ... 6m

Length of electrode in mm

–– ––E

Output state at non activated electrode:

O– Open (NAMUR – Lower current)

C– Closed (NAMUR – Higher current)

Type of output:

N– NPN (open collector)

P– PNP (open collector)

R– NAMUR

Electric connection:

B– Cable outlet (+ Spec. the length of the cable)

C– Connector (+ Spec. type of the socket)

D– Cable outlet (+ Spec. the length of the cable)

Performance:

N– Normal (for non-explosive areas)

NT – High temperature performance

Xd – use in flammable dusts areas (only var. “D”)

Xi – for hazardous areas

XiM – for use in mines

XiT – high temp. performance for hazardous areas

XiMT– high temp. performance for use in mines

Process connection:

G– Pipe thread G3/4"

M27 – Metric thread M27x2

M30 – Metric thread M30x1,5

Cl – Tri-clamp coupling

ORDER CODE10.

CORRECT SPECIFICATION EXAMPLES11.

DLS–27N–10–B–NO–M27 E100 cable 5m

(N) Normal performance; (10) Uncoated bar electrode, (B) Cable outlet with 5 m length cable; (NO) Output type NPN with open state at

non-activated electrode; (M27) Metric thread M27x2 process connection; (E100) Electrode length 100mm

DLS–27NT–21–C–PC–G E580

(NT) High temperature performance; (21) Fully coated rod electrode (FEP); (C) Connector; (PC) Output type NPN with closed state at

non-activated electrode; (G) Pipe thread G3/4" process connection; (E580) Electrode length 580mm.

DLS–27Xi–30–C–RO–M30 E1420

(Xi) Explosion-proof performance; (30) Dismountable uncoated electrode; (C) Connector, (RO) Output type NAMUR with lower current

at non-activated electrode, (M30) Metric thread M30x1.5 process connection; (E1420) Electrode length 1420mm.

DLS–27Xd–20–D–NC–G E430 cable 3m

(Xd) Flammable dust areas performance; (20) Partly coated electrode; (D) Cable outlet; (NC) Output type PNP with closed state at non-

activated electrode; (M30) Metric thread M30x1,5 process connection; (E430) Electode length 430mm.

Cable – Length of cable in m

17

© Dinel, s.r.o. DLS–27

SAFETY, PROTECTIONS, COMPATIBILITY AND EXPLOSION PROOF12.

Level sensor DLS–27 is equipped with protection against electric shock on electrode, reverse polar-

ity, output current overload, short circuit and short time over voltages.

Electromagnetic compatibility is provided by conformity with standards EN 55022/B, EN 61326-1,

EN 61000-4-2, -3 ,-4, -5 and -6.

Explosion proof (DLS–27Xi, XiM and Xd) is provided by conformity with standards EN 60079-0,

EN 60079-11, EN 60079-26 and is examined by FTZÚ – AO210 Ostrava – Radvanice, certificate No.

FTZÚ 02 ATEX 0234X.

Explosion proof (DLS–27Xd) is provided by conformity with standards EN 60079-0, EN 61241-0,

EN 61241-1 and is examined by FTZÚ – AO210 Ostrava – Radvanice, certificate No. FTZÚ 02 ATEX

0234X.

USE, MANIPULATION AND MAINTENANCE13.

The level meter does not require any personnel for its operation.

It is forbidden to make any changes or interventions to the DLS–27 sensor without the

consent of the producer. Any repairs must only be carried out by the producer or author-

ized service organisations.

Assembly, installation, commissioning, service and maintenance of the DLS–27 level

sensor must be carried out in accordance with this manual and the provisions of valid

standards for the installation of electrical equipment must be complied with.

SPECIAL CONDITIONS FOR SAFE USE14.

If the apparatus is used as device of Group II and with using of an approved power supply device,

which output parameters comply with required input parameters, it is necessary to have an galvanic

separation or in case of apparatus without galvanic separation (Zener barriers) it is necessary to

provide equipotential equalizing between sensor and barrier earthing point.

If the apparatus is used in coal mine as device of Group I and with using of an approved power

supply device, which output parameters comply with required input parameters it is necessary to

have an galvanic separation.

When used in zone 0 the present explosive atmosphere of air mixture and gases, vapours of mists

must be comply with: 20°C Tamb 60°C, 0.8 bar p 1.1 bar.

Design DLS–27Xi can be used in zone 0 or zone 20. With design DLS–27XiT can be used in zone 0

and zone 20 only electrode part head with electronics can be used only in zone 1 or zone 21.

Ambient temperature: Tamb = -20°C to +75°C

Temperature of measured medium according to design variant see chapter “Specification”.

For design DLS–27XiMT it is necessary to observe that temperature of any surface of apparatus,

when coal dust can from a layer, do not exceed 150°C.

DLS–27 © Dinel, s.r.o.

18

Level sensors label data DLS–27N and DLS–27NT

Symbol of producer: Dinel logo• ®

Internet and email address: www.dinel.cz, dinel@dinel.cz•

Level sensor type and electrode length: DLS–27N (NT)–__–_–__–_ Exxxx•

Cable length in meters: Cable•

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)•

Electrical connection, wire colours•

Supply voltage: U•

=7 ...36 V=

Current supply: I•

=3 / 7 mA

Switching current: I• omax = 200 mA

Protection class: IP67, Compliance mark:•

Electro-waste take-back system mark:•

Level sensors label data DLS–27Xi and DLS–27XiT

Symbol of producer: Dinel logo• ®

Internet and email address: www.dinel.cz, dinel@dinel.cz•

Level sensor type and electrode length: DLS–27Xi (XiT)–__–_–R_–_ Exxxx•

Cable length in meters: Cable•

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)•

Electrical connection, wire colours•

Label of non-explosive device:•

Performance: II 1 G Ex ia IIB T6 Ga; II 1 D Ex ia IIIC T76°C Da•

Limit operating parameters:U• i

=12 V=, Ii

=15mA; Pi= 45mW; Ci

=15nF; Li

=10H

Ambient temperature range for the zone 0: t• a= -20 ... +60 °C

Ambient temperature range: t• a= -20 ... +75 °C

Number of certificate of intrinsically safety: FTZÚ 02 ATEX 0234X•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Protection class: IP67, Electro-waste take-back system mark:•

BN

BU

BK

+U

0V

U

I

7...36V

3 / 10 mA

200 mA

Iomax

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27N_-__-_-PO_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

IP67

U

I

7...36V

3 / 10 mA

200 mA

BN

BU

BK

+U

0V Iomax

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

IP67

U

I

7...36V

3 / 10 mA

200 mA

BN

BU

BK

+U

0V Iomax

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

IP67

U

I

7...36V

3/10mA

200 mA

BN

BU

BK

+U

0V Iomax

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

IP67

BN

BU

+U

0V

II 1/2 G Ex ia IIB T6 Ga/Gb

U=12V

i

FTZÚ 02 ATEX 0234X

C = 15 nF

i

1026

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic I = 15 mA

iP = 45 mW

i

t = -20...+60 °C (zone 0)

a

L = 10 uH

i

t = -20...+75 °C

a

II 1 D Ex ia IIIC Da/2 /DbT76°C

IP67

DLS-27XiT-__-_-R_-___ E____ No.: ______Cable: __ m

BN

BU

+U

0V

II1GExiaIIBT6Ga

U=12V

i

FTZÚ 02 ATEX 0234X

C = 15 nF

i

1026

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic I = 15 mA

iP = 45 mW

i

t = -20...+60 °C (zone 0)

a

L = 10 uH

i

t = -20...+75 °C

a

II1DExiaIIIC DaT76°C

IP67

DLS-27Xi-__-_-R_-___ E____ No.: ______Cable: __ m

MARKING OF LABELS15.

Real label size is 97x12mm.

19

© Dinel, s.r.o. DLS–27

Level sensors label data DLS–27Xd

Symbol of producer: Dinel logo• ®

Internet and email address: www.dinel.cz, dinel@dinel.cz•

Level sensor type and electrode length: DLS–27Xd–__–_–__–_ Exxxx•

Cable length in meters: Cable•

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)•

Electrical connection, wire colours•

Label of non-explosive device:• , Performance: II 1 D Ex tD A20 T 77°C IP 6X

Supply voltage: U•

=7 ...36 V=

Current supply: I•

=3 / 7 mA

Switching current: I• omax = 200 mA

Ambient temperature range: t• a= -20 ... +75 °C

Number of certificate of intrinsically safety: FTZÚ 10 ATEX 0092X•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Protection class: IP67, Electro-waste take-back system mark:•

Level sensors label data DLS–27XiM and DLS–27XiMT

Symbol of producer: Dinel logo• ®

Internet and email address: www.dinel.cz, dinel@dinel.cz•

Level sensor type and electrode length: DLS–27XiM (XiMT)–__–_–__–_ Exxxx•

Cable length in meters: Cable•

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)•

Electrical connection, wire colours•

Label of non-explosive device:• , Performance: I M2 Ex ia I Mb

Limit operating parameters: U• i

=12 V=, Ii

=15mA; Pi= 45mW; Ci

=15nF; Li

=10H

Ambient temperature range for the zone 0: t• a= -20 ... +60°C

Ambient temperature range: t• a= -20 ... +75 °C

Number of certificate of intrinsically safety: FTZÚ 02 ATEX 0234X•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Protection class: IP67, Electro-waste take-back system mark:•

BN

BU

BK

+U

0V

II 1D T 77°CEx tD A20 IP 6X

Cert. No.: FTZÚ 10 ATEX X0092

U = 7 ... 36 V I=3/10mA

I=200mA

omax t = -20 ... +70 °C

a

IP67

1026

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27Xd-__-D-PC_-___ E____ No.: ______Cable: __ m

BN

BU

BK

+U

0V

II 1D T 77°CEx tD A20 IP 6X

Cert. No.: FTZÚ 10 ATEX X0092

U = 7 ... 36 V I=3/10mA

I=200mA

omax t = -20 ... +70 °C

a

IP67

1026

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27Xd-__-D-PO_-___ E____ No.: ______Cable: __ m

BN

BU

BK

+U

0V

II 1D T 77°CEx tD A20 IP 6X

Cert. No.: FTZÚ 10 ATEX X0092

U = 7 ... 36 V I = 3 / 10 mA

I 200 mA

omax =t = -20 ... +70 °C

a

IP67

1026

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27Xd-__-D-NC_-___ E____ No.: ______Cable: __ m

BN

BU

BK

+U

0V

II1DExtDA20T77°CIP6X

Cert. No.: FTZÚ 10 ATEX 0092X

U=7...36V I=3/10mA

I=200mA

omax t = -20 ... +70 °C

a

IP67

1026

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

DLS-27Xd-__-D-NO_-___ E____ No.: ______Cable: __ m

BN

BU

+U

0V

IM2ExiaIMb

U=12V

i

FTZÚ 02 ATEX 0234X

C = 15 nF

i

1026

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic I = 15 mA

iP = 45 mW

i

t = -20...+60 °C (zone 0)

a

L = 10 uH

i

t = -20...+75 °C

a

IP67

DLS-27XiMT-__-_-R_-___ E____ No.: ______Cable: __ m

BN

BU

+U

0V

IM2ExiaIMb

U=12V

i

FTZÚ 02 ATEX 0234X

C = 15 nF

i

1026

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic I = 15 mA

iP = 45 mW

i

t = -20...+60 °C (zone 0)

a

L = 10 uH

i

t = -20...+75 °C

a

IP67

DLS-27XiM-__-_-R_-___ E____ No.: ______Cable: __ m

DLS–27 © Dinel, s.r.o.

20

TECHNICAL DATA

Supply voltage 7 ... 36 V DC *

Current supply (state OFF / ON) 3 / 10 mA *

Switching current (NPN, PNP output) 200 mA *

Remanent voltage – ON state Max. 1.5 V

Output time delay 0.2 s

Input resistance / Electric strength 1 M/ 1 kV AC

Coupling capacity / Electric strength 47 nF / 250 V AC *

Protection class IP67

Cable (version with cable outlets) PVC 3 x 0.5 mm2 or 2x0.75 mm2

Weight (excl. electrode, cable 2 m) DLS–27_

DLS–27_T

Approx. 0.4kg

Approx. 0.7kg

* Only for variants “N” and “Xd”

USED MATERIALS

Part of the DLS Type Standard material Optional (on request)

Housing All type St. steel W.Nr. 1.4301 (AISI 304) St. steel W.Nr. 1.4571 (AISI 316Ti)

Insulating bushing All type PTFE –

Electrode coating DLS– 27_– 11 PTFE –

Electrode coating DLS– 27_– 20, 21, 31 FEP –

Electrode coating DLS– 27_– 22 PFA –

ELECTRICAL PARAMETERS – variants Xi, XiT, XiM, XiMT

Supply voltage 8 ... 9 V DC

Current supply (state OFF / ON) – NAMUR ≤ 1 mA / ≥ 2.2 mA

Max. internal values Ui=12VDC; Ii=15 mA; Pi = 45 mW; Ci=15nF; Li=10 H

Coupling capacity / Electric strength 2.7 nF / 500 V AC

Cables LC values Typ. C < 150 pF/m

Typ. L < 0.8 H /m

SPECIFICATIONS16.

WORKING AREAS (EN 60079-10, 14 and EN 50281-1-2)

DLS–27N Performance for non-explosive areas.

DLS–27NT High temperature performance for non-explosive areas.

DLS–27Xd Performance for flammable dust areas, II 1D Ex tD A20 T77°C IP 6X, whole sensor

zone 20, 21 and 22.

DLS–27Xi Performance for explosive areas, II 1 G Ex ia IIB T6 Ga; II 1 D Ex ia IIIC T76°C Da with

intrinsically safe supply units, whole sensor zone 0 and 20.

DLS–27XiT

High temperature performance for explosive areas, II 1/2 G Ex ia IIB T6 Ga/Gb;

II 1/2 D Ex ia IIIC T76°C Da/Db with intrinsically safe supply units, electrode part zone 0 and 20,

housing zone 1 and 21.

DLS–27XiM Intrinsically safe explosion-proof performance for use in mines,

I M2 Ex ia I Mb with intrinsically safe supply units.

DLS–27XiMT High temperature intrinsically safe explosion-proof performance for use in mines,

I M2 Ex ia I Mb with intrinsically safe supply units.

This manual suits for next models

7

Table of contents

Other Dinel Accessories manuals

Popular Accessories manuals by other brands

Hama

Hama 00176617 operating instructions

promethean

promethean ActivPanel Digital Pen user guide

Stadler Form

Stadler Form Jasmine operating instructions

Lightolier

Lightolier 1101HCB specification

Niles

Niles CS120 Installation & operation guide

brennenstuhl

brennenstuhl Premium-PROTECT-Line Directions for use