Dinel RFLS-35 User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

High-frequency limit level sensor

RFLS – 35

INSTRUCTION MANUAL

průmyslová elektronika

1. Basic description.......................................................................................................................4

2. Variants of sensors ...................................................................................................................5

3. Dimensional drawing ................................................................................................................5

4. Installation and putting into operation .......................................................................................7

5. Installation instructions .............................................................................................................8

6. Electrical connection...............................................................................................................10

7. Control elements.....................................................................................................................11

8. Settings...................................................................................................................................12

9. Function and status indication ................................................................................................15

10. Order code..............................................................................................................................16

11. Correctspecicationexamples...............................................................................................16

12. Accessories ............................................................................................................................16

13. Safety,protections,compatibilityandexplosionproof...........................................................17

14. Use, manipulation and maintenance ......................................................................................17

15. General, conditions and warranty ...........................................................................................18

16. Marking of labels.....................................................................................................................18

17. Technicalspecications..........................................................................................................20

18. Packings, shipping and storage..............................................................................................22

RFLS–35 © Dinel, s.r.o.

3

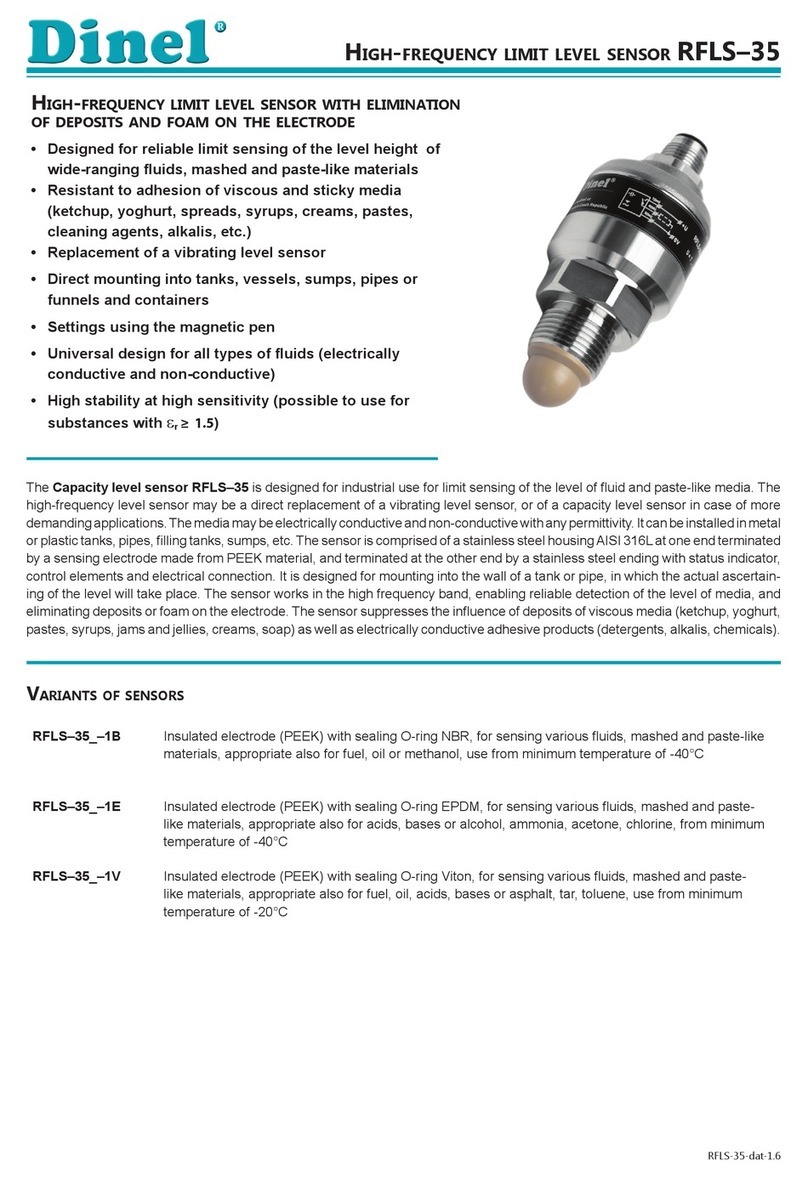

The high-frequency level sensor RFLS–35 is designed for industrial use for limit sensing of the

level of liguid and paste-like media. The high-frequency level sensor may be a direct replacement of

a vibrating level sensor, or of a capacity level sensor in case of more demanding applications. The

media may be electrically conductive or non-conductive with any permittivity. It can be installed in

metalorplastictanks,pipes,llingtanks,sumps,etc.

It is mainly designed for mounting into the wall of a tank or pipe, in which the actual detection of the

level will take place. The sensor works in the high frequency band, enabling reliable detection of

the level of media, and eliminating deposits or foam on the electrode. The sensor suppresses the

inuenceofdepositsofviscousmedia(ketchup,yoghurt,pastes,syrups,jamsandjellies,creams,

soap)aswellaselectricallyconductiveadhesiveproducts(detergents,alkalis,chemicals).

Likewise,itispossibletoutilizeittodierentiateaspecicmediafromothers-the"Mediumwindow"

function.E.g.itcandierentiateoilfromwaterandair,detectonlybeerfoamandignorebeerandair,etc.

The sensor is made from a stainless steel housing at one end terminated by a sensing electrode,

and terminated at the other and by an ending with a status indicator, control elements and electrical

connection.

Toensuremaximumsafetyofcontrolprocesses,wehavedenedthefollowingsafetyinstructions

and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

theseinstructionsmaycausedisturbance,damageordestructionofequipmentormaycauseinjury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

All operations described in this instruction manual have to be carried out by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

4

© Dinel, s.r.o. RFLS–35

• RFLS–35_–1B Insulated electrode (PEEK) with sealing O-ring NBR, for sensing

various liquid, mashed and paste-like materials, appropriate also for fuel,

oil or methanol,

use from minimum temperature of -40 °C

• RFLS–35_–1E Insulated electrode (PEEK) with sealing O-ring EPDM, for sensing

various liquid, mashed and paste-like materials, appropriate also for acids,

bases or alcohol, ammonia, acetone, chlorine,

from minimum temperature of -40 °C

• RFLS–35_–1V Insulated electrode (PEEK) with sealing O-ring Viton, for sensing

various liquid, mashed and paste-like materials, appropriate also for fuel,

oil, acids, bases or asphalt, tar, toluene,

use from minimum temperature of -20 °C

• RFLS–35_–2 Insulated electrode (PTFE) without O-ring, for sensing various liquid,

mashed and paste-like materials, especially suitable for aggressive liquids,

use from minimum temperature of -40 °C.

Therearenextperformancesavailable:N– For normal atmospheres, Xi –Explosionproof–intrinsi-

callysafeforhazardous(explosive)areas.andXiM–Explosionproof–intrinsicallysafeforusein

mineswithmethaneorammabledustpresencedanger(seetechnicalspecications).

Measuring

electrode

Sensor

housing

End of sensor

Cable

gland

RFLS–35_–1–G1/2 RFLS–35_–1–G3/4

*Typeofthreads:G3/4;M27x2

RFLS–35 © Dinel, s.r.o.

5

RFLS–35_–2–Cl50

(Tri-clamp)

RFLS–35_–2–G1/2

RFLS–35_–2–Cl34

(Tri-clamp)

*Typeofthreads:G3/4;M27x2

RFLS–35_–2–G3/4

6

© Dinel, s.r.o. RFLS–35

Variant “A” with short

stainless steel gland

Variant “C”

with connector M12

Variant “V” with plastic cable gland with

spiral relief – in case of increased mechani-

cal wear on the cable.

spiral relief

Variant “H” with cable gland for protect-

ed hoses – for using in an outdoor area or in

area with increased moisture.

protective hose

(ø 13 mm)

Variant “B” with plastic

threaded cable gland

Variant “D” with

dustproof cable outlet

Pleasefollownext3steps:

•

•

•

RFLS–35 © Dinel, s.r.o.

7

RFLS level sensors can be mounted in horizontal or inclined position into the shell of a con-

tainer, storage tank or pipe by screwing into the welding ange, or by axing using a nut.

Basic application recommendations are mentioned below.

During assembly into the metal tank or the storage tank, it is not necessary to separately ground

the base of the level sensor

Inthecaseoftheuse for an aggressive medium isnecessary to provethe chemical compatibility

of used materials of the sensor (Tab. Used materials on page 19). This guarantee ceases when

the product is chemically damaged.

Thanks to its design, the sensor is appropriate for detection of the level of viscous and simultane-

ously electrically conductive media (yoghurt,jamsandjellies,mayonnaise,spreads,liquidsoap,

creams or pastes). After setting the sensitivity of the given media, it reliably reacts to the presence

or absence of a medium level. On the contrary, the sensor does not react to remnants and coatings

of viscous media on the measuring electrode.

Fig. 1: Side installation of sensors into a tank with viscous medium

It is recommended to install

sensors in a horizontal pipe

inclined from the side.

or adhering remnants

of liquid at the bottom

of the pipe.

Upon vertical installation of the

sensor in a pipe, pay attention to

potential formation of air pockets,

!!

Fig. 2: Installation of the sensor in a pipe

8

© Dinel, s.r.o. RFLS–35

In the case of side wall mounting.itisnecessarytoavoidlongttingtubes,wheresensedmedium

could remain. We recommend mounting the sensor so that the whole measuring electrode is inside

the tank.

Fig. 3a: Correct and incorrect installation

with a long tube

Installation of the sensor for reliable checking of the level of a liquid with foam on the surface. Sensi-

tivity of the sensor can be set to detect the liquid interface with foam. After a drop in the liquid level,

the sensor does not react to coatings of foam on the electrode.

The LED indicator

“STATE” is dark

The LED indicator

“STATE” shines

Fig. 4: Monitoring the level of foam media

Small Tri-clamp (ø 34 mm), only for liquids with low viscosity.

Fig. 3b: Correct and incorrect installation with

a long tube for process connection with Tri-Clamp

The sensor can be mounted in a tank or at medium inlets. After setting to the level of the given

mediathesensordoesnotreacttothecurrentofowingmedium.

Fig. 5: Option of mounting the sensor in the medium inlet

RFLS–35 © Dinel, s.r.o.

9

A sensor with PNP output can be loaded only by resistive or inductive load. The positive pole of

thesupplyvoltage(+U)isconnectedtothebrownwireBN or pin connector no.1, the negative pole

(0V)isconnectedtothebluewireBU or pin connector no. 3 and load on the black wire BK or pin

connector no. 4.Thecapacitativeloadsandlowresistanceloads(bulb)areevaluatedbythesensor

as a short circuit.

Connection diagrams are listed in Figures 6, 7.

Connection using connector socket shows in Figure 9.

Sensors RFLS-35 with type of cable outlet A, B, V, D or H are connected to assessing units perma-

nently connected by PVC cable. Design diagrams are provided in images 6, 7.

Sensors RFLS-35 with connection method type C are connected to control units by means of a con-

nectorsocketwithcompressioncable(length2or5m),orbymeansofdismountableconnector

socketwithoutcable(seeaccessories),connectorsocketisnotpartofthesensor.Inthiscasethe

cable is connected to the inside pins of the socket according to Figure 9. The recommended diam-

eterofthiscableis4to6mm(therecommendedcross-sectionalareais0.5to0.75mm2).

The connection of the sensor to the connecting device is performed using a suitable three wire

(variantN)ortwowire(variantXiandXiM)cable.ThelengthofthecablefortheXiandXiMvaria-

tionsmustbeselectedwithrespecttothemaximumpermittedparameters(usuallyinductanceand

capacity)oftheoutsideintrinsicallysafecircuitofsupplyunits(NSSU,NDSU,NLCU).

Intheeventthatdismountableconnectorsocketsareused,theouterdiameterofthecableismax.

6 mm.

Fig. 6: PNP output type sensor connection Fig.7: NAMUR type sensors connection

(variants Xi and XiM)

1

3

4

Legend:

(1,...) – numbers of terminals inside the connector socket

BK – Black

BN – Brown

BU – Blue

output (BK)

0V (BU)

+U (BN)

Fig. 9: Inside of the connector socket

(type ELWIKA or ELKA)

0 V (3)

+U (1)

Fig. 8: Connection of the connector

socket on sensor

Uout (4)

10

© Dinel, s.r.o. RFLS–35

Electrical connection can only be made when de-energized!

The source of the power voltage must comprise of a stabilised safe low power source with

galvanic separation. In the event that a switch-mode power supply is used, it is essential that

its construction effectively suppresses common mode interference on the secondary side. In

the event that the switch-mode power supply is equipped with a PE safety terminal, it must

be unconditionally grounded! Spark-safe devices type (RFLS–35Xi and RFLS-35XiM) must

be powered from a spark-safe power source meeting the above-mentioned requirements.

In the event that the level meater (sensor) is installed in an outdoor environment at a distance

greater than 20 m from the outdoor switchboard, or from an enclosed building, it is necessary

to supplement the electrical cable leading to the level meater (sensor) with suitable overvoltage

protection.

With regard to possible occurrence of electrostatic charge on non-conductive parts of the

sensor for explosive areas (RFLS–35Xi and RFLS–35XiM, sensors must be grounded. It will be

done using conductive tank, conductive lid of tank, or by the auxiliary plate electrode PDE-27.

In the event of strong ambient electromagnetic interference, paralleling of conductors with

power distribution, or for distribution to distances over 30 m, we recommend grounding the

level meter (see above) and using a shielded cable.

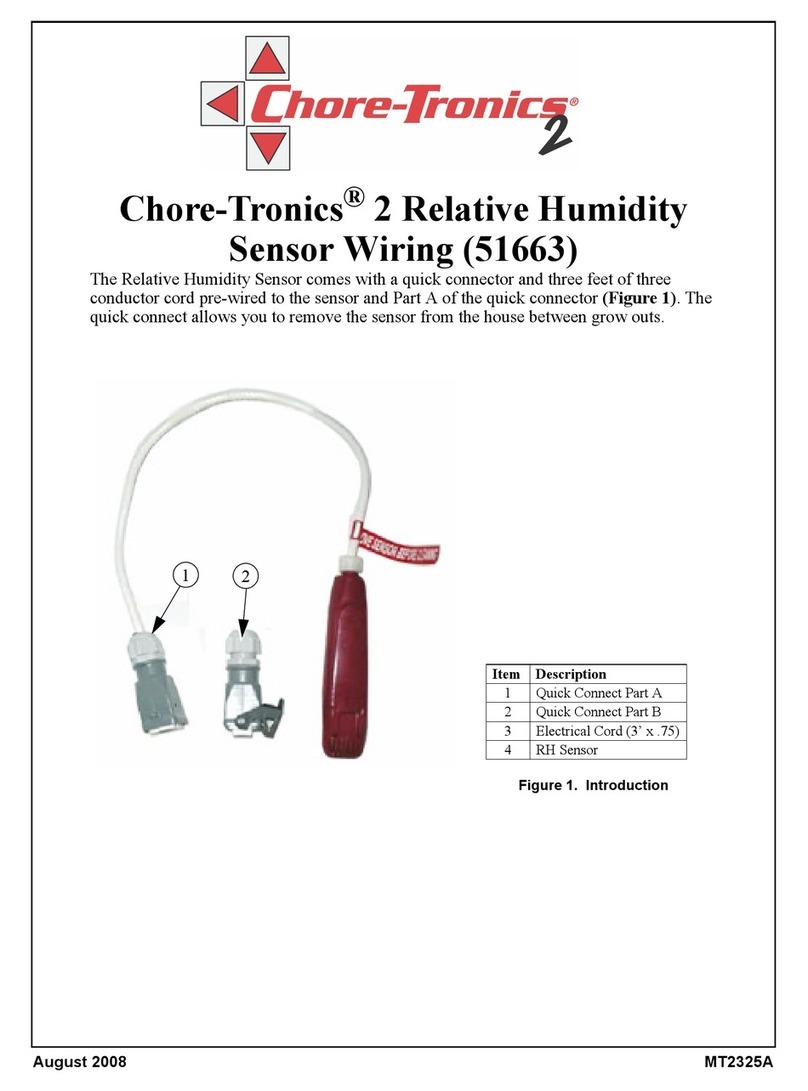

+-

cable gland or

connector

orange LED

sensitive spot +sensitive spot -

green LED

Settings are performed by placing the magnetic pen on the

sensitive spot marked “+” or “

–

” located at the end of the

sensorintwomodes:

1. Quick settings - the user does not know precisely to

what medium the sensor should be set, he only wants

toputthesensorintooperation(usuallyuponreceiving

it) and check to see if the sensor is generally functional

2. Basic settings - the user has the medium available and

canperformonthesensoritsoodinganddrainage

3. Medium window settings - the user has the medium

availableandcanperformonthesensoritsooding

and drainage

Fig. 10: Top view of sensor control

elements

RFLS–35 © Dinel, s.r.o.

11

Thisfunctioncanbeusedforquicksettingofthesensor,orincaseitisnotpossible(orisvery

complicated) to change the level of the medium for setting the sensor. Suitable also before putting

into operation.

(

1. The tank is empty or the level of measured medium in the tank is in a state where the sensor

electrode is no longer submerged.

2. Place the magnetic pen for at least 5 seconds* on the sensitive spot ofthesensor(rstboth

LEDsilluminate,afterapprox.3secondstheorangeLEDwillash3times,andafteranotherap-

prox.2secondstheorangeLEDashesagain3times-nowyoucanremovethemagneticpen).

The sensor is now set to the mode O (itisclosedwhensubmerged).

1. The tank is empty or the level of measured medium in the tank is in a state where the sensor

electrode is no longer submerged.

2. Place the magnetic pen for at least 5 seconds* on the sensitive spot ofthesensor(rstboth

LEDsilluminate,afterapprox.3secondstheorangeLEDwillash3times,andafteranotherap-

prox.2secondstheorangeLEDashesagain3times-nowyoucanremovethemagneticpen).

The sensor is now set to the mode C (itisopenwhensubmerged).

If no other agreement the mode “O” is set on all sensors straight from the factory.

When using the function "Quick settings", the sensor does not eliminate the presence of

deposits and foam on the electrode.

The manufacturer recommends performing Basic Settings as soon as possible.

*) Maximum 10 seconds.

12

© Dinel, s.r.o. RFLS–35

BASIC SETTINGS

For setting the sensitivity and switching mode, where it is possible to submerge the sensor in or

remove it from the medium. When using this setting, the sensor eliminates the presence of deposits

and foam on the electrode.

1. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be covered.

2. Place the magnetic pen for at least 2 seconds** on the sensitive spot ofthesensor(until

both LEDs illuminate) and then remove the magnetic pen. Settings are conrmed by three

ashesoftheorangeLED.

3. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be uncovered. Leave possible deposits on the electrode.

4. Place the magnetic pen for at least 2 seconds** on the sensitive spot of the sensor un-

tilbothLEDsilluminateandthenremovethemagneticpen.Settingsareconrmedbythree

ashesoftheorangeLED

5. Checkthestateofindicators:

- IftheorangeLEDisnotilluminatedandthegreenLEDisashing,thesensoriscorrectlyset.

- IfalternatingashingoftheorangeandgreenLEDoccurs,thesensordidnotrecognizethe

limitsforclosingandopening.Inthiscase,ndoutwhethertheminimumandmaximum

levels are not set too close to one another.

1. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be covered.

2. Place the magnetic pen for at least 2 seconds** on the sensitive spot of the sensor un-

tilbothLEDsilluminateandthenremovethemagneticpen.Settingsareconrmedbythree

ashesoftheorangeLED.

3. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be uncovered.

4. Leave possible deposits on the electrode.

Place the magnetic pen for at least 2 seconds** on the sensitive spot of the sensor un-

tilbothLEDsilluminateandthenremovethemagneticpen.Settingsareconrmedbythree

ashesoftheorangeLED.

5. Checkthestateofindicators:

- IftheorangeLEDisilluminatedandthegreenLEDisashing,thesensoriscorrectlyset.

- IfalternatingashingoftheorangeandgreenLEDoccurs,thesensordidnotrecognizethe

limitsforclosingandopening.Inthiscase,ndoutwhethertheminimumandmaximum

levels are not set too close to one another and possible repeat the settings.

For safety reasons, we recommend setting the mode “O” for level sensing (the sensor is closed

upon immersion). It is for failure safety reasons – eventual failure of sensor behaves similarly as

an exceeding of the limit state. Analogically, for the maximum level it is recommended to set the

mode “C” (the sensor is open upon immersion).

**) Maximum 4 seconds.

RFLS–35 © Dinel, s.r.o.

13

To set the sensitivity and switching mode for the required medium. With this setting, the sensor does

notreacttobeingsubmergedinamediumwithadierentpermittivity.

1. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be covered.

2. Place the magnetic pen for at least 10 seconds on the sensitive spot sensor LEDs are lit,

afterapprox.3secondstheorangeLEDwillash3times,andafteranotherapprox.2seconds

theorangeLEDashesagain3times,andafteranother5stheorangeLEDashesagain3

times - now the magnetic pen can be removed).

ThesensorisnowsettomodeO(itisunswitchedwhensubmergedintherequiredmedium).

3. Checkthestateofindicators:

- IftheorangeLEDisnotilluminatedandthegreenLEDisashing,thesensoriscorrectlyset.

1. Bring the level of the measured medium in the tank to a state so that the sensor electrode would

be covered

2. Place the magnetic pen for at least 10 seconds on the sensitive spot sensor(rstboth

LEDsarelit,afterapprox.3secondstheorangeLEDwillash3times,andafteranotherap-

prox.2secondstheorangeLEDashesagain3times,andafteranother5secondstheorange

LEDashesagain3times-nowthemagneticpencanberemoved).

ThesensorisnowsettomodeC(itisunswitchedwhensubmergedintherequiredmedium).

3. Checkthestateofindicators:

- IftheorangeLEDisnotilluminatedandthegreenLEDisashing,thesensoriscorrectlyset.

Fig 11: Mode “Medium window” - only detection of required medium (for

example: only beer foam, beer and air are ignored)

The LED indicator

“STATE” is dark

The LED indicator

“STATE” shines

The LED indicator

“STATE” is dark

14

© Dinel, s.r.o. RFLS–35

LED indicator colour function

"RUN" green

Measuring function indication

ashing–(approx.0.4s)–correctfunctionofleveldetection

dark – incorrect installation or malfunction.

alternating ashing of the green and orange LED – error in settings

simultaneous shine of green and orange LED – when applying the

mag.pen,whenthesettingisconrmed

"STATE" orange

Settings indication

permanent shine – the sensor is closed

dark – the sensor is open

3 short ashes–settingsconrmed

alternating ashing of the green and orange LED – error in settings

simultaneous shine of green and orange LED – when applying the

mag.pen,whenthesettingisconrmed

For safety reasons, we recom-

mend using the setting of the

mode “O” for min. level sensing

(the sensor is closed upon immer-

sion). It is for failure safety rea-

sons – eventual failure of sensor

behaves similarly as anexceeding

of the limit state. Analogically, for

the max. level it is recommended

to set the mode “C” (the sensor is

open upon immersion).

level state mode output state state indicator

maximum level sensing

C

CLOSED

( in type N )

(illuminated)

HIGHER

CURRENT

( in type Xi )

C

OPEN

( in type N )

(notilluminated)

LOWER

CURRENT

( in type Xi )

level state mode output state state indicator

minimum level sensing

O

CLOSED

( in type N )

(illuminated)

HIGHER

CURRENT

( in type Xi )

O

OPEN

( in type N )

(notilluminated)

LOWER

CURRENT

( in type Xi )

RFLS–35 © Dinel, s.r.o.

15

process connection:

RFLS –35 – – ––

type of output:

P – PNP (open collector)

R – NAMUR (for Xi and XiM variants)

connection method: A– stainless steel compression

gland (+ cable length)

B – plastic threaded cable gland

(+ cable length)

C– connector (socket not included

with sensor, recommended

type - see accessories)

D – nickel-plated brass

threaded cable gland

(+ cable length)

V – plastic cable gland with spiral

(+ cable length)

H– plastic cable gland for

protective hose (+ cable

length)

type and electrode performance:

mech. performance:

G1/2 – pipe thread G 1/2"

G3/4 – pipe thread G 3/4"

M27 – metric thread M27x2

CI34 – Tri-clamp (ø 34 mm)

CI50 – Tri-clamp (ø 50,5 mm)

cable – cable length in m

N– non-explosive areas

Xi – for explosive

environments

XiM – for mining

environments

type el. 1B – insulated electrode (PEEK, O-ring NBR)

type el. 1E – insulated electrode (PEEK, O-ring EPDM)

type el. 1V – insulated electrode (PEEK, O-ring Viton)

type el. 2 – insulated electrode (PTFE, without O-ring) - only variant „N“

optional – for a surcharge

(seecataloguesheetofaccessories)

• cable(overthestandardlength2m)

• connectorsocket(typeELWIKAorELKA)

• standardsteelweldingangeorstainlesssteel

weldingange

• protectivehose(fortypeofcableoutletH)

• stainlesssteelxingnut

• varioustypesofseals(PTFE,Al,etc.)

standard – included in the sensor price

• 1 pcs. magnetic pen MP-8

• 1pcs.seal(asbestosfree)

RFLS–35N–2–Cl50–P–B cable 5 m

(N) designed for normal areas; (2) insulated electrode PTFE; (Cl50) process connection Tri-clamp (ø 50,5 mm); (P) output type PNP;

(B) plastic cable gland.

RFLS–35Xi–1E–G1/2–R–C

(Xi) Explosion-proof performance; (1E) insulated electrode with O-ring EPDM; (G1/2) process connection place by thread G1/2”; (P)

Output type NAMUR; (C) connector.

16

© Dinel, s.r.o. RFLS–35

The level sensor is equipped with protection against electric shock on the electrode, reverse polarity,

output current overload, short circuit and against current overload on output.

Protection against dangerous contact is provided by low safety voltage according to 33 2000-4-41.

ElectromagneticcompatibilityisprovidedbyconformitywithstandardsEN55022/B,EN61326-1,

EN 61000-4-2 to -6.

Explosion proof RFLS–35Xi (XiM) is provided by conformity with standards EN 60079-0,

EN 60079-11, EN 60079-26. Explosion proof RFLS–27Xi (XiM) is veried FTZÚ – AO 210

Ostrava–Radvanice:FTZÚ16ATEX0139X.

AdeclarationofconformitywasissuedforthisdeviceinthewordingofActNo.90/2016Coll., as

amended. Supplied electrical equipment matches the requirements of valid European directives for

safety and electromagnetic compatibility.

SensorsRFLS-35XiandRFLS-35XiM are intendedfor connectiontoapprovedintrinsicallysafe

supply units (insulating transducers) with galvanic separation. In the event that devices without

galvanicseparation(Zenerbarriers)areused,itisnecessarytobalancethepotentialbetweenthe

sensor, resp. water level meter and the grounding barrier location.

Thelimitoutputparametersofintrinsicallysafesupplyunits(insulatingtransducers)mustcorre-

spond to the limit input parameters of the sensor, resp. level meter. When assessing intrinsically

safety of circuits, it is necessary to also take into consideration the parameters of the connected

cable(namelyitsinductionandcapacity).

DesignRFLS–35Xicanbeusedinzone0.

Design RFLS–35XiM it is necessary to observe that temperature of any surface of apparatus,

whencoaldustcanfromalayer,donotexceed100°C.

The level meter does not require any personnel for its operation. Maintenance of this equipment

consistsinvericationofintegrityofthelevelmeterandofthesupplycable.

It is forbidden to make any changes or interventions to the RFLS–35 sensor without the

consent of the producer. Any repairs must only be carried out by the producer or authorized

service organisations.

Assembly, installation, commissioning, service and maintenance of the RFLS–35 level sensor

must be carried out in accordance with this manual and the provisions of valid standards for

the installation of electrical equipment must be complied with.

RFLS–35 © Dinel, s.r.o.

17

Dinel,s.r.o.guaranteesfortheperiodofthree(3)yearsthattheproducthasthecharacteristicsas

mentionedinthetechnicalspecication.

Dinel, s.r.o. is liable for defects ascertained within the warranty period and were claimed in writing.

This guarantee does not cover the damages resulting from misuse, improper installation or incorrect

maintenance.

This guarantee ceases when the user or the other person makes any changes on the product or the

product is mechanically or chemically damaged, or the serial number is not readable.

Thewarrantycerticatemustbepresentedtoexerciseaclaim.

In the case of a rightful complaint, we will replace the product or its defective part. In both cases, the

warrantyperiodisextendedbytheperiodofrepair.

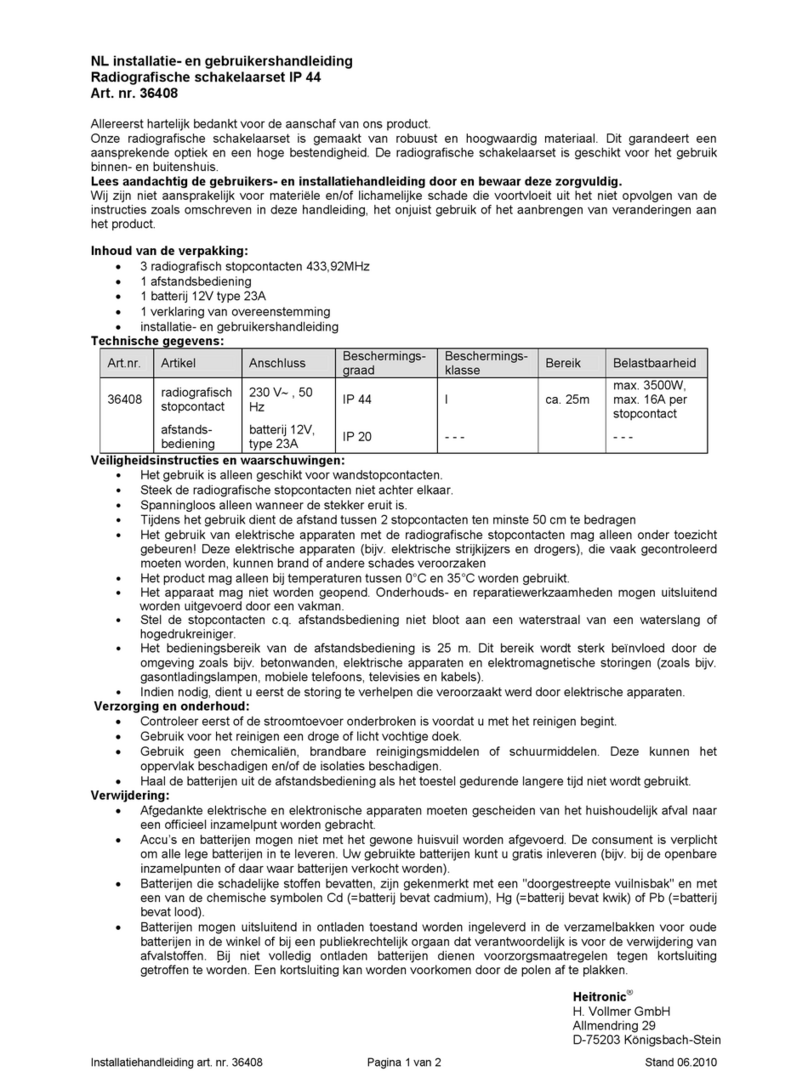

Labels for device of the type RFLS-35N-_-_ _-P-_

IP6_

No.: ______

Dinel

www.dinel.cz

Made in Czech Republic

1(bn)

3(bu)

4(bk) +U

0V I=5mAU=7...34V t = -40 ... +80 °C

a

RFLS 35N-__-__-P-_ Cable:__m-

Iomax = 300 mA

Délka112mm-výška12mm

ŠtítekprovariantyRFLS-35N-__-__-P-_

Symbolofproducer:logoDinel®

Internetaddress:www.dinel.cz

Countryoforigin:MadeinCzechRepublic

Connectionschemeandlabellingofwires:+U,0V

Levelmetertype:

RFLS–35N–_–_ _–P-_

Cablelength:Cable:__m

Serialnumber:Ser.No.:______–(fromtheleft:productionyear,serialproductionnumber)

Supplyvoltage:U=

7 ... 34

V =

Supplycurrent:I=5mA

Maximumoutputcurrent:Iomax=300mA

Ambienttemperaturerange:ta

=

-40...+80°C

Protectionclass:IP6_

(Protectionclassaccordingtoelectricalconnection)

Compliancemark:

Electro-wastetake-backsystemmark:

18

© Dinel, s.r.o. RFLS–35

Symbolofproducer:logoDinel®

Contact:Dinel,s.r.o.,UTescomy249,76001Zlín,CzechRepublic,www.dinel.cz

Connectionschemeandlabellingofwires:+U,0V

Levelmetertype:RFLS–35Xi–__–_–R_–_E______

Cablelength:Cable:__m

Serialnumber:Ser.No.:______–(fromtheleft:productionyear,serialproductionnumber)

Limitoperatingparameters:Ui

=12V=,Ii

=15mA;Pi

=45mW;Ci

=15nF;Li

=10uH

Ambienttemperaturerange:ta=-40...+80°C

Labelofnon-explosivedevice:

Performance:II1GExiaIIBT5Ga

Numberofcerticateofintrinsicallysafety:FTZÚ16ATEX0139X

Protectionclass:IP6_

Compliancemark: ,No.ofauthorizedpersonexaminingcontrolofsystemquality:1026

Electro-wastetake-backsystemmark:

Labels for device of the type RFLS–35Xi

Symbolofproducer:logoDinel®

Contact:Dinel,s.r.o.,UTescomy249,76001Zlín,CzechRepublic,www.dinel.cz

Connectionschemeandlabellingofwires:+U,0V

Levelmetertype:RFLS–35XiM–__–_–R_–_E______

Cablelength:Cable:__m

Serialnumber:Ser.No.:______–(fromtheleft:productionyear,serialproductionnumber)

Limitoperatingparameters:Ui

=12V=,Ii

=15mA;Pi

=45mW;Ci

=15nF;Li

=10uH

Ambienttemperaturerange:ta=-40...+80°C

Labelofnon-explosivedevice:

Performance:IM1ExiaIMa

Numberofcerticateofintrinsicallysafety:FTZÚ16ATEX0139X

Protectionclass:IP6_

Compliancemark: ,No.ofauthorizedpersonexaminingcontrolofsystemquality:1026

Electro-wastetake-backsystemmark:

Labels for device of the type RFLS–35XiM

Size of labels 70 x 20 mm, the size shown does not correspond to reality.

Délka112mm-výška12mm

ŠtítekprovariantyRFLS 35Xi-__-__-R-_-__-

No.: ______

RFLS 35Xi-__-__-R-_-E_____ Cable:__m

+U

0V

1(bn)

3(bu)

II1GExiaIIBT5Ga

FTZÚ 16 ATEX 0139X

U =12V

i

t = - 0...+ °C

a4 80

C = nF

i15

I = 15 mA

i

L = 10 uH

i

P = 45 mW

i

IP6_

1026

ŠtítekprovariantyRFLS 35XiM-__-__-R-_-__-

No.: ______

RFLS 35XiM-__-__-R-_-E_____ Cable:__m

+U

0V

1(bn)

3(bu)

IM1ExiaIMa

FTZÚ 16 ATEX 0139X

U =12V

i

t = - 0...+ °C

a4 80

C = nF

i15

I = 15 mA

i

L = 10 uH

i

P = 45 mW

i

IP6_

1026

Dinel

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Délka112mm-výška12mm

ŠtítekprovariantyRFLS 35Xi-__-__-R-_-__-

No.: ______

RFLS 35Xi-__-__-R-_-E_____ Cable:__m

+U

0V

1(bn)

3(bu)

II1GExiaIIBT5Ga

FTZÚ 16 ATEX 0139X

U =12V

i

t = - 0...+ °C

a4 80

C = nF

i15

I = 15 mA

i

L = 10 uH

i

P = 45 mW

i

IP6_

1026

ŠtítekprovariantyRFLS 35XiM-__-__-R-_-__-

No.: ______

RFLS 35XiM-__-__-R-_-E_____ Cable:__m

+U

0V

1(bn)

3(bu)

IM1ExiaIMa

FTZÚ 16 ATEX 0139X

U =12V

i

t = - 0...+ °C

a4 80

C = nF

i15

I = 15 mA

i

L = 10 uH

i

P = 45 mW

i

IP6_

1026

Dinel

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

RFLS–35 © Dinel, s.r.o.

19

Supplyvoltage(variantRFLS-35N) 7 ... 34 V DC

Powerconsumption(variantRFLS-35N) max.5mADC

Max.switchingcurrent(PNPoutput) 300 mA

Residual voltage – ON state max.1,5V

Couplingcapacity(housing-power)/dielectricstrength 5nF/500VAC(50Hz)

Ambienttemperaturerange: -40...+80°C

Protection class type RFLS-35_-_ _-C-_-_ IP 67

typeRFLS-35_-__-A(B,V,H,D)-_-_ IP 68

Cable(versionswithcableoutlets) Variant(P,N) PVC3x0,5mm2

Variant(Xi,XiM) PVC2x0,75mm2

Weight(withoutcable) cca 0,15 kg

part of the sensor standard material *

Housing stainlesssteelW.Nr.1.4404(AISI316L)

End of sensor stainlesssteelW.Nr.1.4301(AISI304)

electrode coating type el. 1

type el. 2

PEEK

PTFE

Sealing O-ring

RFLS-35_-1B

RFLS-35_-1E

RFLS-35_-1V

RFLS-35_-2

NBR

EPDM

(FPM)Viton

–

Cablegland(variant“A”) stainlesssteelW.Nr.1.4571/NBR

Cablegland(variant“B”,"V”,“H”) plasticPA/NBR

Cablegland(variant„D“) nickel-platedbrass/PA

ConnectorM12(variant“C”) nickel-platedbrass/PA

* Verify chemical compatibility with the media. Upon agreement it is possible to select a dierent type of

material.

– variant Xi and XiM

Power supply voltage 8 ... 9 V DC

Currentconsumption(disconnected/connected)–NAMUR ≤1mA/≥2,2mA

Max. internal values Ui=12VDC;Ii=15mA;

Pi=45mW;Ci=15nF;Li=10µH

Cables LC values typicC<150pF/m

typicL<0,8µH/m

20

© Dinel, s.r.o. RFLS–35

Output Variants

PNP(PC;PO) N

NAMUR(RC;RO) Xi(XiM)

– variant N, Xi and XiM

design variant temperature tp temperature ta maximum overpressure

RFLS-35N-1B(1E) -40°C...+105°C -40°C...+80°C 10 MPa

RFLS-35Xi(XiM)-1B(1E) -40°C...+100°C -40°C...+80°C 10 MPa

RFLS-35N-1V -20°C...+105°C -40°C...+80°C 10 MPa

RFLS-35Xi(XiM)-1V -20°C...+100°C -40°C...+80°C 10 MPa

RFLS-35N-2 -40°C...+105°C -40°C...+80°C 5 MPa to 50°C

2,5 MPa over 50°C

(EN 60079-0, EN 60079-10-1)

Level meter

performance

Type of

electrode Device classication

RFLS – 35N All types Basicperformancefornon-explosiveatmospheres.

RFLS–35Xi 1B, 1E, 1V

Intrinsicallysafeexplosion-proofperformanceforusein

hazardousareas(explosivegasatmospheresorexplosive

atmospheres with dust)

II1GExiaIIBT5Ga;withintrinsicallysafesupplyunits,

whole sensor zone 0.

RFLS–35XiM 1B, 1E, 1V

Intrinsicallysafeexplosion-proofperformanceforuseinmines

with the occurrence of methane or coal dust IM1ExiaI

Ma with intrinsically safe supply units.

type size marking

Pipe thread G1/2'' G1/2

Pipe thread G3/4'' G3/4

Metric thread M27x2 M27

Jointless connection

(Tri-Clamp)*

ø 34 mm

ø 50,5 mm

Cl34

Cl50

* only for type electrode 2

Other manuals for RFLS-35

1

Table of contents

Other Dinel Accessories manuals