DINGLI GTWY8-1200 Series Setup guide

AERIAL WORK PLATFORM

OPERATOR’S MANUAL

with Maintenance Information

(GTWY8-1200/ GTWY10-1200/ GTWY12-1200/ GTWY14-1200 Series)

Zhejiang Dingli machinery Co., Ltd. 2012-12

Important

Read, understand and obey these safety rules and operating instructions before operating this

machine. Only trained and authorized personnel shall be permitted to operate this machine. This

manual should be considered a permanent part of your machine and should remain with the

machine at all times. If you have any questions, call DINGLI MACHINERY.

Contents

Page

Safety Rules ................................................................................................................................ 1

Controls ..................................................................................................................................... 5

Illustration ...................................................................................................................................6

Pre-operation Inspection.............................................................................................................7

Maintenance ...............................................................................................................................9

Function Tests ...........................................................................................................................11

Workplace Inspection ................................................................................................................14

Operating Instructions ...............................................................................................................15

Battery Charging Instructions ....................................................................................................17

Transport Instructions ...............................................................................................................18

Tilt-back Operation Instructions ................................................................................................21

Decals .......................................................................................................................................23

Specifications ............................................................................................................................24

Hydraulic Diagram ....................................................................................................................25

Electrical Diagram ....................................................................................................................26

Inspection and Repair Log..........................................................................................................28

Contact us:

Zhejiang Dingli Machinery Co., Ltd

Address:No.1255 Baiyun South Road, Leidian Town, Deqing, Zhejiang China

Tel: 0086-572-8681688

Fax: 0086-572-8681690

E-mail:[email protected]

Http://www.cndingli.com.cn

Operator’s Manual

Safety Rules

GTWY1200 SERIES 1

Danger

Failure to obey the instructions and

safety rules in this manual will

cause death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of

safe machine operation contained in this

operator's manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer's instructions and safety

rules— safety and operator's manuals and

machine decals.

You read, understand and obey

employer's safety rules and worksite

regulations.

You read, understand and obey all

applicable governmental regulations.

You are properly trained to safely operate

the machine.

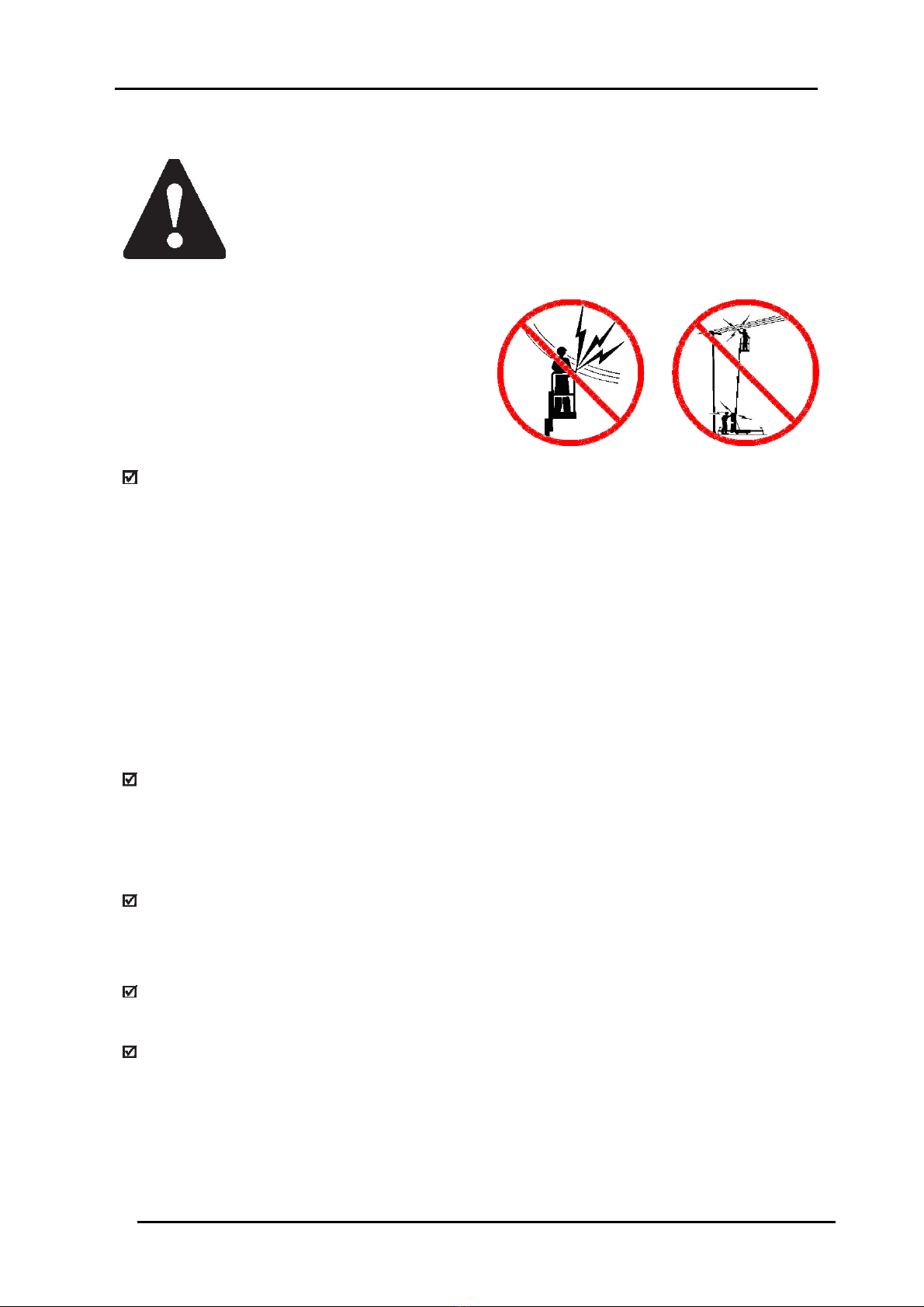

Electrocution Hazards

This machine is not electrically insulated and

will not provide protection from contact with or

proximity to electrical current.

Keep away from the machine if it contacts

energized power lines or becomes electrically

charged. Personnel on the ground or in the

platform must not touch or operate the

machine until energized power lines are shut

off.

Maintain safe distances from electrical power

lines and apparatus in accordance with

applicable governmental regulations and the

following chart.

Minimum Safe Voltage Approach Distance

Phase to Phase Feet Meters

0 to 300V Avoid Contact

300V to 50KV 10 3.05

50KV to 200KV 15 4.60

200KV to 350KV 20 6.10

350KV to 500KV 25 7.62

500KV to 750KV 35 10.67

750KV to 1000KV 45 13.72

Allow for platform movement, electrical line

sway or sag and movement due to strong or

gusty winds.

Do not use the machine as a ground for

welding.

Operator’s Manual

Safety Rules

GTWY1200 SERIES 2

Do not operate an AC powered machine or a

DC battery charger unless using a 3-wire

grounded extension cord connected to a

grounded AC circuit. Do not alter or disable

3-wire grounded plugs.

Tip-over Hazards

Do not raise the platform unless the base is

level, all four outriggers are properly installed

and the leveling jacks firmly contact the floor.

Do not adjust or remove the outriggers while

the platform is occupied or raised.

Do not move the machine while the platform is

raised.

Do not place ladders or scaffolds in the

platform or against any part of this machine.

Do not place or attach overhanging loads to

any part of this machine.

Do not transport tools and materials unless

they are evenly distributed and can be safely

handled by the person in the platform.

Do not raise the platform unless the machine

is level. Do not set the machine up on a

surface where it cannot be leveled using only

the leveling jacks.

Do not cause a horizontal force or side load to

the machine by raising or lowering a fixed or

overhanging load.

Do not push off or pull

toward any object outside

the platform.

Maximum allowable side force 200N

Do not operate the machine near drop-offs,

holes, bumps, debris, unstable or slippery

surfaces or other possible hazardous

conditions.

Do not alter or disable machine components

that in any way affect safety and stability.

Do not replace items critical to stability with

items of different weight or specification. Use

only Dingli authorized replacement parts.

Do not push the GTWY1200 series from the

platform side of the machine.

When moving the machine with a forklift or

other transport vehicle, the platform should be

fully lowered, the machine should be turned off

and no personnel shall remain in the platform.

Do not use the machine on a moving or mobile

surface or vehicle.

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area

exposed to the wind will decrease machine

stability.

Occupants, equipment and materials shall not

exceed the maximum platform capacity.

Operator’s Manual

Safety Rules

GTWY1200 SERIES 3

Maximum capacity

GTWY8-1200 350 lbs 150 kg

GTWY10-1200 350 lbs 150 kg

GTWY12-1200 350 lbs 150 kg

GTWY14-1200 300 lbs 136 kg

Maximum occupancy 1 person

Fall Hazards

The guard rail system provides fall protection.

If occupants of the platform are required to

wear personal fall protection equipment (PFPE)

due to job site or employer rules, PFPE

equipment and its use shall be in accordance

with the PFPE manufacturer’s instructions and

applicable governmental requirements.

Do not sit, stand or

climb on the platform

guard rails. Maintain a

firm footing on the

platform floor at all

times.

Do not exit the platform while raised. If a

power failure occurs, have ground personnel

activate the manual lowering valve.

Keep the platform floor clear of debris.

Lower the platform entry mid-rail before

operating.

Collision Hazards

Operators must comply with employer, job site

and governmental rules regarding the use of

personal protective equipment.

Check the work area for overhead obstructions

or other possible hazards.

Be aware of crushing hazard when grasping

the platform guard rail.

Do not lower the platform unless the area

below is clear of personnel

and obstructions.

Stay clear of descending

platform.

Use common sense and

planning to control the movement of the

machine on or near inclines.

Improper Use Hazard

Do not leave the machine unattended unless

the key is removed to secure from

unauthorized use.

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil

leak. An hydraulic leak can penetrate and/or

burn skin.

Operator’s Manual

Safety Rules

GTWY1200 SERIES 4

Explosion and Fire Hazard

Do not operate the machine or charge the

battery in hazardous locations or locations

where potentially flammable or explosive

gases or particles may be present.

Damaged Machine Hazards

Do not use a damaged or malfunctioning

machine.

Be sure all maintenance has been performed

as specified in this manual and the Dingli

GTWY Series service manual.

Be sure all decals are in place and legible.

Be sure the operator’s manuals are complete,

legible and in the storage container located on

the platform.

Conduct a thorough pre-operation inspection

of the machine and test all functions before

each work shift. Immediately tag and remove

from service a damaged or malfunctioning

machine.

Do not use the machine as a ground for

welding.

Battery and Charger

Safety-DC

Burn Hazards

Batteries contain acid.

Always wear protective clothing and eye wear

when working with batteries.

The battery pack must remain in an upright

position.

Avoid spilling or contacting battery acid.

Neutralize battery acid spills with baking soda

and water.

Explosion Hazards

Batteries emit explosive gas. Keep sparks,

flames and lighted tobacco away from the

battery.

Charge the battery in a well ventilated area.

Do not disconnect charger DC output wires

from the battery when the charger is on.

Operator’s Manual

Controls

GTWY1200 SERIES 5

Ground Controls

65 4

12 3

Platform Controls

67 8

1. Power light 2. Circuit breaker

3. Outrigger interlock display lights (four) 4. Up/down switch

5. Key switch 6. Red Emergency Stop button

7. Up/down switch 8. Control activate button

Operator’s Manual

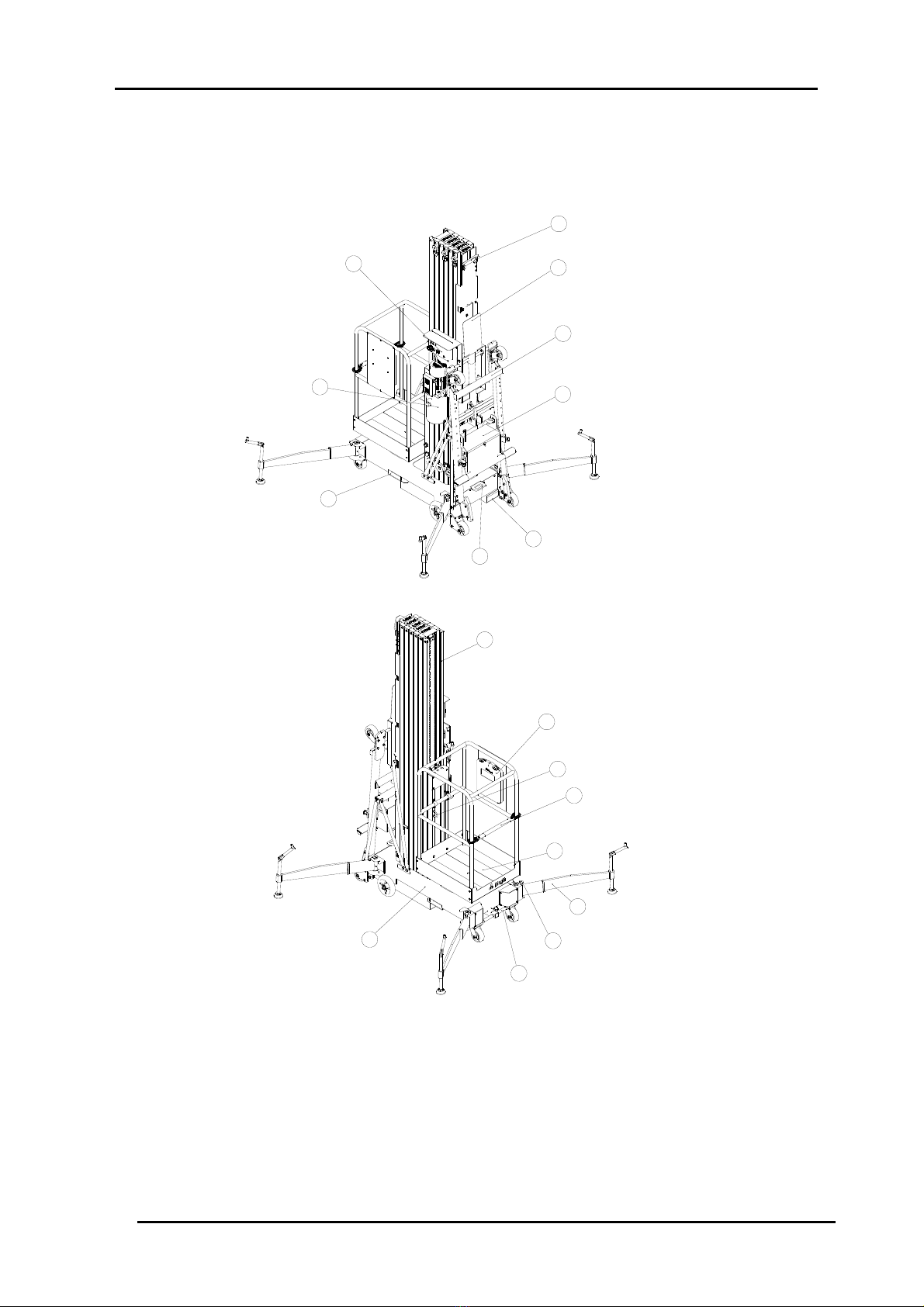

Illustration

GTWY1200 SERIES 6

Illustration

11

3

1

2

16

17

7

4

5

15

8

10

6

12

13

14

9

18

○

1Tilt-back strut ○

7Winching/tie-down point ○

13 Outrigger with leveling jack

○

2Battery box ○

8Manuals storage ○

14 Outrigger lock pin

○

3Lifting eye ○

9Sliding T-handle ○

15 Mast

○

4Hydraulic power unit ○

10 Harness anchor ○

16 Forklift socket

○

5Ground controls ○

11 Tilt-back frame ○

17 Winching/tie-down point

○

6Platform entry mid rail ○

12 Platform ○

18 Base

Operator’s Manual

Pre-operation Inspection

GTWY1200 SERIES 7

Do Not Operate Unless:

You learn and practice the principles of

safe machine operation contained in this

operator’s manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform the function tests prior to

use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Fundamentals

It is the responsibility of the operator to

perform a pre-operation inspection and routine

maintenance.

The pre-operation inspection is a visual

inspection performed by the operator prior to

each work shift. The inspection is designed to

discover if anything is apparently wrong with a

machine before the operator performs the

function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures

are required. Only routine maintenance items

specified in this manual may be performed by

the operator.

Refer to the list following and check each of

the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by

a qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a

pre-operation inspection again before going on

to the function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications

and the requirements listed in the

responsibilities manual.

Operator’s Manual

Pre-operation Inspection

GTWY1200 SERIES 8

Pre-operation Inspection

Be sure that the operator’s manuals are

complete, legible and in the storage

container located on the platform.

Be sure that all decals are legible and in

place. See Decals section.

Check for battery fluid leaks and proper

fluid level. Add distilled water if needed.

See Maintenance section. (DC models)

Check for hydraulic oil leaks and proper

oil level. Add oil if needed. See

Maintenance section.

Check the following components or areas for

damage, improperly installed or missing parts

and unauthorized modifications:

Electrical components, wiring and

electrical cables

AC & DC models: Hydraulic power unit,

hoses, fittings and cylinder

Platform entry mid-rail

Sequencing cables and pulleys

Lifting chains and idler wheels

Nuts, bolts and other fasteners

Mast columns

Breather cap

Outriggers, leveling jacks and footpads

Check entire machine for:

Dents or damage

Corrosion or oxidation

Cracks in welds or structural components

Inspect and clean battery terminals and all

battery cable connections (DC models)

Be sure that all structural and other critical

components are present and all

associated

Operator’s Manual

Maintenance

GTWY1200 SERIES 9

Observe and Obey:

Only routine maintenance items specified in

this manual shall be performed by the

operator.

Scheduled maintenance inspections shall be

completed by qualified service technicians,

according to the manufacturer's specifications

and the requirements specified in the

responsibilities manual.

Maintenance Symbols Legend

The following symbols have

been used in this manual to help communicate

the intent of the instructions. When one or

more of the symbols appear at the beginning

of a maintenance procedure, it conveys the

meaning below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be

required to perform this procedure.

Check the Battery - DC Models

Proper battery condition is essential

to good machine performance and

safe operation. Improper fluid levels

or damaged cables and connections can result

in component damage and hazardous

conditions.

Electrocution hazard. Contact

with hot or live circuits could result in death or

serious injury. Remove all rings, watches and

other jewelry.

Bodily injury hazard.

Batteries contain acid. Avoid spilling or

contacting battery acid. Neutralize battery acid

spills with baking soda and water.

Perform this test after fully

charging the battery. 1 Put on protective

clothing and eye wear.

2 Remove the battery vent caps.

3 Check the battery acid level. If needed,

replenish with distilled water to the bottom of

the battery fill tube. Do not overfill.

4 Install the vent caps.

Operator’s Manual

Maintenance

GTWY1200 SERIES 10

Check the Hydraulic Oil Level

Maintaining the hydraulic oil at the proper level

is essential to machine operation. Improper

hydraulic oil levels can damage hydraulic

components. Daily checks allow the inspector

to identify changes in oil level that might

indicate the presence of hydraulic system

problems.

1 Be sure the platform is fully lowered.

2 Check the hydraulic oil level. Do not overfill.

Hydraulic oil specifications

Hydraulic oil type Chevron Rando HD equivalent

Scheduled Maintenance

Maintenance performed quarterly, annually

and every two years must be completed by a

person trained and qualified to perform

maintenance on this machine according to the

procedures found in the service manual for

this machine.

Machines that have been out of service for

more than three months must receive the

quarterly inspection before they are put back

into service.

Operator’s Manual

Function Tests

GTWY1200 SERIES 11

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform the function tests prior to

use.

Know and understand the function tests

before going on to the next section.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Fundamentals

The function tests are designed to discover any

malfunctions before the machine is put into

service. The operator must follow the

step-by-step instructions to test all machine

functions.

A malfunctioning machine must never be used.

If malfunctions are discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer’s specifications.

Operator’s Manual

Function Tests

GTWY1200 SERIES 12

Setup

1. Position the machine on a firm surface

directly below the desired work area.

2. Connect to the appropriate power source:

DC models: Connect the battery pack. AC

models: Connect to a grounded 15A AC

power supply. Use a 12 gauge / 3.3mm2

3-wire grounded extension cord no longer

than 50 feet / 13 m.

Result: The power light should come on.

3. Turn on the circuit breaker.

4. Insert the key and turn to ground control or

platform control.

5. Twist the red Emergency Stop buttons to

the on position both at the ground and the

platform controls.

6. Pull the outrigger lock pin up, turn an

outrigger out until the outrigger lock pin

snaps into place. Adjust the outrigger to

level the machine and raise the base

casters slightly off the ground. Level the

machine using only the outriggers.

7. Check the interlock display lights at the

ground controls. Confirm that the

corresponding light is on.

8. Repeat this procedure for each of the

remaining outriggers.

9. Use the bubble level and adjust the

leveling jacks until the machine base is

level.

Test Emergency Stop

10. Push in the red Emergency Stop button at

the ground controls to the off position.

11. Push in the up/down switch at ground

control in the direction of intended travel.

(Turn the key switch to ground control)

Result: The up/down function should not

operate

12. Push in the control activate button and

rotate the up/down switch at the platform

in the direction of intended travel. (Turn

the key switch to platform control)

Result: The up/down function should not

operate

13. Push in the red Emergency Stop button at

the platform controls to the off position.

14. Twist the red Emergency Stop button at

the ground controls to the on position.

15. Push in the up/down switch at ground

control in the direction of intended travel.

(Turn the key switch to ground control)

Result: The up/down function should not

operate

16. Push in the control activate button and

rotate the up/down switch at the platform

in the direction of intended travel. (Turn

the key switch to platform control)

Result: The up/down function should not

operate

Operator’s Manual

Function Tests

GTWY1200 SERIES 13

Test Outrigger Interlock

17. Twist to release the red Emergency Stop

button at the platform controls.

Result: The up/down functions should

operate.

18. Unscrew one leveling jack until the

corresponding interlock display light turns

off.

Result: The up function should not operate.

19. Return the leveling jack to the previous

setting and check the bubble level.

20. Repeat this procedure for each outrigger.

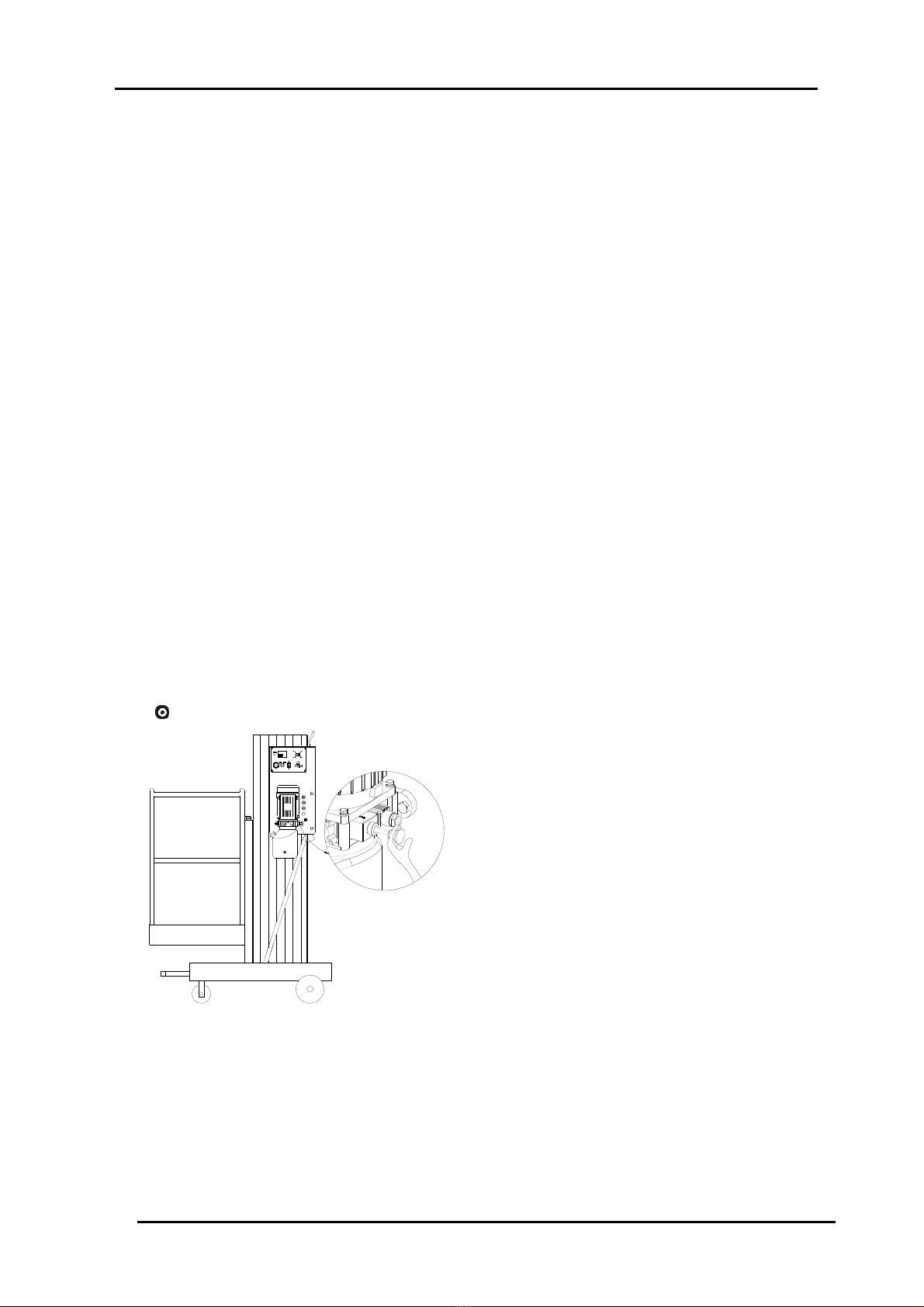

Test Manual Lowering

21. Raise the platform slightly.

22. Activate the manual lowering valve located

at the side of the hydraulic unit.

Result: The platform should lower.

Operator’s Manual

Workplace Inspection

GTWY1200 SERIES 14

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

Know and understand the work place

inspection before going on to the next

section.

5 Only use the machine as it was intended.

Fundamentals

The workplace inspection helps the operator

determine if the workplace is suitable for safe

machine operation. It should be performed by

the operator prior to moving the machine to the

workplace.

It is the operator’s responsibility to read and

remember the workplace hazards, then watch

for and avoid them while moving, setting up

and operating the machine.

Workplace Inspection

Be aware of and avoid the following hazardous

situations:

●Drop-offs or holes

●Bumps, floor obstructions or debris

●Slopes that exceed the machine’s leveling

capability

●Unstable or slippery surfaces

●Overhead obstructions and high voltage

conductors

●Hazardous locations

●Inadequate surface support to withstand all

load forces imposed by the machine

●Wind and weather conditions

●The presence of unauthorized personnel

●Other possible unsafe conditions

Operator’s Manual

Operating Instructions

GTWY1200 SERIES 15

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Fundamentals

The Operating Instructions section provides

instructions for each aspect of machine

operation. It is the operator's responsibility to

follow all the safety rules and instructions in

the operator's, safety and responsibilities

manuals.

Using the machine for anything other than

lifting personnel, along with their tools and

materials, to an aerial work site is unsafe and

dangerous.

If more than one operator is expected to use a

machine at different times in the same work

shift, each operator is expected to follow all

safety rules and instructions in the operator’s

manual. That means every new operator

should perform a pre-operation inspection,

function tests and a work place inspection

before using the machine.

Setup

1. Position the machine on a firm surface

below the desired work area directly.

2. Connect to the appropriate power source:

DC models: Connect the battery pack. AC

models: Connect to a grounded 15A AC

power supply. Use a 12 gauge / 3.3mm2

3-wire grounded extension cord no longer

than 50 feet / 13 m. The power light is on.

3. Turn the circuit breaker on .

4. Insert the key and turn to ground control

or platform control as you want.

5. Twist to release the red Emergency Stop

buttons both at the ground and the

platform controls.

6. Pull the outrigger lock pin upt ,Turn the

outriggers out and adjust to level the

machine and raise the base casters

slightly off the ground.

7. Be sure all four interlock display lights at

the ground controls are on and all four

outriggers are in firm contact with the

ground.

8. Use the bubble level

to make sure the

machine is level.

Note: If adjustment is

necessary, check the bubble level and

interlock display again to make sure the

machine is level and all four interlock display

lights are on.

Operator’s Manual

Operating Instructions

GTWY1200 SERIES 16

Emergency Stop

Push in the red Emergency Stop button at the

platform controls or at the ground controls to

stop the up/down function.

Platform Raise and Lower

1. Twist to release the red Emergency Stop

buttons to the on positions at the platform

controls and at the ground controls.

2. You could move the platform by push in

the up/down switch at ground control in

the direction of intended travel. (Turn the

key switch to ground control)

3. You can also move the platform by Push

in the control activate button and rotate

the up/down switch at platform control in

the direction of intended travel. (Turn the

key switch to platform control)

Manual Lowering

1. Activate the manual lowering valve

located at the side of the hydraulic unit.

2. The platform should lower.

Fall Protection

Personal fall protection equipment (PFPE) is

not required when operating this machine. If

PFPE is required by job site or employer rules,

the following shall apply:

All PFPE must comply with applicable

governmental regulations and must be

inspected and used in accordance with the

manufacturer’s instructions.

After Each Use

1. Push in the red Emergency Stop buttons

at the platform controls and the ground

controls.

2. Remove the key to secure from

unauthorized use.

3. Turn off the circuit breaker and the power

light is out. Cut out the power and fixed

the cable.

4. Select a safe storage location—firm, level

surface, weather protected, clear of

obstruction and traffic.

5. Chock the wheels to prevent the machine

from rolling.

6. DC models: Recharge the battery.

Operator’s Manual

Battery Charging Instructions

GTWY1200 SERIES 17

Battery and Charger

Instructions

Observe and Obey:

Do not use an external charger or booster

battery.

Charge the battery in a well-ventilated area.

Use proper AC input voltage for charging as

indicated on the charger.

Use only Dingli authorized battery and

charger.

To Charge Battery

1 Open the battery pack lid to access the

battery.

2 Remove the battery vent caps and check

the battery acid level. If necessary, add only

enough distilled water to cover the plates.

Do not overfill prior to the charge cycle.

3 Replace the battery vent caps.

4 Be sure that the DC output cord is properly

connected to the battery. Black to negative,

red to positive.

5 Connect the battery charger to a grounded

AC circuit.

6 The charger will turn off automatically when

the battery is fully charged.

7 Check the battery acid level when the

charge cycle is complete. Replenish with

distilled water to the bottom of the fill tube.

Do not overfill.

(Maintenance free battery needn’t do them all,

recharge it directly)

Operator’s Manual

Transport Instructions

GTWY1200 SERIES 18

Transport Instructions

Observe and Obey:

Be sure the transport vehicle capacity and

loading surfaces are sufficient to support the

machine weight. See the serial label for the

machine weight. Some pick-up truck tailgates

are not strong enough to support the weight of

the machine and may require reinforcement.

Do not load the machine onto a transport

vehicle unless it is parked on a level surface.

The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

The machine must be securely fastened to

the transport vehicle. Use chains or straps of

ample load capacity.

Be sure to lock both swivel casters on the

tilt-back frame.

Do not transport with the machine resting on

the tilt-back frame.

Lifting Instructions

The number of people required to load and

unload a machine is dependent on a number

of factors, including but not limited to:

●the physical condition, strength and

disabilities or prior injuries of the people

involved

●the vertical and horizontal distances the

machine has to be moved

●the number of times the machine will be

loaded or unloaded

●the stance, posture and grip used by the

people involved

●the lifting techniques used

●the site conditions and weather in which the

activity is being performed (i.e., slippery, icy,

raining)

The appropriate number of people and proper

lifting techniques must be used to prevent

physical injury.

Loading for Transport

1. Fully lower the platform.

2. Push in the red Emergency Stop buttons,

turn the key switch to the off position and

remove the key. Turn off the circuit

breaker. Cut out the power and fixed the

cable.

3. Pull the lock pin up, turn the outriggers in

and place them in the storage station.

4. DC models: Disconnect the battery cable

and remove the battery pack.

5. Inspect the entire machine for loose or

unsecured items.

6. Slide the stop bracket to the top lock

position.

a

b

a. stop bracket b. loading pivot

All models without tilt-back frame

This manual suits for next models

3

Table of contents

Other DINGLI Lifting System manuals