6

LIFT CAPACITIES

It’s recommended that the total loaded weight of

the water craft doesn’t exceed 75-85% of the to-

tal lift capacity. The total capacity of a lift is the

combined capacity of each of the boat lifts two

main lifting beams.

Never exceed the weight capacity of either main

lift beam. For instance a 5,000 lb capacity boat lift

is limited to 2,500 lbs for each main lift beam. It is

very easy for a 4,000 lb boat to exceed the capac-

ity of a 5,000 lb boat lift by not parking on the lift in

the correct position.

BEFORE PUTTING A BOAT ON THE

LIFT YOU NEED TO KNOW THREE

VERY IMPORTANT THINGS:

1. Determine the total loaded boat weight?

Weigh your boat loaded with fuel, water and ev-

erything in that you could ever have in it when it is

parked on the boat lift. Not all manufacturers pub-

lished boat weights are accurate because they

don’t account for motors, gear, fuel, water, etc.

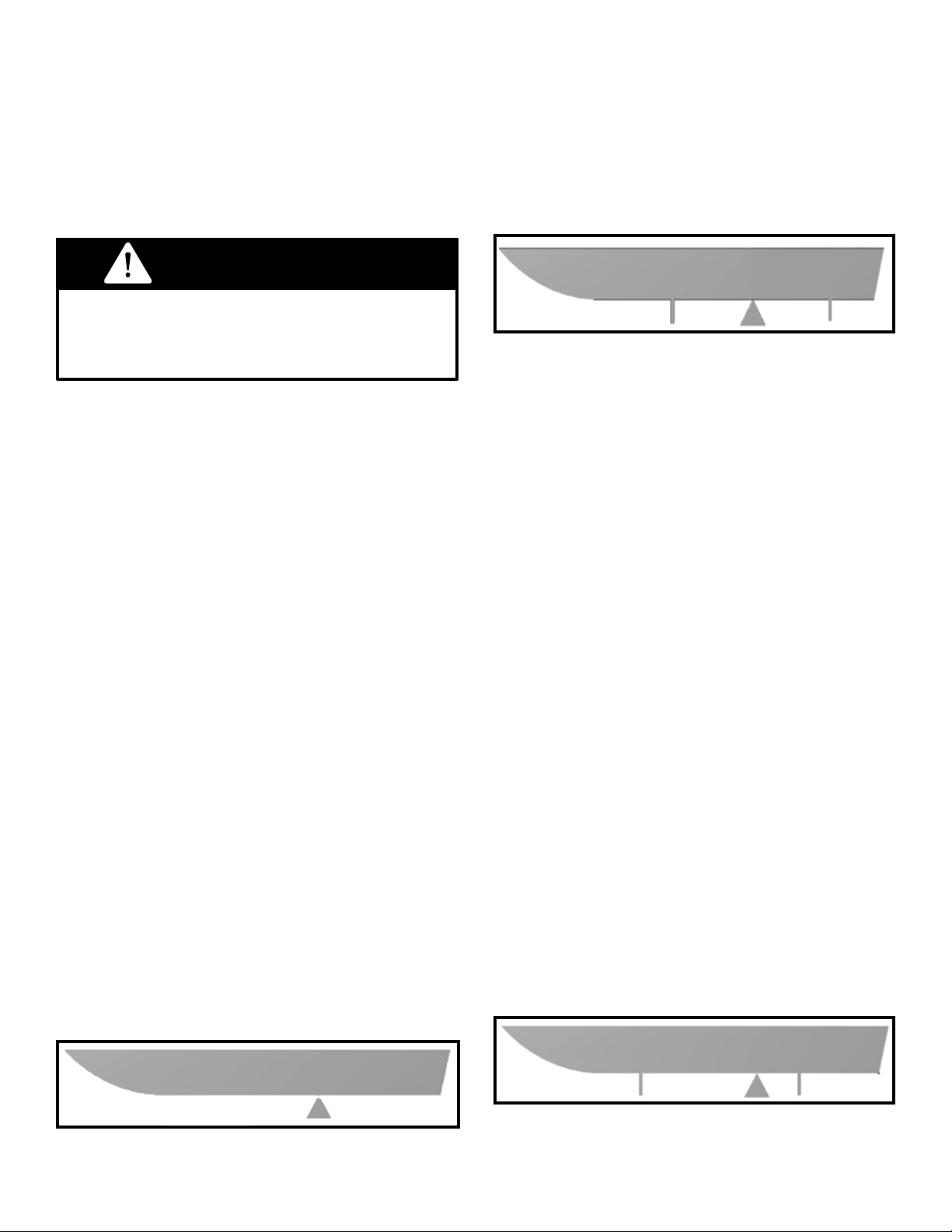

2. Determine the boats center of gravity or CG?

A boat’s CG is the location under the boat hull

which the boat will balance if sitting on a narrow

object ((Illustration A). Your dealer or the manu-

facturer of the boat should be able to help you

locate the boat’s CG. Be sure that the motor and

gear weight have been taken into consideration.

Never exceed the lift’s rated capacity. Doing

so could cause structural/mechanical failure

and serious injury or death.

WARNING

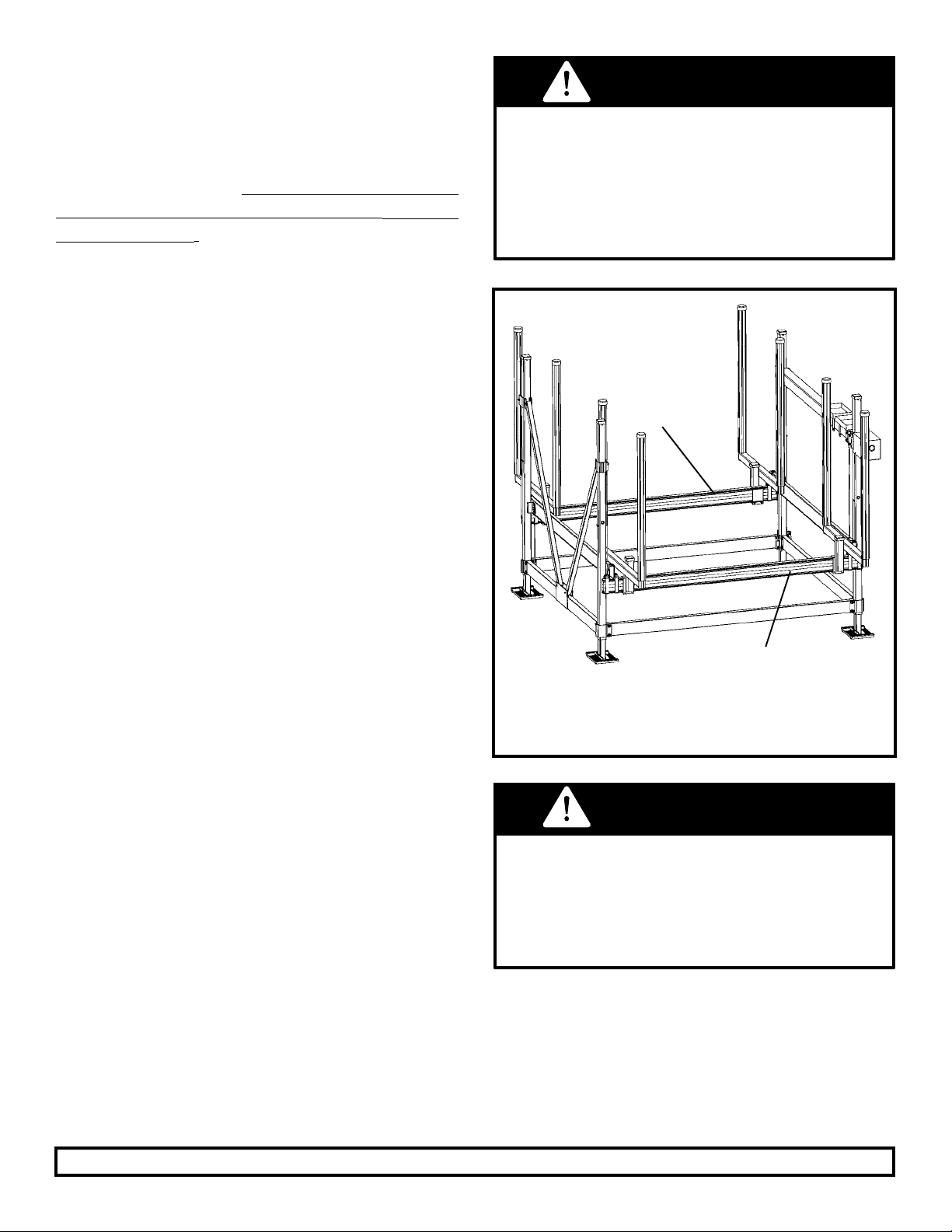

3. Determine that the boats center of gravity (CG)

is centered between the two main lift beams

The boat should be parked so that the boat’s CG

or balance point is centered between the two

main lift beams (Illustration B). Each of the lift

beams should be supporting the same amount of

weight.

Once you know that your boat is well within the

boat lifts rated capacity and the location of the

boat’s CG develop a positioning method that will

ensure that all users of the boat lift will park with

the Boat’s CG in the center of the lift. Here are a

couple of suggestions to do this consitently:

• Use a motor stop.

• Note the proper location of the boat on the lift

and use some sort of marking system or labels.

• If equipped with canopy, center the canopy

over the boat when the boat’s CG is in the

center of the lift, park with the boat centered

under the canopy.

• You can even hang an object such as a

tennis ball so it just touches the windshield

when the boat is properly positioned.

If your boat is not positioned properly, you can

extremely overload one of the main lifting beams

(See Illustration C, below).

Illustration A: above shows the boat’s balance

point of center of gravity (CG).

x

Illustration B: shows the boat’s center of gravity

(CG) centered between the two main lift beams

– each of the lift beams is supporting the same

amount of weight.

Illustration C: shows a boat’s center of gravity

(CG) improperly positioned so that it extremely

overloads one of the main lifting beams.