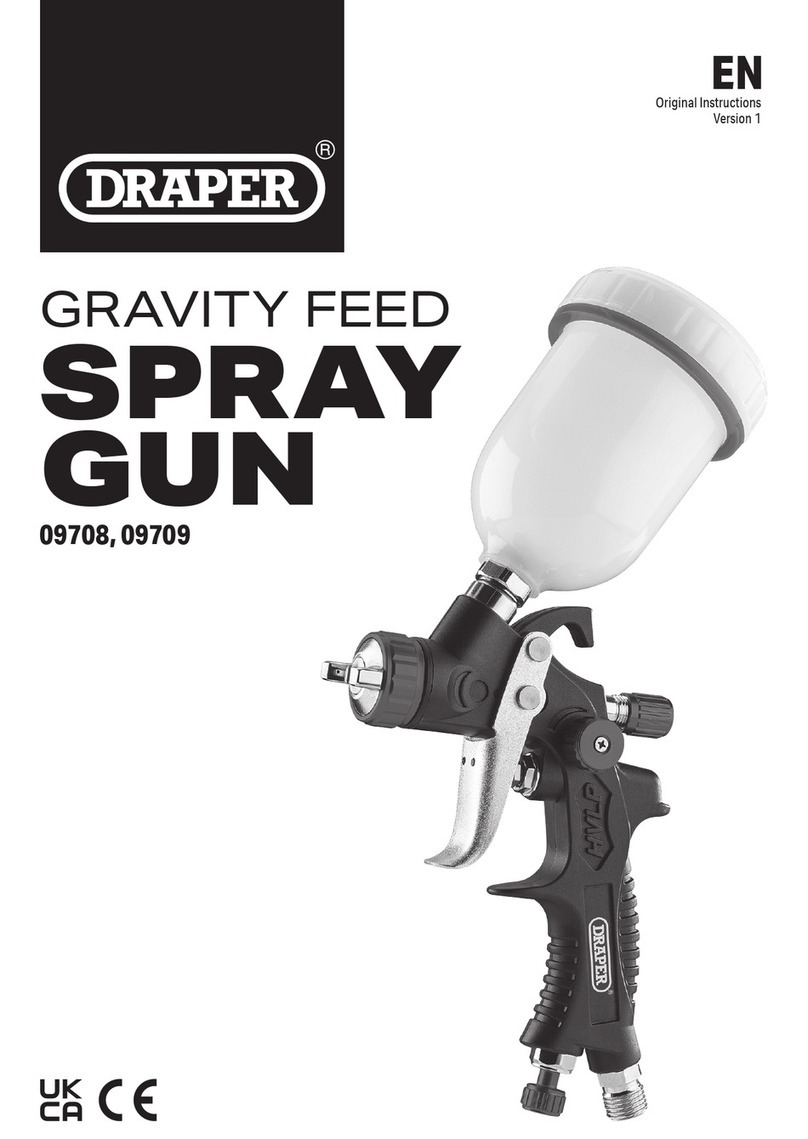

Croplands AgriPak LA300 User manual

OPERATORS MANUAL

Croplands AgriPak

Linkage Sprayers

MODELS:

300 Litre

600 Litre

800 Litre

1000 Litre

09/07/2016

LP-OMLINK-B

2 3

18/09/2016

LP-OMLINK-B

WELCOME

Congratulations on the purchase

of your new Croplands sprayer.

Croplands are in the business

of building and selling spraying

equipment and have been since

1972 (over 40 years). We supply

sprayers to farmers, contractors, growers and others

involved in growing crops & controlling pests and

diseases.

Use the contact details listed on the back page to

contact our staff during business hours. After hours,

e-mail us and expect a reply the following morning.

We trust you will get years of good use from your

Croplands AgriPak Linkage Sprayer.

Yours sincerely,

Sean Mulvaney

General Manager.

CONTENTS

1. Warranty policy

2. Foreword

3. Safety information

4. Sprayer Specifications

5. Operation

a. Hook up and PTO information

b. Start up

c. Controller information

d. Boom spraying

e. Filtration system, spray gun operation

and hose reels

6. Spraying information

a. When & how to spray safely

b. Application rates, ground speed and boom

height settings

7. Daily start up and useful information

8. Lubrication & maintenance

9. Parts information

10. Contact details

4 5

18/09/2016

LP-OMLINK-B

SECTION 2: FOREWORD

Croplands Equipment is a subsidiary of Nufarm

Australia Ltd and operates as Croplands Equipment

Pty Ltd in Australia and Croplands Equipment Ltd in

New Zealand. Croplands are a leading importer,

manufacturer and supplier of spraying equipment.

This operator’s manual covers the Croplands’ range

of three-point linkage AgriPak sprayers with tank

capacities of 300 litres through to 1000 litres.

Manufactured to a high standard for use in

Agriculture and Horticulture, every effort has been

made to include all information needed for the safe

and effective operation of your AgriPak sprayer.

As the owner of a Croplands AgriPak sprayer,

please read this manual thoroughly to fully

familiarise yourself with all aspects of the safe and

correct operation of your sprayer. Maintenance

information and useful tips have been included. We

trust you will use these tips to get the best from your

sprayer.

Crolands has taken steps to ensure this operator’s manual is as current and as accurate as possible. Due to the

ever changing markets of cropping and farming, Croplands is constantly striving to be at the forefront of innovation

and technology. While the information in this manual is considered accurate at the time of writing, Croplands

reserves the right to change this information without notice. Croplands will not accept liability for any inaccuracy in

this publication, or changes forthwith.

Terminology

These terms/symbols used throughout this

manual:

About This Manual

This manual provides setting up information, safety

tips and operating & maintenance instructions for the

Croplands AgriPak Linkage Sprayer range.

Some model types have different options available.

Some features explained in this manual may not

be installed on your sprayer. Please pass on this

manual with the sprayer at the time of resale for

usage by the new owner.

Before Operating Your Sprayer

1. Before attempting to use your sprayer, make sure

you read the Operator’s Manual and properly

understand:

»All Safety Issues

»Operation, set up & pre-delivery instructions

»Calibration of the sprayer

»Sprayer Maintenance

2. Read and follow instructions on chemical

manufacturers’ labels.

3. Always wear applicable protective clothing.

NOTE

To convey useful operating information.

NOTE

For full conditions of warranty and

warranty policy, please see the

Warranty & Pre-Delivery booklet

provided with this sprayer.

CAUTION

To highlight potential injury or

machinery damage.

WARNING

To stress potential dangers and the

importance of personal safety.

DANGER

Probability of death or serious

injury if accident occurs.

WARNING

Read and understand this

operators’ manual before operating

the AgriPak Sprayer.

SECTION 1: WARRANTY POLICY

Refer to your Croplands Warranty and

Pre-delivery Booklet supplied with your

AgriPak sprayer. Always make contact with

your Croplands Dealer first and foremost for

warranty matters.

6 7

18/09/2016

LP-OMLINK-B

SECTION 3: SAFETY

INFORMATION

Rules for Safe AgriPak Sprayer Operation

»Always read your sprayer operator’s manual

thoroughly before operating. Accidents occur

every year because of careless use of farm

chemicals and farm machinery. You can avoid

these hazards by observing these safety

instructions.

»Dispose of all chemical containers as per

instructions on label. Failure to do so could result

in contaminating the environment with chemicals.

»Inspect hose and hose connections daily. Always

wear rubber gloves when tightening connections.

Damaged, loose or worn hoses could result in

operator being exposed to toxic chemicals, which

could result in serious illness or faulty sprayer

operation.

»Always use the proper application rate. To

assure proper application rate calibrate

sprayer correctly. The wrong application rate

of a pesticide or herbicide concentration that

is too high may expose the operator and the

environment to danger.

»Be sure to disconnect all power connections (if

applicable) before attempting welding repairs.

»Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Failure to

do so could result in serious injury.

»When working on your sprayer, always stay out

from under the sprayer unless it is resting on the

ground or supported on solid blocks. Hydraulics

or jacks could fail letting the sprayer fall. This

could result in pinning or crushing of personnel.

ALWAYS have the booms folded and in the

parking position when working on the sprayer.

»Check the entire sprayer, prior to each use, for

any loose bolts or mechanical connections. These

precautions can prevent injury to personnel and

damage to equipment.

»Use only genuine Croplands parts for any

necessary replacement. All parts are important

to the equipment design. Homemade parts

may look the same but might be dangerous in

operation.

»Follow the chemical manufacturers precautions

before cleaning the sprayer. Exposure to

chemicals could result in serious illness or death.

»Always wear gloves and wash the sprayer before

doing any disassembly repair work. Chemical

residues on the machine parts could contaminate

operator or service personnel causing serious

illness.

»Always relieve system pressure before doing

any work on the machine. Failure to do so could

cause operator to be exposed to high pressure

spray of chemical resulting in serious injury or

machine damage.

»Always be sure all guards are properly installed

on machine before operating. Failure to do so

could result in entanglement in moving parts

resulting in serious injury to operator.

»Always keep PTO guards in place. Failure to do

this might result in entanglement. This is a leading

cause of serious accidents & death on farms.

»Do not ride on machine when in motion. This is

an unsafe practice and can lead to serious injury

should the rider fall from the sprayer or tractor.

»Always stand well clear of sprayer when

operating. Any particle or spray drift is dangerous

and may be hazardous to humans.

»Do not disconnect any hoses nozzles or filters

while sprayer is operating. Disconnecting

components while under pressure will result in

uncontrolled spray discharge, which may be

hazardous.

»Should any welding be required on the steel

parts of the sprayer, always clean the linkage

sprayer and disconnect the power before doing

any repairs. Cover rubber hoses, and all other

flammable parts. Keep a fire extinguisher near

the sprayer when welding. Have good ventilation

when grinding or welding painted or galvanised

parts. Wear dust mask when grinding. Toxic dust

or gas can be produced.

SAFETY DECALS

WARNING

PTO shafts in particular are

extremely dangerous, ensure the

PTO is disengaged prior to doing any

adjustment or work on your sprayer.

Never operate the PTO if any person is

near the sprayer.

8 9

18/09/2016

LP-OMLINK-B

SAFETY WITH CHEMICALS

The Hazard

All agricultural chemicals or pesticides, as they are

commonly called, are biologically active. When

handled incorrectly or carelessly, they can be

dangerous to all living organisms such as humans,

birds, fish, bees, domestic animals and plants.

Method of Pesticide Entry

»Oral - Direct by drinking, splashing into mouth,

eating and smoking with contaminated hands,

eating sprayed produce, cleaning nozzles with

mouth.

»Inhalation - Nose, mouth, but predominately

the lungs.

»Dermal - Absorption through the skin. Increased

when skin is broken or perspiring.

»What protective clothing and equipment is

needed?

»Know the correct first aid/safety in case of

poisoning.

»Seek medical advice if chemicals affect health.

Mixing the Product

»Reduce or eliminate operator contact by using

closed loading systems such as chemical mixing

units, wettable powder mixtures or wettable

dispersible granules.

»Use the right protective clothing when handling

the concentrate. The user is at greatest risk when

handling chemical in concentrate form.

»Open bags carefully. Cut to open, do not tear.

»Do not stir chemicals with hands or arms.

»Choose the mixing site carefully & the fate of the

probable residues.

»Do not mix more spray solution than is needed

and avoid needless disposal of unwanted

chemicals.

Rate of Absorption

»While pesticides are absorbed more completely

orally and by inhalation, greater exposure and

more poisonings occur through skin (dermal)

contact. Ensure protective clothing is worn at all

times during chemical handling.

Hazard and Chance of Poisoning

»The hazard and chance of poisoning is much

higher when handling pesticides in concentrate

form than in the dilute form.

Safe Handling - Know your Pesticides:

»STOP!! Read the label

»Is it the right product?

»What is its poisons schedule or toxicity?

»What safety precautions are required?

»What is its persistence and withholding period?

»What is its mode of action?

»Will it be a hazard to neighbouring crops and

people?

Plan your Spray Route

»Observe weather conditions, especially wind

direction & speed.

»Try to travel across wind and into untreated crop.

»Prevent double or over spraying.

»Prevent or minimise drift onto other crops, workers,

etc.

Disposal of Unwanted Pesticides and

Containers

»Calibrate correctly to ensure you do not have a

large quantity of unwanted spray left over.

»Rinse empty containers and pour residue into the

spray tank.

»Dispose of containers in the correct manner and

where provided, use pesticide drum disposal

schemes.

Decontamination

»Change out of protective clothing and shower as

soon as possible after spraying.

»Wash before eating, drinking or smoking.

»Provide clean water at filling site and on sprayer

in case of field contamination.

»Wash and clean respirators regularly. Replace

respirator cartridges at recommended intervals.

Keep Sprayers and Safety Equipment in

Good Working Condition

»Replace hoses and fittings when they leak.

»Clean sprayer regularly.

»Replace respirator filters regularly.

»Do not use worn, faulty or contaminated safety

equipment.

Storage

»Store pesticides in a locked, well-ventilated store

– check your local regulations to ensure your

store complies.

»Do not pour pesticides into other containers;

especially not drink containers.

Pesticide Free Tractor Cabs

»Ensure the cab filter is adequate for the pesticide

used.

»Be careful not to contaminate the cabin

environment.

»Cabin filters alone are not adequate when the

operator is required to leave the cab to refill the

sprayer. Safety equipment used outside the cab

should not be stored in the cab.

WARNING

Every product for sale will have a detailed label with application instructions, rate

of application, safety information and withholding periods. Always follow these

instructions carefully.

10 11

18/09/2016

LP-OMLINK-B

SAFETY WITH CHEMICALS

CONTINUED

Protective Safety Equipment

»The amount and type of protective clothing

and equipment is determined by the type of

chemicals, degree and duration of exposure,

weather conditions and application equipment

used. Read and follow the direction on the label.

Over protection can be uncomfortable and

unnecessary. A respirator left hanging around

your neck is useless.

Measuring

»Croplands’ calibrated, easy-pour 1, 3 and 5 litre

measuring jugs and the 25 litre chemical mixing

bucket are practical, easy to clean, U.V. resistant

and chemical resistant.

Clothing

»Cover as much of the body as possible,

especially the neck, chest and forearms. Use

washable fabric overalls, disposable overalls or

preferably waterproof clothing especially when

coming in direct contact with pesticides. Wear

the trouser legs outside the boots.

Gloves and Boots

»Never use leather or cloth materials because they

absorb pesticides and provide a constant source

of contamination. Gloves should be un-lined for

this reason. Croplands Nitrile Chemical Handling

Gloves are recommended.

Head & Face

»Hard hats, washable hats, goggles, spray helmets

and face shields are important when handling

concentrates. Purchase Goggles that feature

sealed, anti-fog lenses for practical, comfortable

eye protection. Croplands Kasco Spray Hood is

fully approved for use with agrichemicals.

Respirators

»Choose the correct type and have the correct

cartridge fitted. Replace cartridges regularly and

write the date on each cartridge. Ensure there is

an adequate fit to the face. Croplands’ respirators

are recommended for most spraying applications.

Operator Safety

»When handling pesticides, always use elbow-

length gloves, long clothes and above all, a

respirator. If you and your clothing become

contaminated with spray, DO NOT WORK

ON. Stop work; remove clothing and wash

affected areas thoroughly with soap and water.

Put fresh clothing on before starting again. Ensure

that contaminated clothing is washed thoroughly

before being used again.

»Don’t guess when choosing protective equipment.

Feel free to call Croplands and make use of our

safety information.

Spraying Precautions

»Agricultural chemicals applied under

unfavourable weather conditions or from poorly

adjusted and operated equipment can cause

damage due to run-off and/or drift problems.

»Crops and pastures are more susceptible to

spray drift of herbicides while people, stock and

water supplies are generally more susceptible to

insecticide drift. Pollution, crop damage and the

potential health hazards are something agriculture

can ill afford. It is simply not acceptable, socially

or environmentally. Additionally, pesticide, which

drifts or runs off the target, reduces the efficiency

of the pesticide on the target. Spray failures are

a waste of money and effort. In most cases you

have a legal obligation to ensure damage to

crops outside your property does not occur.

1. Be SURE the equipment is functioning correctly.

Check that nozzles are in good condition. Check

all other aspects of machine operation are

correct.

2. Be SURE pesticides are mixed thoroughly and

according to the label.

3. Be SURE the recommended registered pesticide

is used for the job at hand.

4. Be SURE pesticides are applied at

recommended rates.

5. Be SURE only target plants are sprayed.

6. Be SURE to follow the safety precautions

on the label.

CAUTION

Always read the chemical label carefully.

12 13

18/09/2016

LP-OMLINK-B

SECTION 4: SPRAYER

SPECIFICATIONS

Product Identification

Whenever possible, use the serial number of the

AgriPak linkage sprayer when requesting service or

parts information.

Where a serial plate is not provided or is no longer

on the unit, use the part number from the bar code

affixed to this manual or the Warranty & Pre-delivery

booklet.

LA300 AgriPak LA600 AgriPak

»AR Triple-diaphragm positive displacement pump fitted

»Standard Pump capacity 80 litres/min

»Optional high-pressure AR30 and AR503 for vertiboom

»10 litre Hand Wash tank

»40 litre Fresh Water Flushing Tank

»Fully hot-dipped galvanised frame

»Easy access & fully protected suction filter

»ARUCM full-bypass 4 or 5 tap control unit fitted with

master on/off lever

»Isometric pressure gauge for accuracy in setting pressure

»Protected pump, rear mounted for excellent PTO angle

»Quality PTO shaft supplied

»Safety labels

»Translucent tank material for easy volume reference

»Easy-slide boom mounting

»Options for controllers, booms, hosereels, spray guns,

foam markers & GPS systems – refer Croplands Optima

Buyers Guide on-line

»AR Triple-diaphragm positive displacement pump

fitted

»Standard Pump capacity 80 litres/min

»Optional 140 L/min

»Optional high-pressure AR30 and AR503 for

vertiboom

»15 litre Hand Wash tank

»80 litre Fresh Water Flushing Tank

»Fully hot-dipped galvanised frame

»Easy access & fully protected suction filter

»ARUCM full-bypass 4 or 5 tap control unit fitted with

master on/off lever

»Isometric pressure gauge for accuracy in setting

pressure

»Protected pump, rear mounted for excellent PTO

angle

»Quality PTO shaft supplied

»Safety labels

»Translucent tank material for easy volume reference

»Easy-slide boom mounting

»Options for controllers, booms, hosereels, spray guns,

foam markers & GPS systems – refer Croplands

Optima Buyers Guide on-line

Pump model & Serial number

The Pump model & pump serial number is located

on the pump itself. The plate shows the name of

the manufacturer, type and model of the pump,

serial number, maximum working pressure and

oil requirements. For further information on parts

for your pump, refer to the parts section on the

Croplands website. Use the pump model as the

reference.

LA800 AgriPak LA1000 AgriPak

»AR Triple-diaphragm positive displacement pump fitted

»Standard Pump capacity 80 litres/min

»Optional 140 L/min

»15 litre Hand Wash tank

»80 litre Fresh Water Flushing Tank

»Fully hot-dipped galvanised frame

»Easy access & fully protected suction filter

»ARUCM full-bypass 4 or 5 tap control unit fitted with

master on/off lever

»Isometric pressure gauge for accuracy in setting pressure

»Protected pump, rear mounted for excellent PTO angle

»Quality PTO shaft supplied

»Safety labels

»Translucent tank material for easy volume reference

»Easy-slide boom mounting

»Options for controllers, booms, hosereels, spray guns,

foam markers & GPS systems – refer Croplands Optima

Buyers Guide on-line

»AR Triple-diaphragm positive displacement pump

fitted

»Standard Pump capacity 80 litres/min

»Optional 140 L/min

»15 litre Hand Wash tank

»Fully hot-dipped galvanised frame

»Easy access & fully protected suction filter

»ARUCM full-bypass 4 or 5 tap control unit fitted with

master on/off lever

»Isometric pressure gauge for accuracy in setting

pressure

»Protected pump, rear mounted for excellent PTO

angle

»Quality PTO shaft supplied

»Safety labels

»Translucent tank material for easy volume reference

»Multiple bolt holes for boom mounting

»Options for controllers, booms, hosereels, spray guns,

foam markers & GPS systems – refer Croplands

Optima Buyers Guide on-line

NOTE

For further information on Croplands

AgriPak sprayers,

see www.croplands .com.au

14 15

18/09/2016

LP-OMLINK-B

SECTION 4: SPRAYER

SPECIFICATIONS GENERAL

INFORMATION

Tanks

Croplands AgriPak tanks are constructed from a

UV stabilised, medium density polythene for low

distortion qualities and impact resistance. Tanks

come with capacities of 300, 600, 800 and 1000

litres. A screw down main lid is installed on all

models and comes standard with a basket strainer.

Agitation is provided by a constant bypass system

back to tank. A venture agitator is standard on some

models and optional on others.

Pumps

Croplands uses positive displacement oil-backed

diaphragm pumps. The size and output of pumps

vary depending on the machine specifications

ordered. The maximum operating pressure is shown

below at a PTO output of 540 rpm.

Do not exceed the maximum PTO output of

540rpm.

Drive

A 540 rpm PTO shaft with safety shields & safety

chains is provided with every AgriPak.

Controls

Standard Croplands linkage sprayers come with a

manual bypass control with a screw type pressure

regulator valve (PRV) that has been pressure

tested before leaving the factory. A glycerine

filled pressure gauge is fitted, with 2 – 6 control

outlets depending on sprayer model. If an electric

or automatic rate controlled is fitted, refer to the

separate manufacturer’s manual provided.

Filtration

Refer to the table below for filtration point

information. Other combinations are available to

order.

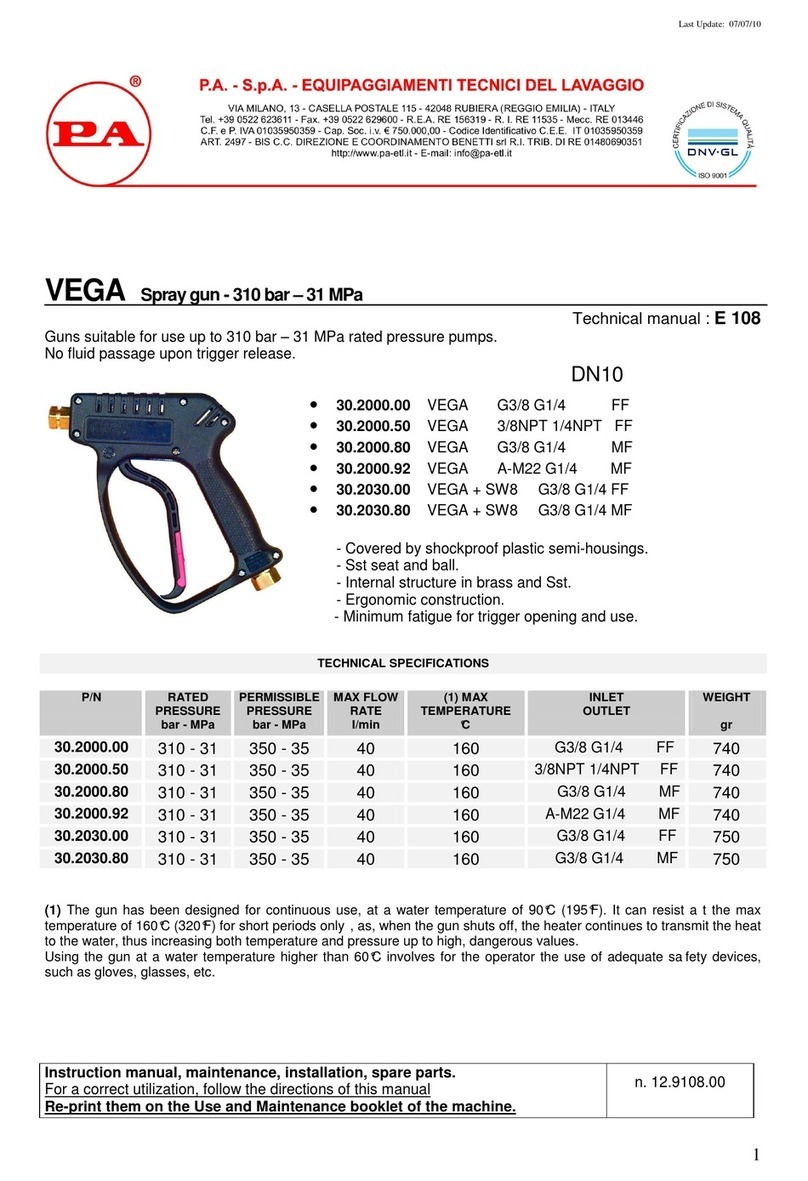

Pump models Max L/min Max Press.

AR45LFP 43.3 20 bar

AR80LFP 76.4 20 bar

AR140LFP 132.9 15 bar

AR30 35 40 bar

AR503 54.1 40 bar

Tank lid strainer 18 mesh

Suction filter 50 mesh

Boom nozzle strainers (if

fitted)

50 mesh

Optional in-line pressure

filter(s)

100 mesh

BOOM OPTIONS

Manual folding, cross-fold booms

MBX series

3, 4 & 6 metre cross-fold galvanised boom, stainless

steel boom tubes, AirMix™ nozzles & non-drip

nozzle bodies.

MAX series

8, 10 & 12 cross-fold metre galvanised boom,

stainless steel boom tubes, AirMix™ nozzles & non-

drip nozzle bodies. 8, 10 & 12 metre have flip-over

outer wings. Options include leveller and lift device.

Hydraulic crossover fold booms

GEX Series

Galvanised 6, 8 and 10 metre cross-fold with

hydraulic cylinders operating the inner arm fold.

Outer wings on the 8 & 10 metre are manually

folded.

Hydralink series

(Only suitable for use on the 1000 litre model) 12

& 15 metre hydraulic “X-fold” galvanised boom,

stainless steel boom tubes, AirMix™ nozzles & non-

drip nozzle bodies. Integral self-leveller with manual

lock fitted. Breakaway on outer arms as standard.

Under-tree and vine booms

MSC/MSCL-2 covered boom for vines or trees,

left, right, double sided & centre section covers

available.

Vertiboom

High pressure boom, with left/right upright boom

tubes and high pressure nozzles for use in small

horticultural vertical row crops such as berries.

Boom suitability AgriPak 300 AgriPak 600 AgriPak 800 AgriPak 1000

MBX Series √ √ √ X

MAX series MAX08 only √ √ √

GEX series X√ √ √

Hydralink series XXX√

MSCL covered boom √ √ √ X

Vertiboom (high pressure

horticultural use only)

√ √ X X

NOTE

For more information on booms and the

model fitted to your sprayer, please see

the Croplands Spray Boom Operator

and Parts Manual.

16 17

18/09/2016

LP-OMLINK-B

Hose reels & guns for hand spraying

For more information, refer your hose reel manual

or www.croplands.com.au

Chemical Mixing and induction hopper

For more information, refer your mixer manual or www.croplands.com.au

30 litre A5033301 version shown here.

Foam marker or GPS unit

For more information refer the manufacturers manual

or visit www.croplands.com.au

Optional step for 600, 800 and 1000 litre versions

MBX series booms

3, 4 and 6 metres available – for more information, refer your boom

manual or www.croplands.com.au

MAX series booms

8, 10 & 12 metres available – for more information, refer your boom

manual or www.croplands.com.au

MAX level

Hydraulic boom height adjuster or lift device

For remote lifting of the spray boom using tractor hydraulic remotes.

Shown is lift for LP-800 & MAX booms – for more information visit www.

croplands.com.au

GEX series booms

6, 8 & 10 metres available – for more information, refer your boom

manual or www.croplands.com.au

MHL series booms

12 & 15 metre as available (1000 litre AgriPak only) – for more

information, refer your boom manual or www.croplands.com.au

XP Boom kit

For use where a boom is impractical – for more information, refer your

boom manual or www.croplands.com.au

Vertiboom

For use in vertical row crops where high pressure is needed (AgriPak must

have a suitable pump fitted) – for more information, refer your boom

manual or www.croplands.com.au

OPTIONAL EQUIPMENT

SEPARATE MANUALS PROVIDED

18 19

18/09/2016

LP-OMLINK-B

SECTION 5: OPERATION HOOK

UP AND PTO INFORMATION.

Connecting to the tractor

Croplands AgriPak sprayers have models to suit

Categories I, II and III tractor linkage connections.

300, 600 & 800 litre models have Cat II for the

lower linkage arms, and Cat I for the top link with

sleeve if your tractor has Cat II.

The 1000 litre AgriPak sprayer has a clevis-type Cat II

& III hitch for the lower arms and Cat II for the top link.

Procedure

Lower the tractor linkage arms and attach the

sprayers lower hitch pins, using the suitable

category for your setup.

NOTE

Check all of the individual parts before

operation. Check the pump oil level

before operating the sprayer. You can

use SAE30 or SAE 20/40 multi grade

engine oil to top up the oil if needed.

CAUTION

Your Croplands sprayer dealer is

responsible for correctly setting and

installing the supplied PTO shaft for the

first time it is set up. This can involve cutting

the shaft to length to ensure correct, safe

operation. The above information is for

reference purposes only.

WARNING

Always ensure the tractor PTO is

disengaged before attempting to hook

up the PTO shaft!

Lift the tractor linkage up to the level you wish to

spray at. Now you can adjust the length of the

top linkage arm to level the sprayer. Clean off and

grease the PTO splines on the sprayer and tractor

stub shafts. Put the PTO shaft onto both splines

making sure the spring loaded locking pins click

into place and is completely secure on the splines.

Attach the PTO shaft safety chains ( attached on the

PTO guards) to the tractor & the pump PTO guard.

Raise and lower the sprayer to check that the tubes

of the PTO overlap by at least 1/3 of their length,

and not less than 150mm, in all operating positions.

Start up

After the pre-delivery checklist has been done and

your AgriPak linkage is hooked up correctly to your

tractor, it is advised that a water test be done to

check for leaks and to familiarise yourself with your

new sprayer. These checks have been conducted

in the factory; however there is a chance that transit

could have loosened some fittings. Running the

machine with fresh water is a good safe way to

calibrate and learn about your sprayer, and set your

sprayer up properly to maximise results in the field.

Fill the tank partially with water to allow testing of

the sprayer before you start your test or spraying

job.

The Suction filter is either fitted with a shut off valve

(yellow or red removable twist plug), or with a 3

way ball valve to shut off the flow in the suction line

before the filter. This allows you to clean the filter

mesh while there is fluid in the spray tank. Always

ensure this valve is correctly set prior to start up so

that liquid from the main tank can flow through the

pump and control unit.

To start the sprayer, ensure the PTO is set in 540

RPM mode.

Make sure the pressure

relief valve on the

control unit is backed

off anti-clockwise prior

to engaging the PTO.

Increase the tractor

PTO speed up to no

more than 540rpm.

WARNING

Double check this step as some tractors

have a 1000 RPM setting – this will

destroy the pump if engaged!

NOTE

You may not need to run the pump at 540

RPM to achieve the desired spray output.

In most cases a PTO speed of 400RPM or

thereabouts is sufficient.

Twist plug to shut off liquid flow.

20 21

18/09/2016

LP-OMLINK-B

The pump will draw liquid from the tank and bypass

this until such time as you open the manual taps and

flick the main lever on the manual control unit to the

open position. Refer to the section below AR UCM

controller operation.

Once the boom taps and master on/off lever on

the manual control unit are in the open position,

the nozzles should spray. Using the rotary pressure

relief valve knob, you can now adjust the pressure

to the recommended spraying pressure by rotating

the PRV knob. Anti-clockwise rotation will reduce

the pressure; clockwise rotation will increase the

pressure. Using the pressure gauge on the control

unit, you can determine the spraying pressure. For

most boom-spraying jobs, a pressure between 1

and 5 bar (30 to 70 psi) is the norm. The AirMix™

low-drift nozzles can be safely operated within a

1-6 bar pressure range, but note that the Spray

Quality will be influenced by your spraying pressure.

For more information on Spray Quality, you can

access the Croplands Buyers Guide on line

and check the chart for AirMix™ nozzles – this

information is in the nozzle section.

Most chemical labels advise the application

rate and spray quality for the product being

used. Youmay wish to discuss this with your local

agronomist if you are unsure.

If you have electric controls or an Auto-Rate spray

controller fitted to you AgriPak linkage sprayer,

please refer to the Croplands manual relevant to the

model you have purchased to learn how to use this

prior to start up. Croplands Technical support can

also be contacted should you need assistance (see

back page for contact details)

Flushing tank – standard on 300, 600 and

800 litre models

A 3-way ball valve is provided on the suction line to

allow the operator to select suction from either the

main spray tank, or the fresh-water flushing tank.

CAUTION

Never use the fresh water flushing or

handwash tank for chemical use. These

tanks are designed specifically for

holding fresh water for either flushing the

sprayer, or in the case of the hand-wash

tank, for the operator to use for cleaning

hands or the suction filter in the field.

To flush the sprayer in the field after spraying, shut

off the boom using the liquid controls, stop the PTO

and leave the boom in the unfolded operating

position. Using the ball valve, select the fresh water

flush tank. Climb back into the tractor cab, start the

PTO and open the manual or electric control to

allow fresh water to flow through the spraying circuit

and the nozzles. If you have remaining spray left in

the main tank, flush only for one to two minutes to

flush the pump and boom lines.

If you have finished your spraying job and the

main tank is empty, you can flush the system for 5

minutes, or until the flushing tank is empty, to ensure

the system is thoroughly flushed with fresh water. It

is recommended to do this in the field so that any

chemical residue is deposited in the area you have

been spraying to avoid continual deposits back at

the spray shed site.

A thorough tank clean once back at the shed is

recommended if you have finished your spray

job. Always drain the main tank when finished. To

avoid algae build up in the fresh water tanks, it is

recommended these also be drained and refilled

just prior to the next spraying job.

This will ensure your AgriPak sprayer is ready to go

prior to its next use. To clean the filters:

»Ensure the shut-off tap is in the “off” position, or

the shut off plug is removed from the filter housing

»Remove the filter element from the housing by

undoing the main filter housing nut

»Clean the filter element with fresh water (note,

if the suction filter does become blocked during

spraying, this can be cleaned in the field by using

the handwash tank

»If a pressure filter is fitted (normally if the sprayer

has electric controls fitted), also remove the filter

cartridge and clean with fresh water

»Inspect the nozzle filters, at least one from each

boom section, and if required, clean these in fresh

water. The nozzles filters are up inside the nozzle

body and can be accessed by removing the

nozzle cap. If care has been taken to have clean

water used for spraying, and the suction filter is

kept clean, the nozzle filters should not block.

After and extended time of non-use, it is

recommended you check the filters before your next

spray job. Often spiders or wasps can get into the

filter housing.

NOTE

Always use gloves when handling filters.

NOTE

Always clean the filters when your

spraying job is completed.

22 23

18/09/2016

LP-OMLINK-B

ARUCM Controller operation

A four or five outlet control unit is used (five outlet

where 3 boom sections & a hose reel is fitted) and

is standard. on all AgriPak linkage models. The

main on/off lever “A” will be used in most instances,

and when liquid supply to the boom or nozzles

is closed, all liquid will be bypassed to the tank.

System pressure is regulated by turning the red (or

on some valves black) knob “B” and by observing

the reading on the pressure gauge (D”). Turning the

knob clockwise increases the pressure and turning

anticlockwise decreases pressure. The pressure can

only be accurately set with the boom lines open

and the master lever open. Fluid is directed to the

boom lines or other spraying devices by the outlet

valves “C” which may be operated individually.

The outlet valves are marked with a “0” or a “1”

to indicate if they are on or off. If you wish to stop

spraying but leave the tractor PTO running, either

the master on/off lever or the individual taps can

be used. For a parts breakdown see the controller

manual provided.

Spray guns and hose reels (if fitted)

A variety of spray guns and hose reels are available

for use with Croplands AgriPak linkage sprayers.

A hose reel may be mounted to the side or rear

of the sprayer frame with the inlet end of the hose

connected to one outlet of the control unit. When

fitted, the standard reel contains 20 metres of 10mm

hose at a pressure rating of 20 Bar. The heavy duty

steel reel holds 30 metres of hose.

The heavy duty hose reel can hold up to 50 metres

of 10mm spray hose. For any unit has a 40-bar

pump and a hose reel fitted, the spray hose will

have the corresponding higher-rated pressure

hose fitted.

The spray lance gun fitted on the standard

Croplands hose reel is an RL10, rated up to 20 Bar

pressure. On the heavy duty reel, the standard spray

gun is a Turbo400 model rated to 50-bar pressure.

Other options include:

»TeeJet® range of spray guns

»Spot Gun 300

Talk to your dealer if you want a different spray gun

for a specific purpose. To operate the RL10 spray

lance or Turbo400 spray gun, start the sprayer and

have pressure available in the system. Ensure the

tap corresponding to the spray line going to the

gun is in the on position. Squeeze the main trigger

adjacent to the handle and aim the gun at the plant

to be sprayed. For the RL10, you can adjust the

spray pattern by rotating the nozzle on the end of

the lance. On the Turbo400 gun, adjust the spray

pattern with your thumb by pushing the orange side-

lever up or down. For a fine “fog” spray, the widest

angle should be selected using the side-lever, then

the orange end-cone should be adjusted to slide out

as far as possible on the gun barrel. This is ideal for

very fine spraying such as fungicide application in

nursery plants etc.

Spray Booms

A variety of booms may be used with Croplands

AgriPak linkage sprayers depending upon the

model and field application – see table on page

15-17 for this information. All have non-drip nozzle

bodies with AirMix™ flat fan nozzles. Booms are

part of the standard equipment on some models,

in some cases they may be installed by the dealer

or owner. On all types of boom, the setting of the

correct operating height is most important to achieve

a uniform spraying pattern. This needs to be at a

height above the target which will achieve 50%

overlap of the spray from adjacent nozzles.

WARNING

Safety information about Spray guns

and lances:

1. NEVER aim the spray gun at anyone

2. ALWAYS shut the system off when you

are not using the spray gun

3. ALWAYS ensure your spray application

is not drifting beyond the target

4. NEVER operate the gun beyond the

pressure capability of the system

Secure the gun on the spray unit and roll

up the hose when the job is finished.

NOTE

For more information on hose reels and

spray guns fitted to your sprayer, please

see the Croplands Reels & Spray Guns

Operator and Parts Manual.

NOTE

Section 6 will only be relevant if your

AgriPak Linkage sprayer is fitted with a

Croplands boom.

24 25

18/09/2016

LP-OMLINK-B

SECTION 6: SPRAYING

INFORMATION

This section also provides information

relevant to Calibrations in section 7

When to spray

Spraying results are best when the wind speed and

the temperature are low but the relative humidity

is reasonably high. An ideal time is at sun up or

nearing the end of the day when these conditions

are more likely to occur.

For more information, contact Croplands about our

SprayWise® program, or purchase a copy of the

SprayWise Application Guide from Croplands.

Also, the use of the WINDMATE™ Wind meter

would be of excellent value to anyone doing

regular spraying.

Field patterns

For the best coverage, spray two swath widths

around the outer perimeter of the field as shown

in the diagram. This establishes a good headland

and will give you adequate room to turn around.

Turn the booms off when you come back on to the

headland to prevent over spraying and wastage.

Using a guidance system such as GPS or foam

markers can prevent overlaps and ensure you get

better coverage.

Ground Speed

Modern tractors should have sufficient speed

accuracy for sprayers of this size. To check the

speed, fill the tank and open the boom to simulate

usual spraying conditions. See section 7 to learn

how calculate ground speed if your tractor does not

have a reliable speedometer.

For spraying with an AgriPak linkage sprayer, the

speed will you can safely & accurately spray at

will depend on the conditions, terrain, and product

being applied. In general, speeds of 5 to 15 km/hr

are most often within the range for linkage spraying.

Spray Quality

Spray quality is becoming extremely important for

the correct application of chemicals. Refer to your

advisor, local DPI or check the Croplands Buyers

Guide for more information. Many chemical labels

now specify the spray quality required for the

product being used. Loosely, spray quality falls into

a droplet range of:

»Ultra Coarse

»Extremely Coarse

»Very Coarse

»Coarse

»Medium

»Fine

»Very fine

Field patterns

CAUTION

Most spray applications will fall into the

Medium to Very Coarse range, depending

on the application. Talk to a qualified

Agronomist or Advisor if uncertain.

Nozzle spacing and height

Nozzles overlap should be 50% at the point of

contact with the spraying surface. Croplands booms

operate with a nozzle spacing of 500mm (50cm)

with nozzles slightly offset to avoid interference.

Nozzles are supplied with 110° angled patterns.

The recognized height to achieve the required

50% overlap is 400mm-500mm for 110° nozzles

(measured from the target to be sprayed).

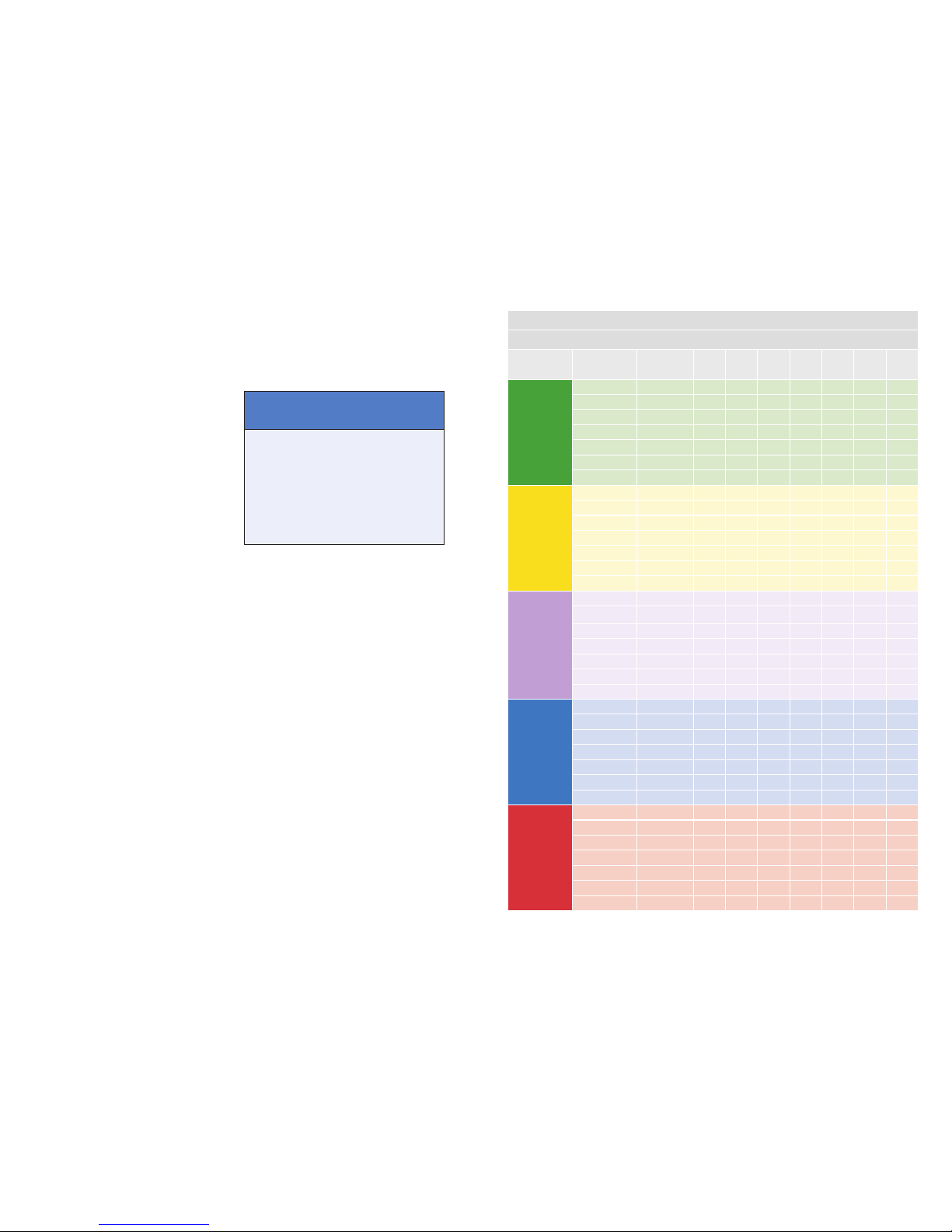

Spray pattern and uniformity

Your nozzle spray pattern, overlap and uniformity

need to be monitored and can be tested in the

following manner. Keep a spare new nozzle to with

which you can compare the other nozzles on your

unit. Place the new nozzle at a central point on the

boom and fill the tank with fresh, clean water and

switch the boom on. Examine the spray patterns

against a dark background and replace any that

show signs of damage or sufficient wear as shown

below.

26 27

18/09/2016

LP-OMLINK-B

BOOM SPRAYER

CALIBRATION

Each Croplands boom is fitted standard with non-

drip nozzle bodies so that when the liquid flow

is switched off, the bodies will not drip. Supplied

on all Croplands’ booms are AirMix air-induction

ultra-low drift nozzles - now an industry standard to

reduce the likelihood of spray drift.

The liquid flow to the boom can be stopped

& started as required (such as when turning at

headlands or where the operator does not want to

spray) by using the spray control unit provided on

the sprayer.

To ensure the right application of herbicide or crop

protection product is applied to the target crop, the

user should calibrate the AgriPak linkage sprayer

to ensure the correct application rate is used for the

chemical being used.

The information for the product to be applied (spray

target rate and spray quality) is usually supplied

by the chemical manufacturer on their product

label. Alternatively, a trained agronomist should be

consulted.

Part of the calibration process is to determine the

flow required to meet the required target spray rate,

and this information can be used to determine what

speed of travel will best suit your application and

what nozzle and spraying pressure to use.

Failure to calibrate a sprayer before operating may

result in ineffective or crop damage

Calibration

To accurately apply crop protection or herbicides

through a spray boom, the following procedure

should be undertaken.

1. Measure your speed of travel.

2. Check the nozzle spacing, and

3. Select an appropriate nozzle for the product

being applied, and check nozzle output in Litres

per minute (L/min), along with spraying pressure.

CAUTION

Check the current Croplands Optima

Buyers Guide for Nozzle information,

or purchase a copy of the Nufarm

Spraywise™ Spray Application Guide.

CAUTION

Do not operate a sprayer without

calibration or before calibration has

been completed.

WARNING

Always only use clean water when

calibrating or checking a sprayer. Never

calibrate with chemical present in the tank.

Failure to follow this instruction can lead to

poisoning and serious illness.

1. Speed of travel

Check your tractor speed. If you have an accurate

speedometer, this will suffice. If not, measure the

distance you have travelled in one minute in metres,

and divide this by 16.7:

»e.g. 120 metres travelled in one minute ÷ 16.7 =

7.18 km/hour.

»If this is impractical, measure the distance

travelled in 30 seconds, double it, and then

divide by 16.7.

»Repeat at least twice, from a running start, to

ensure accuracy.

2. Nozzle spacing

Standard nozzle spacing on a Croplands boom

is 50cm. This is also an industry standard for the

use of 110 degree nozzle tips as fitted standard to

Croplands booms.

3. Select Nozzle Type & Size

Select the Nozzle Type & Size according to:

»Chemical recommendations.

»Application rate required.

»Pressure setting.

»Swath width.

»Chosen speed of travel (Use actual speed of

travel, refer to step 2).

The right nozzle, application rate, spray quality

and nozzle pressure will best be advised by your

agronomist or consulting with the manufacturer

of the product you are applying. The Croplands

calibration guide covers these options in more

detail.

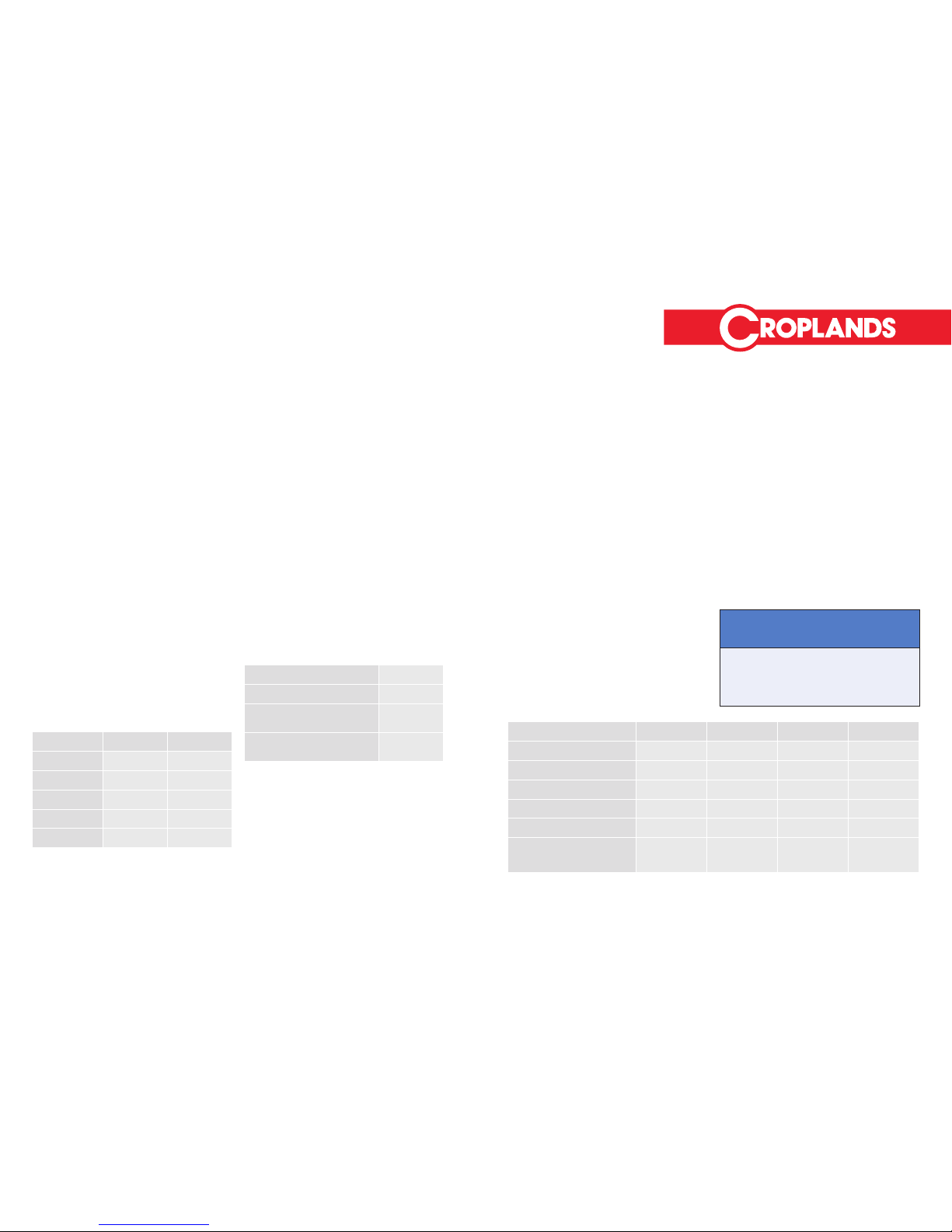

Included on page 29 is a basic nozzle chart to

show nozzle sizes, outputs and application rates at

varying speeds.

NOTE

Nozzle spray patterns and spray

angles should be visually checked for

accuracy and the nozzle replaced if not

spraying correctly.

2928

18/09/2016

LP-OMLINK-B

BROADCAST AND TURF APPLICATIONS

L/HA 50CM NOZZLE SPACING

Nozzle type Pressure bar Flow rate

l/min

5

kph

6

kph

7

kph

8

kph

10

kph

12

kph

16

kph

110-015 1.0 0.346 81.6 68.0 48.3 51.0 40.8 34.0 25.5

1.5 0.424 101 84.0 72.0 63.0 50.4 42.0 31. 5

2.0 0.490 115 96.0 82.3 72.0 5 7. 6 48.0 36.0

3.0 0.600 142 118 101 88.5 70.8 59.0 44.3

4.0 0.693 163 136 117 102 81.6 68.0 51.0

5.0 0.775 182 152 130 114 91.2 76.0 5 7. 0

6.0 0.849 199 166 142 125 99.6 83.0 62.3

110-02

STANDARD

1.0 0.462 110 92.0 78.9 69.0 55.2 46.0 34.5

1.5 0.566 134 112 96.0 84.0 6 7. 2 56.0 42.0

2.0 0.653 156 130 111 9 7. 5 78.0 65.0 48.8

3.0 0.800 190 158 135 119 94.8 79.0 59.3

4.0 0.924 218 182 156 137 109 91.0 68.3

5.0 1.033 245 204 175 153 122 102 76.5

6.0 1.131 269 224 192 168 134 112 84.0

110-025 1.0 0.577 137 114 9 7. 7 85.5 68.4 5 7. 0 42.8

1.5 0.707 168 140 120 105 84.0 70.0 52.5

2.0 0.816 194 162 139 122 9 7. 2 81.0 60.8

3.0 1.000 238 198 170 149 119 99.0 74.3

4.0 1.154 2 74 228 195 171 137 114 85.5

5.0 1.291 310 258 221 194 155 129 9 7. 0

6.0 1. 414 339 283 242 212 170 141 106

110-03 1.0 0.693 163 136 117 102 81.6 68.0 51.0

1.5 0.849 199 166 142 125 100 83.0 62.3

2.0 0.980 230 192 165 144 115 96.0 72.0

3.0 1.200 283 236 202 177 142 118 88.5

4.0 1.386 326 272 233 204 163 136 102

5.0 1.549 365 304 261 228 182 152 114

6.0 1.697 401 334 286 251 200 167 125

110-04 1.0 0.924 218 182 156 137 109 91.0 68.3

1.5 1.113 269 224 192 168 134 112 84.0

2.0 1.306 310 258 221 194 155 129 96.8

3.0 1.600 379 316 271 237 190 158 119

4.0 1.848 437 364 312 273 218 182 137

5.0 2.066 490 408 350 306 245 204 153

6.0 2.263 535 446 382 335 268 223 167

4. Select Nozzle Type & Size according to:

»Chemical recommendations

»Application rate required

»Pressure setting

»Swath width

»Chosen speed of travel. (Use actual speed of

travel, refer to step 2).

5. Fit the selected nozzles to the boom as per

the nozzle manufacturers specifications.

6. Check the nozzle accuracy as outlined

above in spraying information.

7. Add the correct amount of chemical to the

tank as per the directions on the chemical

label.

8. Adjust the boom height to suit your nozzles

as explained in the Nozzle section in

spraying information above.

9. Don’t forget to record your data for future

reference.

NOTE

To find more information on how to

calibrate a boom for varying application

rates:

»Refer to the Croplands web site at www.

croplands.com.au or

»Contact the Croplands Customer Service

or

»Technical Support: Phone 1300 650 724.

30 31

18/09/2016

LP-OMLINK-B

SECTION 7: DAILY START UP

AND USEFUL FORMULA

Daily start up procedure

A careful, common sense approach to water quality,

mixing of chemicals and care of filters, hoses and

tank will ensure trouble free spraying.

To ensure trouble free operation, follow the

procedure below at the start of each day:

1. Ensure that no solids enter the system to block or

damage pump or nozzles.

2. Check that suction line filter is clean and not

damaged. It should be checked & cleaned

regularly (see Page 21 for more information). Be

careful not to damage or deform the mesh or

O-Ring while cleaning and refitting the suction

line filter. If a filter screen is damaged, replace

with a new screen.

3. Put enough clean

water into the spray

tank to operate the

pump and hand gun

or boom (if fitted).

The tank can be

fully filled once your

start up check is

completed.

4. Activate the pump (see Page 19 for tips on

start up).

5. If fitted, adjust the pressure relief valve to obtain

the required pressure. Excess liquid will bypass

back to the tank. Once the pressure is set, it is

normal for minor fluctuations to show on the

pressure gauge when switching the hand gun or

boom on & off if you have these options fitted.

For more information on your pressure control unit,

refer to Page 22 or the separate manual supplied

for electric controls (if fitted).

6. Check that all hoses, hose clamps and

connections do not leak. Repair or replace

damaged components.

7. Read and follow the instructions on the chemical

manufacturers label before mixing and adding

chemicals to the spray tank. For safety information

refer to section 3 in this manual.

8. Add chemical to the tank and proceed with your

spraying application.

Operating Pointers

While spraying continually observe that:

1. Adequate operating pressure is being

maintained.

2. Your hand gun coverage is correct and constant

for effective cover and that your nozzle is

operating correctly (if you have a hose reel &

gun fitted).

3. Periodically check and clean filters – between

tanks is ideal

4. Your boom height is maintained at the correct

height above your target (if you have a boom

fitted).

5. Avoid going too slow because over application

will occur. Conversely, avoid going to fast

because under application will occur. Refer to

your calibration information.

CAUTION

Do not add chemicals to the spray tank

until the initial start-up or daily start-up

procedure has been carried out. This avoids

having a tank full of chemical mix and then

finding a sprayer problem

Useful Formula

1. Calculating the Tank Spray Area

Use this formula to calculate the area each tank full

of spray will cover.

Area Covered (ha)= Tank Volume (litres)

Spray Application Rate (L/ha)

eg. 300 (litres)

100 (L/ha)

= 3 hectares.

2. Calculating the Total Liquid Volum Required

Use this formula to calculate the amount of spray

liquidrequired to spray a given area.

Total Liquid Volume Required (litres)

= Area (ha) x Spray Application Rate (L/ha)

eg. 2 (Ha) x 100 (L/ha)

= 200 litres required

32 33

18/09/2016

LP-OMLINK-B

SECTION 8: LUBRICATION AND

MAINTENANCE

Daily Sprayer maintenance

In the first few days of sprayer usage, thoroughly

check the machine before starting each day of

spraying. Check all nuts and bolts and check

plumbing for leaks. Grease the PTO shaft at the time

intervals shown on the diagram below. The diagram

is only a guide, greasing may need to be more

frequent if spraying under extreme conditions.

Pump

Check the oil level on the pump sight gauge and

top up with SAE 20/40 multi grade engine oil if

needed.

Filters

It is important to clean filters daily as they can have

a major impact on your sprayer’s performance.

Wash them out with a soft brush and constantly

CAUTION

Do not leave water in the machine,

particularly in cooler climes as this can

freeze and ruin the pump.

WARNING

Make sure the tractor is switched off, the

machine is lowered to the ground and

the PTO drive shaft is disconnected.

check for holes or tears. Clean the suction filter

every time the tank is filled and at the end of the

days spraying. Make sure O rings are in good

condition and grease them with O ring grease in

necessary. Clean out nozzle filters if installed. See

page 22 for picture of filter screen.

Spray lines

Never leave chemicals

in the tank or the pump.

Rinse the tank out

completely with fresh

water and operate

machine to clear all spray

lines. Remove boom lines

caps if you have a boom

fitted and flush boom lines.

Annual sprayer maintenance

General sprayer care

When spraying season has finished, clean the

machine completely.

Check all electrical fuses as these can easily blow if

corroded in the off season.

Pump

Flush and drain the pump completely before

storage. Check the valves and diaphragms for wear

and damage before the start of the new season. Set

the air pressure in the chamber to around 10 – 20%

of the usual operating pressure. Drain the oil before

the commencement of the next season and replace

completely with new oil (SAE 20/40 multi grade

engine oil).

NOTES:

3534

18/09/2016

LP-OMLINK-B

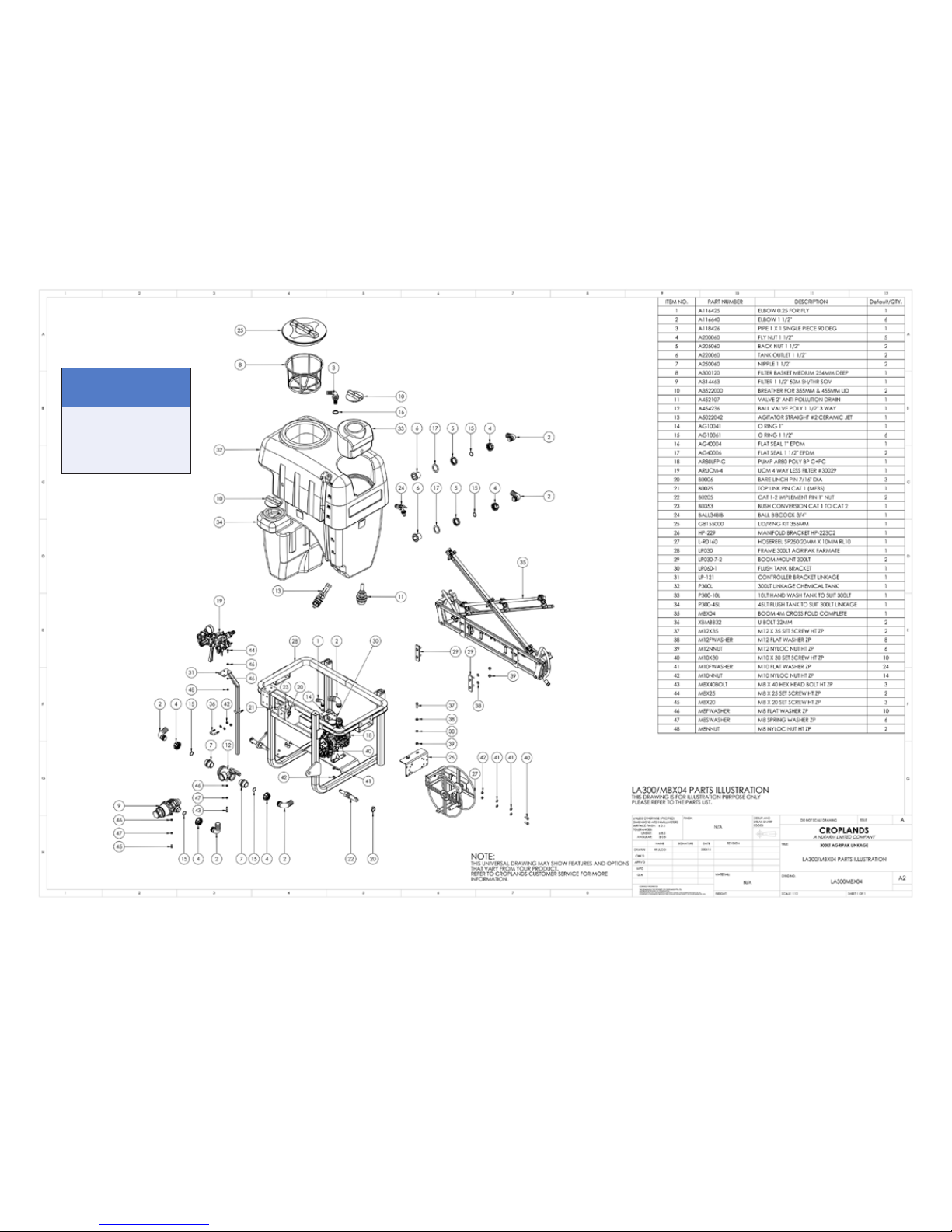

LA300 LINKAGE: 300 LITRE

WITH MBX04 BOOM &

HOSE REEL

NOTE

»This parts list is indicative

of this model sprayer. For

further parts information

refer to:

www.croplands.com.au

3736

18/09/2016

LP-OMLINK-B

LA600 LINKAGE:

600 LITRE WITH

AR80 PUMP

NOTE

»This parts list is indicative

of this model sprayer. For

further parts information

refer to:

www.croplands.com.au

3938

18/09/2016

LP-OMLINK-B

LA800 LINKAGE: 800 LITRE

WITH MAX10 BOOM,

LEVELLER, LIFT & HOPPER

NOTE

»This parts list is indicative

of this model sprayer. For

further parts information

refer to:

www.croplands.com.au

Other manuals for AgriPak LA300

1

This manual suits for next models

3

Table of contents

Other Croplands Paint Sprayer manuals

Croplands

Croplands Pinto 2000 User manual

Croplands

Croplands CROPPAK US200F User manual

Croplands

Croplands GEX Series User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands PEGASUS WEED-IT 4000 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands MHL12 User manual

Croplands

Croplands RSRL3-100RC REEL User manual

Croplands

Croplands WEED-IT User manual