TABLE OF CONTENTS 3

TABLE OF CONTENTS

TO THE OWNER ..................................................1

SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE

WITHOUT NOTICE........................................................ 1

ART’S-WAY MANUFACTURING CO., INC. STATEMENT OF

PRODUCT LIABILITY.....................................................1

IMPORTANT WARRANTY INFORMATION...........................1

LIMITATIONS OF THIS MANUAL....................................... 1

PARTS & SERVICE..............................................2

TABLE OF CONTENTS .......................................3

LIMITED WARRANTY..........................................5

SAFETY FIRST.....................................................6

NOTICES OF DANGER, WARNING, AND CAUTION ...........6

SAFETY GUIDELINES.........................................7

BEFORE OPERATING ...................................................7

DURING OPERATION.................................................... 7

MAINTENANCE SAFETY ................................................7

HYDRAULIC SAFETY ....................................................7

TRANSPORTATION SAFETY........................................... 8

STORAGE SAFETY.......................................................8

TIRE SAFETY ..............................................................8

ASSEMBLY SAFETY......................................................8

SAFETY DECALS................................................9

DECAL LOCATIONS & IDENTIFICATION............................9

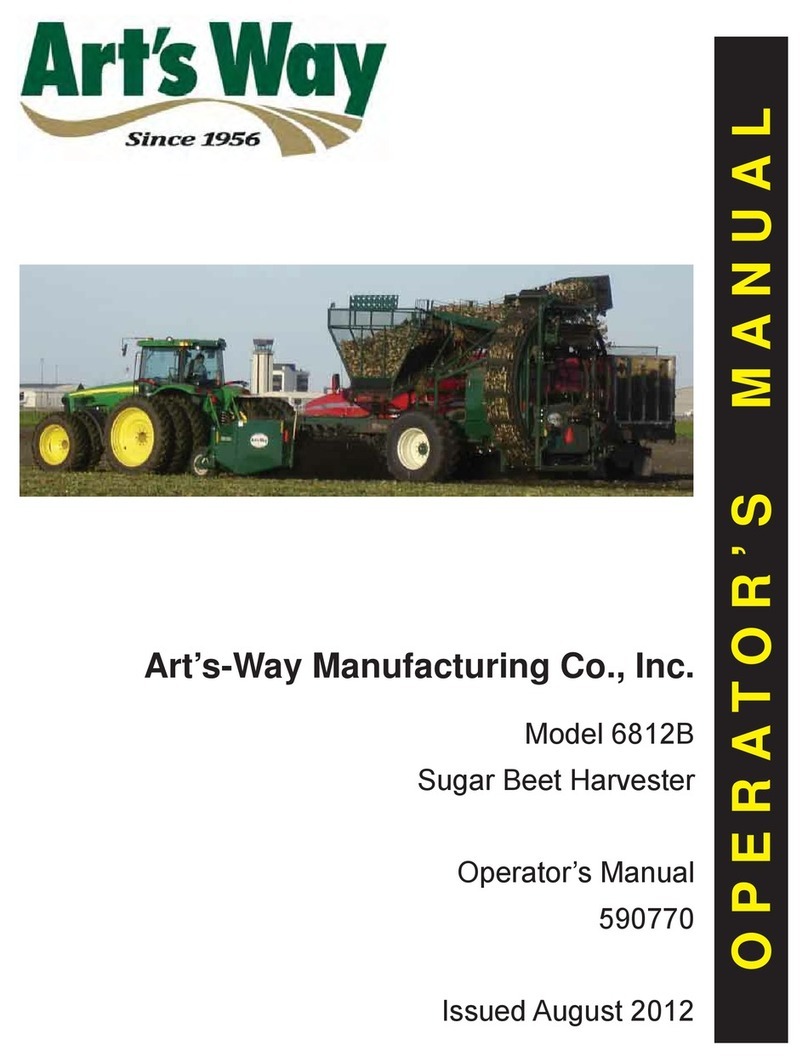

HARVESTER OVERVIEW..................................15

BEET FLOW HARVESTING SEQUENCE..........................15

HARVESTER STRUCTURE ...........................................15

ELECTRICAL SYSTEM................................................. 16

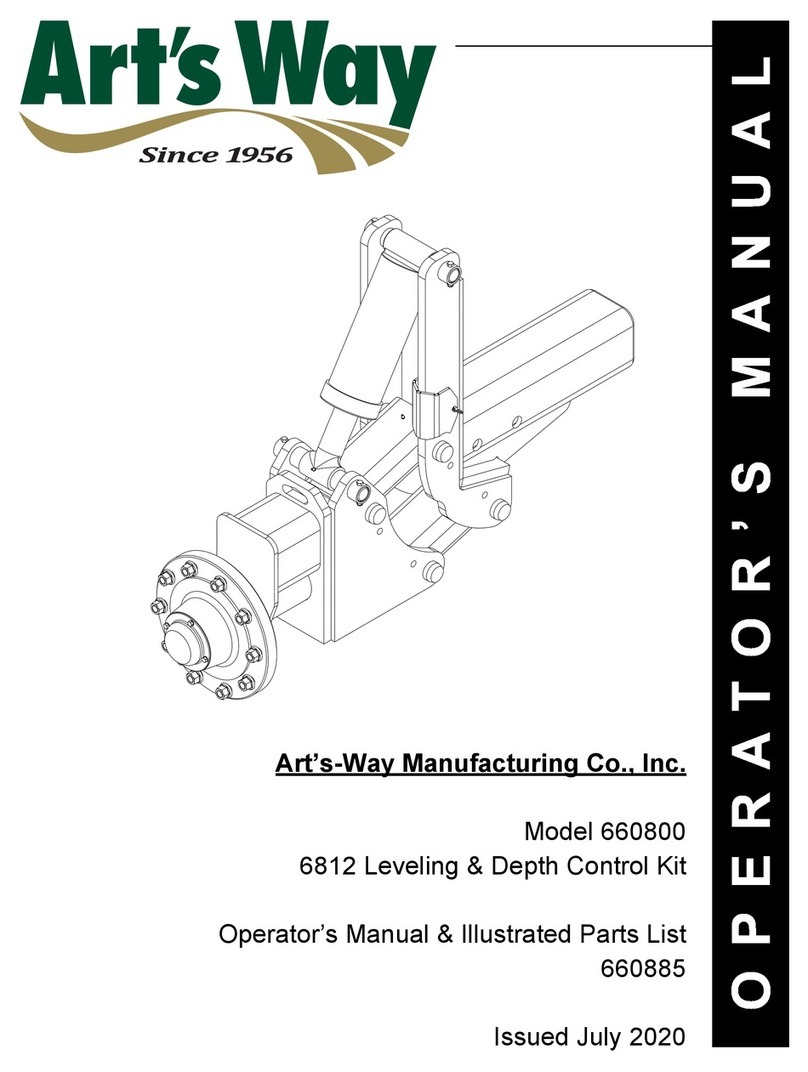

HYDRAULIC SYSTEM.................................................. 16

Harvester/Tractor Hydraulic System.................. 16

Harvester Self-Contained Hydraulic System...... 17

MECHANICAL SYSTEM................................................17

Drive Shafts And Gearbox.................................17

TRACTOR/HARVESTER CONNECTION..........20

TRACTOR REQUIREMENTS.......................................... 20

TRACTOR/HARVESTER CONNECTION PROCEDURES...... 20

FIELD OPERATIONS.........................................22

OPERATING SPEEDS.................................................. 22

BASIC CONTROLS......................................................22

Power Takeoff (PTO) – Constant Velocity.........22

Harvester Lift Cylinder....................................... 22

Steering Cylinder............................................... 22

Rowfinder ..........................................................22

Header...............................................................23

Short Conveyor..................................................25

Harvester Grab Rollers...................................... 25

Wheel Elevator.................................................. 26

Stripper.............................................................. 27

Transfer Conveyor.............................................27

Truck Boom Conveyor....................................... 27

Truck Boom.......................................................28

HARVESTER ADJUSTMENTS ......................... 29

POWER TAKEOFF (PTO) – CONSTANT VELOCITY .........29

HARVESTER LIFT CYLINDERS......................................29

ROWFINDER STEERING CYLINDER...............................29

ROWFINDER..............................................................29

Feeler Arm Spacing ...........................................29

Feeler Arm Centering.........................................29

Rowfinder Height ...............................................29

Feeler Arm Down Pressure................................30

HEADER ...................................................................30

Lifter Wheels......................................................30

Scrapers.............................................................31

Cylinder floatation in rocky conditions................31

Flex Struts..........................................................31

Paddles..............................................................31

Barriers and Covers...........................................32

Paddle Shaft Slip Clutch ....................................33

Roller Chain Tensions........................................33

Roller Belt Drive.................................................33

SHORT CONVEYOR....................................................34

HARVESTER GRAB ROLLERS ......................................34

WHEEL ELEVATOR RETAINER .....................................35

WHEEL ELEVATOR.....................................................36

Wheel drive chain to hydraulic motor.................36

STRIPPER .................................................................36

TRUCK CONVEYOR ....................................................37

HYDRAULIC SYSTEM ..................................................37

Tractor/Harvester Hydraulic System ..................37

Harvester Self-Contained Hydraulic System......37

TIRES.......................................................................38

Installing Tires....................................................38

TROUBLE SHOOTING GUIDE.......................... 41

BASIC MACHINE.........................................................41

ROWFINDER..............................................................43

LUBRICATION SCHEDULE.............................. 44

GENERAL..................................................................44

QUICK REFERENCE BY SYSTEM..................................44

QUICK REFERENCE BY HOUR .....................................46

SEASONAL STORAGE..................................... 47

PREPARING THE HARVESTER FOR STORAGE................47

RETURNING THE HARVESTER FROM STORAGE.............47

TRANSPORTING THE HARVESTER ............... 48

DEALER ASSEMBLY INSTRUCTIONS............ 49

PRE-DELIVERY..........................................................49

ASSEMBLY INSTRUCTIONS ..........................................49

HARVESTER ADJUSTMENTS ........................................55

ASSEMBLY INSTRUCTIONS 44 INCH BOOM EXTENSION ..55

PRE-DELIVERY TEST RUN ..........................................57

SPECIFICATIONS ............................................. 58

GENERAL..................................................................58

Model.................................................................58

Overall Dimensions............................................58

Tires...................................................................58

Row Spacing......................................................58

Lifter Wheels......................................................58