Dionex RF-2000 User manual

Fluorescence Detector

RF-2000

Operating Instructions

Version: 1.40

Datum: July 7, 2000

© 2000 Dionex Softron GmbH

Doc.: RF2000_OI_E_V140.doc

Operating Instructions RF-2000

DECLARATION OF CONFORMITY

We, Dionex Softron GmbH, declare that the product Fluorescence Detector

RF-2000

to which this declaration relates, is in conformity with the following European standards:

# EN 50081-1 (1992): Electromagnetic compatibility - Generic emission standard

Part 1: Residential, commercial and light industry

# EN 50082-1 (1992): Electromagnetic compatibility - Generic immunity standard

Part 1: Residential, commercial and light industry

Attention Dionex Softron will not accept any liability for damage, direct or indirect,

caused by connecting this instrument to devices which do not meet relevant

safety standards.

January 27, 1998 QM-Manager

Operating Instructions RF-2000

i

CONTENTS

1Precautions ................................................................................................ 3

1.1 Warnings in these Operating Instructions ................................................................ 3

1.2 Warning Labels on the Unit ..................................................................................... 3

1.3 Replacement of Fuses............................................................................................. 5

1.4 Precautions on Installation Site and Handling of the Unit......................................... 6

1.5 Precaution in the region where 240V is used as working voltage............................. 7

1.6 Precautions on Static Electricity............................................................................... 8

2General Information................................................................................. 11

2.1 Outline................................................................................................................... 11

2.2 Features ................................................................................................................ 11

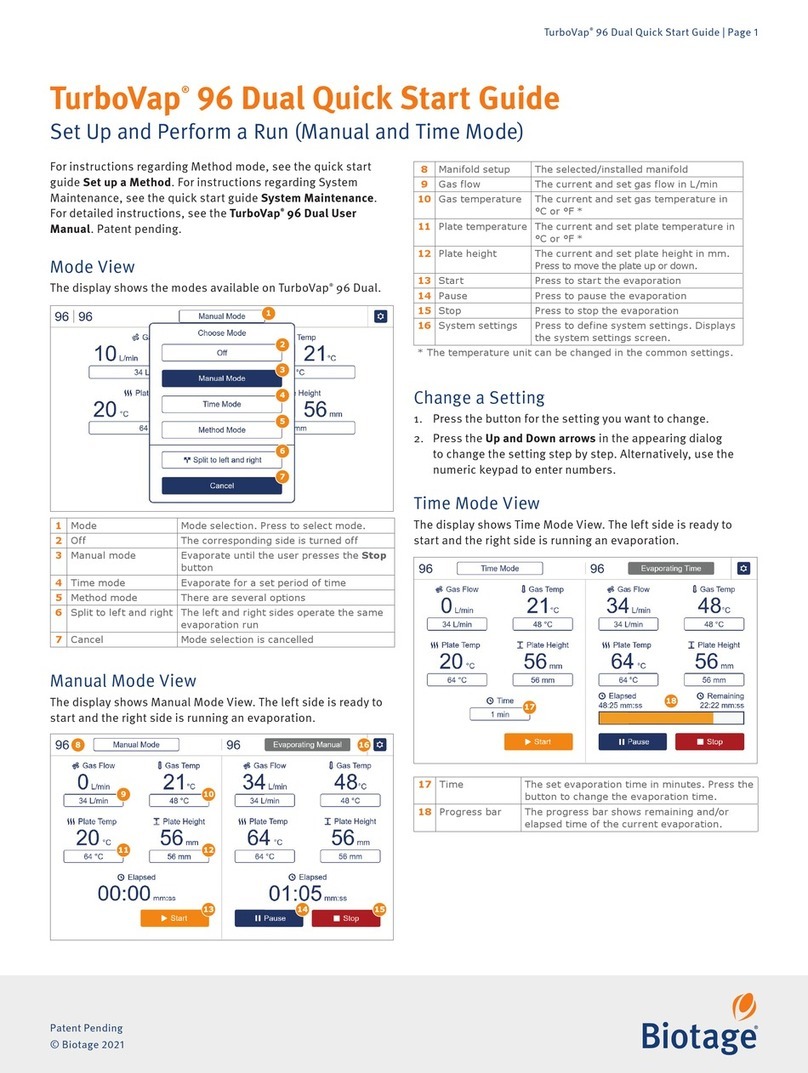

3Component Location and Function ....................................................... 12

3.1 Front View ............................................................................................................. 12

3.2 Top Side and Right Side........................................................................................ 13

3.3 Bottom Side........................................................................................................... 13

3.4 Rear View.............................................................................................................. 14

4Installation ................................................................................................ 15

4.1 Basic Installation Requirements............................................................................. 15

4.2 Electrical Connections ........................................................................................... 16

4.3 Fluidic Connections ............................................................................................... 17

4.4 Connecting the Recorder and the Integrator.......................................................... 18

4.5 Connecting a Drain Tube for Solvent Leakage ...................................................... 19

4.6 Installing the Xenon Lamp ..................................................................................... 19

4.7 Adjusting the Xenon Lamp Alignment .................................................................... 23

5Operation .................................................................................................. 26

5.1 Precautions for Operation...................................................................................... 26

5.2 Fundamentals of Operation ................................................................................... 26

5.3 Operating Procedure in Spectrum Scanning Mode................................................ 33

5.4 Creating and Executing a Time Program ............................................................... 36

5.5 Additional Functions .............................................................................................. 42

6Performance Verification ........................................................................ 50

6.1 Outline of System Validation.................................................................................. 51

6.2 Repeatability Test of Chromatographic Data (Isocratic LC) ................................... 51

6.3 Repeatability Test of Chromatographic Data (Gradient LC) ................................... 53

7Control from External Equipment .......................................................... 56

7.1 Connecting External Input and Output Terminals................................................... 56

7.2 Control from External Equipment via RS-232C...................................................... 58

Operating Instructions RF-2000

ii

8Maintenance ............................................................................................. 64

8.1 Maintenance of Flow Cell ...................................................................................... 64

8.2 Checking the Xenon Lamp .................................................................................... 70

8.3 Replacing the Fuse................................................................................................ 72

8.4 Changing the Set Power Supply Voltage ............................................................... 73

8.5 Periodical Cleaning................................................................................................ 74

9Troubleshooting ...................................................................................... 75

9.1 Summary of the Most Frequently Problems........................................................... 75

9.2 List of Error Messages........................................................................................... 80

10 Specifications ....................................................................................... 84

11 Standard Accessories .......................................................................... 86

12 Replacement Parts ............................................................................... 86

Operating Instructions RF-2000

3

1 Precautions

The Dionex RF-2000 is the fluorescence detector for the high performance liquid

chromatograph. In order to operate the unit safely, strictly observe the following

points. It is dangerous not to comply with the following points.

• Use the unit for any purpose mentioned above.

• Follow the procedures described in the operating instructions.

• Observe the warnings and cautions.

• Do not disassemble or modify the unit without approval from Dionex. Failing to do

so may lead to a dangerous situation or damage to the instrument.

• For internal repair of the product, contact the Dionex Service .

1.1 Warnings in these Operating Instructions

Warning: Indicates that failure to take note of the accompanying

information may result in personal injury.

Important: Indicates that failure to take note of the accompanying

information may cause wrong results or damage to the instrument

Please note: Indicates General information to assist you in obtaining optimum

performance.

1.2 Warning Labels on the Unit

For safety of operation, this unit is provided with the mark at the portion where

special cautions are required. When operating the parts where this mark is indicated,

exercise special caution after reading the operating instructions.

Warning:

• The xenon lamp may explode in the course of long use (more than 1000hours).

Replace the lamp of expired life (500 hours) with a new one.

• Be sure to wear protective gears, such as protective mask, heavy and long-

sleeved shirt and gloves, when handling the xenon lamp. Since high pressure gas

is charged in the xenon lamp, if the lamp is strongly shocked or the glass surface

is scratched, the lamp may explode and pieces of glass may scatter.

• When mounting or replacing the xenon lamp, be sure to turn OFF the power

switch and disconnect the power cable. Voltage is applied to the electrode by the

electric charge right after the power switch is turned OFF. Therefore, leave the

xenon lamp for more than five minutes after turning the power switch OFF before

opening the cover of the light source chamber.

• The xenon lamp is very hot when it is lit. Therefore, when replacing the xenon

lamp, wait for more than an hour after turning the power OFF to cool the lamp

enough for replacement.

• High voltage (approx. 30 kV) is applied to the xenon lamp during ignition. When

turning ON the power, be sure to mount the lamp and close the cover of the light

source chamber.

Operating Instructions RF-2000

4

Important:

Be sure to read this instruction manual before supplying power to this unit.

• Be sure to mount the xenon lamp correctly before supplying the power to this unit

(refer to 4.7 Installing the Xenon Lamp). Failing to do so may damage the main

unit because high voltage around 30kV is applied to electrode when turning ON

the xenon lamp.

• Use the power supply voltage at the state which conforms to the power supply

setting (display of the power supply connector unit at the rear) of this unit. For

changing the power supply setting of this unit, refer to 8.4 Changing the Set Power

Supply Voltage. However, when the voltage is 220V ±10%, set the power supply

voltage of this unit at 230Vac.

Operating Instructions RF-2000

5

1.3 Replacement of Fuses

This unit uses the following fuse. Be sure to replace the fuse of the same type and

capacity.

Power supply voltage: 220-240 V

Part no. 706.072.0165221

250V 3.15AT

Important: When the xenon lamp is lit, the flow cell is irradiated by the

excitation light beam. Do not look into the excitation light beam,

while the xenon lamp is lit.

Operating Instructions RF-2000

6

1.4 Precautions on Installation Site and Handling of the Unit

Generally, a large amount of organic solvents is used in the high-performance liquid

chromatograph. Sufficient care should be taken in installation site and handling of the

unit. Please take care of the notices in the text, not to mention the precautionary

requirements listed below:

1.4.1 Ventilation

Solvents used in the high-performance liquid chromatograph are inflammable

and/or toxic. Be sure to ventilate the room well.

1.4.2 Fire

The lighting of fires is prohibited in the room where high-performance liquid

chromatograph is installed. Do not install any devices which may emit sparks

in the room. It is also necessary to provide a fire extinguisher preparing for the

worst.

1.4.3 Safety goggles

Wear safety goggles in handling solvents.

1.4.4 Other equipment

A washstand or the like is necessary to be furnished nearby preparing for the

cases such that solvent comes into the personnel's eyes or the personnel

touches toxic solvent.

1.4.5 Power source

Working voltage range and power consumption of this system are as follows.

Be sure to connect to the power source conforming to them.

Part No. 706.228.35353.38, 220-230V ~ ±10%/240V ~ ±10%, 350VA,

50-60Hz

If working with a different working range, different fuses must be used! Please

contact the Dionex Service.

1.4.6 Grounding

To prevent electric shock and to secure safe operation of the system, always

make grounding.

1.4.7 Repair and maintenance of the unit

Normal maintenance of this unit can be performed without removing the

cover. Do not remove the cover at the normal maintenance. Contact the

Dionex Service if repair requires to remove the cover of the main body.

Operating Instructions RF-2000

7

1.5 Precaution in the region where 240V is used as working

voltage

1.5.1 Confirming the working voltage

The voltage setting must correspond to the working voltage used. When the working

voltage is between 220V and 230V, it is not necessary to change the factory setting

(230Vac). However, when the working voltage is 240V, change the voltage setting as

follows:

(1) Turn OFF the power switch.

(2) Pull out the power supply cable from the power supply connector.

(3) Open the fuse holder cover at the rear of this unit by a slotted screwdriver.

(4) Change the rotary switch showing the voltage in the fuse holder to display

240Vac.

(5) Close the fuse holder cover until a clicking sound is heard.

Operating Instructions RF-2000

8

1.6 Precautions on Static Electricity

Liquid chromatography using flammable organic solvents as mobile phase requires

proper care against fire, explosion, etc. Particularly, among various possible

accidents, those caused by static electricity are difficult to anticipate, and tend to

occur only with unexpected conditions which often make countermeasures

insufficient. At a site where preparative liquid chromatography is practiced, a large

amount of flammable substances may be used. Therefore, once an accident

happens, it could lead to tremendous damage. The mechanism of accident caused

by static electrical discharge and preventive measures are described below. Take

due care in safety measures in handling of equipment.

1.6.1 Mechanism of Static Electrical Discharge Accident (Example)

Accidents caused by static electricity take place through the following processes.

When liquid is fed at high speed through a small-diameter tube like the pipe of a

liquid chromatograph, static electrical charge occurs by friction between solid and

liquid as shown in the figure below

Fig.: Occurrence of Static Electricity by Friction between Solid and Liquid

When the charged liquid is collected in an insulated vessel, the static charge

accumulates gradually, and the voltage can easily reach a few kilovolts. If some other

conductive object is brought near the vessel, electricity is discharged at a certain

distance from the vessel releasing heat energy. If flammable gas of sufficient

concentration exists nearby, ignition is caused by this energy.

Operating Instructions RF-2000

9

Fig.: Conditions which may cause accidents

1.6.2 Preventive Measures against Accidents

The principal preventive measure is the prevention of charging and storage of static

electricity among those items shown in Mechanism of Static Electrical Discharge

Accidents. The preventive measures are shown below. It is recommended to

exercise two or more measures simultaneously.

• Particularly when a large quantity of flammable solvent is held in a large vessel,

be sure to observe the preventive measures 1, 2, and 3.

Preventive measure 1.

Use metallic (conductive) waste liquid vessel which is well grounded. This releases

the charge of the waste liquid and vessel to ground.

• Be sure to ground the vessel properly. Disconnecting of grounding wire or poor

grounding defeat the purpose of using a metallic vessel.

• There are some metallic cans which have no conductivity due to an oxidized

coating or lacquer on their surface. Be sure to confirm the grounding of vessels by

a tester before application.

• When a liquid with almost no conductivity (of 10-10s/m or less) is discharged into

the vessel, it is necessary to mix it with another liquid with some conductivity. (The

other liquid can be placed in the vessel in advance.)

Preventive measure 2.

Minimize the clearance of both inlet and outlet of vessel to prevent flame from

entering the vessel.

• Use a cap with three holes for 18 liter and 4 liter cans.

Operating Instructions RF-2000

10

Fig.: Anti-static electricity measures for vessel

Preventive measure 3.

Do not approach the vessel with charged objects including the human body.

Charging prevention measures for human body

a) Prevention of charging of shoes and clothes

b) Grounding of human body

c) Make working floor conductive

Suitable products to be used for those measures a), b), and c) are available on the

market.

• When persons who use no charge prevention measures approach dangerous

sections, they have to be grounded beforehand. (For example, they should

contact grounded metal by hand.)

Preventive measure 4.

Use pipes with inner diameter of 2mm or more for waste liquid line for large flow

rates.

• Inclusion of bubbles in the tube may increase the amount of charging by ten times.

Check that there is no inclusion of air via tube joints.

Preventive measure 5.

When it is impossible to use a conductive vessel, use caution in the following points.

a) Set the vessel so that the pipe outlet will be placed below the liquid level in

the vessel. Or, dip a grounded metal (ex. pipe connected to the main body of

device) in the liquid. Please note: This method is not effective for liquid with

small conductivity (10-10s/m or less).

b) Use a vessel of the smallest possible capacity to minimize the damage by fire

if it should occur.

c) Prevent the room from being dry. Humidity of 65% or more has charge

prevention effects.

Operating Instructions RF-2000

11

2 General Information

2.1 Outline

The basic design concept of the Dionex Fluorescence Detector RF-2000 is to

enhance productivity of analysis through its highest performance and stability.

This concept is realized by the highest sensitivity of the detector (higher than 300

signal to noise ratio for Raman spectrum of water), the highest wavelength accuracy

(±2nm), the highest wavelength reproducibility (±0.2nm) and the GLP/GMP

compliance support and improvement of operational safety.

The Dionex RF-2000 supports operation via the data system CHROMELEON.

Please refer to the sections "7.2 Control from External Equipment via RS-232C" and

"7.2.3 Controlling the RF-2000 via CHROMELEON" for details.

2.2 Features

• Greater sensitivity

The reengineered RF-2000 optical system provides significantly increased

sensitivity (signal-to-noise ratio greater than 300 for Raman spectrum of water).

Furthermore, use of appropriate excitation and emission spectral scan conditions

together with wavelength time programming allow high sensitivity detection of

multiple components at trace level concentrations.

• Enhanced wavelength accuracy

The RF-2000 offers unsurpassed wavelength accuracy (±2nm) and wavelength

reproducibility to further enhance the reliability of wavelength selectivity and unit-

to-unit performance.

• Support for GLP/GMP compliance

Daily checks and log-keeping can be automated*. The standard validation

documents such as Certificate of Compliance and Hardware Validation SOP are

provided to facilitate compliance with regulatory requirements.

*With optional System Check software

• Enhanced safety features

Both heat and leak sensors are provided as a standard feature. In addition, the

lamp may be turned ON/OFF via time program, minimizing unnecessary lamp

consumption during continuous, unattended runs.

Operating Instructions RF-2000

12

3 Component Location and Function

3.1 Front View

No. Description Function

1 Control panel Performs setting and display.

Operating Instructions RF-2000

13

3.2 Top Side and Right Side

No. Description Function

1 Light source chamber cover Remove this cover when replacing the

lamp.

2 Cell cover Remove this cover when replacing the

cell.

3 Cell inlet tubing Marked with blue cover tubing.

4 Cell outlet tubing

3.3 Bottom Side

No. Description Function

1 Drain tube for solvent leakage Drain tube is connected here.

Operating Instructions RF-2000

14

3.4 Rear View

No. Description Function

1 Horizontal direction adjusting

screw

Adjusts horizontal alignment of the lamp

on replacement.

2/upper Vertical direction adjusting screw Adjusts vertical alignment of the lamp on

replacement.

2/lower Lamp fixing screw Used to fix the lamp.

3 Fan Removes internal heat.

4 External input and output

terminals

Terminals used for connection with

external instruments.

5 Grounding terminal Grounding is made through this terminal.

6 Fuse holder Fuse is set in this holder.

7 Power supply connector Connector for power cable

8 RS-232C connector Connector for control by CHROMELEON

Operating Instructions RF-2000

15

4 Installation

4.1 Basic Installation Requirements

Warning: To take full advantage of the RF-2000 performance capabilities and

to ensure its operational stability over a long service life, verify that

the selected installation site satisfies the following requirements.

1. Ventilation Ventilate the room where the high performance liquid

chromatograph is located since the solvent used is

flammable and/or toxic.

2. Fire Never use fire in the same room where the high

performance liquid chromatograph is installed. Also, avoid

installation in the same room of other devices which may

spark. Always keep a fire extinguisher nearby in case of

accident.

3. Sink Install a sink nearby for flushing eyes or skin which have

been in contact with solvent.

4. Corrosive gas and

dust

Avoid installation in a place exposed to corrosive gases or

dust.

5. Electromagnetic noise Avoid locations subject to intense magnetic or

electromagnetic fields. Use an additional noise filter if

power line noise interferes.

6. Space requirements This system is designed to be used on a table or stand,

preferably a solid and flat surface with a depth of 70cm or

more.

7. Others Select an installation site with the following parameters to

maintain full performance of the system.

(1) Maintain room temperature within 4~35C, without

extreme fluctuations.

(2) Avoid direct output of a heater or a cooler.

(3) Avoid exposure to direct sunlight.

(4) Avoid locations subject to strong vibrations or

prolonged weak vibrations.

(5) Maintain relative humidity within 45~85%.

(However, humidity should be below 70% when the

room temperature is 30C or higher.)

Operating Instructions RF-2000

16

4.2 Electrical Connections

Warning: When the power supply voltage is 220-230V~, operate the unit with

the voltage setting of the power supply connector at the rear of this

unit at 230Vac. When the power supply voltage is at 240V~, set the

power supply connector at 240Vac. For changing the setting of

power supply connector, refer to "8.4 Changing the set power

supply voltage".

If the power supply is not stable or the capacity insufficient,

satisfactory performance is not possible. Verify for the total power

supply for the system before preparing power supply.

• Verify that the power switch of the main unit is turned OFF.

4.2.1 Connection to outlet

(1) Connect the female connector of the power supply cord supplied with the unit

to the power supply cord connector at the rear of the unit, and plug the male

connector into a power supply outlet.

(2) Supplied power supply cord is of three-conductor (3P) type.

When connecting to two-conductor (2P) type power supply outlet, use the

provided power supply adaptor.

4.2.2 Grounding

(1) When three-conductor (3P) type power supply outlet is used, the unit is

grounded by the power supply cord.

(2) When two-conductor (2P) type power supply outlet is used, the unit is not

grounded. In this case, carry out grounding from the grounding terminal on

the unit rear panel.

To prevent electric shock and to secure safe operation of the system, always

ground the unit.

Operating Instructions RF-2000

17

4.3 Fluidic Connections

4.3.1 Connecting the Detector and the Column

Typical connection between this equipment and the column is described in this

section.

(1) Cut the piping tube (SUS Tube 1.6 x 0.3, standard accessory) at the length

necessary for connecting the column outlet and the cell inlet pipe (pipe with

blue tape) of this equipment.

Cut the tube perpendicular. If the tube is cut diagonally, dead volume is

generated to deteriorate separation.

(2) Connect the piping between the column and the cell inlet pipe with the

supplied male PEEK nut and the male to male union as shown in the figure

below. Tighten the male PEEK nut by the hand firmly. It is not necessary to

use a tool for tightening.

Please note: Insert the piping tube into the column joint and the male to male

union securely until it comes to the end and then tighten the

male PEEK nut. Similarly, insert the cell inlet pipe until it comes

to the end and tighten the male PEEK nut so that dead volume

is avoided.

4.3.2 Detector Outlet Side Piping

(1) Prepare a waste liquid bottle.

(2) Connect the male to male union and the Tefzel tube (standard accessories of

this product) to the cell outlet pipe and put the other end in the waste liquid

bottle, as shown in the figure.

Please note: Pressure tolerance of the cell is 1960 kPa {20kgf/cm2} (Value in

{} is for reference). Pressure exceeding this level may cause

leak of liquid or damage of the cell. To prevent such troubles,

pay attention to the following points:

Operating Instructions RF-2000

18

• Do not apply excessive back pressure to the outlet side of the cell.

• In order to prevent clogging in the flow line, thoroughly clean the flow line before

stop delivery of solvent when the analysis is finished. Especially, when the buffer

solution is used, salts may be crystallized inside flowline. Be sure to clean the flow

line.

• When delivery of the solvent is stopped temporarily, put the tip of the flow line

outlet in the waste liquid in the bottle to prevent clogging of the flow line. This is to

keep inside the flowline being wet.

Important: When a mobile phase with high insulation, such as hexane,

is used, it is dangerous since static electricity is changed

at the waste liquid bottle. Use a metal liquid bottle for

waste and ground the bottle.

(Refer to section "1.6 Precautions on Static Electricity")

4.4 Connecting the Recorder and the Integrator

4.4.1 Connecting with a Recorder

Connect the RECORDER terminal of this instrument and the recorder using the

provided signal cable.

When using a stranded wire, twist the end tightly, or tin it with solder. Using a small

screwdriver or other tool, depress the rectangular button adjacent to the appropriate

terminal hole. Insert the wire and release the button to clamp the wire in position, as

shown in the figure below.

Important: Be sure to turn the power of the main unit OFF before

connecting the signal cable.

4.4.2 Connecting with an Integrator

Connect the integrator to the INTEGRATOR terminals in the external input/output

terminals at the rear of the RF-2000. Connect the cable supplied with the integrator.

Connect each terminal of the signal cable to the terminal block supplied with the

integrator.

Table of contents

Other Dionex Laboratory Equipment manuals

Dionex

Dionex UltiMate 3000 User guide

Dionex

Dionex As User manual

Dionex

Dionex AS-HV User manual

Dionex

Dionex ICS-2100 User manual

Dionex

Dionex TCC-100 User manual

Dionex

Dionex UltiMate 3000 User guide

Dionex

Dionex ICS-90 User manual

Dionex

Dionex ICS-3000 User manual

Dionex

Dionex P680 User manual

Dionex

Dionex ICS-900 User manual

Dionex

Dionex DX-120 User manual

Dionex

Dionex P680 User manual

Dionex

Dionex P680 User manual

Dionex

Dionex ICS-1000 User manual

Dionex

Dionex IONPAC AG9-SC GUARD COLUMN User manual

Dionex

Dionex MSQ User manual

Dionex

Dionex ICS-90 User manual

Dionex

Dionex UltiMate 3000 Series User manual

Dionex

Dionex ProPac WCX-10 Assembly instructions