DISCO DAD321 User manual

2006-08

MAINTENANCE MANUAL

Automatic Dicing/Cutting Saws

DAD321

DAC351

DAD361

SOFTWARE VERSION 5.4 SERIES

UHESME*054C

Copyright of this document is owned by Disco Corporation ("Disco").

No part of this document may be copied or reproduced in any form

or by any means, without the express written permission of Disco.

Also, this document may not be disclosed or transferred to third

parties.

This document is printed on recyclable Lint-Free paper.

- The blue paper is recyclable as used paper just like plain paper.

- The cover paper and adhesive portions are non-recyclable.

(Remove the cover and adhesive portions before recycling.

Recycle the blue paper only.)

Sample

READ CAREFULLY BEFORE USING THIS

MANUAL

Introduction

This machine is a dicing saw for cutting silicon wafers and glass circuit boards

(workpieces, hereafter).

It has the rotary sections which rotate at high speed, the high-voltage sections

which may cause electric shock hazards and the drive sections which may

catch the operator's body and clothing.

If the machine is not properly operated, safety hazards may cause serious

injury or death.

Read before using the machine

Before using the machine, thoroughly read this manual and follow the

instructions set forth in this manual.

To assure safety in the operation and maintenance of the machine, it is

important that you know the location of potential safety hazards. It is difficult

for DISCO to foresee each and every potential safety hazard. However, this

manual carries various precautionary notes and warnings to indicate the

presence of all foreseeable potential safety hazards. For increased safety

assurance, it is therefore essential that you observe all the precautions and

other relevant instructions set forth in this manual.

If you modify the machine without prior consent of DISCO or repair it in a

manner not stated in this manual, the safety assurance features of the machine

may be seriously affected.

Never attempt to modify or repair the machine in a manner not approved by

DISCO.

Sample

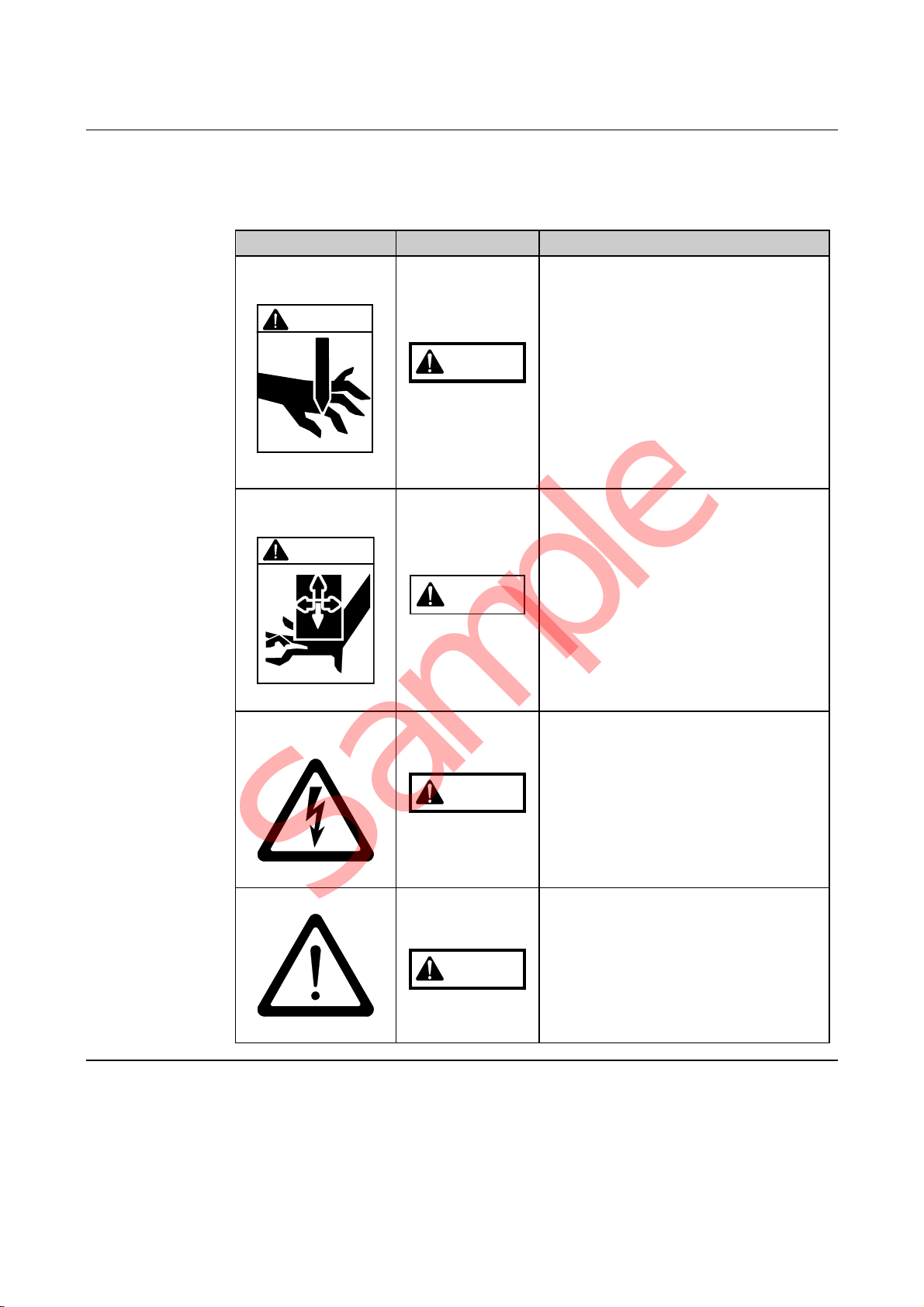

Hazard level

The safety precautions set forth in this document are classified into DANGER,

WARNING and CAUTION categories which represent three degree of hazards

latent in the machine. These categories are defined as detailed below in

accordance with the seriousness and probability level of the hazard. In addition

to the above three safety precaution levels, CAUTION without the safety alert

symbol ( ) and NOTICE are used to give safety usage instructions to the

user.

Before using the machine, be sure to read and understand all the associated

safety precautions set forth in the manual.

Hazard levels are classified as follows:

DANGER

If you cannot avoid the incident in question, a critical

situation in which either critical injury or death is very

likely to result.

This symbol is used for the incident in which the injury

is critical and there is high probability of occurrence.

WARNING

If you cannot avoid the incident in question, a serious

situation in which either critical injury or death may

result.

This symbol is used for the incident in which the injury

is serious but there is not high probability of occurrence.

CAUTION

If you cannot avoid the incident in question, a medium

or slight injury may result.

This symbol is used for the incident in which the injury

is slight and there is not high probability of occurrence.

CAUTION

If you cannot avoid the incident in question, an accident

of physical damage may be caused.

NOTICE

Indicates the safe way of using the machine as well as

precautions to avoid accidents resulting damage to

property.

Sample

Safety label

Safety labels are affixed to the hazardous sections of the machine. Before

using the machine, verify the label positions and thoroughly understand the

precautions and warning indicated by the safety labels.

Label Hazard Level Meaning of Label

Rotary Blade

Label

WARNING

WARNING

It is possible that your hands and

fingers may be cut by the rotating

blade.

Observe the following precautions

for at least 15 seconds until the

spindle comes to a complete stop:

- Do not place your hands or fingers

near the blade or flange.

- Ensure that the splash cover is

kept closed.

Driving Section

Label

CAUTION

CAUTION

It is possible that yours hands and

fingers may be caught and injured

by the driving section.

While the power is ON, ensure that

the cover is kept closed.

Electrical Shock

Hazard Label

WARNING

Use care to avoid possible electrical

shock hazard.

General Label

WARNING

General caution/warning/danger

label.

Sample

Intro-1

INTRODUCTION

About this manual

This Maintenance Manual explains the maintenance and inspection items and

data setup checkout that are necessary for customer-side maintenance of

Automatic Dicing/Cutting Saws 3*1 Series Models DAD321, DAC351 and

DAD361. This manual is written for the maintenance personnel.

To ensure safety

To ensure safety, be sure to thoroughly read and understand the contents of this

manual before performing maintenance or adjustment. Note that this manual is

based on the software versions of 5.4 series.

When installing or adjusting the machine, be sure to follow the procedures set

forth in this manual.

Be sure that the maintenance should be done by a qualified person who has

completed DISCO's education curriculum (hereinafter referred to as the

maintenance personnel).

Definition of a manager and an operator

This manual defines a manager and an operator as follows:

Category Applicable

personnel Job

Manager Management

representative The person who is responsible for overall

management of machines and operators.

Maintenance

personnel The qualified person who received DISCO

machine maintenance training.

Operator Data maintenance

personnel The qualified person who is responsible

for management of software data of the

machine.

Operator The person who operates the machine to

process workpieces.

Minimum retention period of the maintenance functional parts

Maintenance functional parts required for repair or modification will be

retained by Disco for at least seven years after the B/L date.

Sample

Intro-2

Part replacement

When replacing parts, be sure to use the genuine DISCO brand. If any parts

other than DISCO's genuine parts are used, DISCO shall assume no liability

for any damage of any kind.

When replacing components using the UL-listed parts, be sure to use the UL-

listed parts to be installed.

When replacing any critical parts, consult your nearest DISCO office. If any

critical parts are replaced without consulting DISCO, DISCO shall assume no

liability for any consequences arising therefrom.

Part warranty period

Part warranty period is as follows:

Part Warranty period

Electrical parts having contact points Six months from the B/L date

Consumable parts Not covered

Parts other than the above 12 months from the B/L date

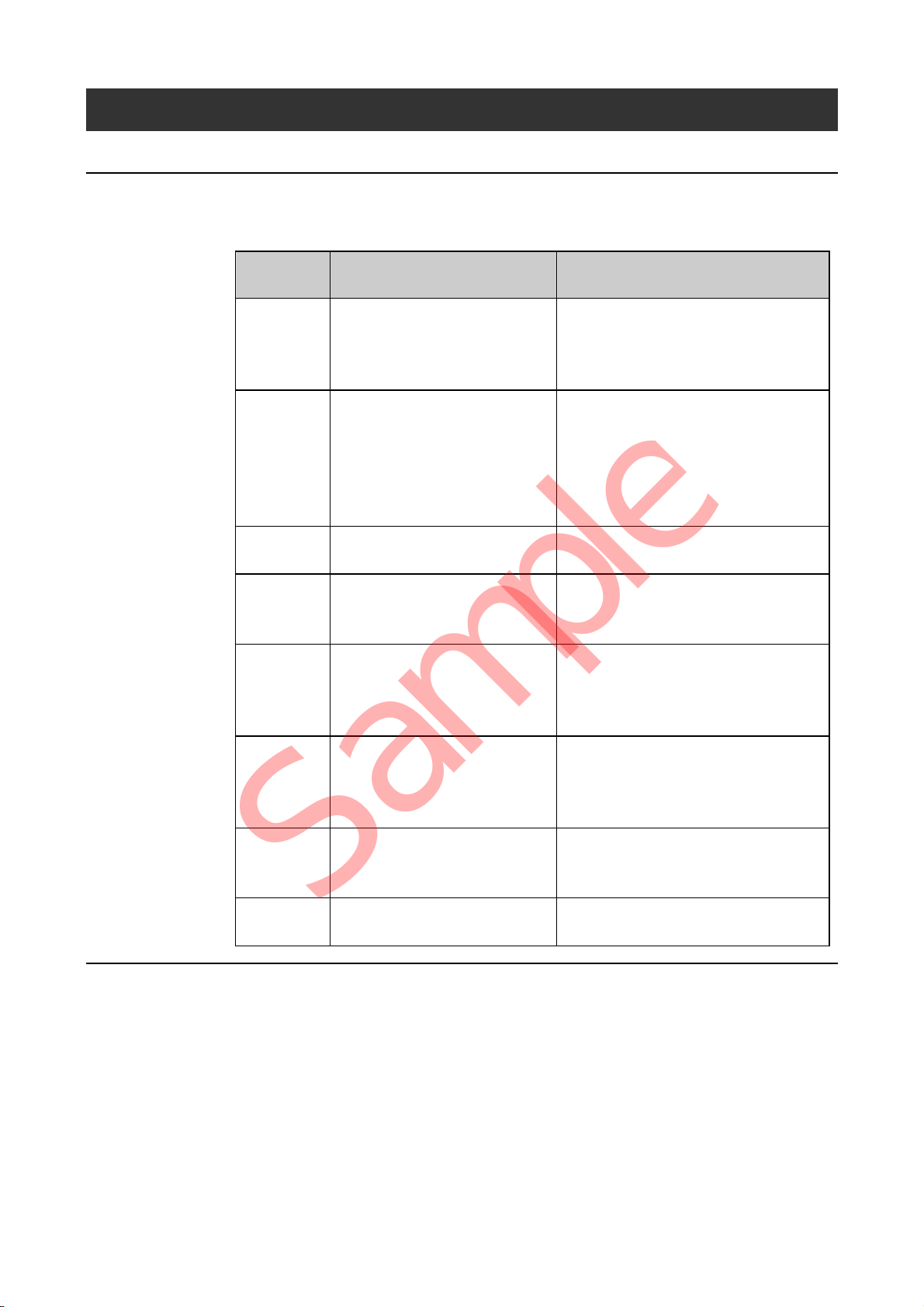

Documentation for this machine

The following five written manuals are provided for this machine.

This manual is the Maintenance Manual indicated by the arrow.

Manual Who should read Contents

Installation Manual Maintenance

personnel Operational procedures for

machine installation and

adjustment

Operation Manual Operator Operational procedures to be

performed by operators

Data Maintenance

Manual Data maintenance

personnel Screen contents for data entry and

data entry procedures

Maintenance

Manual Maintenance

personnel Servicing, inspection and

adjustment procedures to be

performed by customers

Technical

Reference Maintenance

personnel Machine specifications,

circuit diagrams, illustrations and

part lists

Unit notation

International System of Unit is adopted to express any unit. The values in the

parenthesis are reference data. Also, all the pressure values are expressed in

gauge pressure.

Sample

Intro-3

Notation of part number

In this document, the part numbers are shown as follows.

New style part no. Former style part no.

XXXX-XXXXXX-X (YYYYYYYY--Y)

Sample

Intro-4

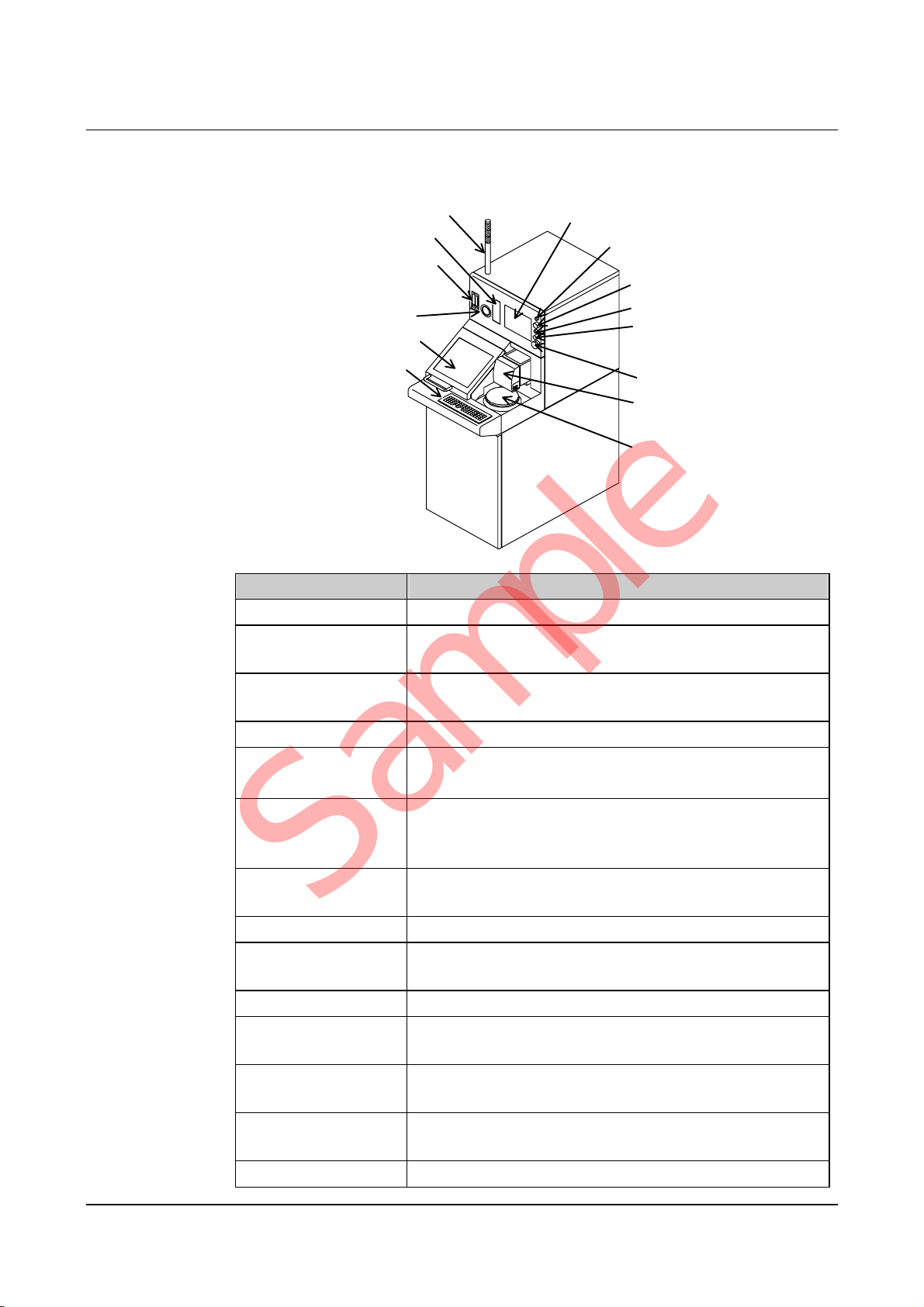

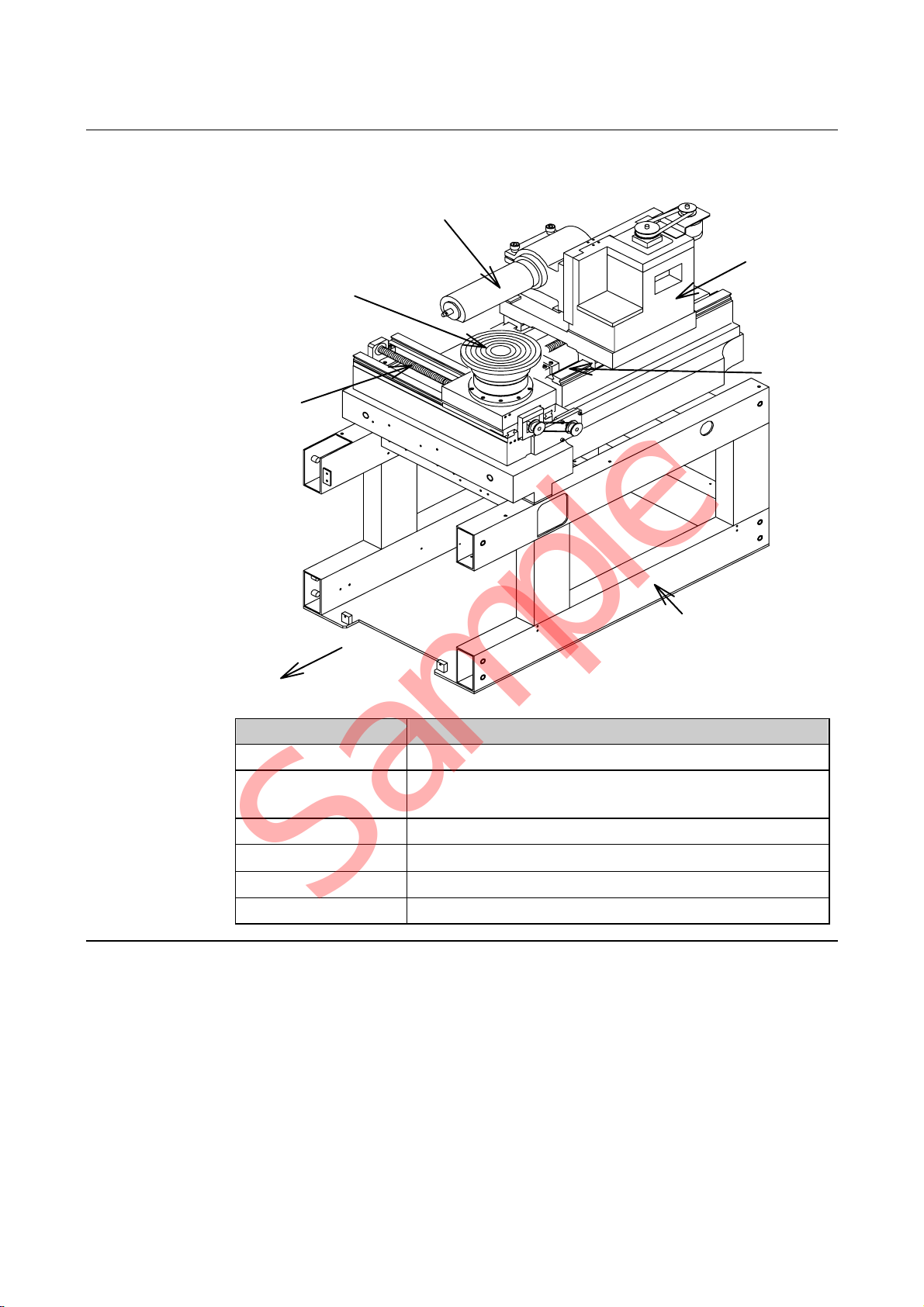

Section diagram

The diagram and table below show the names and functions of each section.

Operation control

section

Cutting section

Name Function

Cutting Section Cuts workpieces.

Operation Control

Section Keys on the operation panel are used for data entries,

and the function keys perform operations.

Also, the monitor displays operation-related

information and microscope images in accordance

with operation panel manipulation.

Sample

Intro-5

External view

The diagram and the table below show the external view, names and functions

of main constituents.

Operation panel

Splash cover

Vacuum gauge

Flowmeter

Disk drive

Pilot lamp Monitor

Ke

y

switch

POWER lam

p

Maintenance switch

Light intensity

adjustment dial

EMO switch

Chuck table

Microscope

Name Function

Operation Panel Consists of operation control keys.

Splash Cover Prevents water from splashing around during spindle

rotation and functions as a safety device.

Vacuum Gauge Indicates the chuck table vacuum pressure to attract

the workpiece to the chuck table.

Flowmeter Indicates the flow rate of the wheel coolant water.

Disk Drive Functions as an external storage device.

[Optional accessory]

Pilot lamp Indicates the machine operating status with the green

and yellow lamps. If an error occurs, the red lamp

flashes on and off.

Monitor Displays operating information and microscope

images.

POWER Lamp Lights while the power is ON.

Key Switch Used to turn ON and OFF the machine by inserting

and rotating the key.

Maintenance Switch Used by the maintenance personnel.

Light Intensity

Adjustment Dial Adjusts the microscope image light intensity.

EMO Switch Functions as the emergency stop switch. When

pressed, shuts off the electrical power supply.

Microscope Used to view workpieces for alignment and other

purposes.

Chuck Table Used to mount workpieces on it.

Sample

Intro-6

Axis arrangement diagram

The diagram and the table below show axis arrangement, names and functions

of each axis.

X-axis

θ-axis

(except 351)

Spindle axis

Z-axis

Y-axis

Main body frame

Front

Name Function

X-axis Moves the chuck table to the right and the left.

Y-axis Moves the spindle axis and the microscope forward

and backward.

Z-axis Moves the spindle up and down.

θ-axis Rotates the chuck table.

Spindle-axis Rotates a blade at a high speed.

Main Body Frame Supports the machine main body.

Sample

Contents-1

CONTENTS

READ CAREFULLY BEFORE USING THIS MANUAL

INTRODUCTION ................................................Intro-1

CONTENTS ................................................ Contents-1

A. IMPORTANT SAFETY INFORMATION........... A-1

1. General Safety Precautions .................................................................A-2

2. Safety Precautions to Be Observed During Operation..........................A-4

3. Inherently Hazardous Areas and Ways to Avoid Hazards...................A-10

3-1. Inherently HazardousAreas for Operation and Ways toAvoid Hazards...... A-11

3-2. Inherently HazardousAreas for Maintenance

and Ways to Avoid Hazards ......................................................................... A-13

4. EMO Switch.......................................................................................A-16

5. Power Circuit Breaker ........................................................................A-19

6. Interlock Mechanism ..........................................................................A-22

6-1. Interlock Mechanism of Splash Cover..........................................................A-24

6-2. Interlock List ................................................................................................A-30

7. Safety Labels .....................................................................................A-43

8. Critical Component List......................................................................A-48

B. WHOM TO CONTACT IN AN EMERGENCY .. B-1

Sample

Contents-2

CONTENTS

C. MACHINE COMPONENTS

AND FUNCTIONS............................................C-1

1. Machine Outer Cover...........................................................................C-2

2. Axis Section.........................................................................................C-5

2-1. Axis Arrangement ..........................................................................................C-6

2-2. X-axis Section................................................................................................C-7

2-3. Y-axis Section................................................................................................C-9

2-4. Z-axis Section.............................................................................................. C-11

2-5. θ-axis Section..............................................................................................C-13

2-6. Microscope Section .....................................................................................C-16

2-7. Spindle-axis Section ....................................................................................C-17

3. Main Body Section.............................................................................C-21

4. Detection Function.............................................................................C-25

4-1. Personnel Protection ...................................................................................C-26

4-1-1. Safety switch/lock cylinder of the splash cover ..................................C-27

4-2. Machine Protection......................................................................................C-28

4-2-1. Air pressure sensor............................................................................C-29

4-2-2. Flow rate sensor [Optional accessory]...............................................C-30

D. ADJUSTMENT OPERATION...........................D-1

1. Chuck Table Replacement....................................................................D-2

1-1. Chuck Table Classification ...............................................................................D-3

1-2. Chuck Table Replacement ...............................................................................D-6

1-2-1. Precautions for replacing the old type chuck table...............................D-7

1-2-2. Chuck table replacement procedure ..................................................D-12

1-2-2-1. Removing the chuck table ..................................................................................D-14

1-2-2-2. Mounting the chuck table....................................................................................D-16

1-3. Changeover to the New Type Chuck Table ....................................................D-18

2. Flange/Wheel Mount Replacement ....................................................D-19

2-1. Flange Replacement....................................................................................D-20

2-1-1. Removing the flange..........................................................................D-22

Sample

Contents-3

CONTENTS

2-1-2. Mounting the flange............................................................................D-24

2-2. Wheel Mount Replacement .........................................................................D-26

2-2-1. Removing the wheel mount................................................................D-28

2-2-2. Mounting the wheel mount.................................................................D-30

3. Sensor Adjustment.............................................................................D-32

3-1. Air Pressure Sensor Adjustment..................................................................D-33

3-1-1. Removing the outer covers ................................................................D-34

3-1-2. Adjusting the air pressure sensor.......................................................D-35

E. ENGINEERING MAINTENANCE

OPERATIONS.................................................. E-1

1. Calling up ENGINEERING MAINTENANCE Screen ............................E-2

2. Wheel Mount/Flange Conditioning .......................................................E-5

2-1. Movement in Conditioning............................................................................. E-6

2-1-1. Flange conditioning.............................................................................. E-7

2-1-2. Wheel mount conditioning....................................................................E-8

2-2. Executing Conditioning..................................................................................E-9

2-2-1. Replacing the chuck table.................................................................. E-11

2-2-2. Verifying CONDITIONING screen data..............................................E-12

2-2-3. Executing conditioning....................................................................... E-15

2-2-4. Checking the end face accuracy........................................................ E-19

2-2-5. Completion of conditioning................................................................. E-20

3. Axis Operation Check.........................................................................E-21

4. Sensor/Solenoid Valve Check............................................................E-25

4-1. Digital I/O Check..........................................................................................E-26

4-2. Axis Sensor Check ......................................................................................E-29

5. Customizing Setting...........................................................................E-33

5-1. Setting on USER DEFINE DATA1 Screen ..................................................E-34

5-2. Setting on USER DEFINE DATA2 Screen ..................................................E-43

5-3. Setting Password......................................................................................... E-47

5-4. Setting on HAIRLINE ADJUSTMENT Screen..............................................E-50

6. Log Viewer.........................................................................................E-53

7. Maker Data.........................................................................................E-61

Sample

Contents-4

CONTENTS

F. TROUBLESHOOTING ......................................F-1

1. Remedies for Problems Invoking No Error Code Indication

- Problems at Power ON - ....................................................................F-2

1-1. Power Receiving Lamp Problems.................................................................. F-3

1-2. Main Circuit Breaker Problems...................................................................... F-4

1-3. Main Power Supply Problems........................................................................ F-5

1-4. POWER Lamp (Power-On Lamp) Problems.................................................. F-7

1-5. Monitor Problems........................................................................................... F-8

1-6. Microscope Light Source Problems............................................................. F-10

1-7. EMO Switch Problems................................................................................. F-12

2. Remedies for Problems Invoking Error Code Indication .....................F-13

2-1. Error Code Classification............................................................................. F-14

2-2. Error Code List ............................................................................................ F-15

2-3. Error Remedies ........................................................................................... F-17

2-4. Axis-Related Error Remedies...................................................................... F-57

G. MAINTENANCE AND

REGULAR INSPECTION.................................G-1

1. Maintenance Whose Interval Differs Depending on

theUseConditionsoftheDevice.............................................................G-3

1-1. Cleaning the Non-contact Setup Sensor

(Detection Surface) [Optional Accessory].......................................................G-4

1-1-1. Calling up the NON-CONTACT SENSOR CLEAN screen ...................G-5

1-1-2. Cleaning the non-contact setup sensor................................................G-7

1-1-3. Cleaning the non-contact setup sensor with abrasives

[Optional accessory].............................................................................G-9

1-1-4. Adjusting the non-contact setup amplifier...........................................G-11

1-1-5. Completion of cleaning the non-contact setup sensor........................G-15

1-2. Cleaning the Blade Breakage Detector Sensor [Optional Accessory]..........G-16

1-2-1. Removing the blade breakage detector .............................................G-17

1-2-2. Cleaning the blade breakage detector sensor....................................G-19

1-2-3. Adjusting the amplifier of blade breakage detector ............................G-22

1-2-4. Completion of cleaning the blade breakage detector sensor .............G-24

1-3. Cleaning the Spindle....................................................................................G-25

Sample

Contents-5

CONTENTS

1-3-3. Cleaning the spindle main body.........................................................G-30

1-3-4. Cleaning the edge of the spindle........................................................G-31

1-3-5. Completion of spindle cleaning ..........................................................G-32

FYI: Possible problems of the spindle due to stains.....................................G-32

2. Maintenance and Inspection to Be Done Every Day...........................G-33

2-1. Maintenance and Inspection Before Turning ON the Power........................G-34

2-2. Maintenance and InspectionAfter Turning ON the Power...........................G-35

3. Maintenance to Be Performed at 7-Day

(Recommended) Intervals..................................................................G-36

3-1. Cleaning the Cutting Room..........................................................................G-37

3-1-1. Water case outer area cleaning..........................................................G-38

3-1-2. Water case inside cleaning ................................................................G-40

3-1-3. Completion of cleaning the cutting room............................................G-41

4. Maintenance to Be Performed at 30-Day

(Recommended) Intervals..................................................................G-42

4-1. Conditioning the Flange...............................................................................G-42

5. Maintenance to Be Performed at 90-Day

(Recommended) Intervals..................................................................G-43

5-1. Cleaning the Electrical box Filter

(in case this machine is used outside the cleanroom)..................................G-44

6. Maintenance to Be Performed at 183-Day

(Recommended) Intervals..................................................................G-49

6-1. Conditioning the Wheel Mount.....................................................................G-49

6-2. Greasing theAxes and Ball-Bearing Leadscrews........................................G-50

6-2-1. Greasing the X-axis............................................................................G-51

6-2-1-1. Cleaning the rail and ball-bearing leadscrew .....................................................G-52

6-2-1-2. Greasing the left side of the X-axis.....................................................................G-54

6-2-1-3. Greasing the right side of the X-axis ..................................................................G-56

6-2-1-4. Completion of greasing the X-axis......................................................................G-58

6-2-2. Greasing the Y-axis............................................................................G-59

6-2-2-1. Greasing the rear of the Y-axis...........................................................................G-60

6-2-2-2. Greasing the front of the Y-axis ..........................................................................G-63

6-2-2-3. Completion of greasing the Y-axis......................................................................G-66

6-2-3. Greasing the Z-axis............................................................................G-67

6-2-3-1. Greasing the Z-axis ............................................................................................G-68

6-2-3-2. Completion of greasing the Z-axis......................................................................G-71

Sample

Contents-6

CONTENTS

6-3. Cleaning the Spindle Coolant Water Path....................................................G-72

6-3-1. Cleaning the spindle coolant water path ............................................G-73

6-3-2. Completion of cleaning the spindle coolant water path ......................G-75

7. Maintenance to Be Performed at 365-Day

(Recommended) Intervals..................................................................G-76

7-1. Adjusting the Timing Belt.............................................................................G-77

7-1-1. Adjusting the X-axis timing belt..........................................................G-78

7-1-2. Adjusting the Z-axis timing belt ..........................................................G-81

7-2. Cleaning the Vacuum Ejector ......................................................................G-84

7-3. Cleaning the Electrical box Filter

(in case this machine is used inside the cleanroom)....................................G-87

H. CONSUMABLE PARTS REPLACEMENT.......H-1

1. Consumables to Be Replaced at 365-Day

(Recommended) Intervals....................................................................H-2

1-1. Replacing the Filters for Air............................................................................H-3

1-2. Replacing the Halogen Lamp ........................................................................H-6

1-3. Replacing the Spindle Carbon Brush.............................................................H-9

1-4. Replacing the Waterproof Sponge...............................................................H-12

1-5. Replacing the Spindle Waterproof Plate/Ring..............................................H-14

1-5-1. Removing the blade/wheel cover.......................................................H-15

1-5-2. Replacing the spindle waterproof plate/ring.......................................H-17

2. Consumables to Be Replaced at 700-Day

(Recommended) Intervals..................................................................H-19

2-1. Replacing the Operation Panel Overlay Sheet............................................H-20

2-2. Replacing the Flowmeter (Tap Water Line)..................................................H-22

2-2-1. Removing the machine outer cover....................................................H-23

2-2-2. Replacing the flowmeter.....................................................................H-25

2-2-3. Completion of replacing the flowmeter...............................................H-26

2-3. Replacing the Spindle/Wheel Coolant Water Flow Rate Sensor

[Optional accessory].....................................................................................H-27

2-3-1. Removing the machine outer cover....................................................H-28

2-3-2. Replacing the flow rate sensor...........................................................H-30

2-3-3. Completion of replacing the flow rate sensor.....................................H-31

Sample

Contents-7

CONTENTS

2-4. Replacing the Solenoid Valve......................................................................H-32

2-4-1. Removing the machine outer cover....................................................H-33

2-4-2. Replacing the solenoid valve..............................................................H-35

2-4-3. Completion of replacing the solenoid valve........................................H-37

3. Consumables to Be Replaced at 1000-Day

(Recommended) Intervals..................................................................H-38

3-1. Replacing the Chuck Table Waterproof Cover

/Chuck Table O-ring/Bellows........................................................................H-39

3-1-1. Removing the chuck table..................................................................H-40

3-1-2. Replacing the waterproof cover/O-ring/bellows..................................H-41

3-1-3. Completion of replacing the waterproof cover/ O-ring/bellows...........H-44

3-2. Replacing the Chuck Table Center Ring......................................................H-45

I. DATA SHEET.......................................................I-1

1. Noise Level ........................................................................................... I-2

CHECK SHEET 1 - MAINTENANCE

AND REGULAR INSPECTION -..........Appendix-1

CHECK SHEET 2 - CONSUMABLE

PARTS REPLACEMENT - ...................Appendix-2

INDEX...............................................................Index-1

ADDRESS LIST

IN AN EVENT OF AN ACCIDENT

Sample

A-1

A. IMPORTANT SAFETY INFORMATION

Contents of this chapter

This chapter describes various precautions to assure safety in the operation and

safety protective functions employed in this machine.

Section

No. Title Contents

1General Safety Precautions - Safety precautions to be

understood before operation

- Safety precautions to be

observed during operation

2Safety Precautions to Be

Observed During Operation - Safety precautions that operators

should understand before

operation

- Safety precautions that operators

should observe during

performing any work

3Inherently Hazardous Areas

and Ways to Avoid Hazards - Potentially hazardous sections

and the ways to avoid hazards

4EMO Switch - Construction of the EMO

(Emergency OFF) switch

- Function of the EMO switch

5Power Circuit Breaker - Construction of the power circuit

breaker

- Function of the power circuit

breaker

6Interlock Mechanism - Construction of the interlock

mechanism

- Function of the interlock

mechanism

7Safety Labels - Type of safety labels

- Affixing positions of safety

labels

8Critical Component List - List of critical components used

in the machine

Sample

A-2

1. General Safety Precautions

General safety precautions

This section describes the general safety precautions that should be understood

before operation and observed during operation.

CAUTION

Machine installation environment

Comply with the recommended machine installation conditions

(such as room temperature, humidity or temperature of spindle

coolant water and wheel coolant water). If the machine is installed in

an environment that does not conform to the installation conditions

recommended by DISCO, rust formation may occur due to moisture

condensation or other factor, thereby adversely affecting the cutting

accuracy.

For the recommended environmental conditions, see section C-1 of

Installation Manual, [Installation Specifications and Environment].

NOTICE

- Responsibility for instructing workers

Instruct the operators and maintenance personnel to read the

safety precautions set forth in the Maintenance Manual before

proceeding to work. Also, if the operator performs various tasks,

direct them to read the points of note concerning the safety given in

the respective manuals.

The written instructions for this machine are Installation Manual,

Operation Manual, Data Maintenance Manual, Maintenance

Manual and Technical Reference.

- Responsibility for instructing workers who don't seem to understand

the points of note

For the workers who don't seem to understand what is given in the

manuals, explain the safety items described in this chapter so that

they understand what the points mean.

- Regular inspection

The machine must be inspected on a regular basis.

If any accidents occur while an appropriate regular inspection

program is not adhered to, DISCO is not responsible for the results.

- Maintenance personnel

Maintenance must be conducted by qualified personnel who have

received the maintenance training.

- Proper installation of safety device

If the covers or other parts with safety interlocks are broken,

immediately stop the machine and repair broken parts.

Sample

A-3

General safety precautions (Continued)

NOTICE

- Air exhaust, water drainage and contamination control

Since harmful substance may be generated depending on the

cutting work type and machining characteristics, air exhaust, water

drainage and contamination control/disposal must be properly

completed in compliance with applicable environmental protection

codes.

- Exhaust sampling port

The machine requires an exhaust operation. When measuring the

exhaust for the machine to fulfill legal requirements, use the

sampling port, which is provided at the location indicated below.

(connection port: Rc (PT) 1/8 female)

View [A]

Duct

[A]

Sampling port

[Rc(PT)1/8 female]

- Facility side interlock connection terminal (Special user

specification)

To permit the facility side to provide air exhaust and water drainage

interlock, the machine is equipped with air exhaust and water

drainage reservoir tank interlock connection terminals.

When connecting these terminals to the facility side interlock

system, contact your nearest DISCO office.

- Machine relocation/disposal

In the case of relocation or disposal of the machine, the

presentation of detailed precautionary notes and the management

of new installation site data will be done by DISCO.

If you want to relocate or disposal the machine, contact your

nearest DISCO office or DISCO service office.

Sample

Other manuals for DAD321

1

This manual suits for next models

2

Table of contents

Other DISCO Saw manuals

Popular Saw manuals by other brands

Makita

Makita BPB180 technical information

PEUGEOT

PEUGEOT EnergySaw-185ASP manual

Parkside

Parkside PDKS 120 A2 operation and safety notes original operating instructions

Makita

Makita SP6000 instruction manual

Woodtec

Woodtec XW032 instruction manual

AEG Powertools

AEG Powertools PSD18B-254X Original instructions