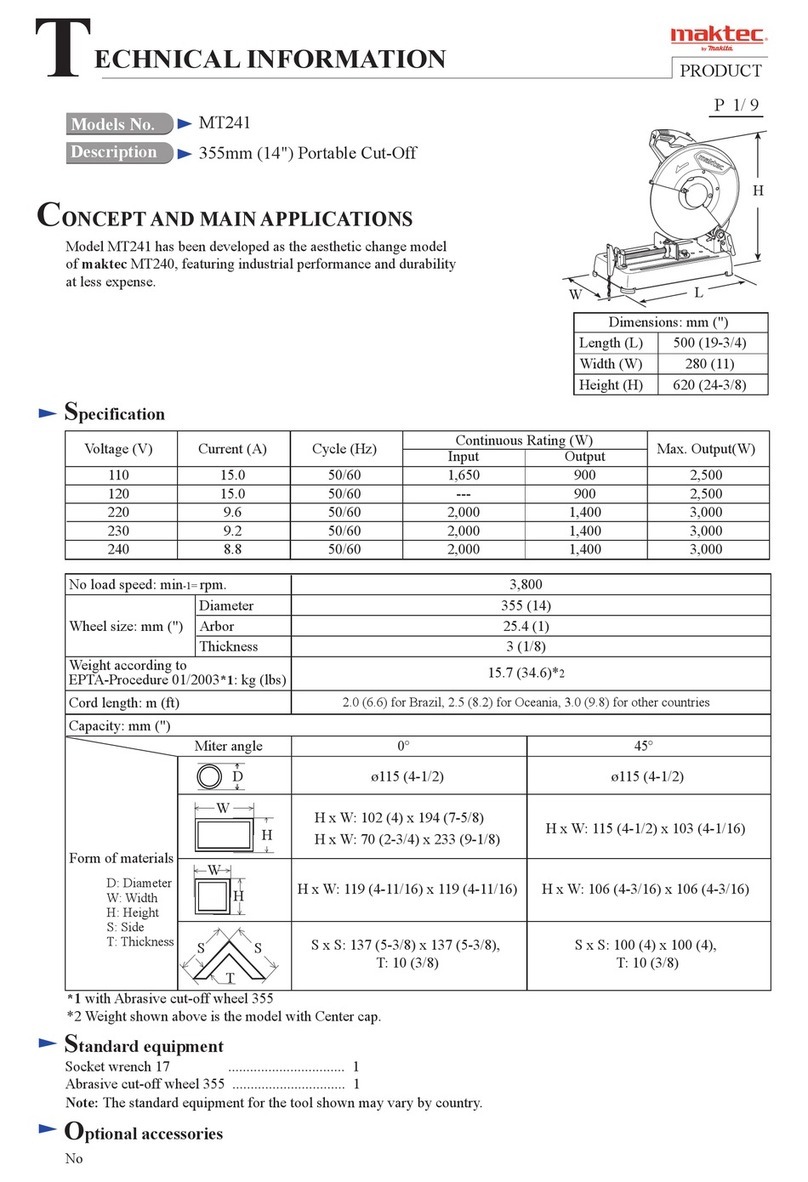

Model No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1 / 10

Specification

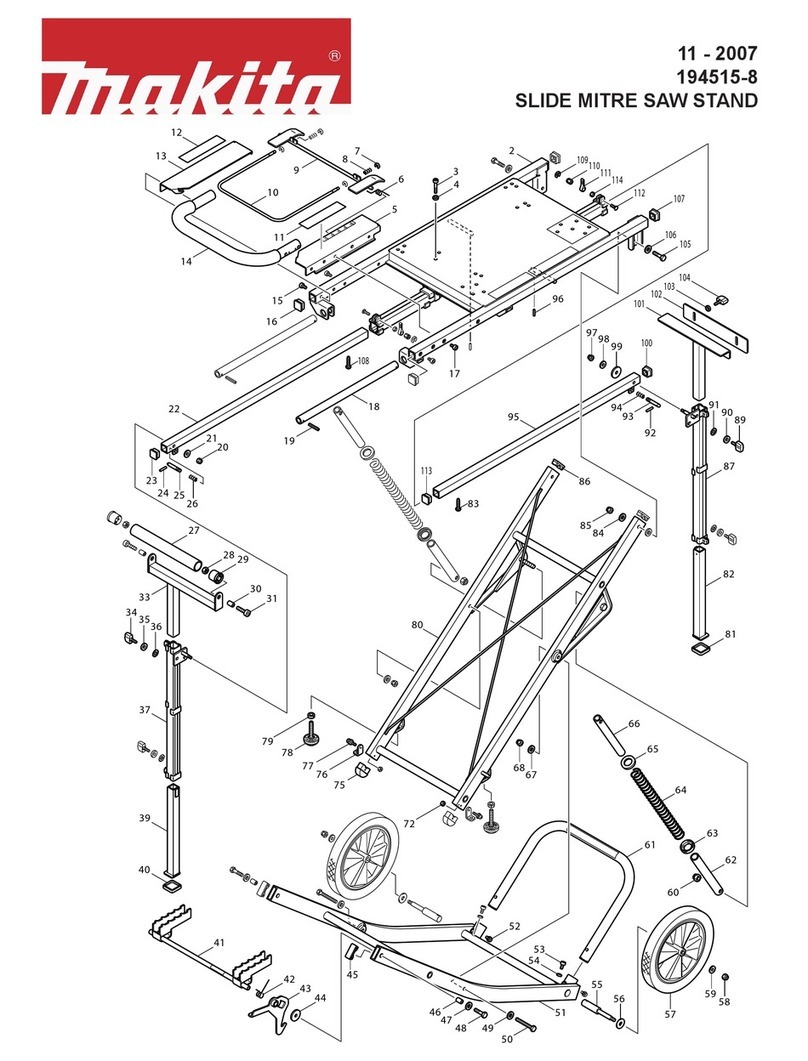

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 523 (20-5/8)

231 (9-1/8)

313 (12-3/8)

BPB180

Cordless Portable Band Saw

Model BPB180 has been developed as a cordless portable band saw

powered by 18V/ 3.0Ah Li-ion battery.

Features extremely lightweight design, yet still ensures high performance

that is backed by the same technology as applied to Model 2107F,

Makita AC portable band saw.

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may differ from country to country.

HSS bimetal band saw blade

(18 teeth per inch) .................................. 1

Battery BL1830 ..................................... 2

Battery charger DC18SC ....................... 1

Plastic carrying case .............................. 1

Hex wrench 4 ......................................... 1

Charger DC18SC

Charger DC24SA

Charger DC24SC

Li-ion battery BL1830

Carbon steel band saw blade (14, 18, 24 teeth per inch)

HSS bimetal band saw blade (14, 18, 24 teeth per inch)

Cutting wax

Battery

Variable speed control dial

Blade speed: m/s (ft/min)

Type

Voltage: V

Capacity: Ah

Li-ion

18

3.0

Yes

Net weight [with blade]: kg (lbs) 6.4 (14.1)

Overload protector Yes

1.4 -2.7 (275 - 530)

Max output (W) 330

L

W

H

Square pipe (width x height)

Length

Width

Height

Cutting capacity:

mm (")

Blade size:

mm (")

Round pipe (diameter)

120 x 120 (4-3/4 x 4-3/4)

13 (1/2)

0.5 (0.02)

1,140 (44-7/8)

120 (4-3/4)

TECHNICAL INFORMATION

This new product is available in the following variations.

BPB180SFE

BPB180 BL1830

(Li-ion 3.0Ah) DC18SC

Model No. type quantity Charger Country

2Other countries

USA, Canada, Mexico, Panama

Battery