Installation & Setup Guide

DE1548 INT issB s1 July 2012

Safety

Always wear the required Personal Protective Equipment (including gloves and goggles that must be worn when

potentially exposed to any hazardous materials and when carrying out hazardous work tasks). Turn the

dispenser off during cleaning and note that parts may be contaminated with product. If possible, flush tubing out

with water prior to carrying out any maintenance. For information on products that are used in this dispenser,

please carefully read the product label and Material Safety Data Sheet (MSDS).

Installation Standards

Ensure that the unit is always installed in accordance with the Diversey “General Standards of Installation” guide

(Ref. JDE1537) and meets local regulatory requirements.

Any specific installation recommendations relating to this unit are explained in this Installation and Setup Guide.

Specifications

Dimensions/Weight

(Dimensions do not include fitting

or solution “break” tube)

Operating Parameters

thin chemical at

2.5bar

Gap*

1.0 bar

(14.5 PSI)

5.5 bar

(80 PSI)

65°C

(149°F)

3.2:1

560:1

(14.5 psi)

0.85 GPM

(80 psi)

2.1 GPM

(36 psi)

1.4 GPM

Gap*

1.0 bar

(14.5 PSI)

5.5 bar

(80 PSI)

65°C

(149°F)

5:1

800:1

(14.5 psi)

2.1 GPM

bar (80 psi)

5.2 GPM

(36 psi)

3.4 GPM

Gap

1.5 bar

(22 PSI)

5.5 bar

(80 PSI)

65°C

(149°F)

2.7:1

490:1

(14.5 psi)

0.68 GPM

(80 psi)

1.4 GPM

(36 psi)

0.95 GPM

Gap

1.5 bar

(22 PSI)

5.5 bar

(80 PSI)

65°C

(149°F)

5:1

800:1

(14.5 psi)

1.5 GPM

bar (80 psi)

4.68 GPM

(36 psi)

3.25 GPM

Installation

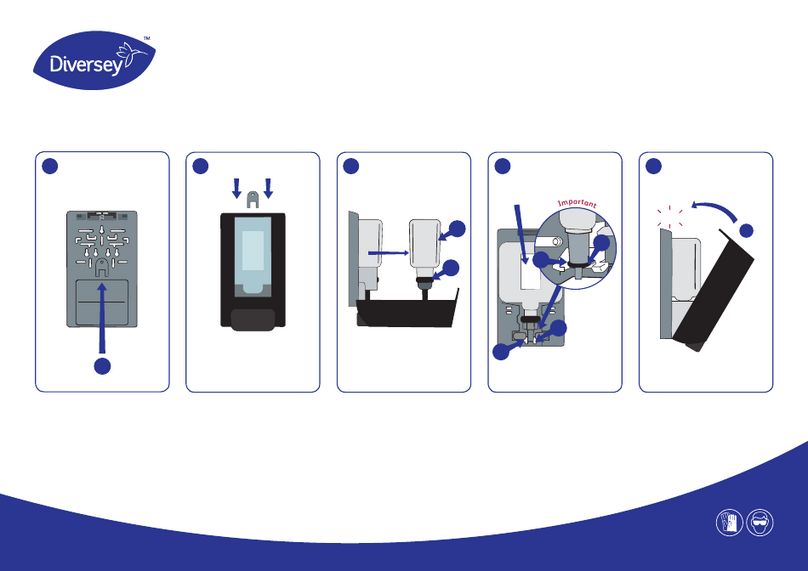

Open the QFM by inserting the “C”- shaped steel clip into the front cover then lift cover upward. The cover will

only come away completely from the backplate when it is pulled up by an angle of 45°. (Fig 1.1)

Fig 1.1