AFE8B

BATTERY POWERED CRIMP TOOL DATASHEET

________________________________________________________________________________________________

AFE8B-DS ©2012 Daniels Manufacturing Corp., All Rights Reserved Page 4 of 7 REV. D 6/20/2014

Daniels Manufacturing Corporation

526 Thorpe Road, Orlando, FL 32824 USA

Phone: 407-855-6161 Fax: 407-855-6884 Email: DMC@dmctools.com

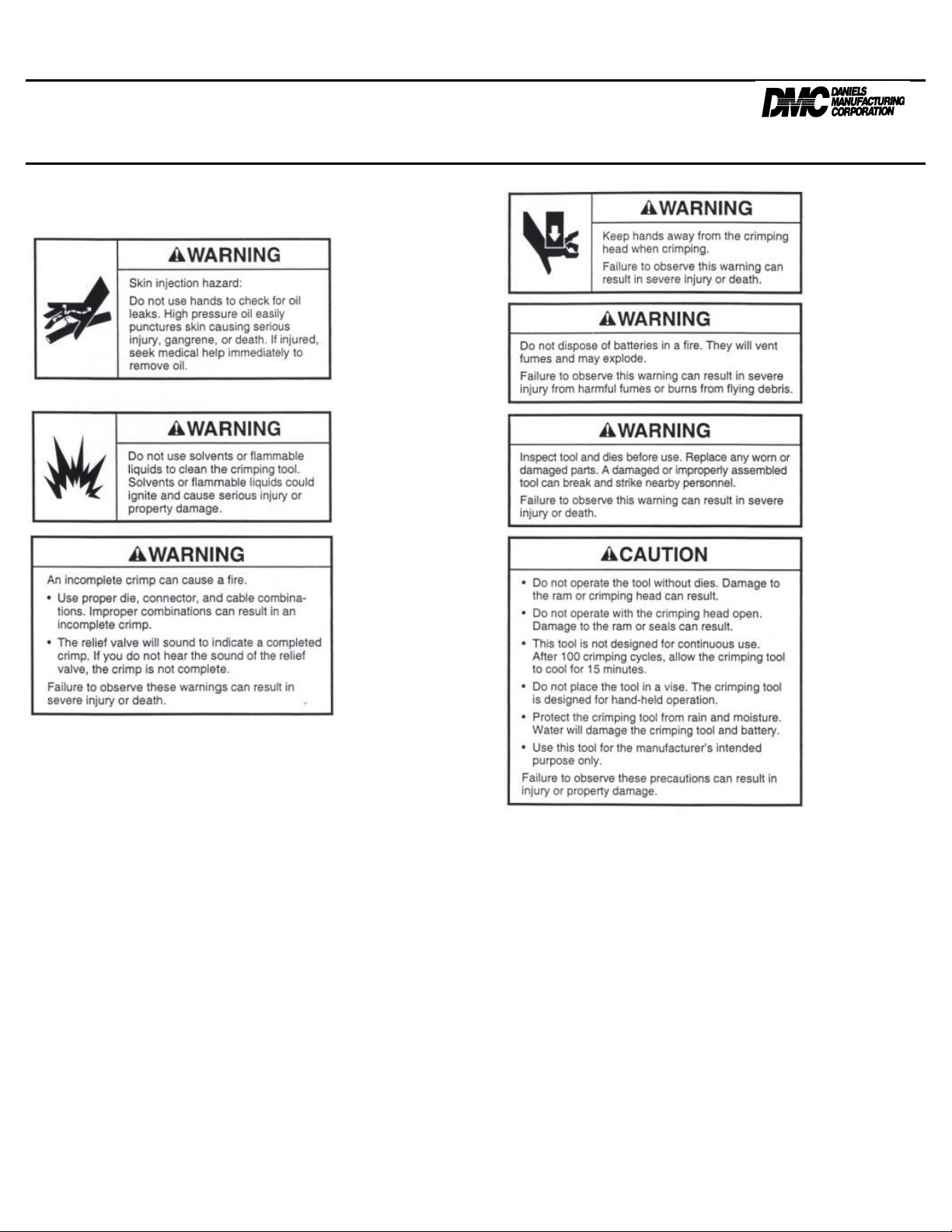

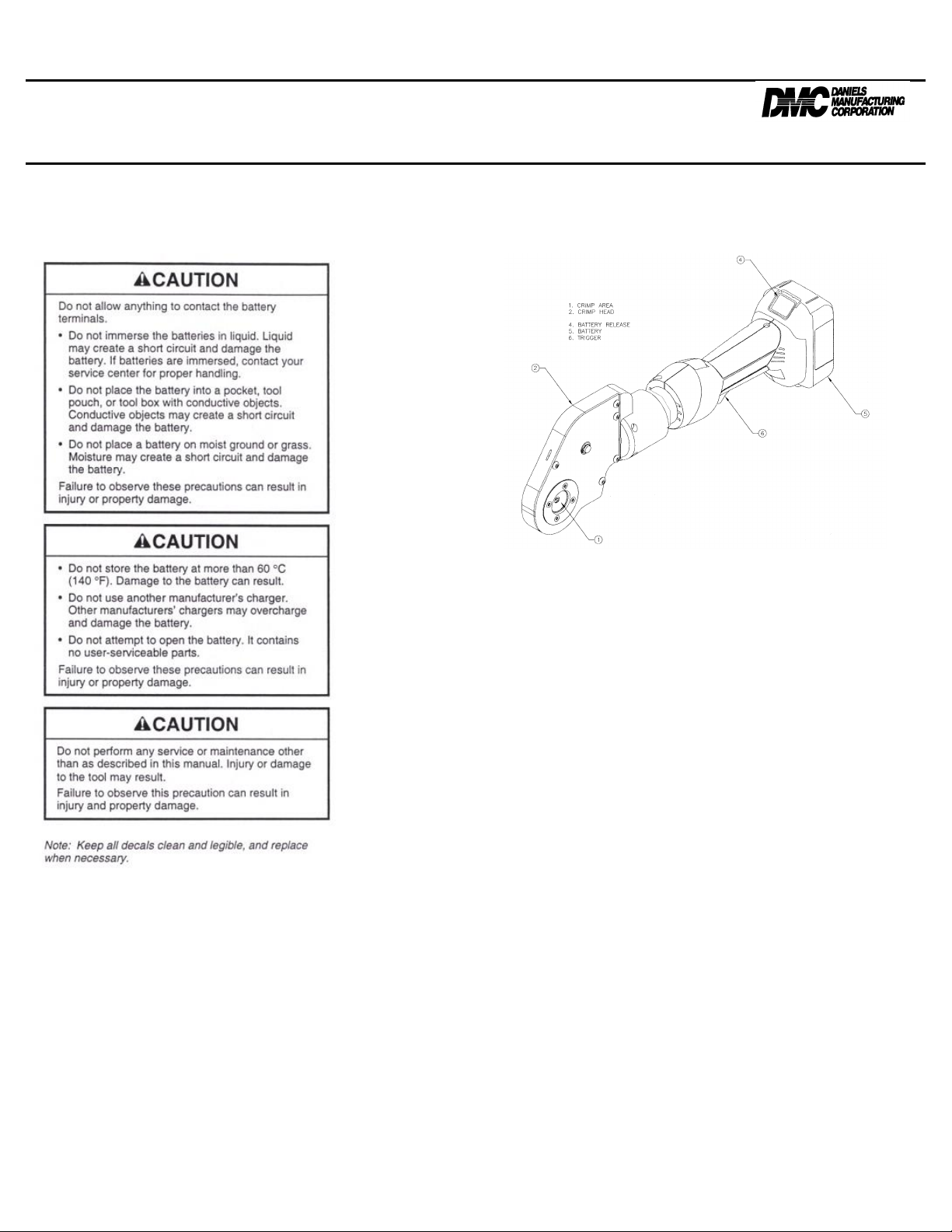

Operation

LED Work Light (White)

This LED automatically turns on when the trigger is pulled.

It remains on for 10 seconds after the trigger is released.

LED Indicator (Red)

This tool is equipped with a special circuit board

incorporating several important features to inform the user

about the current status of the unit. The Red LED on the

side of the tool signals in the following cases:

Battery is inserted in tool

Constant light for 20

seconds at end of

cycle

Battery charge is below 17V at

beginning of cycle

Tool will not start,

and constant light

for 20 seconds when

trigger is released

Battery charge is below 16V at

beginning of cycle

Tool will stop, and

constant light for 20

seconds after trigger

is released

Battery voltage drops below 13V

during cycle

Tool will stop, and

flashing light for 20

seconds when

trigger is released

Motor current exceeds 20A during

cycle

Circuit has become too hot

Pressure Sensor

This tool is equipped with a pressure sensor that alerts the

user of an incomplete crimp.

If the tool is manually retracted before completion of

a crimp, the red LED and audible beep will be active

for 2 seconds.

If the tool is unable to reach the required crimp

force, the red LED, work light, and an audible beep

will pulse until after the trigger is released.

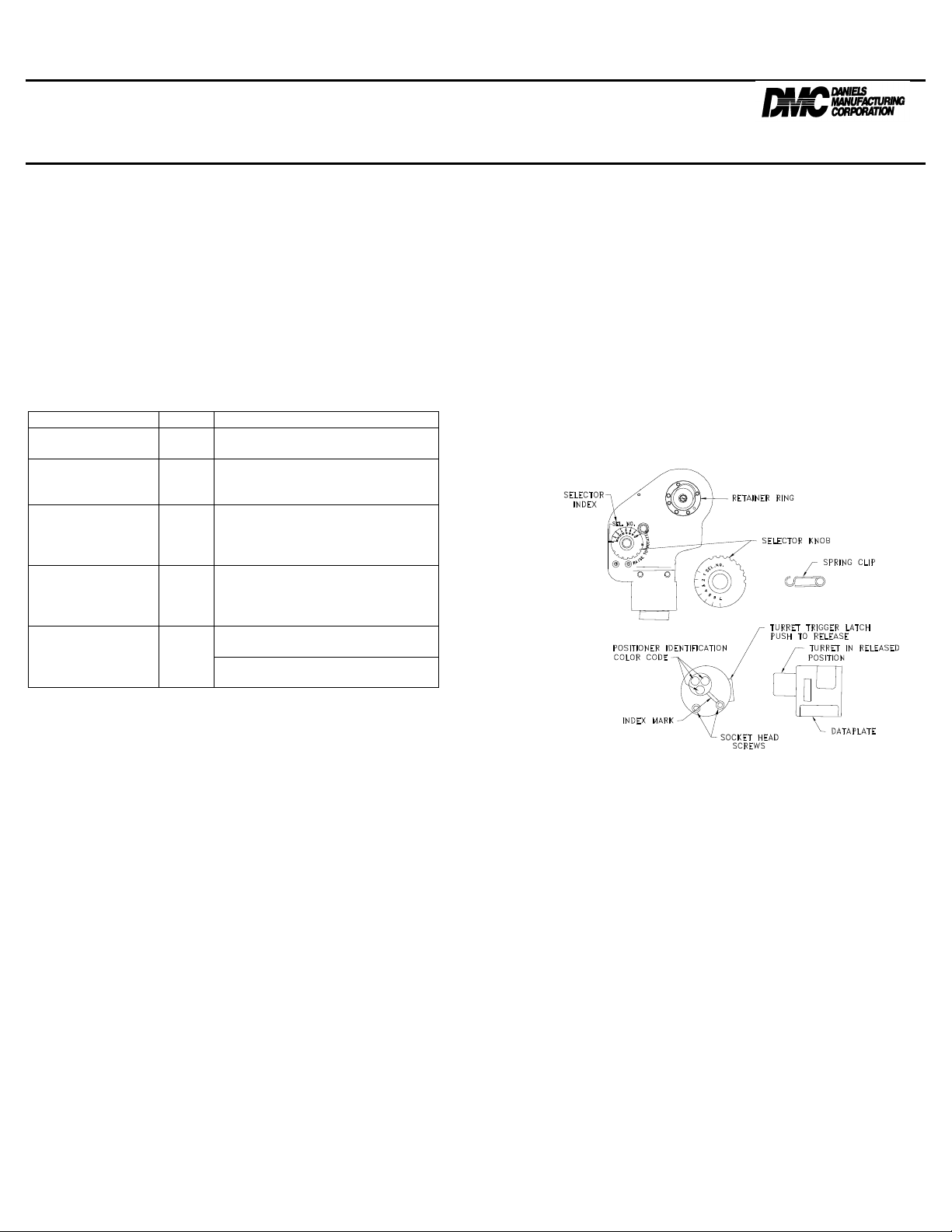

Installation of Positioners

1. Press turret trigger latch which releases turret to

indexing position.

2. Place the selected turret head assembly onto the

retainer ring with the alignment pin and socket head

screws lined up with their respective holes.

3. After the turret head is seated against the retainer

ring fully, tighten the socket head screws with a

9/64” hex key.

4. Refer to dataplate on turret head. From the color

code column, select the positioner color that

corresponds with the appropriate part number and

size of contact to be crimped.

5. With the turret in the indexing position, rotate until

color coded positioner is in line with the index mark.

Press turret until it snaps in latched position.

6. Refer to dataplate on turret head. From proper wire

size column, determine the selector number that

corresponds with the contact being used.

7. Remove spring clip from the selector knob.

Depress the retract button to fully retract the

tool piston. Raise the selector knob, and

rotate until selector number is in line with

index mark. Replace the spring clip.

Preparing Cable

Follow the lug/connector manufacturer’s instructions for

appropriate cable strip length, and contact/wire assembly.

Crimping Cable

1. Insert the properly assembled contact and wire into

the crimp area.

2. Press the trigger to make the crimp.

3. Hold the trigger down until crimping tool achieves

pressure relief, which is accompanied by an audible

“pop”.

4. The crimp tool push rod retracts automatically.