COPYRIGHT © ALL RIGHTS RESERVED

3

REV. B 3/99 FILE # DS0076 DOC. # DCT4-119-DS

DCT4-119

DATA SHEET

3. Allpins,pivotpoints,andbearingsurfacesshouldbe

protected with a thin coat of any good SAE No. 20

motoroil. Donot oil excessively.

4. When the tool is not in use, keep the handles closed

topreventobjectsfrombecominglodgedinthecrimp-

ing jaw. Store the tool in a clean, dry area.

Periodic Inspection:

Regular inspections of the tool should be performed by

qualitycontrolpersonnel. Arecordofscheduledinspec-

tionsshould remainwiththetoolorbesuppliedtosuper-

visorypersonnelresponsibleforthetool. Inspectionfre-

quencyshouldbebasedupontheamountofuse,working

conditions,operatortrainingandskill,andestablishedcom-

pany standards.

Visual Inspection:

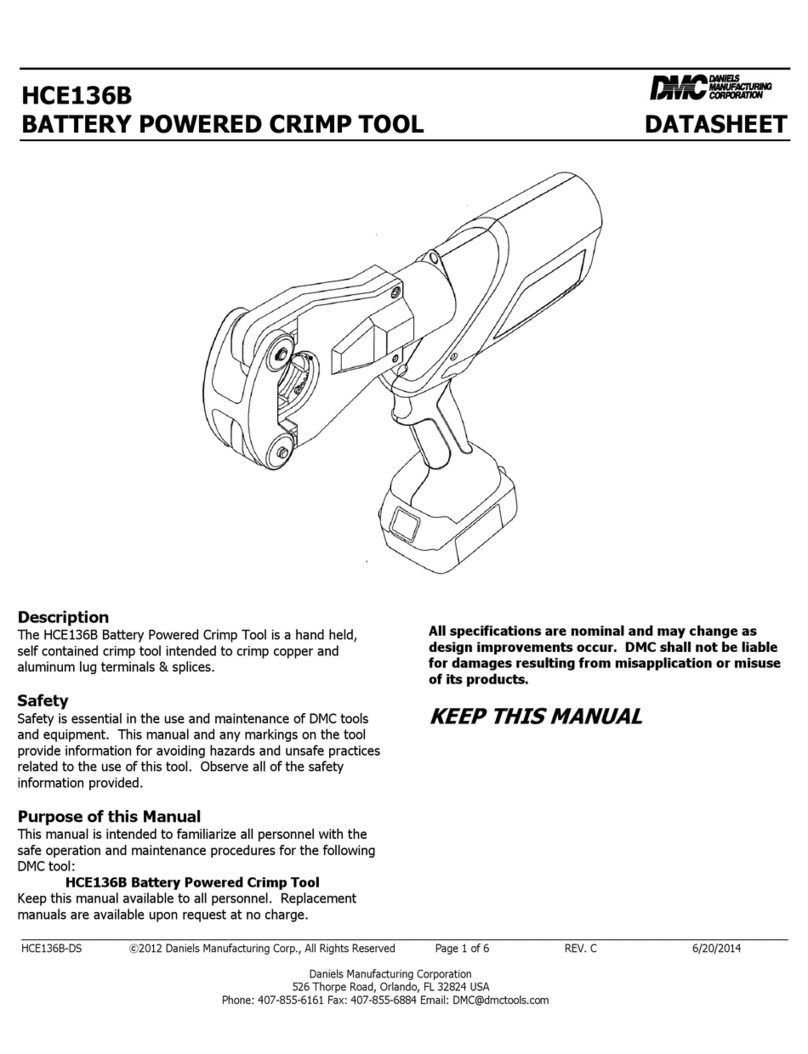

1. Make certain that all retaining pins are in place and

securedwithretainingrings.

2. Close tool handles until ratchet releases and allow

them to open freely. If they do not open quickly and

fully, the spring is defective and must be replaced.

3. Inspect the tool frame for wear or damage, paying

particular attention to the tool jaws and pivot points.

If tool is acceptable, lubricate and return to service.

4. Check the crimping dies occasionally to make sure

dies are not broken or chipped.

ADJUSTING RATCHET:

The ratchet adjustment is preset at the factory. If adjust-

ment is necessary, contact the factory for instructions.

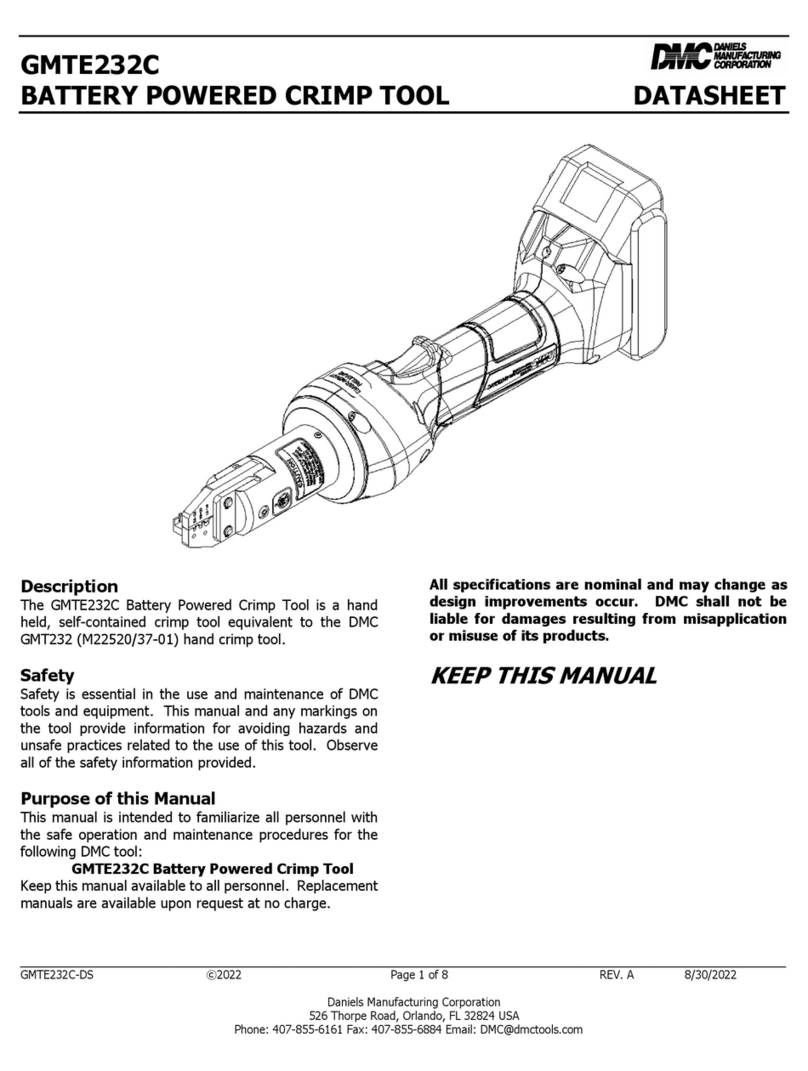

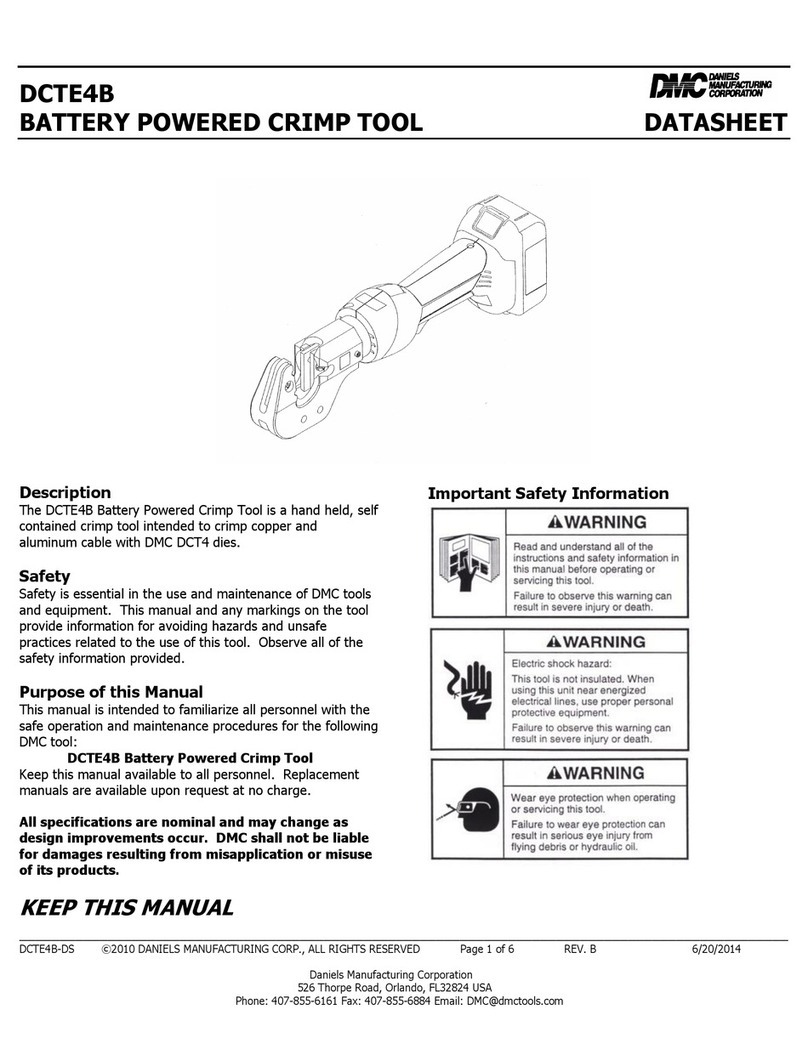

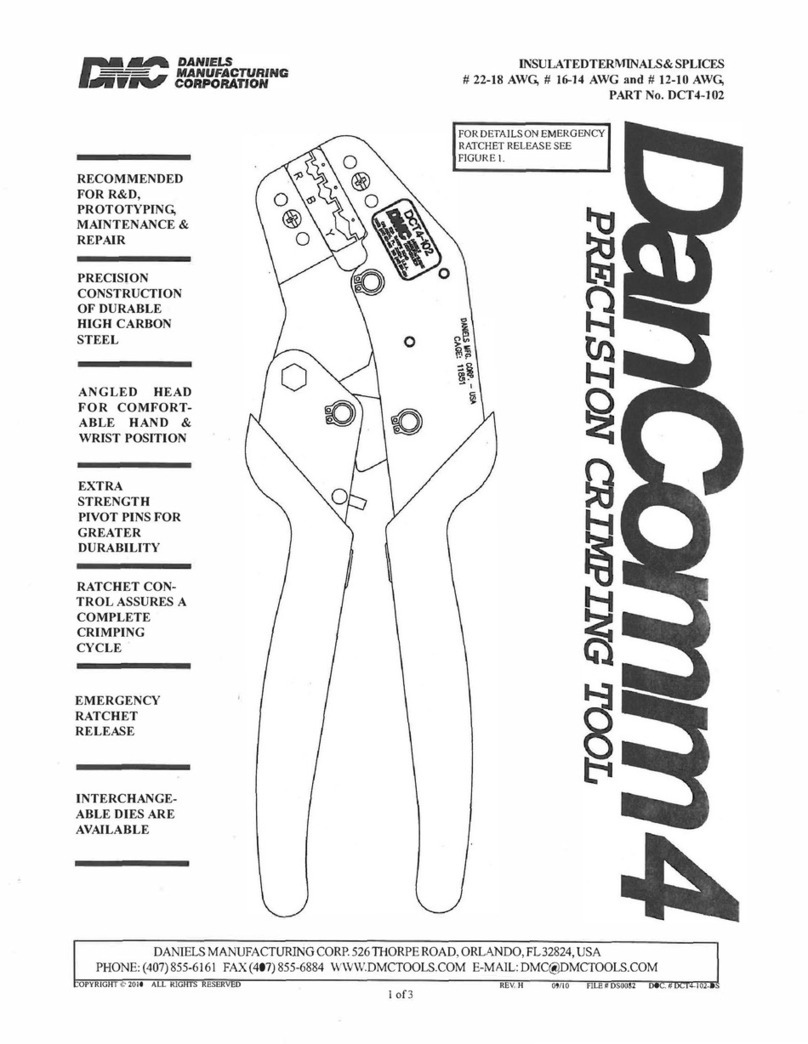

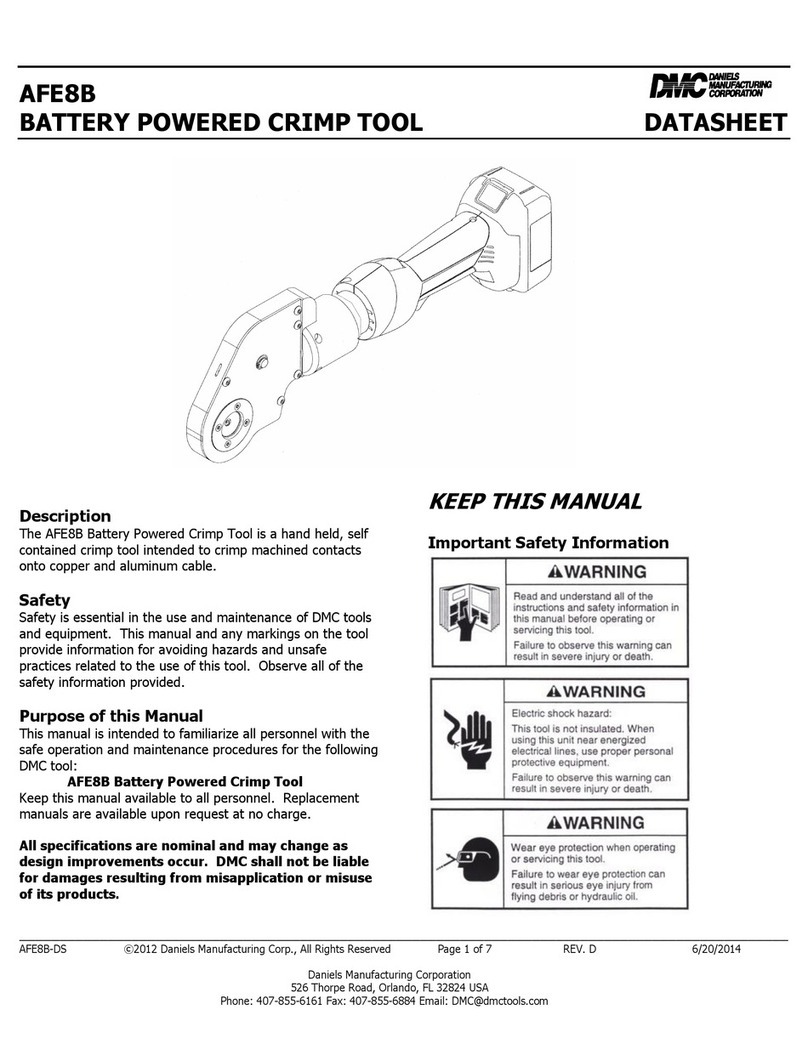

DIE INSTALLATION:

InstalldiesetintotoolframeasshowninFigure1.Install

andtightenretainingscrewsmakingsurediesarealigned

and fully seated against tool frame.

CONSULT FACTORY FOR OTHER DIE

CONFIGURATIONS

DMC P/N

DCT4-101

DCT4-102

DCT4-103

DCT4-104

DCT4-105

DCT4-106

DCT4-107

DCT4-108

DCT4-119

DCT4-121

DESCRIPTION

AMP STD. & MOISTURE RESISTANT CAPS

R/B/Y INSULATED TERMINALS

SLIDE ON R/B

HEAT-N-SEAL R/B/Y

UNINSULATED TERMINALS

.052 SQ./ .128 HEX/ .178 HEX

.068 HEX/ .178 HEX/ .324 HEX

.068 HEX/ .213 HEX/ .255 HEX

R/B/W SPLICES

.039 SQ./ .195 HEX

LIMITATION OF LIABILITY / LIMITED WARRANTY*

DANIELSMANUFACTURINGCORPORATIONISNOTLIABLEFORCONSEQUENTIALORSPECIAL

DAMAGESOFANYNATUREORKINDRESULTINGFROMTHEUSEOFANYOFITSPRODUCTS. OWNERS

ANDUSERSOFDMCPRODUCTSASSUMEFULLRESPONSIBILITYFORINSTRUCTINGTHEIREMPLOYEES

INTHEPROPERANDSAFEUSEOFSUCHPRODUCTS.

Daniels Manufacturing Corporation warrants each new unit sold by it to be free from defects in material and

workmanship under normal use and service. Its obligation under this warranty is limited to the free correction or, at its

option,therefundofthe purchasepriceofanysuchunit whichprovesdefectivewithinninety(90) daysafterdeliveryto

thefirst user, providedthat the unit is returnedto itwith all transportationchargesprepaid,and which shall appear toits

satisfaction,uponinspectionbyit,tohavebeendefectiveinmaterialorworkmanship. Thiswarrantyshallnotcoverany

damage to such products, which in the opinion of Daniels Manufacturing Corporation, was caused by normal wear,

misuse,improperoperationoraccident. Thiswarrantyisinlieuofallotherwarrantiesexpress orimplied. Nowarranty,

express or implied, is made or authorized to be made or assumed with respect to products of Daniels Manufacturing

Corporation, other than that herein set forth.

*asdefinedbyPL93-637

DanComm 4

TM TOOLS