©2022 DANIELS MANUFACTURING CORP., ALL RIGHTS RESERVED

Daniels Manufacturing Corporation

526 Thorpe Road, Orlando, FL 32824 USA

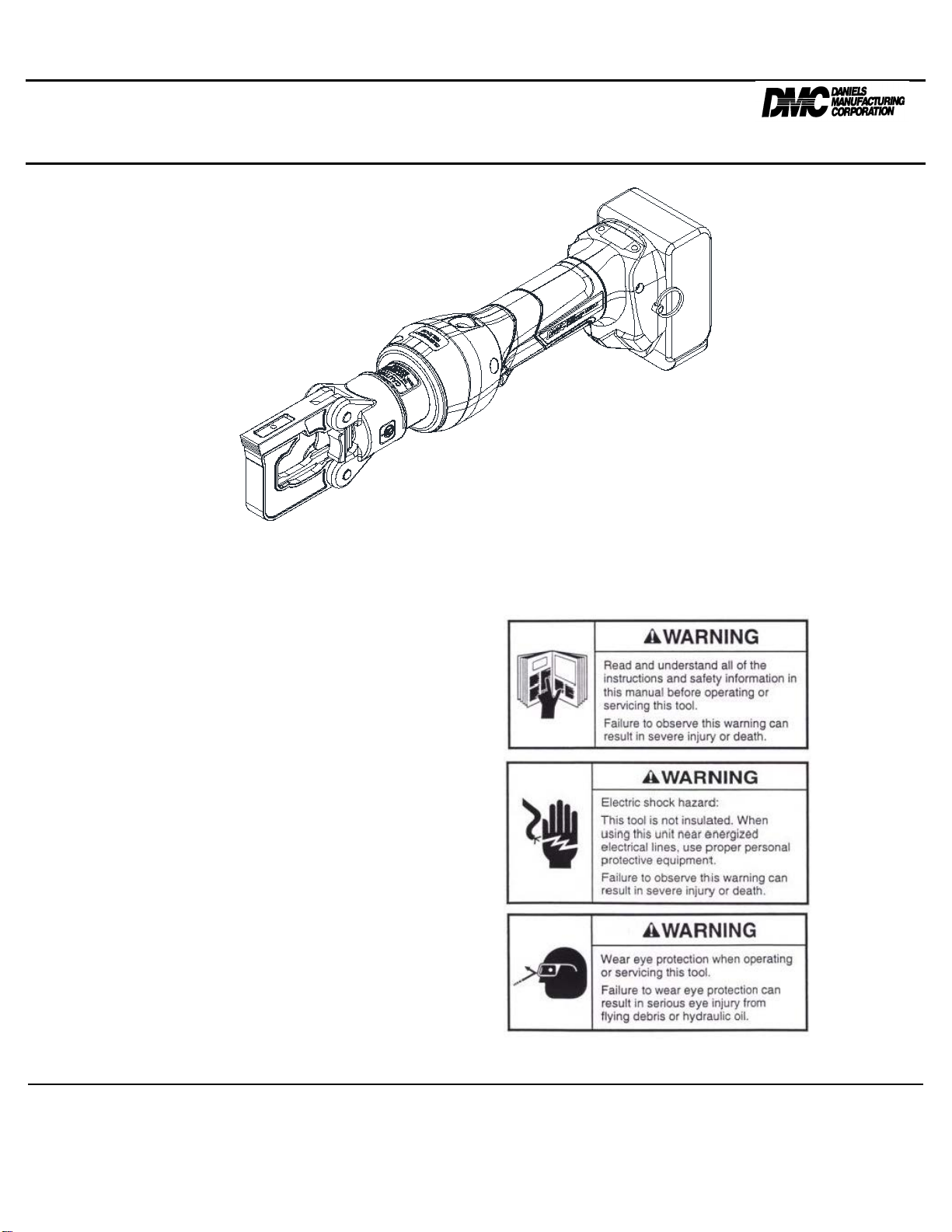

HDE51C

BATTERY POWERED CRIMP TOOL

Operation

LED Work Light (White)

This LED automatically turns on when the trigger is

pulled. It remains on for 10 seconds after the trigger is

released.

LED Indicator (Red)

This tool is equipped with a special circuit board

incorporating several important features to inform the user

about the current status of the unit. The Red LED on the

side of the tool signals in the following cases:

•• Battery is inserted in tool

seconds at end of

Battery charge is below 17V at

beginning of cycle

and constant light

for 20 seconds when

Battery charge is below 16V at

beginning of cycle

constant light for 20

seconds after trigger

Battery voltage drops below 13V

during cycle

flashing light for 20

seconds when

••••

Motor current exceeds 20A during

cycle

Circuit has become too hot

Pressure Sensor

This tool is equipped with a pressure sensor that alerts

the user of an incomplete crimp.

•

If the tool is manually retracted before completion

of a crimp, the red LED and audible beep will be

active for 2 seconds.

•

If the tool is unable to reach the required crimp

force, the red LED, work light, and an audible

beep will pulse until after the trigger isreleased.

Installing Dies

1.

Select the proper dies for the intendedcrimp.

2.

Slide the die into the crimping head until it

“snaps” into place.

3.

Properly position the second die, and repeat step 2.

Preparing Cable

Follow the lug/connector manufacturer’s instructions for

appropriate cable strip length, and contact/wire assembly.

Crimping Cable

1.

If necessary, lift the upper latching arm to open

the crimping head.

2.

Insert the properly assembled connector into

the crimping head.

3.

Close the crimping head, if it was opened.

4.

Pull the trigger to make thecrimp.

5.

Hold the trigger down until crimping tool achieves

pressure relief, which is accompanied by an

audible “pop”.

6.

The crimp tool push rod retractsautomatically.

7.

If necessary, open the crimping head and

remove the crimped connector.

Note:If itis necessaryto retractthe toolpushrod before

a crimpcycleiscompleted,pushand hold the

Emergency Release button. Pushing and holding the

Emergency Releasebuttonwillresultinthecomplete

retractionofthe pushrod.

Maintenance

Each Operating Day

Before Use:

1.

Inspect dies for wear or damage such as

cracks, gouges, or chips.

2.

Inspect the tool for damage or leaks. If damage

is detected, return the tool to the DMC repair

center for inspection.

After Use:

1.

Wipe all tool surfaces clean with a damp cloth

and mild detergent.

2.

Charge the battery.

3.

Fully retract the tool push rod.

4.

Place the tool in the carrying case.

5.

Store in a cool dry place.

Monthly

1.

Thoroughly clean all surfaces.

2.

Oil the push rod outer surface.

Annually or after 10,000 Crimps

1. Return the tool to the DMC repair center for

inspection & calibration.