4 FUNCTIONING

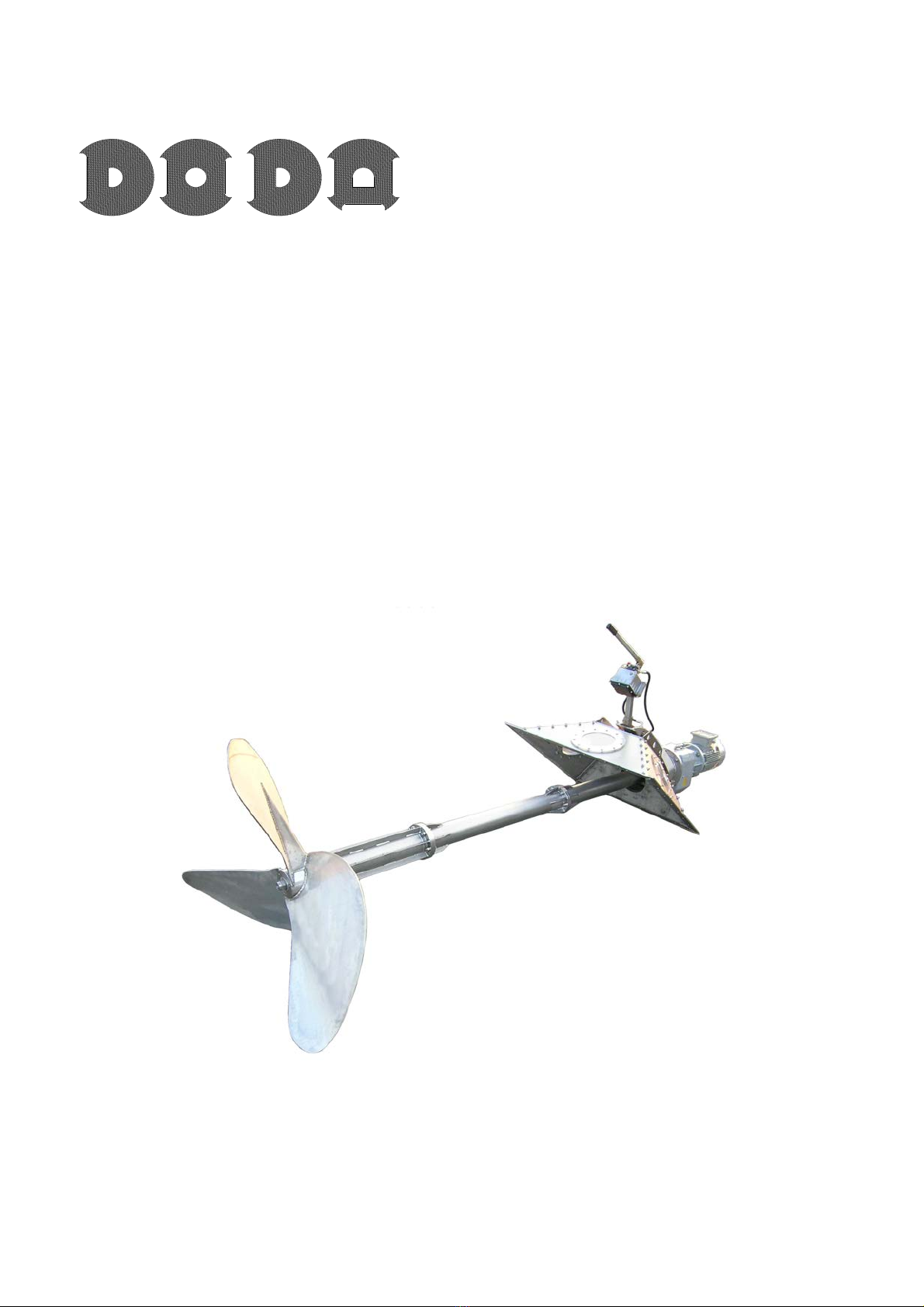

According to the requested installation, the mixer is provided with a roof or wall mounting

frame.

Usually the mixer arm inclines towards the left with regards to the tank wall, but on request

the mixer can be supplied with arm leaning towards the right.

The machine is equipped with a hydraulic device for the mixing propeller tilt regulation.

The propeller turns clockwise.

With full tank, the rotation direction is recognizable only through the thrust effect

generated by the fluid present in the tank, which should move towards its middle.

The functioning of the mixer in the opposite direction to the recommended one could

cause strong vibrations, as well as serious damages to both the mixer and the tank.

On account of the different composition of the substrate to be mixed, it is necessary to adjust

the mixing propeller of immersion depth and to check that the propeller vanes are completely

covered by fluid during mixing.

During functioning no vortex or splashes have to be noticed in the fermenting medium.

The mixer has to work always in a enough full tank and with the propeller vane covered

at least 0,5m by the fluid; otherwise, a strong side vibration above all around the

Motor-Drive line unit will be noticed, which could damage the mixer.

Even during normal operating the mixer could swing sideways. Anyway, if the vibration does

not exceed 2 cm, that is not dangerous in consideration of the provided vibration-resistant

frame. Besides, this vibration can be prevented by increasing the revolutions per minute by

means of an inverter.

On the contrary, by too low rotation speed, strong side vibrations could occur,

therefore if necessary raise the revolutions per minute in order to avoid possible

damages to the mixer and the tank.

If, in spite of the compliance with the above-mentioned instructions, you do not obtain a

satisfactory mixing performance (e.g. because of a large tank diameter o a high content of dry

matter) , contact promptly the dealer or the manufacturer .

The dealer or the manufacture can not be considered responsible for damages due to incorrect

employment of the mixer.