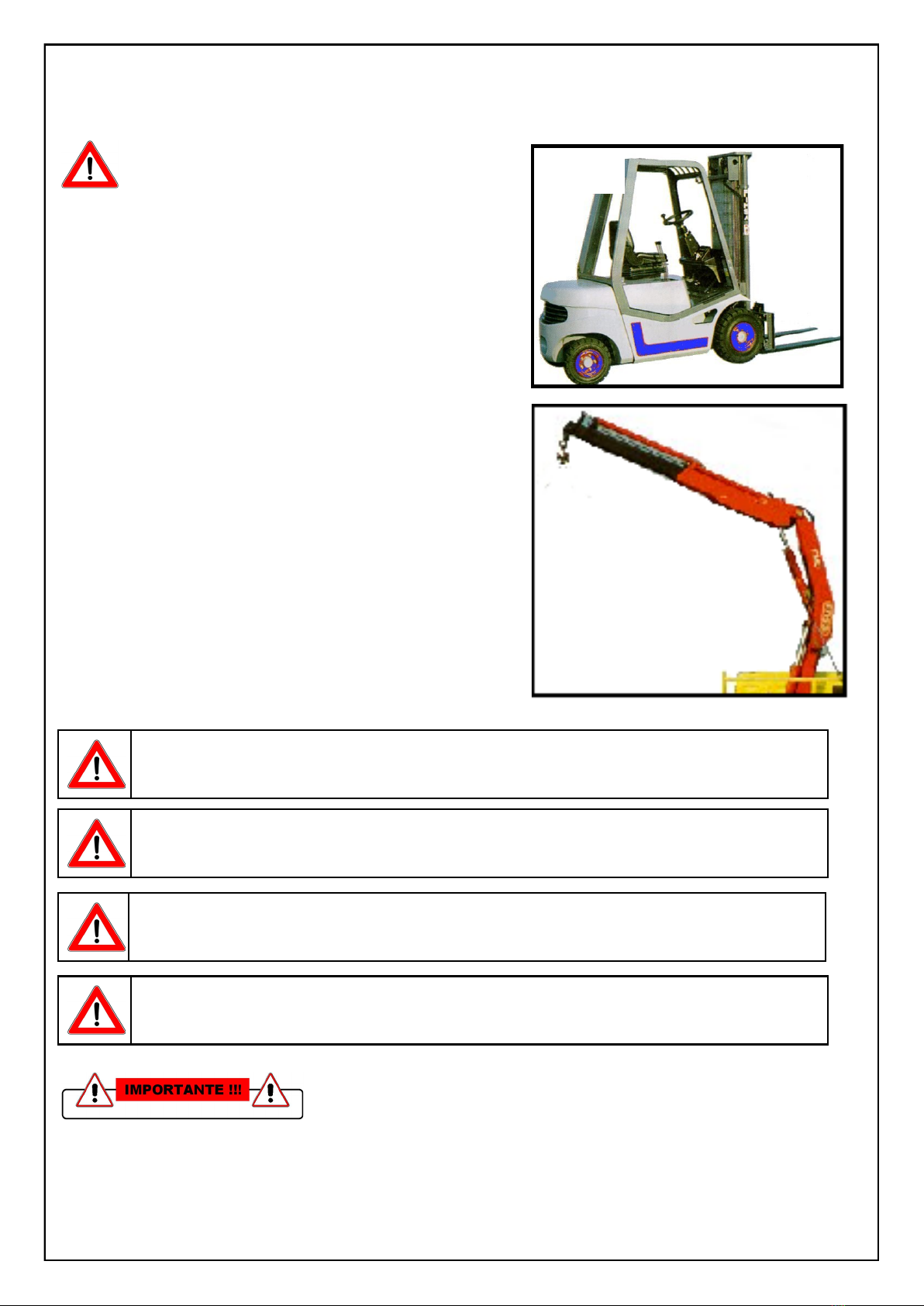

INDICATIVE OIL QUANITITY LEVELS

FOR TRANSMISSION PIPE

4. PRELIMINARY CHECKS

pg. 6

7) Before operating the machine, it is essential to read the instructions contained in the

Use and Maintenance Booklet. In par ticular, ensure that you have fully under-

stood the operation of the machine.

8) The machine was designed and constructed to treat water and sewage, but not chemical

products. Treating the latter substances may cause permanent damage.

9) Check that the length of the machine is appropriate to the depth of the tank.

10) As regards machines with oil bath transmission, the transmission pipe and the gear

units, if present, should be filled with oil.

11) During assembly, ensure that the rubber parts of the machine do not come into contact

with oil, grease or oil derivatives .

add synthetic oil for reducers that are resistant to

high temperatures (AFI REVERSE GEAR UNIT

ONLY);

wait at least 3 hours (FOR TRANSMISSION

PIPES ONLY) before checking the oil level by

way of the specific cap;

close the caps.

Check the level cap periodically: the oil must nev-

er fall below the level .

The machines are supplied without lubricating oil both in the transmission pipes and the

gear units. Before starting the machine, ensured they are filled correctly:

unscrew the caps: fill and vent;

add SAE 90 oil very slowly, see oil quantity table;

fig. 8

1- 2- 3

Cardan joint transmission type Type A (4 m) Type B (5 m) Type C (6 m)

Oil quantity (kg) 7.7 9.5 15

N.B. During filling and checking, when the ma-

chine is stopped, the transmission pipe should be

in the horizontal position.

1) OIL Inlet Cap

2) OIL Outlet Cap

3) OIL Level Cap