BG80 USE AND MAINTENANCE BOOKLET

Rev.1 of 23/04/2013 of BG80 uk agg2013 Page 9 of 40

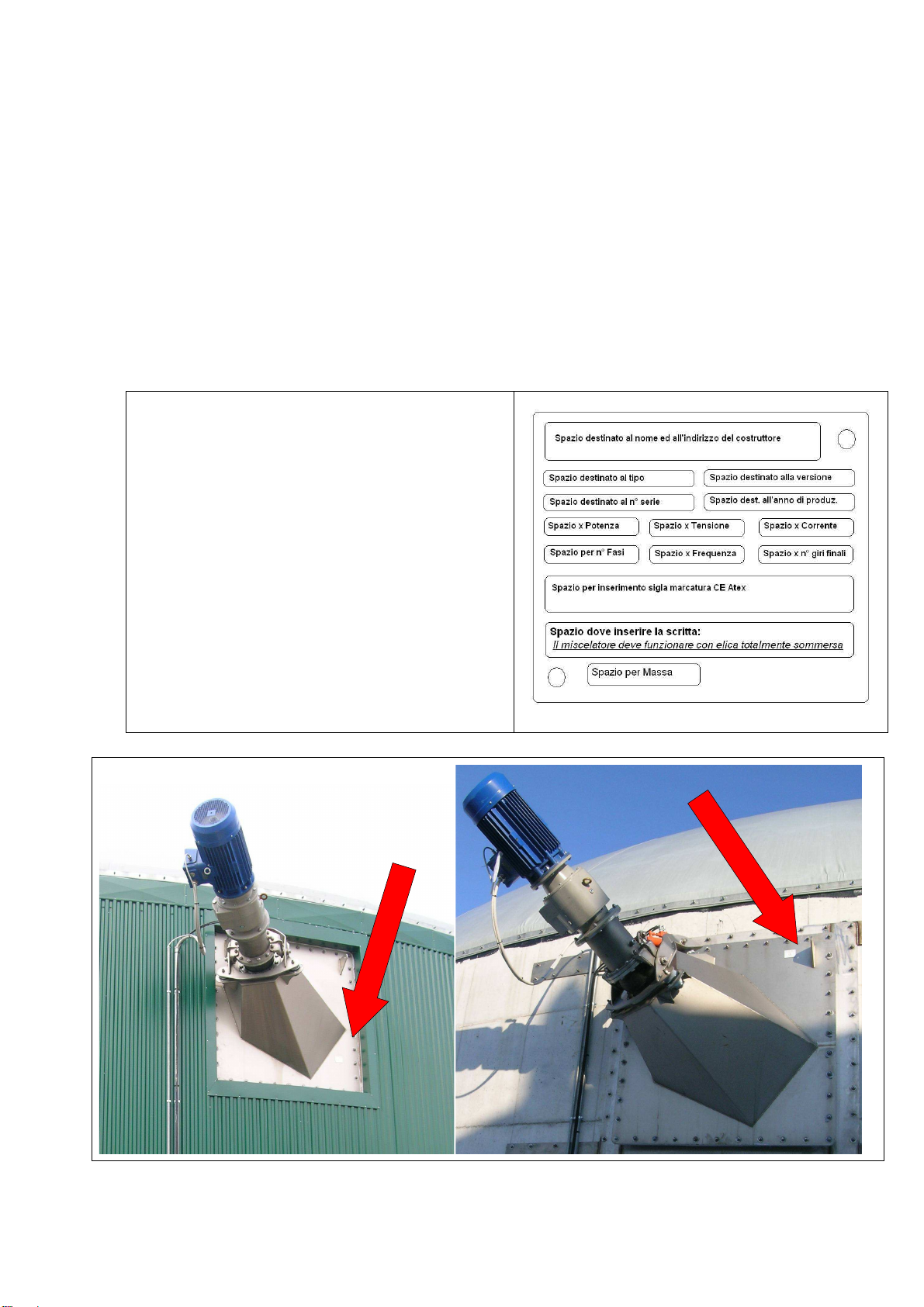

To ensure Atex conformity as declared, the mixer propeller must be immersed in the biomass at all

times during operation.

The biomass level must never fall below the body of the propeller; to this end, implement a level gauge

system using floats, level probes or, alternatively, introduce supervised operation (person present)

Any intervention that modifies the mixer parts may result in the Risk of Explosion.

The mixer must only be used in environments compatible with the specifications shown on the plate

Smoking, and the use of naked flames, mobile phones or portable radio transceivers are

prohibited in areas at risk of explosion

3

3

DESCRIPTION OF THE MACHINE

The BG80 mixer has been designed primarily to operate in fermentation tanks, where a high degree of dry matter

is present (co-ferments, ...)

The purpose of the mixer is to prevent the formation of floating layers of sediment in the fermentation tank and to

ensure that the ferments are properly mixed.

The BG80 machine is equipped with a hydraulic cylinder to enable the angle of inclination of the propeller in the

tank to be adjusted, thus ensuring optimal mixing efficiency. A manual oil pump is usually supplied to operate the

cylinder; this is fixed to the frame of the mixer, or located near the machine. Upon request it is possible to fit the

machine with a kit to operate the cylinder using an electric hydraulic pump.

The ferments and the digester gas are securely hermetically-sealed thanks to a robust expansion joint with a

flange; this is firmly secured to the transmission and to the mixer frame.

As the bacteria is mixed with a stroke that is both vigorous and gentle, the gas bubbles that form in the fermented

matter are encouraged to rise to the surface and are consequently released.

This is in contrast to the alternative uncontrolled "growth" of the ferment.

The operating time of the mixer can be varied to meet specific requirements; it is generally advisable to use an

inverter to adjust the number of motor revolutions to suit the type of substrate being treated. This prevents

unnecessary operations, and optimises electric energy consumption.

It is important to set the correct operating time and the number of revolutions of the mixer motor, particularly

during the filling and start-up phases.

It is generally recommended that the motor is set to a high number of revolutions initially; this should then be

gradually reduced when normal the operating cycle begins.

There should be no white patches on the surface of the fermentation material (sulphur deposits) and no material

of any kind should be deposited in the tank.

Furthermore, attention must be paid to the maximum refill level in the tank, particularly in the case of high walls or

large quantities of manure.

In the event that either an amount of product is introduced into the tank which leads to an unexpected increase in

the mass, or an increase in sulphur deposits occurs, the mixer operating time should be increased, and the

number of motor revolutions should also potentially be increased.

Optimal mixing is obtained using a three blade propeller and the correct inclination of the propeller.