Operating Instructions

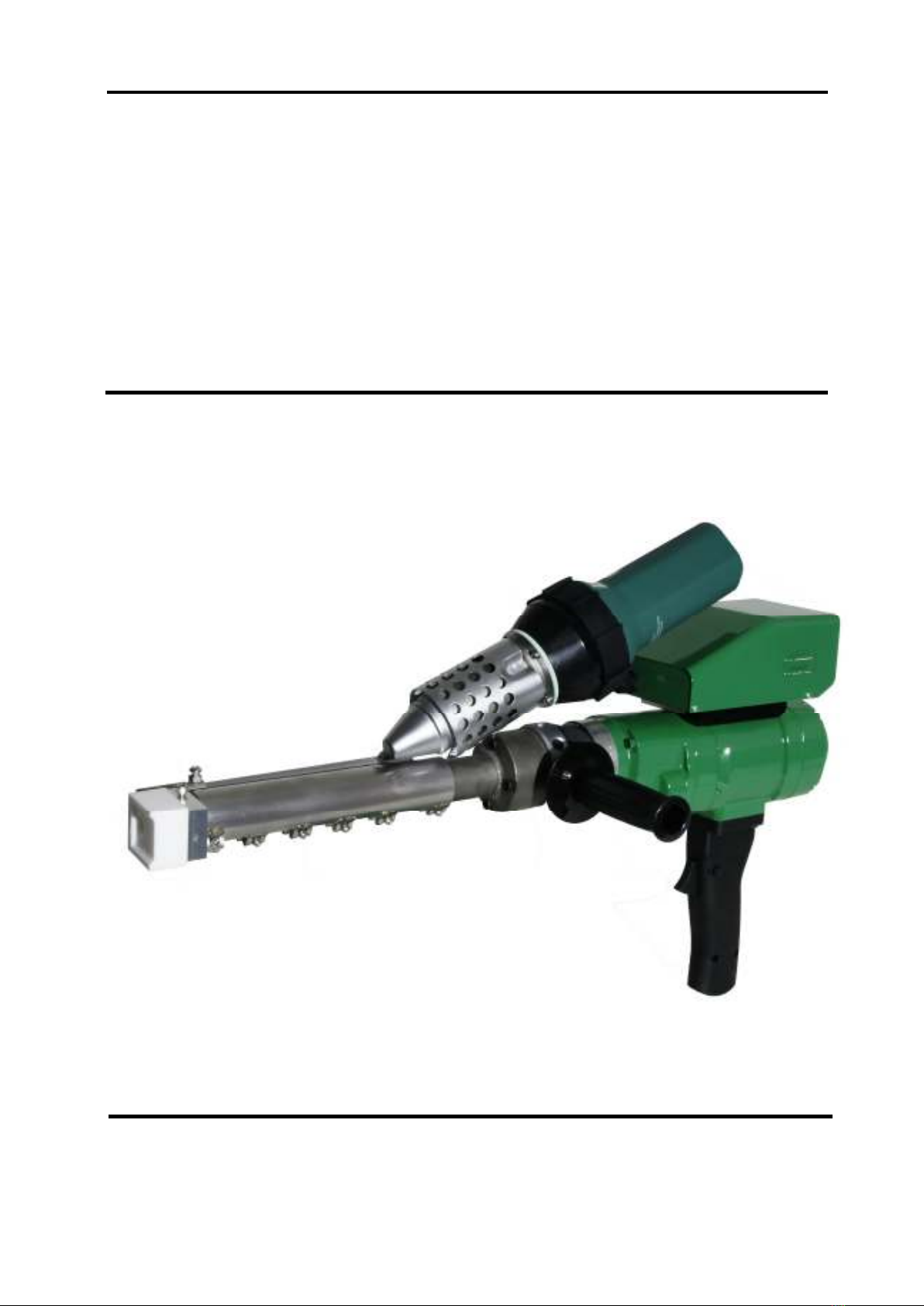

DOHLE Hand Welding Extruder ExOn5

DOHLE Extrusionstechnik GmbH 24

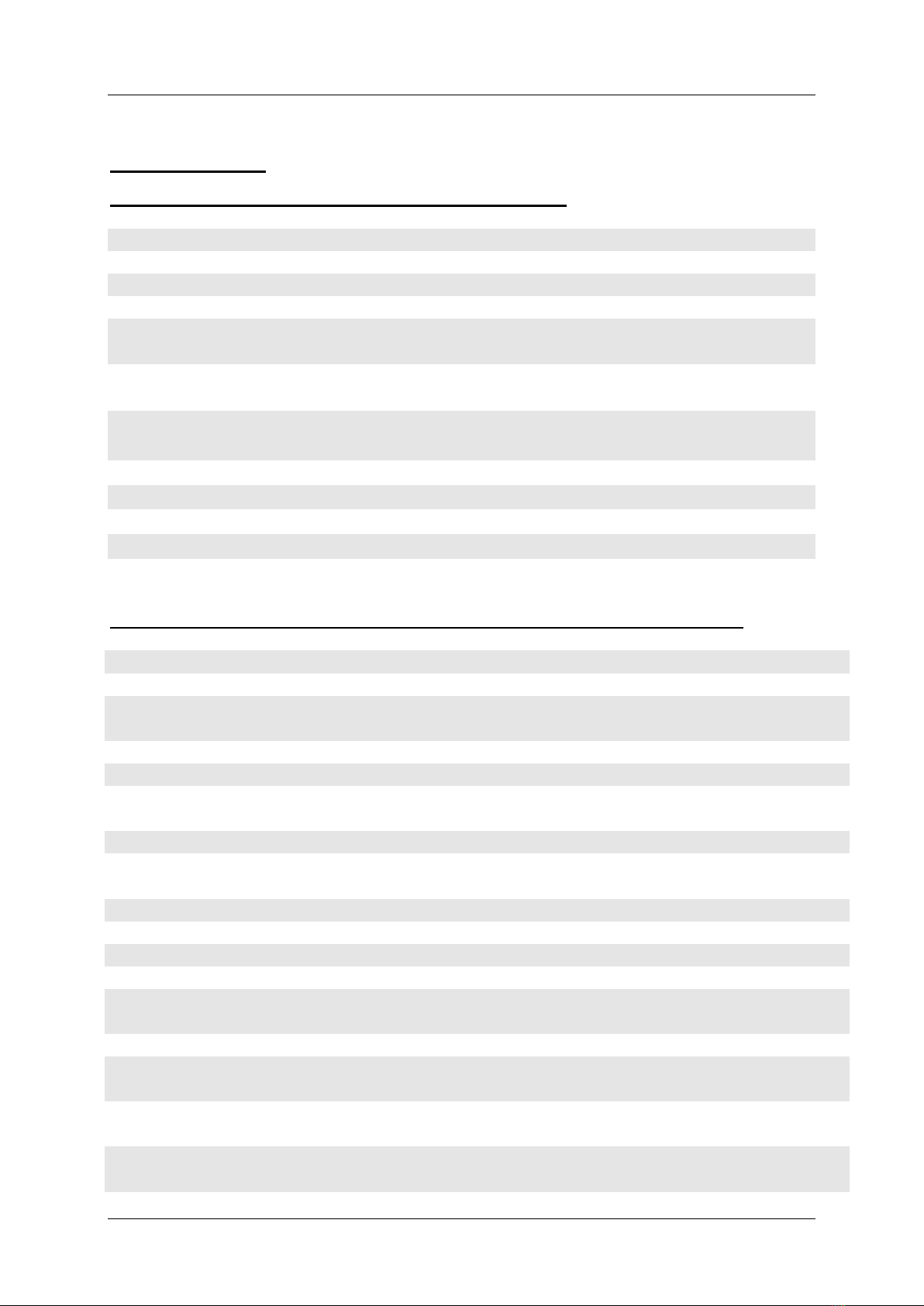

4. Error tracing

Malfunctioning Error– No.

Driving motor does not start 01,02,04,05,06,07,08,09,10,11,12

Driving motor s itches off 03,04,05,06,07,08,09,10

Extruder remains cold 04,05,06,07,08,09,15,17

Hot air remains cold 05,07,08,09,12

Hot air temperature is under 11,13

desired value

Extrusion temperature is under 11

desired value

Extruder does not deliver extruded 11

material from the die

Display does not light up 01

Display sho s: S . e r r 15

Display not constant 17

Display sho s rong direction of action 18

Error-No. possible cause Elimination of error

01 No po er supply Provide po er supply

02 Incorrect mains voltage Have checked by skilled technician

03 Extension cord becomes hot Check cable diameter

Run out cable completely from reel

04 Thermoelement for mass defective Exchange thermoelement

05 Thermoelement for air defective Exchange thermoelement

06 Temperature control unit for mass

defective

Exchange temperature control unit

07 Temperature control unit for air defective Exchange temperature control unit

08 On/Off s itch for heating units in OFF

position

Put s itch to ON position

09 Defect on cable connections Have checked by skilled technician

10 Carbon brushes of drive motor orn Replace by ne carbon brushes

11 Pre-heating time too short Heat up extruder

12 External air supply not connected Connect external air supply

13

Air flo too high hen using external air

supply

Reduce to prescribed quantity

15 Breakage of monitoring thermoelement Replace thermoelement

16 Unsuccessful attempt to change a

blocked parameter

Blockage can only be removed by a

skilled technician

17 Thermoelement failure or loose

connections

Check thermoelement

Check connections

18 Sensor incorrectly connected,

+ and – mistaken

Check connections