Table of Contents

Introduction ............................................................................................4

Congratulations

......................................................................................5

Acronyms and Definitions .........................................................................5

Safety .........................................................................................................5

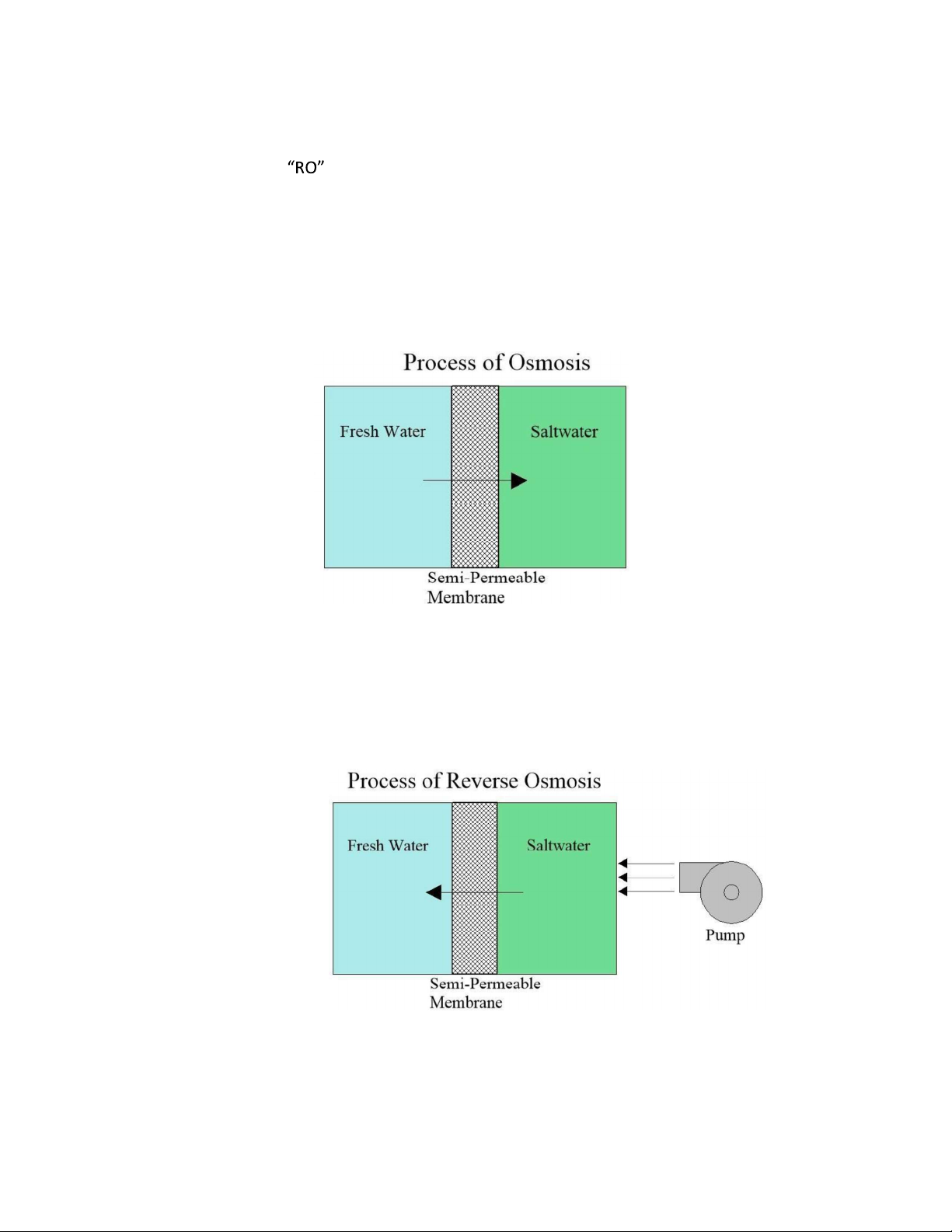

Principles of Reverse Osmosis

..............................................................6

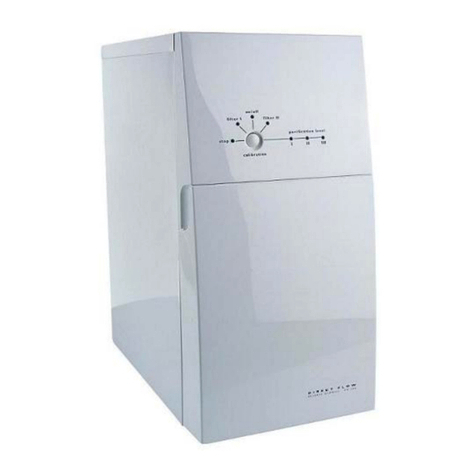

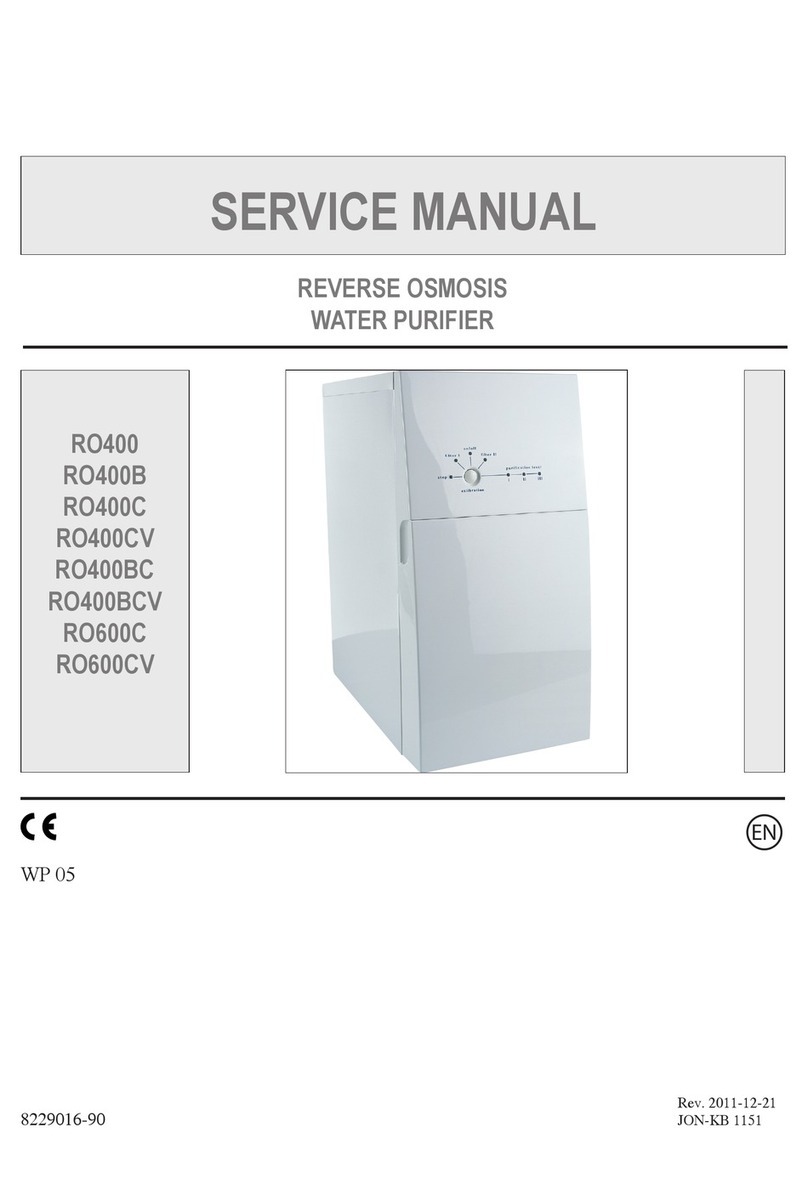

Unit Specifications .....................................................................................7

Installation and Commissioning ................................................................8

SZIII Install Kit ............................................................................................9

System Requirements and Operation Guidelines .................................. 10

Plumbing .......................................................................................... 10

Tube Cutting and Installation Procedure for Quick Connect Fittings 10

Electrical ........................................................................................... 11

SZIII Wiring Diagram

............................................................................ 12

SZIII One Line Flow Diagram

.............................................................. 13

PRE-FILTRATION ............................................................................... 14

Pre-Filtration Plumbing .................................................................... 14

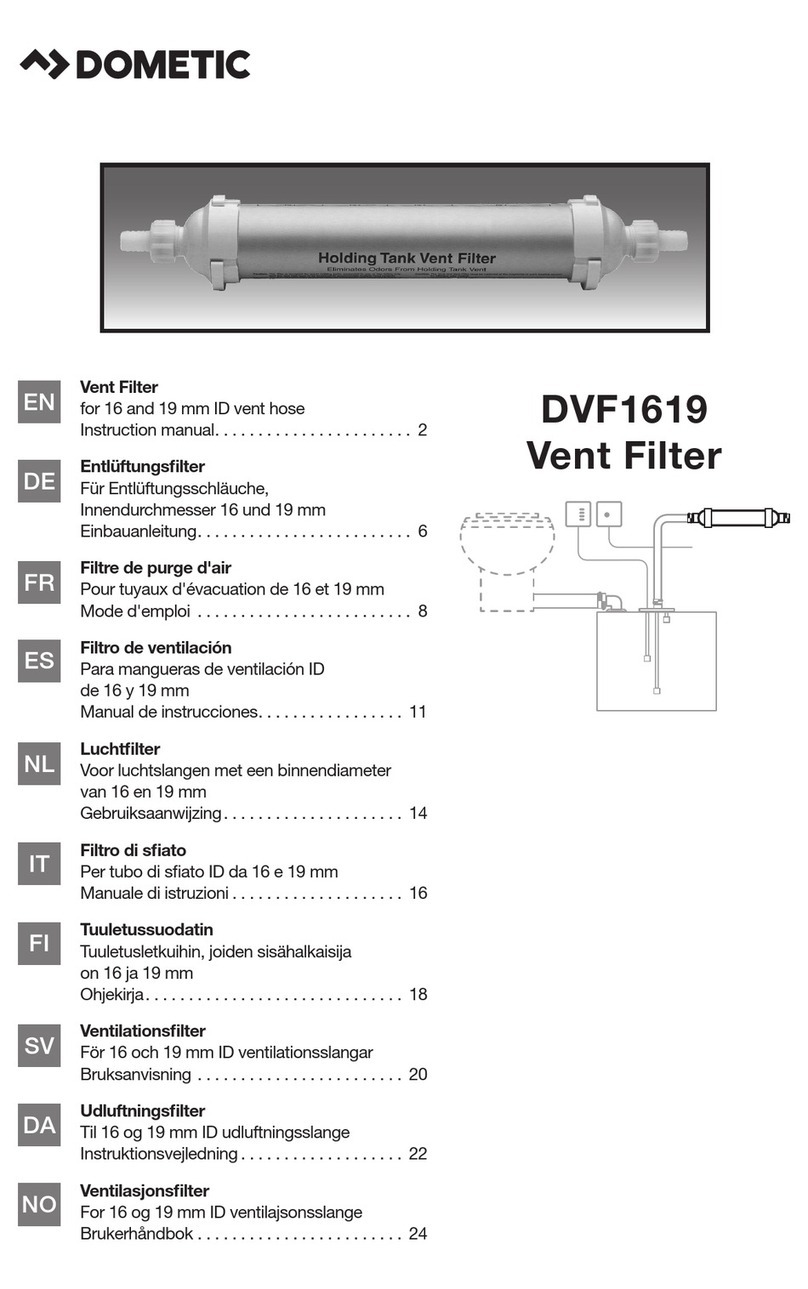

Overboard Connection ..................................................................... 15

Product to Tank Connection ............................................................. 15

Feed From Watermaker ................................................................... 16

Membrane Supply ............................................................................ 16

Membrane Return ............................................................................ 17

Membrane Product .......................................................................... 17

Operation and Maintenance .................................................................. 18

Operation Specifications ........................................................................ 19

Feed Water Specifications

........................................................... 19

System Standard Operating Parameters ................................................ 20

TEMPERATURE CORRECTION FACTORS FOR MEMBRANE

PRODUCTION ................................................................................... 21

Rejection, Recovery, and Flow Rates ............................................... 22

Components of the SZIII Unit ................................................................. 23

System Controller ............................................................................. 23

Freshwater RO Pump ....................................................................... 23

Membranes ...................................................................................... 23

Membrane Operation Guidelines .................................................... 23