-6-

•Lifting and erection

•Electrical installation, inspection and

maintenance

•Pneumatic installation, inspection and

maintenance

4.1 Location

It is recommended to mount the TDS dust

collector on a reinforced concrete

foundation. It is also possible to install the

dust collector on another structure.

For the calculation of the load on the

foundation or on the structure; the

following factors will have to be

considered: the weight of the dust

collector, if necessary including fan/motor

units, as well as the maximum weight of

the dust taking into account the hopper

capacity and eventually the snow and the

wind conditions to be expected locally.

(see scope of delivery, specification sheet

and outline).

There should not be any obstructions

near the place where the collector is to be

located, for pipes, wires or protruding

roofs could cause problems for the crane

which in most cases will be necessary to

put the collector on the right spot.

To save time it is recommended to

prepare the foundation before the

collector arrives and in that case it is

essential to locate the anchor bolts

correctly.

The dust collector should be located with

consideration for:

•emptying the dust disposal (item 11, fig. 1)

•shortest runs of inlet and outlet ductwork

•radius bends on elbows as big as possible

•easy access to electrical and compressed

air connections

•convenience of maintenance.

4.2 Required tools and equipment

•Crane/Fork lift

•Slings/ Clevis Pins and adequate lifting

equipment

•Standard tools (e.g. screwdrivers,

wrenches, etc.)

•Drill

•Pipe Sealant

5. INSTALLATION

5.1 Unloading and transporting to

location

èNOTE

Before unloading remove all packing and

strapping.

•A crane is recommended for the

unloading, transport and installation of the

dust collector. A crane will be needed to

put the hopper in position on the

foundation and after that, the top section of

the collector on top of the hopper.

CAUTION

Chains or slings with an adequate safe

working load must be used. Refer to the

collector nameplate for weight of

equipment supplied by Torit DCE. The

chains must be long enough to ensure

that the lifting angle between diagonal

chains is not greater than 90°. When

using a forklift the forks must be of a

suitable length and adjusted to ensure a

stable lift.

èNOTE

Depending on the order, the hopper and

leg set come already pre-mounted. Only

the collector will still need to be mounted

on the hopper. Follow steps 6 and 7 when

this is the case.

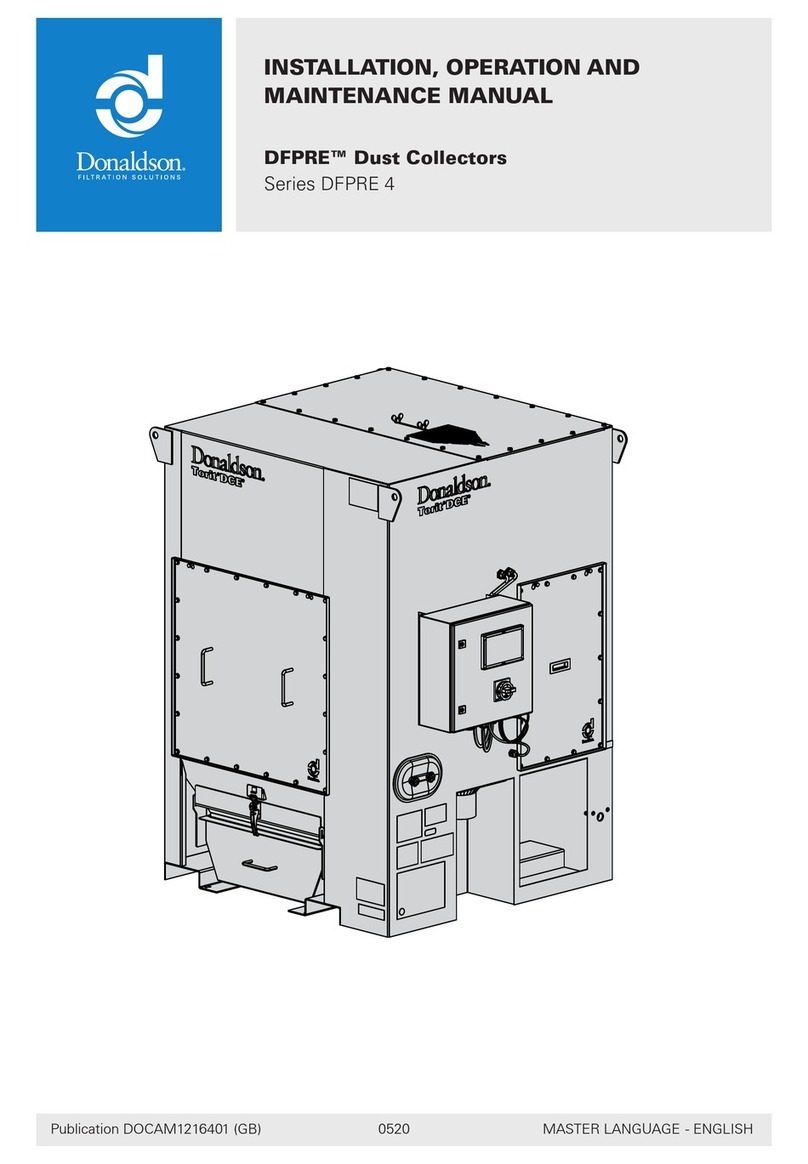

1. Stand the hopper(s) up with the disposal

end up (hopper outlet).

2. Use drift pins to align the holes in the

hopper gussets and legs, and attach the

legs with the M16 x 40 bolts, washers and

nuts. Do not tighten hardware at this

time!

3. Use drift pins to align the holes in the

crossbracings on the rear side of the leg

set.

4. Recheck the position of the legs and

crossbracings against Figure ‘Leg bolting

details and ‘Standard Leg Packs’ and the

drawing.

5. Flip over the now-assembled hopper/leg

pack assembly so that it is standing on its

legs (hopper outlet pointing down). This

step may require a crane.

6. Lift the assembled collector onto the

foundation. Fasten each footplate of the

leg anchor bolts with flat washers, lock

washers and nuts. Do not tighten

hardware at this time! (Depending on the

type of anchor bolts, anchor bolts can be

mounted afterwards).

CAUTION