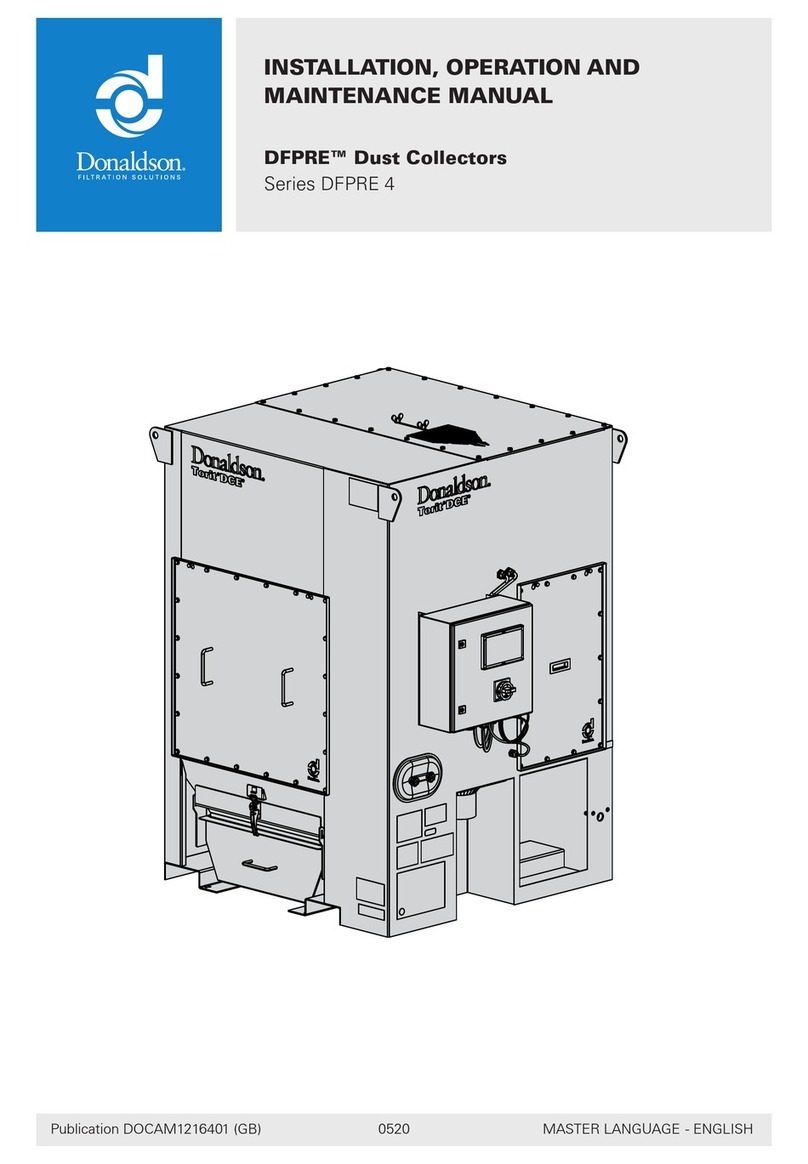

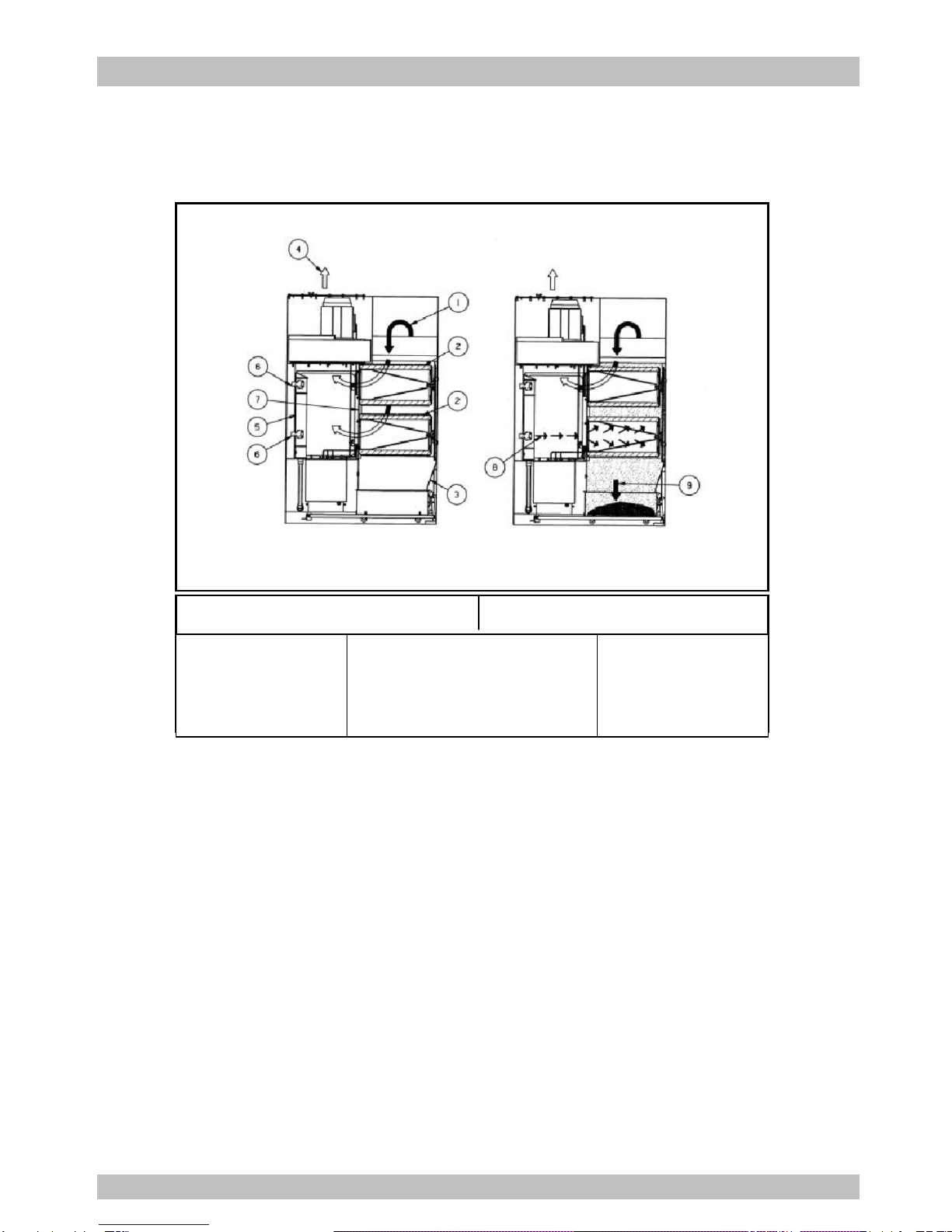

The dust collector is used for the collection of

airborne dust and particulate. Whether in

answer to the problem of air pollution, or as

part of a manufacturing process, the dust

collector provides highly efficient and

continuous on-line dust collection.

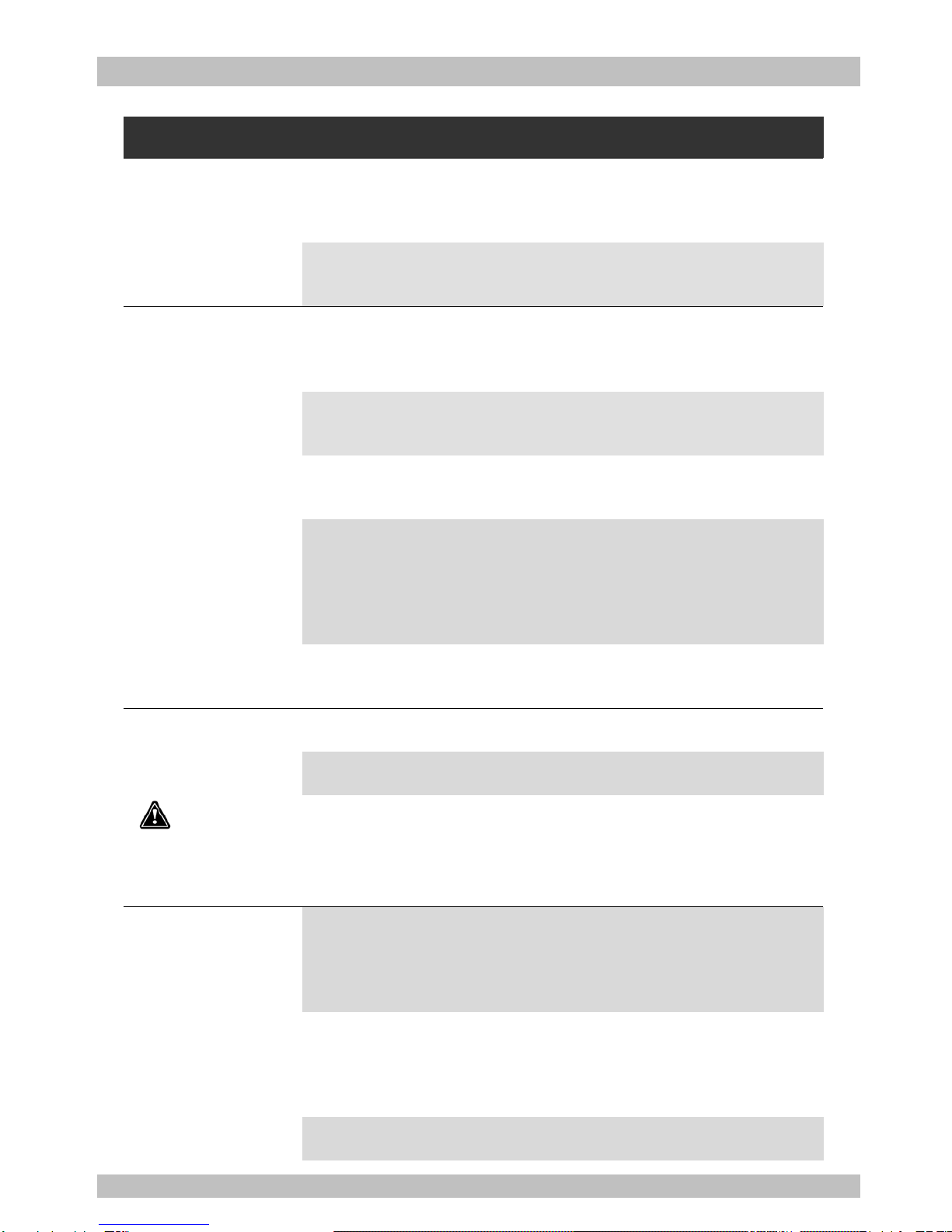

The filter elements are the heart of the dust

collector. These filter elements help ensure

the only cleaned air is returned to the plant

environment.

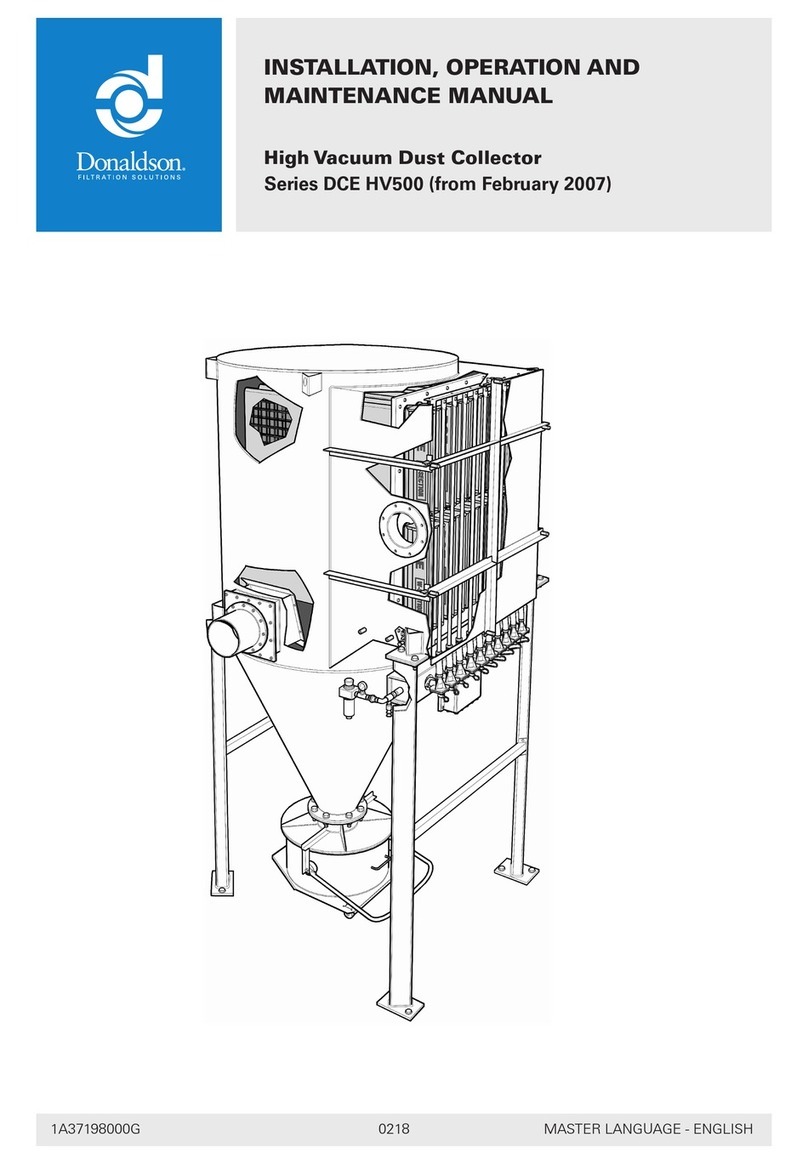

During operation, contaminated air enters the

dust collector through the dirty air inlet area

and passes through the filter elements. Dust

is collected on the surface of the filter

elements. The filtered air flows through the

centre of the filter elements into the clean air

chamber, where it exhausts through the

clean air outlet re-circulated into the

environment.

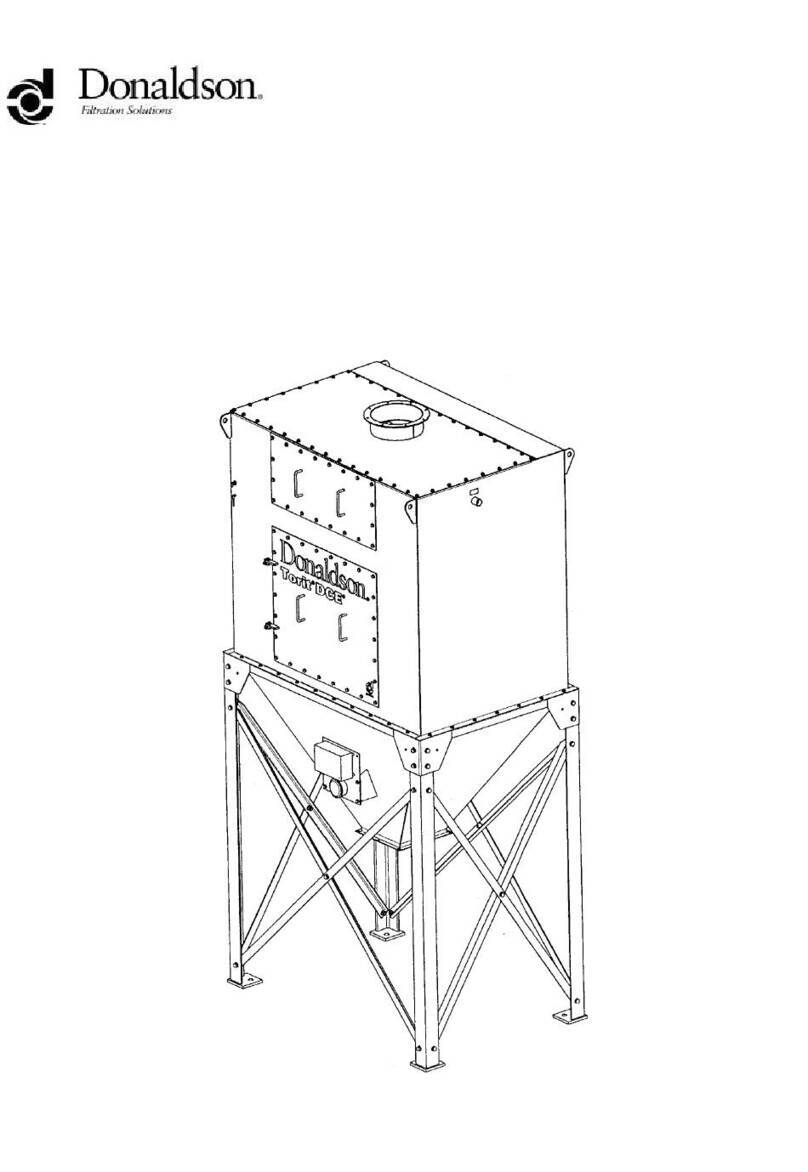

To ensure the optimal performance of your

dust collector it is necessary that the filter

elements are cleaned automatically

sequentially. During the filter sequence, the

timer energizes a solenoid valve, causing the

corresponding diaphragm valve to send a

pulse of compressed air through the filter

elements (from the inside outwards),

removing the collected dust from the outside

surface of the filter elements. The dust falls

through the hopper into the dust disposal

system.

Ensure all persons carrying out work on the

supplied equipment follow any relevant

recognized standards or codes and are

competent to do so.

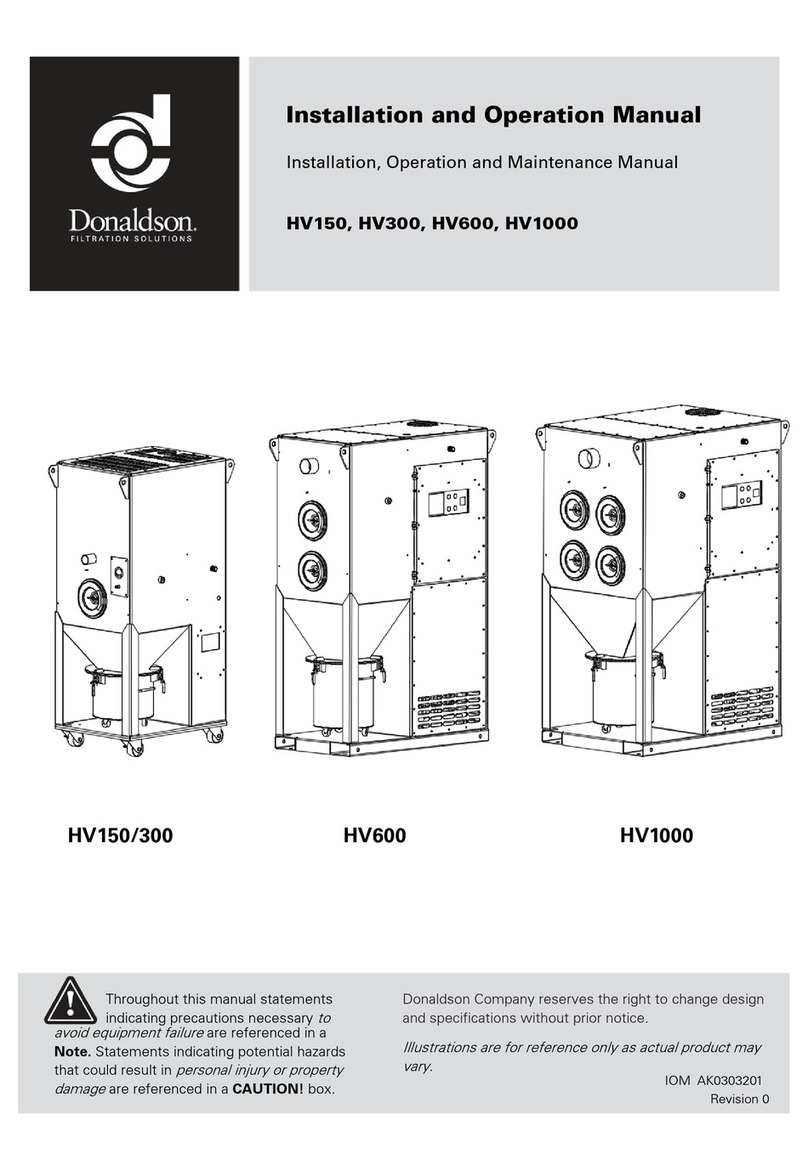

2.1 Compressed Air Connection

Compressed air pressure must be at 6 bar.

Be sure that all compressed air components

are adequately sized to meet the maximum

system requirements of 45 Nliters per pulse

at 6 bar supply pressure (= design pressure).

Compressed air supply has to be both oil and

moisture free.

Connect the compressed air supply line to

the compressed air connection of the dust

collector.

A compressed air shut-off valve, a filter/water

separator with automatic condense drain, a

pressure regulator with gage must be

installed on the compressed air supply line.

2.2 Electrical Connection

Enter the cable through the cable gland

locate at the lower right corner of the

collector. And enter the cable to the control

box through the cable gland locate at the

bottom of the enclosure. Please follow the

electrical diagram provided for connection.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

6