D439E Service Manual Index3

Index

1. General Information

General................................................................. 7

General........................................................... 7

General Precautions for Servicing ................. 11

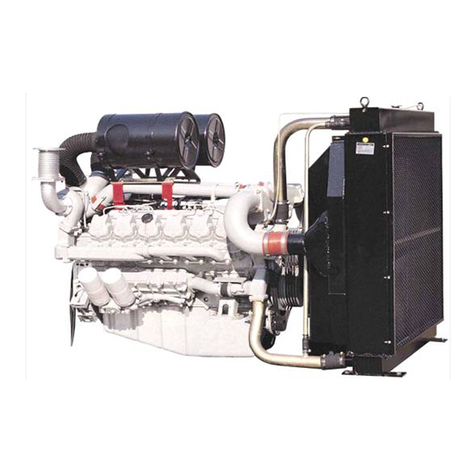

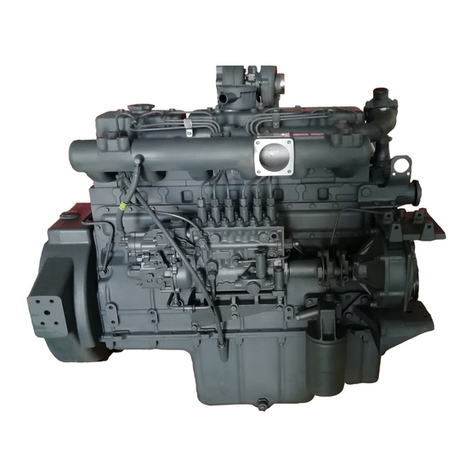

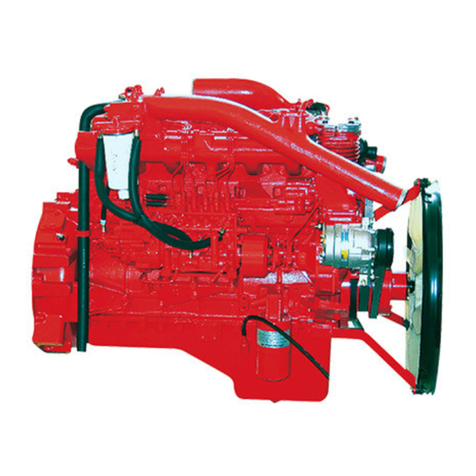

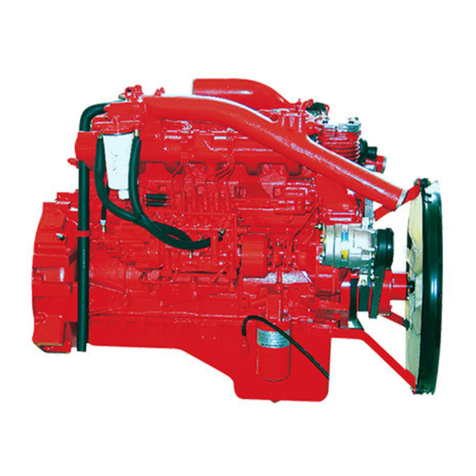

2. Engine Mechanical System (D439E)

General............................................................... 16

Description.................................................... 16

Specification ................................................. 20

Tightening Torque......................................... 24

Special Tool.................................................. 28

Diagnosis...................................................... 30

Adjustment.................................................... 32

Timing System ................................................... 33

Timing Gear Assembly.................................. 33

Removal ....................................................... 35

Inspection ..................................................... 39

Replacement................................................. 42

Installation .................................................... 43

Cylinder head Assembly.................................... 49

Components ................................................. 49

Removal ....................................................... 51

Disassembly ................................................. 54

Inspection ..................................................... 55

Replacement................................................. 59

Reassembly.................................................. 61

Installation .................................................... 63

Crankcase .......................................................... 65

Flywheel ....................................................... 65

Removal ....................................................... 66

Inspection ..................................................... 66

Installation .................................................... 67

Cylinder Block Assembly .................................. 69

Components ................................................. 69

Removal ....................................................... 71

Disassembly ................................................. 74

Inspection ..................................................... 75

Reassembly.................................................. 81

Installation .................................................... 82

Intake and Exhaust System............................... 86

Specifications................................................ 86

Troubleshooting ............................................ 87

Turbocharger......................................................89

Components ..................................................89

Removal........................................................91

Inspection......................................................92

Installation .....................................................93

Intake Manifold ...................................................95

Components ..................................................95

Removal........................................................96

Installation .....................................................97

Exhaust Manifold................................................98

Components ..................................................98

Removal........................................................99

Installation ...................................................100

Lubrication System ..........................................101

Description ..................................................101

Specification ................................................105

Troubleshooting...........................................107

Adjustment ..................................................109

Oil Pump ...........................................................111

Components ................................................111

Disassembly................................................113

Oil Cooler..........................................................114

Components ................................................114

Disassembly................................................115

Inspection....................................................115

Reassembly.................................................116

Cooling System ................................................117

Description ..................................................117

Specification ................................................118

Trouble Shooting .........................................120

Water pump ......................................................122

Components ................................................122

Removal......................................................123

Inspection....................................................124

Installation ...................................................125