A Series Diesel Engine Index

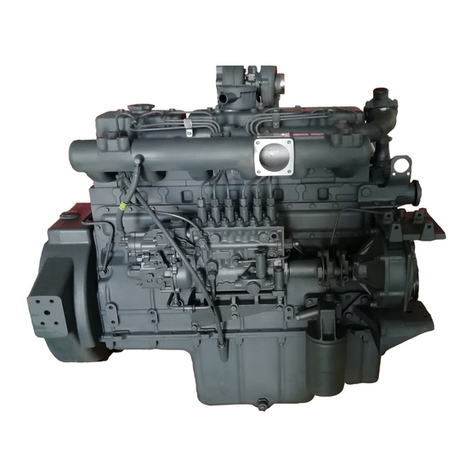

Base Engine Components

Operation and Description .....................................148

Cylinder Head and Valve Train ..............................149

Front Gear Housing and Gear Train......................150

Front Crankshaft Seal............................................150

Camshaft, Tappets and Push Rods .......................150

Flywheel Housing and Flywheel ............................151

Piston and Rod Assemblies...................................152

Crankshaft and Main Bearings...............................154

Oil Pan ...................................................................156

Base Engine Component.......................................156

Air and Fuel System...............................................157

Compression Check...............................................158

Piston Ring Seal ....................................................158

Valce Sealing .........................................................158

Valve Seal Wear.....................................................160

Front Gear Housing and Gear TRain.....................161

Rocker Levers........................................................162

Piston and Rod Assembly......................................163

Crankshaft and Main Bearings...............................165

Cylinder Block........................................................166

Flywheel Housing and Flywheel ............................166

Base Engine Componen Specifications.................168

Gear Train..............................................................169

Camshaft................................................................169

Tappets...................................................................169

Pistons ...................................................................170

Connecting Rod .....................................................171

Crankshaft..............................................................171

Cylinder Block........................................................171

Cylinder Bore .........................................................172

Base Engine Components .....................................173

Rocker Levers........................................................174

Rocker Levers Assembly .......................................179

Valve Clearance.....................................................179

Four Cylinder Engine .............................................179

Camshaft and Tappet.............................................180

Camshaft Inspection ..............................................181

Camshaft Bushing Inspection ................................182

Tappet Inspection...................................................183

Gear Housing or Gasket........................................186

Flywheel Ring Gear and Rear Sel.........................187

Brass Drift Pin........................................................187

Flywheel.................................................................188

In Chassis Overhaul...............................................189

Cylinder Head Removal.........................................190

Main Bearing Preliminary Inspection .....................191

Main Bearing..........................................................194

Piston and Rod ......................................................196

Piston, Pin and Connecting Rod............................197

Piston Ring Gap.....................................................202

Piston Rings...........................................................202

Piston and Rod Assembly......................................204

Cylinder Head and Gasket.....................................207

Cylinder Head.........................................................211

Valves.....................................................................214

Valve Seats ............................................................216

Cylinder Head ........................................................220

Hydraulic Pump Drive Gear and Shaft...................221

Balancer-Remove ..................................................221

Balancer-Install ......................................................222

Engine Replacement and Testing

Engine Replacement..............................................223

Engine Removal.....................................................224

Engine Installation..................................................225

Engine Testing........................................................227

Specifications

General Engine......................................................228

Fuel System...........................................................228

Lubricating Oil System...........................................228

Cooling System......................................................229

Air Intake System...................................................229

Exhaust System.....................................................229

Electrical System....................................................229

Drive Belt Tension..................................................229

Capscrew Markings and Torque Values.................230

Fraction, Decimal, Millimeter Conversions.............233

Newton-Meter to Foot-Pound Conversions............234

Pipe Plug Torque Values........................................234

Weights and Measures-Conversion Factors..........235

Special Tools

Special Tool List.....................................................237

4