www.doulton.com

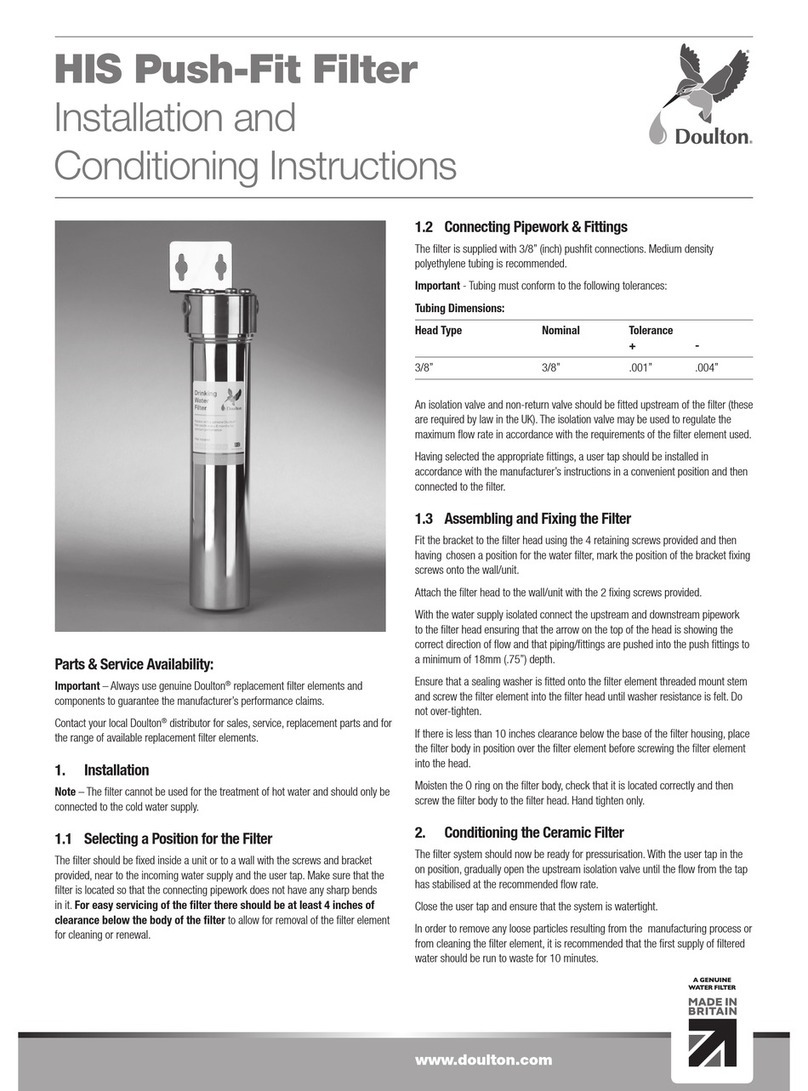

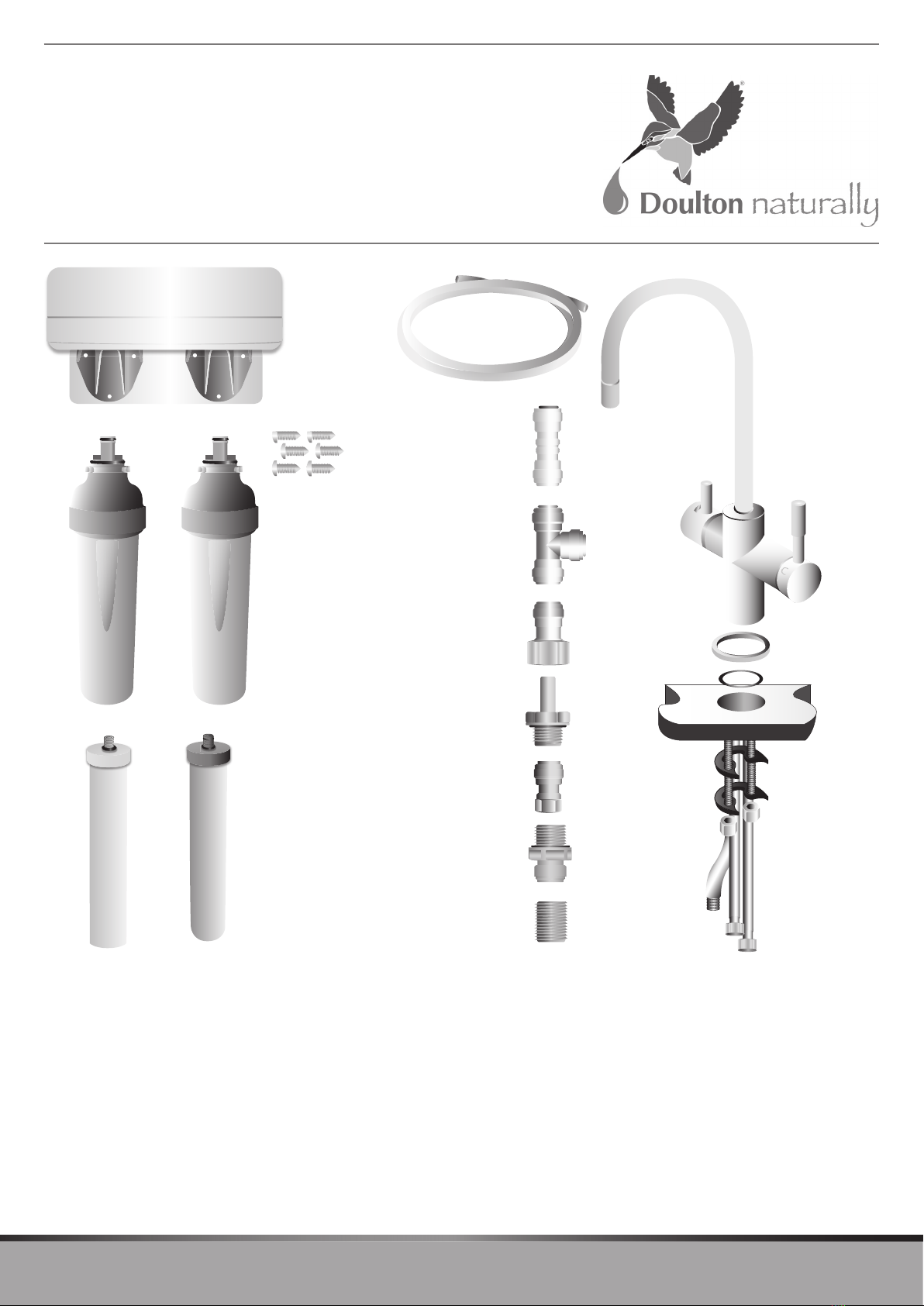

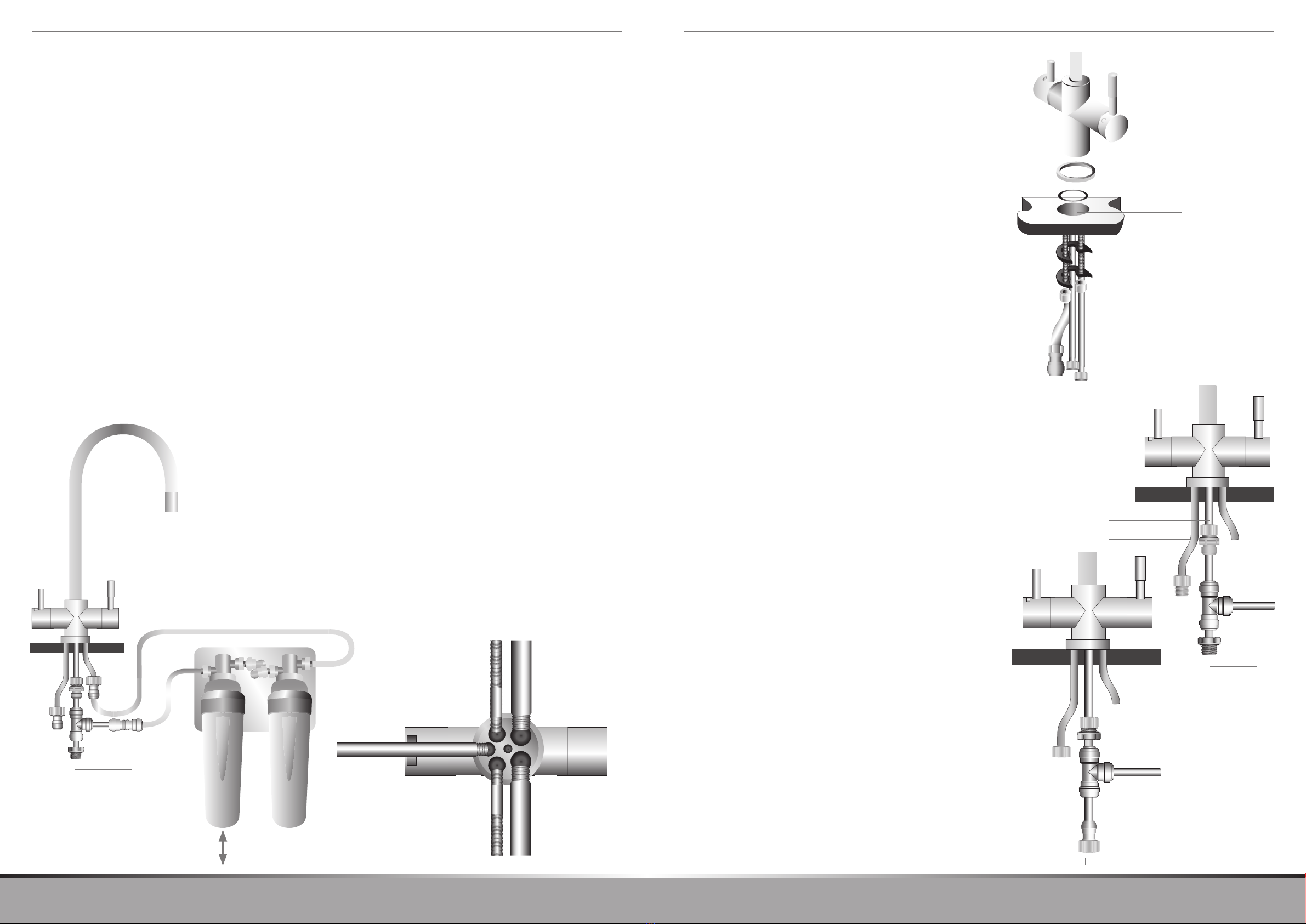

7. Position the Filter and Assemble the Filter for each

Housing – see figure 5a to 5d

7.1 Mark the required head position for fixing using the paper template supplied

Figure 5a

7.2 Grip the grey filter caps (E) and twist to the ‘unlock’ position

7.3 Pull down to disengage the filter caps (E) from the heads (C) and put the

filter caps (E) and filter bodies (F) to one side

7.4 Remove all packaging and fix the mounting plate (B) and filter heads (C) to

the unit or wall with the 6 screws (D) provided

Figure 5b

7.5 Unscrew the filter bodies (F) from the filter caps (E), open the filters and

discard the protective bags from the pre filter (G) of the left hand housing

and the ceramic filter (H) of the right hand housing

Figure 5c

7.6 Screw the threaded pre filter (G) into the grey filter cap (E) of the left hand

housing until washer resistance is felt, repeat for the ceramic filter (H) for

the right hand housing - do not over tighten

7.7 Screw the white filter bodies (F) into the grey filter caps (E) until a positive

stop is felt

Figure 5d

7.8 Align the arrow on the grey filter cap (E) of the assembled pre filter to the

unlock position on the left hand filter head (C) and push the assembled

filter firmly into the head until the clicks into position. Repeat this for the

assembled ceramic filter into the right hand filter head.

7.9 Twist the grey filter cap (E) of the assembled pre filter until the arrow is

aligned with the locked position on the left hand filter head (C). Check that

the arrows align to ensure that the filter is fully locked. Repeat this for the

assembled ceramic filter into the right hand filter head

Note: it is important that pre filter and ceramic filter are fitted in

the correct locations - See figure 6

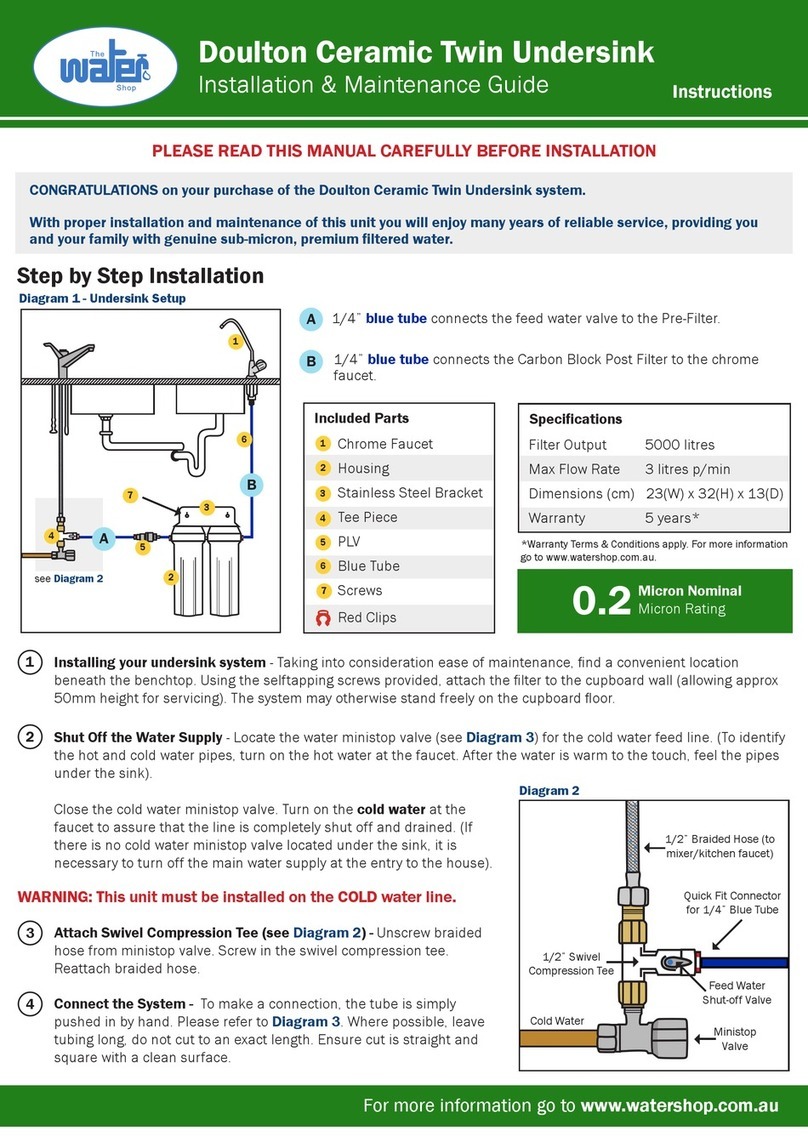

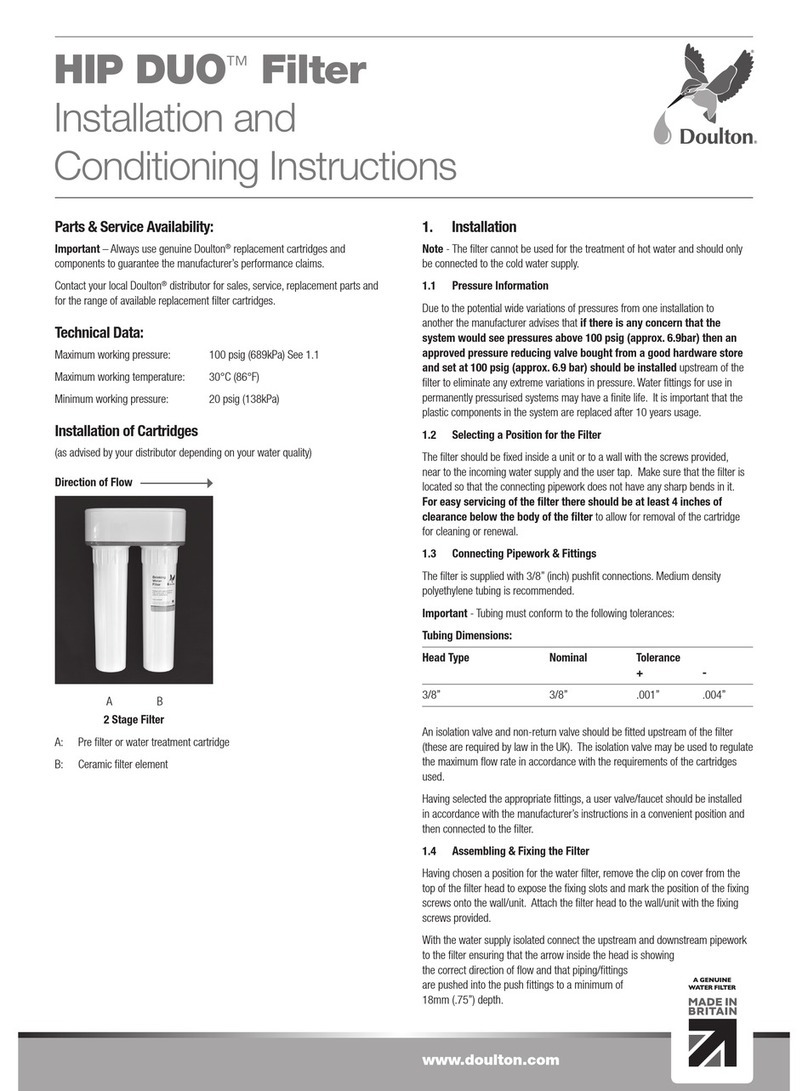

8. Install the pipe work and non return valve – see

figure 6

8.1 Measure and cut the tubing (I) to the length required to connect the inlet

port of left hand filter head (C) to the Tee adaptor (K). The length of the

tubing must be a minimum of 200 mm (8”). Take the cut length of tubing

and cut it in half

8.2 Fit one end of each tube into the non return valve (J)

8.3 Connect the non return valve (J) to the inlet port of the left hand filter head

(C) and the tee adaptor (K) with the tubing (I). Ensure that the flow arrow

on the non return valve (J) is pointing in the direction of the filter head (C)

8.4 Measure and cut the tubing (I) to the length required to connect the

outlet port of the right hand filter head (C) to the 7/16” adaptor (N) on the

filtered water hose on the mixer tap. Connect the tubing to the filter head

outlet port and mixer tap

8.5 Check that the arrows on non return valve (J) and the ports of the left

and right hand filter heads (C) are pointing in the correct direction of flow

towards the mixer tap – see page 1 and figure 7

9. Check the system for leaks

For guidance on identification of system components see page 1 and

figure 1

9.1 With the mixer tap filtered and hot/cold water taps open, slowly turn on the

mains water to allow the system to fill gradually until all of the trapped air

has been expelled from the system

9.2 Check for leaks around the mains supply pipes and adaptors, non return

valve, filter head inlet and outlet ports and filtered water adaptor. Also

check for leaks between the filter head, cap and filter body

9.3 If there are leaks from the adaptors, non return valve or filter head

ports:

• Turnoffthemainswatersupply

• Openthemixertaplteredandhot/coldwatertapstoreleasepressure

from the system

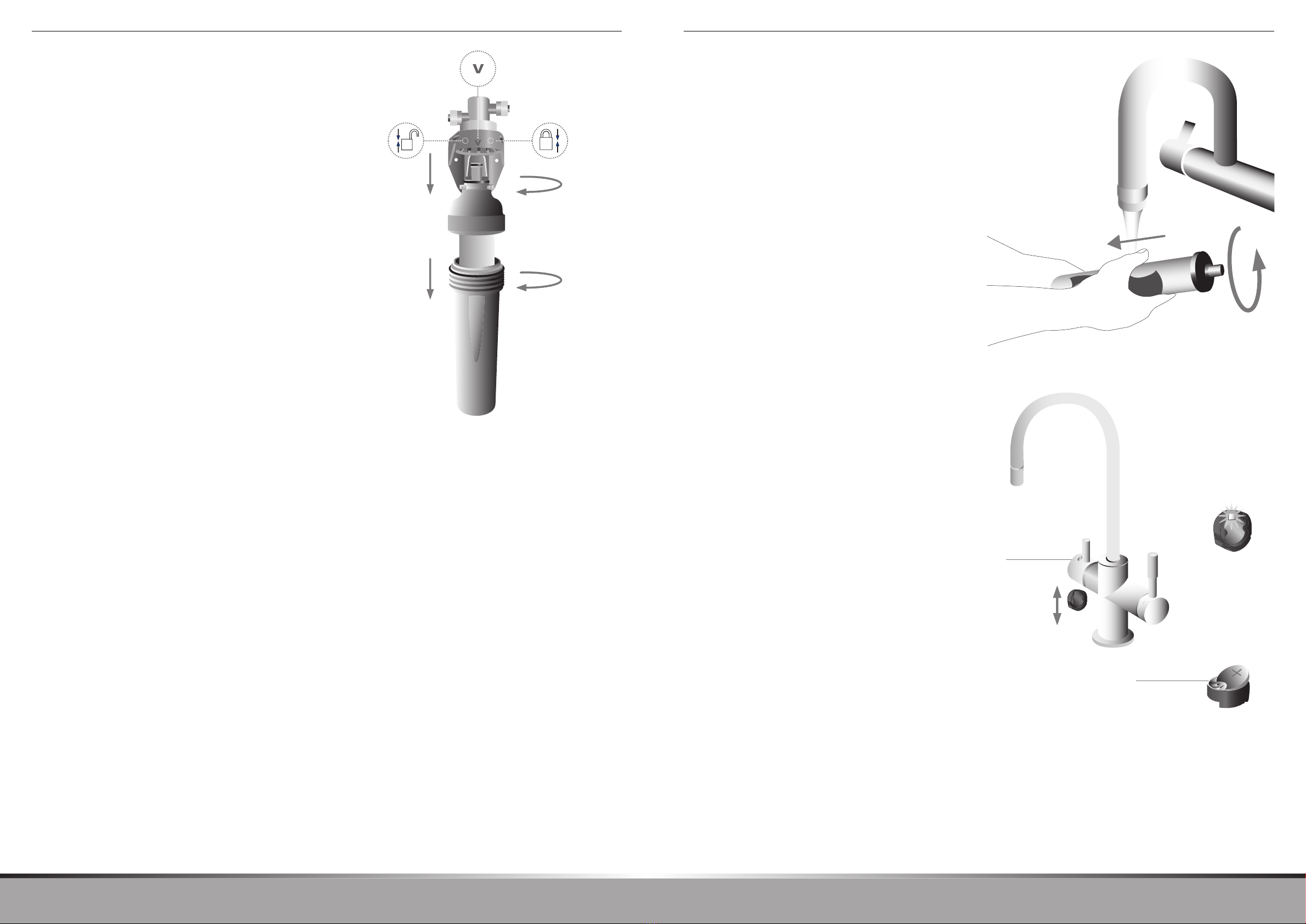

• Pressinonthecollararoundthetubingwhereitenterstheadaptor,see

figure 8

• Pullthetubingtoreleaseitfromtheadaptor

• Checktomakesurethatthetubingiscutsquareandthatthatitisnot

scratched or crimped

• Ifthetubingisunevenlycutorscratched,cutoffthedamagedsection

squarely and re install the tubing

• Withthemixertaplteredandhot/coldwatertapsopen,slowlyturnonthe

mains water to allow the system to fill gradually

• Checkthesystemforleaks

9.4 If there are leaks from the filter head:

• Turnoffthemainswatersupply

• Openthemixertaplteredandhot/coldwatertapstoreleasepressure

from the system

• Removethelterassembly,asdescribedinsection7.2–7.3/gure5a

• ChecktheO-ringsaroundthetopofthegreyltercap(E), ensure that

they are in place and free from dirt and particles, see figure 9

• Re-tthelterassembly,asdescribedinsection7.8–7.9/gure5d

• Withthemixertaplteredandhot/coldwatertapsopen,slowlyturnonthe

mains water to allow the system to fill gradually

• Checkthesystemforleaks

9.5 If there are leaks from the filter cap and filter body:

• Turnoffthemainswatersupply

• Openthemixertaplteredandhot/coldwatertapstoreleasepressure

from the system

• Removethelterassembly,asdescribedinsection7.2–7.3/gure5a

• Unscrewthelterbody (F) from the filter cap (E)

• ChecktheO-ringaroundthetopofthelterbody,ensureitisinplaceand

free from dirt and particles

• Removethelterelementbyunscrewingfromtheltercapandplaceto

one side ensuring that the open ended plastic mount is kept clean to avoid

contamination

• ChecktheinsideoftheltercaponthesurfacewherethebodyO-ring

seals, ensure it is free from dirt and particles, see figure 9

• Retthethreadedlterelementandreassemblethelterasdescribedin

section 7.6 – 7.9/ figures 5c & 5d

• Withthemixertaplteredandhot/coldwatertapsopen,slowlyturnonthe

mains water to allow the system to fill gradually

• Checkthesystemforleaks

9.6 If there are leaks from the mixer tap adaptor:

• Turnoffthemainswatersupply

• Openthemixertaplteredandhot/coldwatertapstoreleasepressure

from the system

• Pressinonthecollararoundthetubingwhereitentersthe7/16”tap

adaptor (N).See figure 8

• Pullthetubingtoreleaseitfromtheadaptorandunscrewtheadaptorfrom

the filtered water flexible supply pipe on the mixer tap

• Checkthattheblacksealingwasheriscorrectlyseatedinthethreaded

hole of the tap adaptor

• Makesuretheblacksealingwasherisundamagedandfreefromdirtand

particles

• Screwthetapadaptor (N) to the filtered water flexible supply pipe on the

mixer tap - do not over tighten

• Ensuresurethatthetubingiscutsquareanditisnotscratchedorcrimped

• Ifthetubingisunevenlycutorscratched,cutoffthedamagedsection

squarely and re install the tubing

• Withthemixertaplteredandhot/coldwatertapsopen,slowlyturnonthe

mains water to allow the system to fill gradually

• Checkthesystemforleaks

10. Prepare the filter for use

10.1 The 3 way mixer tap (Q) has an indicator light to inform the user when the

ceramic filter requires changing. The light flashes ‘blue’ when the filtered

water tap is operated, if the light flashes ‘red’ the ceramic filter requires

changing. Remove the plastic battery protection strip from the underside

of the mixer tap filtered water tap lever to enable the filter replacement

indicator function, see figure 2b

10.2 Open the mixer tap filtered water tap and run the water to waste for

10 minutes (or 15 litres)

10.3 Leave to stand for 24 hours to condition the ceramic filter element, then

run water to waste for a further 10 minutes. The filter is now ready for use

Figure 5a Figure 5b

Figure 5c Figure 5d

C

E

E

G/H

F

C

E

F

Figure 7

Direction of flow

Incoming mains

water

To mixer tap

Bag

F

Push collar

Pull

Tubing Collar Adaptor Body O-ring seal face inside

Figure 8 Figure 9 O-ring

O-ring

Figure 6

N

K

I

M

Mains cold

water supply

Q. 3 way Mixer Tap

J

P

O

I

I

I

E

F

Prefilter Ceramic Filter

G/H