10084443

Rev. B 11/07

Hydro Systems 3798 Round Bottom Road, Cincinnati, OH 45244 s Phone: (513) 271-8800 sFax:(513) 271-0160

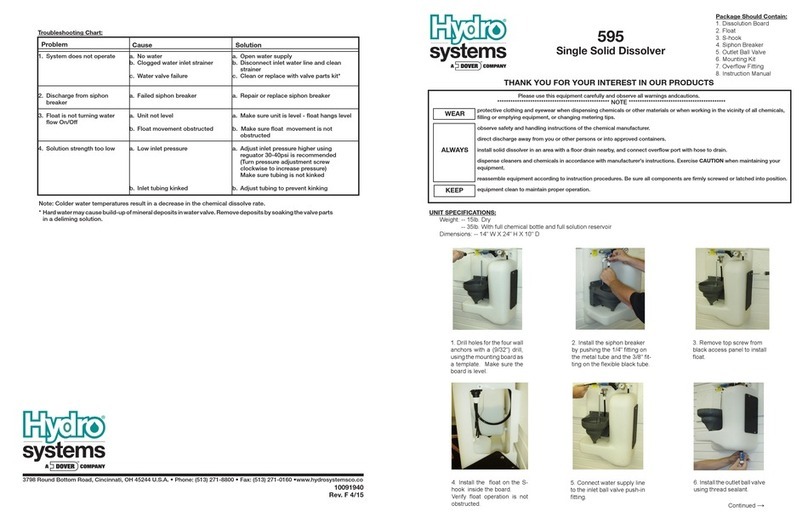

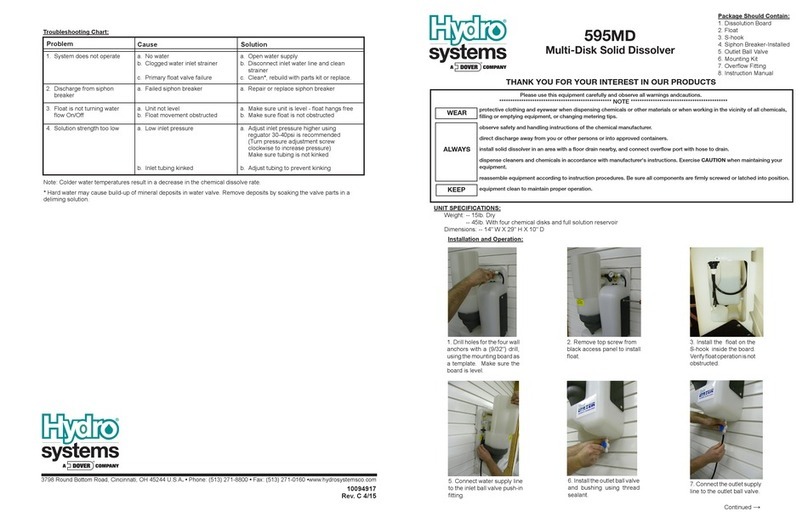

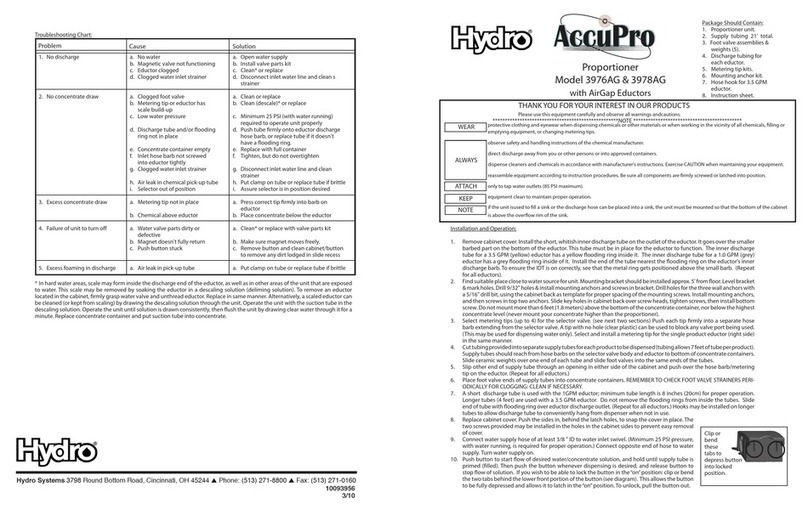

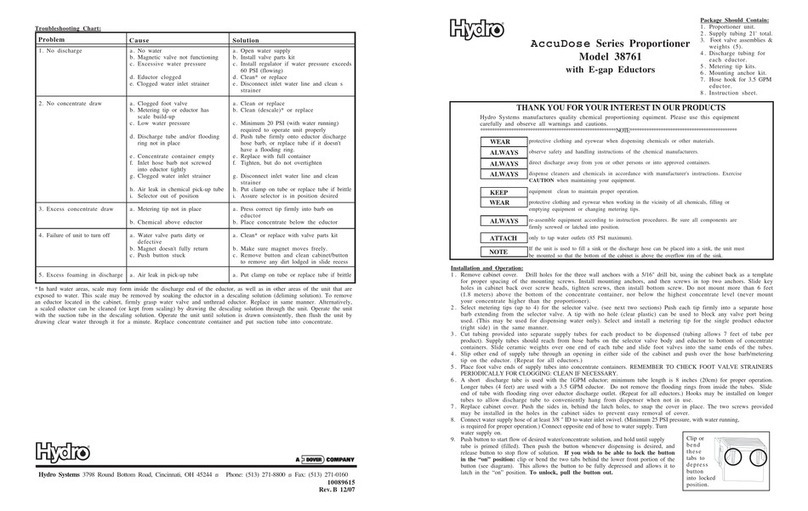

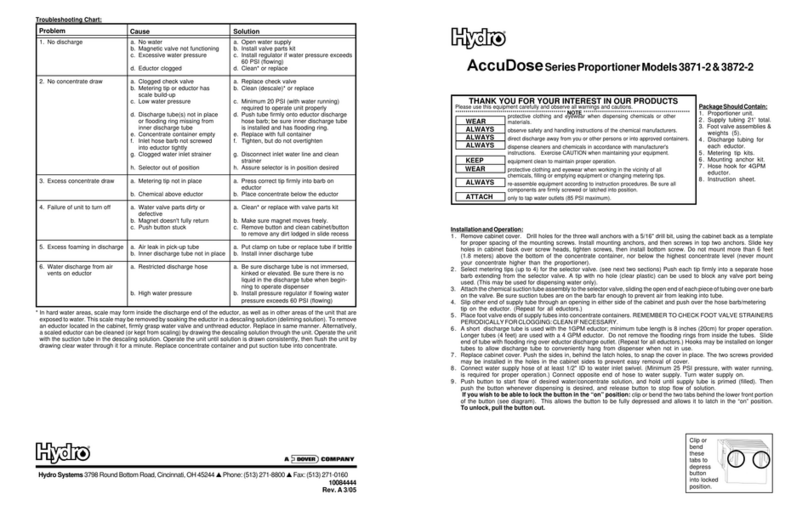

Installation and Operation:

1. Remove cabinet cover. Drill holes for the three wall anchors with a 5/16" drill bit, using the cabinet back as a template for

proper spacing of the mounting screws. Install mounting anchors, and then screws in top two anchors. Slide key holes in

cabinet back over screw heads, tighten screws, then install bottom screw. Do not mount more than 6 feet (1.8 meters) above

the bottom of the concentrate container, nor below the highest concentrate level (never mount your concentrate higher than

the proportioner).

2. Select a metering tip (see next section), and insert into hose barb on eductor body. (Repeat for all eductors.)

3. Supply tube should reach from hose barb on eductor to bottom of the concentrate container. Cut supply tube provided to

length required. Slide a ceramic weight over one end of tube and slide a foot valve into the same end of the tube. (Prepare

a tube for each eductor.)

4. Slip other end of supply tube through an opening in either side of the cabinet and push over the hose barb/metering tip on

the eductor. (Repeat for all eductors.)

5. Place foot valve ends of supply tubes into concentrate containers. REMEMBER TO CHECK FOOT VALVE STRAINERS

PERIODICALLY FOR CLOGGING: CLEAN IF NECESSARY.

6. A short discharge tube is used with the 1GPM eductor; minumum tube length is 8 inches (20cm) for proper operation.

Longer tubes (4 feet) are used with a 4 GPM eductor. Do not remove the flooding rings from inside the tubes. Slide end

of tube with flooding ring over eductor discharge outlet. (Repeat for all eductors.) Hooks may be installed on longer tubes

to allow discharge tube to conveniently hang from dispenser when not in use.

7. Replace cabinet cover. Push the sides in, behind the latch holes, to snap the cover in place. The two screws provided may

be installed in the holes in the cabinet sides to prevent easy removal of cover.

8. Connect water supply hose of at least 3/8" ID to water inlet swivel. (Minimum 25 PSI pressure, with water running, is required

for proper operation.) Connect opposite end of hose to water supply. Turn water supply on.

9. Push button to start flow of desired water/concentrate solution, and hold until supply tube is primed (filled). Then push the

button whenever dispensing is desired, and release button to stop flow of solution. If you wish to be able to lock the button

in the "on" position: clip or bend the two tabs behind the lower front portion of the button (see diagram). This allows the

button to be fully depressed and allows it to latch in the "on" position. To unlock, pull

the button out.

AccuDose SeriesProportioner

1, 2, or 3 button units

Package Should Contain:

1. Proportioner unit.

2. Supply tubing.

3. Foot valve assembly & weight for each eductor.

4. Discharge tube for each eductor.

5. Metering tip kit(s).

6. Mounting anchor kit.

7. Hook(s) for discharge tube(s) -- Models with 4 GPM eductors only.

8. Instruction sheet.

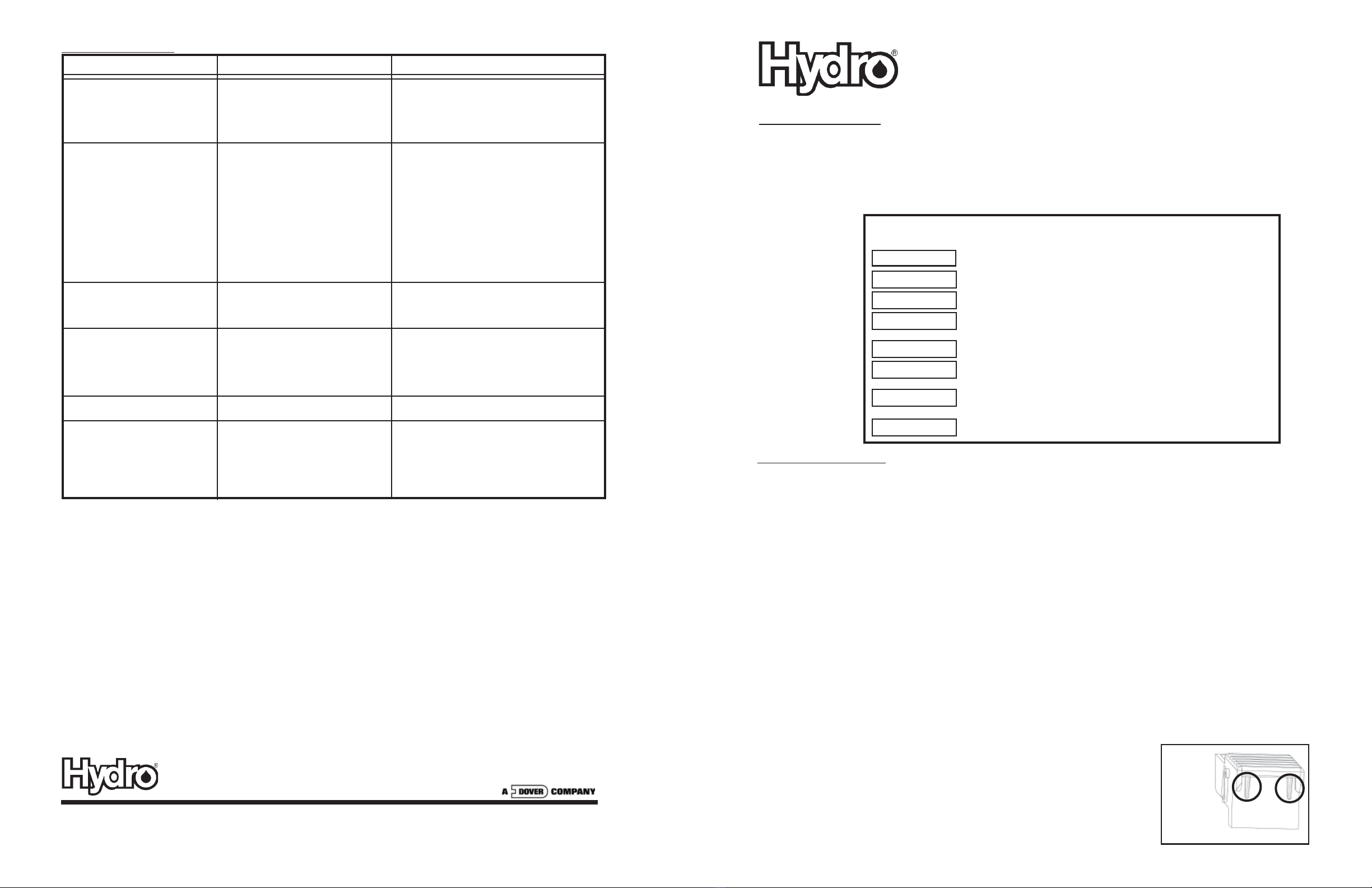

Clip or

bend

these tabs

to

depress

button

into

locked

position.

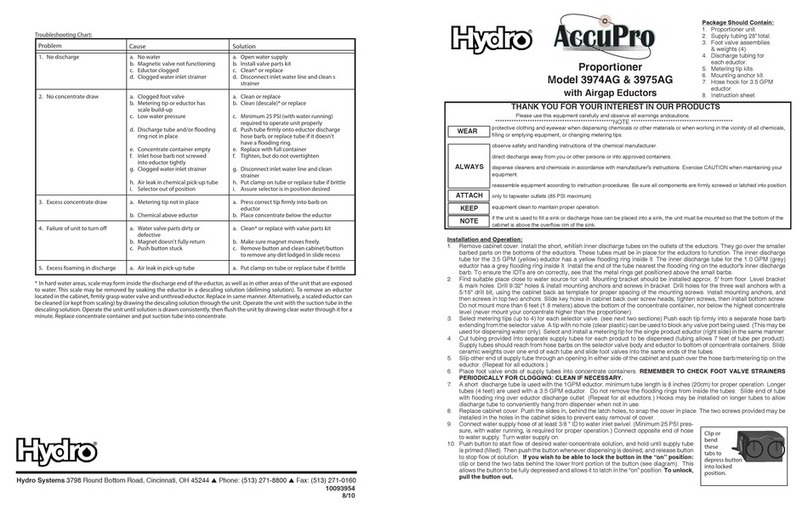

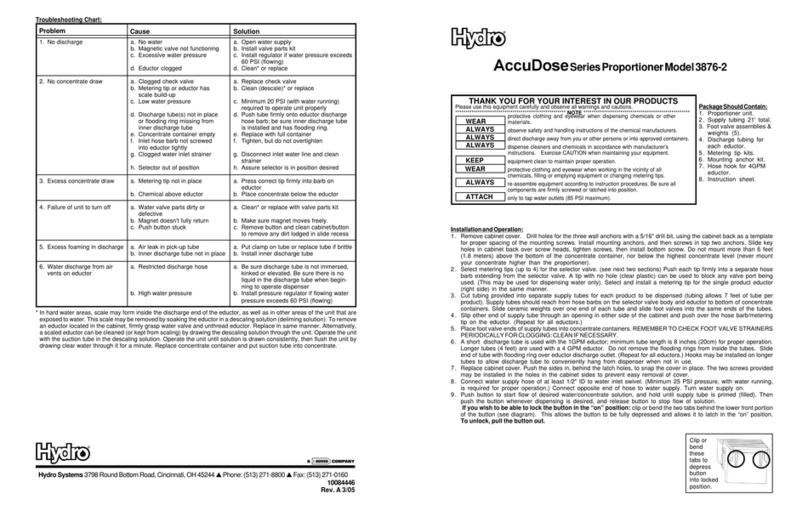

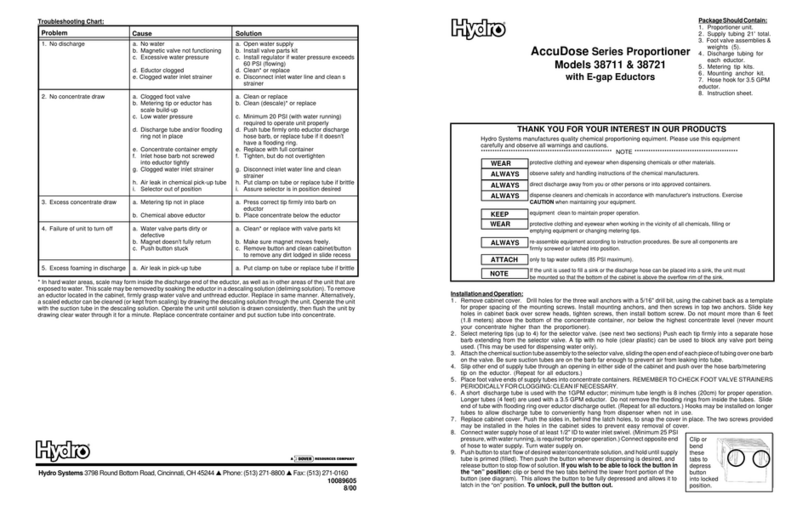

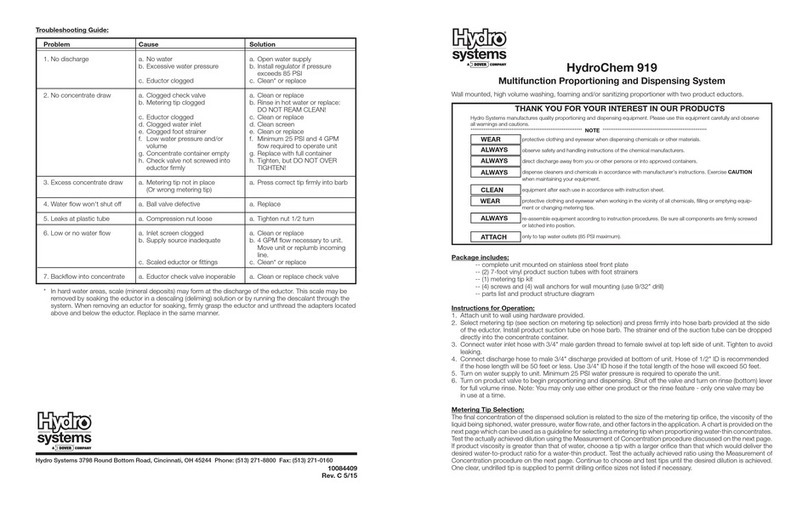

Troubleshooting Chart:

*In hard water areas, scale may form inside the discharge end of the eductor, as well as in other areas of the unit that

are exposed to water. This scale may be removed by soaking the eductor in a descaling solution (deliming solution). To

remove an eductor located in the cabinet, firmly grasp water valve and unthread eductor. Replace in same manner.

Alternatively, a scaled eductor can be cleaned (or kept from scaling) by drawing the descaling solution through the unit.

Operate the unit with the suction tube in the descaling solution. Operate the unit until solution is drawn consistently, then

flush the unit by drawing clear water through it for a minute. Replace concentrate container and put suction tube into

concentrate.

1. No discharge a. No water a. Open water supply

b. Magnetic valve not functioning b. Install valve parts kit

c. Excessive water pressure c. Install regulator if water pressure exceeds

60 PSI (flowing)

d. Eductor clogged d. Clean* or replace

2. No concentrate draw a. Clogged foot valve a. Clean or replace

b. Metering tip or eductor has b. Clean (descale)* or replace

scale build-up

c. Low water pressure c. Minimum 20 PSI (with water running)

required to operate unit properly

d. Discharge tube not in place d. Push tube firmly onto eductor discharge

hose barb

e. Concentrate container empty e. Replace with full container

f. Inlet hose barb not screwed f. Tighten, but do not overtighten

into eductor tightly

g. Clogged water inlet strainer g. Disconnect inlet water line and clean

strainer

3. Excess concentrate draw a. Metering tip not in place a. Press correct tip firmly into barb on

eductor

b. Chemical above eductor b. Place concentrate below the eductor

4. Failure of unit to turn off a. Water valve parts dirty or a. Clean* or replace with valve parts kit

defective

b. Magnet doesn't fully return b. Make sure magnet moves freely.

c. Push button stuck c. Remove button and clean cabinet/button

to remove any dirt lodged in slide recess

5. Excess foaming in discharge a. Air leak in pick-up tube a. Put clamp on tube or replace tube if brittle

6. Water discharge from air a. Restricted discharge hose a. Be sure discharge tube is not immersed,

vents on eductor kinked or elevated. Be sure there is no

liquid in the discharge tube when begin-

ning to operate dispenser

b. High water pressure b. Install pressure regulator if flowing water

pressure exceeds 60 PSI (flowing)

SolutionCause

Problem

THANK YOU FOR YOUR INTEREST IN OUR PRODUCTS

Please use this equipment carefully and observe all warnings and cautions.

******************************************************NOTE****************************************************

protective clothing and eyewear when dispensing chemicals or other materials.

observe safety and handling instructions of the chemical manufacturers.

direct discharge away from you or other persons or into approved containers.

dispense cleaners and chemicals in accordance with manufacturer's

instructions. Exercise CAUTION when maintaining your equipment.

equipment clean to maintain proper operation.

protective clothing and eyewear when working in the vicinity of all

chemicals, filling or emptying equipment or changing metering tips.

re-assemble equipment according to instruction procedures. Be sure all

components are firmly screwed or latched into position.

only to tap water outlets (85 PSI maximum).

ALWAYS

ALWAYS

ALWAYS

WEAR

ALWAYS

WEAR

KEEP

ATTACH