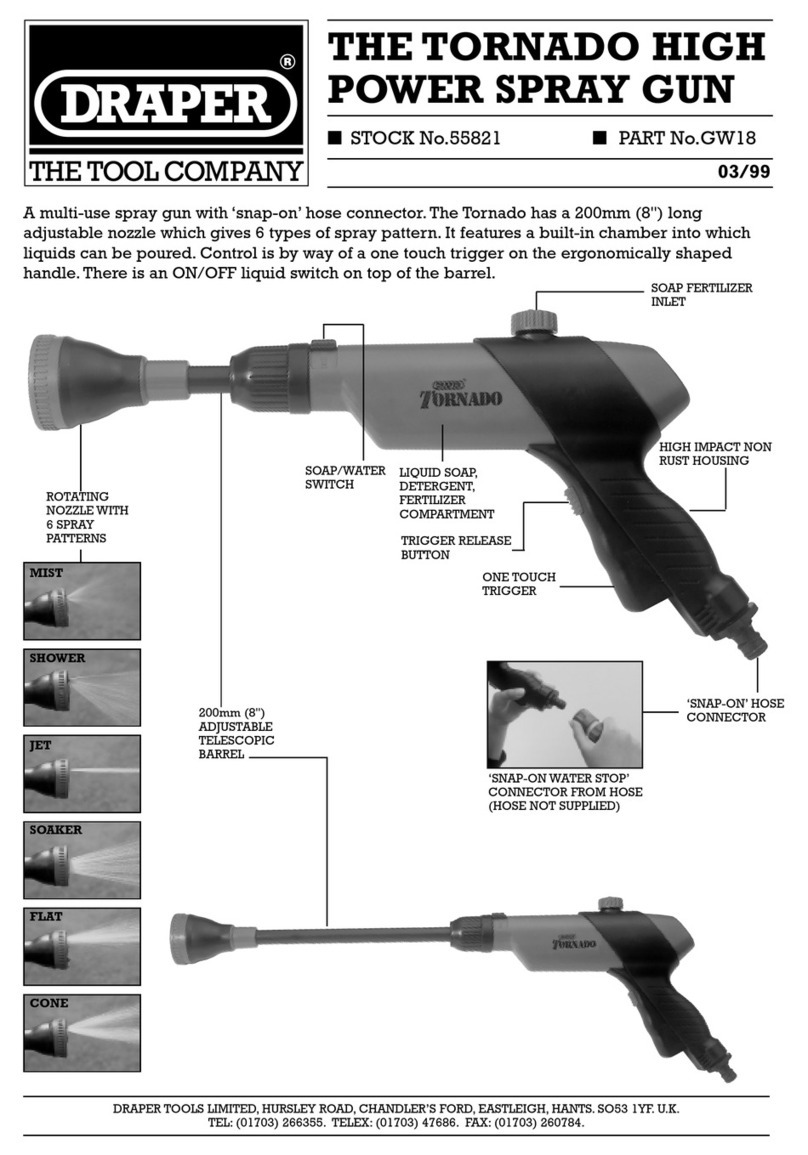

Connect the painting cup complete with material. Before operating ensure the air

pressure and material to be sprayed is suitable for this product. Do not connect

air hose until you are absolutey ready to begin work.

• The paint quantity sprayed maybe increased or decreased using the fluid

control knob ✪✌, Fig.1.

• The spray pattern maybe adjusted from a round pattern to a fan pattern

turning

the knob ✫✌, Fig.1 left or right. For the fan pattern the operating pressure may

have to be increased slightly.

• Hold the gun at a right angle to the working surface and move it parallel.

• Keep the gun about 6-10 inches away from the surface (depending on the

material and operating pressure), see Fig.2.

• Start the stroke before squeezing trigger and release it just after ending the

stroke.

• Always keep the material deposited even and wet.

• Operate at the correct air pressure for a fine finish and safe performance.

Never exceed the maximum operating pressure.

WARNING WHEN SPRAYING:

• Do not spray in enclosed areas and maintain good ventilation.

• Never spray close to or in the proximity of a naked flame.

• Always use suitable eye protection.

• Wear an appropriate face mask.

OPERATION

WHY USE HVLP ?

HVLP (High Volume Low

Pressure) spraying

equipment has been

developed as a result of the

introduction of the

Environmental Protection Act

1990. This legislation is aimed at

cutting solvent emissions

produced from both commercial

and car refinish products.

HVLP equipment uses less

air (less the 10psi, 0.69 bar at

the air cap), but with a higher

throughput resulting in more

paint staying on the workpiece

and less being released into the

atmosphere. With traditional

spray guns there is a

tendency for the automized

paint and solvent to bounce off

the workpiece and pollute the

atmosphere.

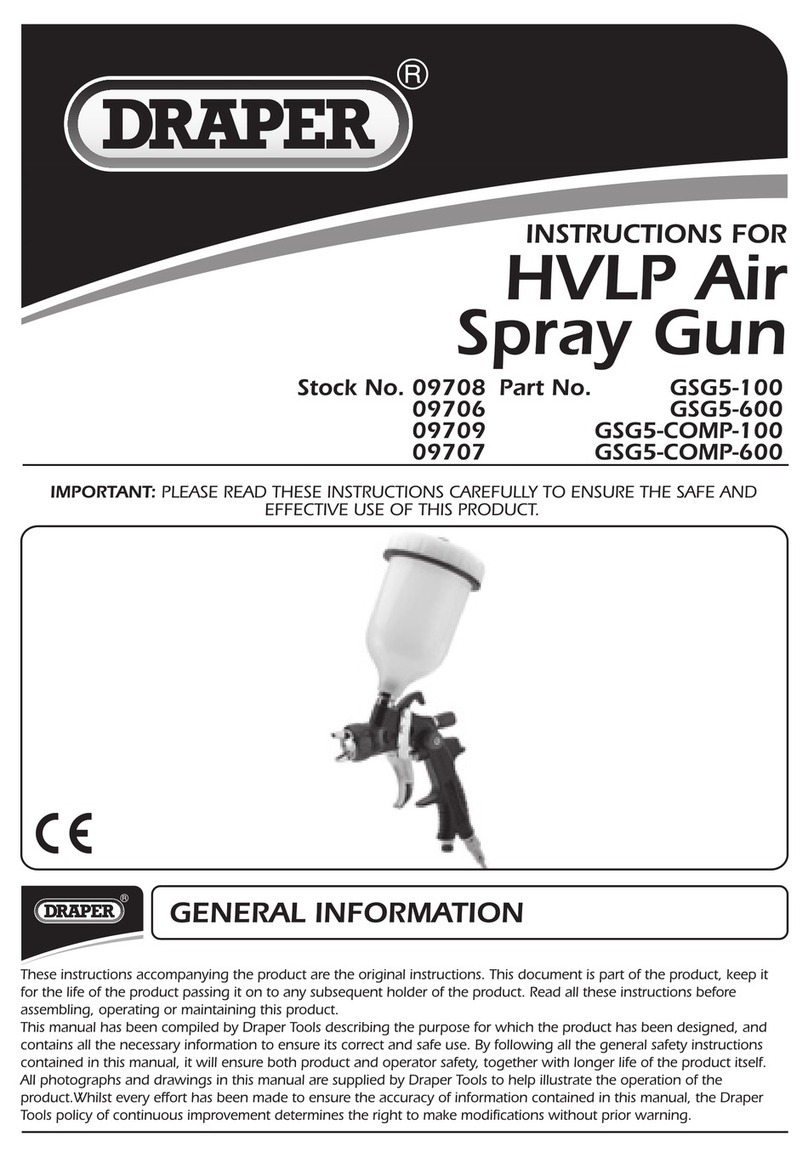

HVLP SPRAY GUN

STOCK No.54436/54437. PART No.HVLP2/HVLP3.

Operating air pressure ....................22 to 38psi/1.5–2.6 bar

Air consumption....................................................14-17cfm

Air inlet .....................................................................1⁄4" BSP

Cup capacity: HVLP2 ..............................................1 Litre

HVLP3 ...............................................600cc

Nozzle: HVLP2..............................................1.9mm

HVLP3..............................................1.5mm

Weight: HVLP2..............................................1048g.

HVLP3................................................762g.

SPECIFICATION DECLARATION OF

CONFORMITY

We Draper Tools Ltd. Declare under our sole

responsibility that the product:

Part No:- HVLP2/HVLP3. Stock No:- 54436/54437.

Description:- Spray gun.

To which this declaration relates is in conformity with the

following directive(s):-

89/392/EEC, 91/368/EEC, 93/44/EEC and 93/68/EEC.

With reference to EN414 (point 8), EN292.1(4.9), EN292.2(3.6).

J.N. DRAPER

Managing Director 10/97

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY TO ENSURE THE SAFE AND

EFFECTIVE USE OF THIS TOOL.

This spray gun is manufactured from quality materials and carefully checked by the manufacturer before its despatch.

To get the best from this quality product read the following instructions carefully before operating your spray gun.

• It is advisable to lubricate the needle with oil at the beginning of the working day. The operation is quite simple and it

increases its durability and working order.

• Never remove nozzle No.2 with universal pliers, only use the hexagonal wrench, take care not to damage the nozzle.

• The ideal working pressure is stated in the above specification table. It can vary though, according to the density of the

paint.

NOTE: Maximum operating pressure 38psi (2.6 bar).

CORRECT

INCORRECT

15-25cm

(6-10 inch)

Fig.2.

Fig.3. Fig.5.

Fig.4.

Fig.1.

HIGH PRESSURE

HVLP

FLUID

LINE

AIR

LINE

AIR

SUPPLY

PRESSURE TANK

WIDER

SPRAY

PATTERN

NORMAL

SPRAY

PATTERN

NARROW

SPRAY

PATTERN

45ºROUND JET

VERTICAL JET

HORIZONTAL JET

6"

8"

05/98