disassembled or opened, cleaned with a small brush, and at the same time, use a vacuum cleaner

to absorb the dust in each part. For the negative high-voltage power cord of the photomultiplier

tube, the high-voltage cords and connectors of the computer monitor, use gauze moistened with

a little absolute alcohol to carefully wipe off the carbon and dust.

For the dust removal of the instrument, the help of electronic instrument repair professionals. If

the user or manager of the instrument does not understand the structure of the instrument, do

not move it easily to avoid accidents. The dust removal should be carried out before stopping and

turning off the power supply.

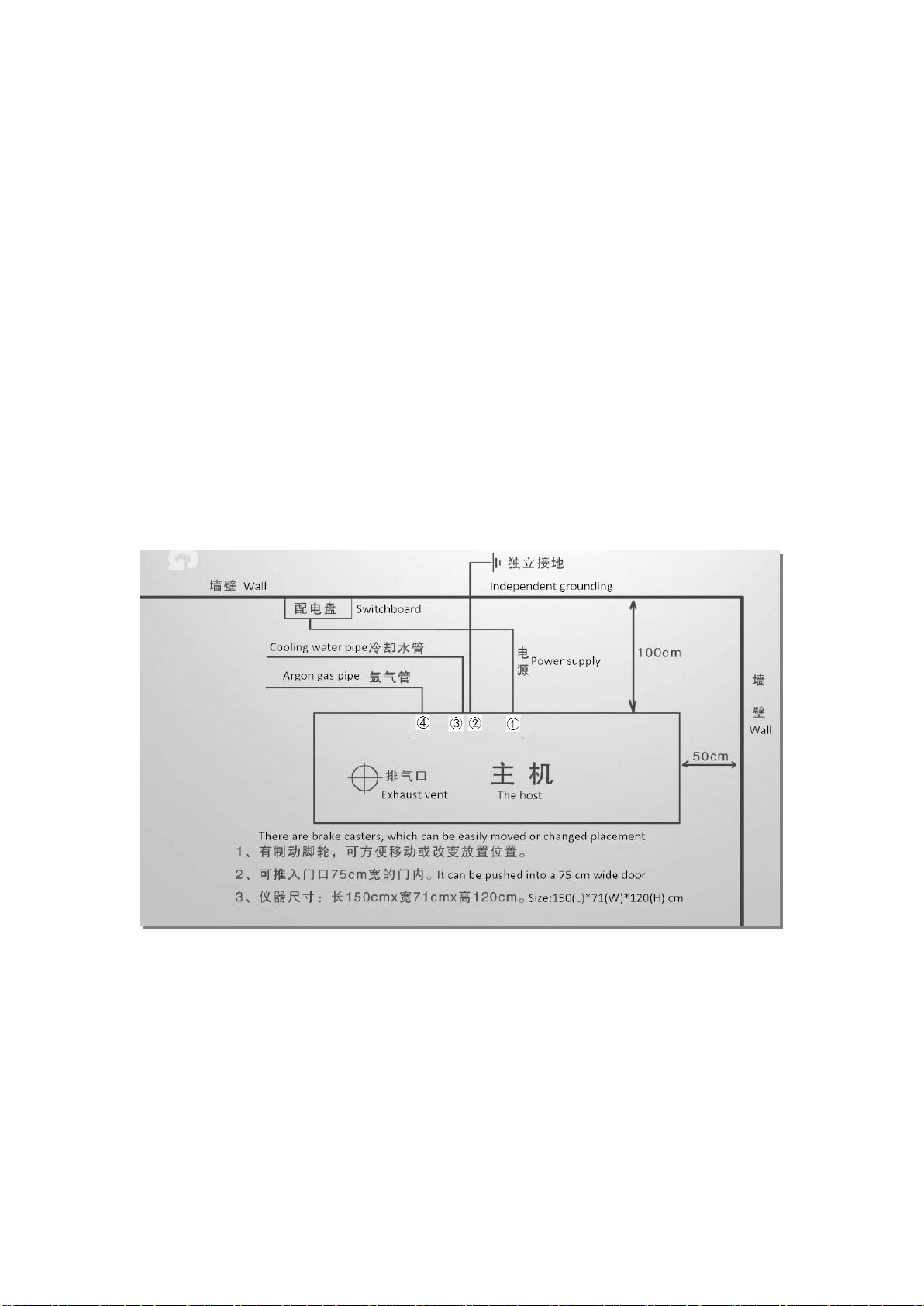

2.2 Power Supply and Auxiliary Material Configuration

2.2.1 Stable Power Supply System

In order to ensure the safe operation of the ICP-AES, the power supply line must have a large

enough capacity, otherwise the voltage drop of the line during the operation of the instrument is

too large, which will affect the life of the instrument. As a precision measuring instrument, it also

needs a relatively stable power supply, and the change in power supply voltage generally does

not exceed ±1%, If it exceeds this range, you need to use a precision purified AC power supply, as

the general voltage stabilizer generates clipping when the voltage is high, it causes electric pulses,

which affects the work of electronic computers, microprocessors and phase sensitive amplifiers,

and causes malfunctions. The continuous sine wave power supply can ensure the normal

operation of these electronic circuits. The power supply circuit of the instrument should be

obtained separately from the distribution board of the power supply transformer. Try not to

share a power supply line with large motors, large ventilators, air conditioners, muffle furnaces

and other large electrical equipment. In order to avoid large fluctuations in the voltage of the

power supply line when these electrical equipment are started, resulting in unstable operation of

the instrument. Generally, the ground wire resistance of the spectrometer should be less than 4Ω,

and the computer ground wire resistance should be less than 0.25Ω(ASTM) to prevent mutual

interference.

In the operation of the instrument, the operator should always pay attention to the change of the

power supply voltage, and you cannot work under over-voltage or under-voltage for a long time.

When the instrument works under over-voltage, the life of the tube will be greatly

shortened(below 20% of the normal life). If working under the condition of insufficient voltage,

the temperature of the electron tube filament is too low, it will also easily cause the aging of the

electron emission material, and also shorten the life of the electron tube. Large fluctuations of

the power supply voltage during the operation of the instrument will also cause the instability of

the output power of the high-frequency generator, which will have a great impact on the

measurement results. Therefore, the quality of the power supply must be guaranteed.

2.2.2 Power Requirements

DW-TY-9900 ICP-AES needs AC single-phase 220V/50Hz power supply. If the voltage fluctuation is

greater than ±1V, it needs to be equipped with 10KVA precision purification AC regulated power

supply(output accuracy ≤±1%, response time ˂ 20-80ms). The power requirements of each part

are as follows:

DW-TY-9900 ICP-AES host: single-phase AC(220±1)V/50Hz, 2kVA(The wire cross section is not

less than 4mm2).

Microcomputer system:single-phase AC(220±1)V/50Hz, 500VA

Cooling water tank:single-phase AC(220±1)V/50Hz, 1.5kVA