SVI II AP Instruction Manual

iv

DRAFT 6/8/10

Dresser Masoneilan

Wiring the SVI II AP.................................................................................................................... 33

Connecting to the Control Loop............................................................................................ 33

Verify Wiring and Connections.............................................................................................. 33

3: Check Out and Power Up ............................................................................................................ 35

Overview..................................................................................................................................... 35

Position Sensor Principles.......................................................................................................... 35

Check Out Procedures................................................................................................................ 36

Physical Inspection..................................................................................................................... 36

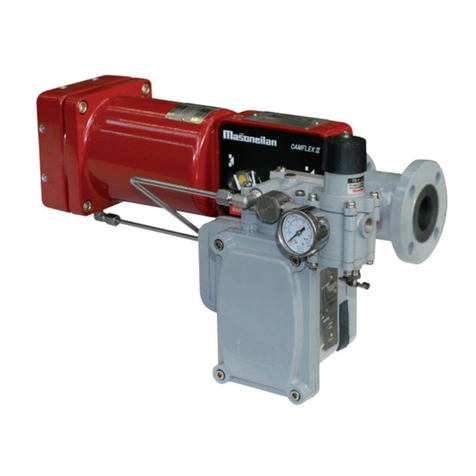

Actuator, Linkages, or Rotary Adapter.................................................................................. 36

Verify Mounting and Linkage Adjustment .............................................................................37

Checking the Magnet............................................................................................................37

Checking the Air Supply........................................................................................................39

Checking the Electronic Module Connections ...................................................................... 40

Operational Checkout................................................................................................................. 42

Connecting to the Current Source ........................................................................................ 42

Powering Up the SVI II AP.................................................................................................... 42

Pushbutton Locks and Configuration-Lock Jumper..............................................................43

4: Using the Digital Interfaces .......................................................................................................... 45

Overview..................................................................................................................................... 45

Local Display and Pushbuttons.............................................................................................45

HART Handheld Communicator ........................................................................................... 45

ValVue .................................................................................................................................. 46

Pushbuttons and Local Display...................................................................................................46

Pushbuttons.......................................................................................................................... 47

Display Menus ............................................................................................................................ 49

NORMAL Operating Mode and MANUAL Mode Menus.......................................................49

Configure Menu .................................................................................................................... 50

Calibration Menu................................................................................................................... 54

VIEW DATA Menu................................................................................................................ 55

FAILSAFE Mode...................................................................................................................57

VIEW ERR Diagnostics Messages....................................................................................... 58

Display and Clear Error Messages............................................................................................. 61

Positioner Fault Messages....................................................................................................61

Return to Normal Operation.................................................................................................. 62

Hand Held Communicator........................................................................................................... 62

ValVue ........................................................................................................................................ 63

Installation of ValVue Software, and Registration.................................................................63

System Requirements........................................................................................................... 64

5: Configuration and Calibration ...................................................................................................... 65

Configuration and Calibration ..................................................................................................... 65

ValVue Software................................................................................................................... 65

Pushbuttons and Local Display for Configuration and Calibration........................................ 66

Pushbuttons Summary.......................................................................................................... 66

Pushbutton Locks and Configuration-Lock Jumper..............................................................67

Hardware Configuration Lock ............................................................................................... 67