Instruction ES2007 4/98

Models 4700P and 4700E

4

or reverse action (increasing instrument signal produces

a decrease in output pressure). See Figures 2 and 3.

Note that the 4700E is not available with reverse action,

hence if the application demands reverse action, a 4700P

with an external I/P Transducer is required.

CAUTION: When installing a positioner on a

valve, it is necessary to choose the proper valve

action and positioner action. It is absolutely

necessary to place valve travel at the point

corresponding to the low end of the signal range

when removing or installing a cam. At this point,

feedback spring compression is at lowest value

and will facilitate cam removal or installation.

Prior to performing any work, read and under-

stand all items under “General Description and

Operation” and under “Mounting and Orienta-

tion.” Define the scope of work to be performed

and find the appropriate section that should be

followed.

The 4700 series Positioners have the same mounting

and linkage attachment dimensions as the 4600, 4600A,

4600B and 4700B series Positioners but have a different

layout of pneumatic connections. They can replace the

older models if operational requirements are identical and

pneumaticconnectionsarechanged. Themountingdetails

in this instruction cover only the more widely used valves

and actuators.

Cover Removal

The snap-on cover must be removed to access the zero

and span adjustments and to mount the positioner on the

valve.

To remove the cover, depress the latch bar inward as

shown in the figure below, pull cover away from body until

latch tab is clear, then pull along body axis to free the two

top locking tabs.

Optional Bypass Valve

(4700P, Direct Acting Model only)

During normal operation, the instrument signal is applied

directly to the positioner diaphragm and the regulated

supply pressure flows through the pilot valve to or from

the actuator.

The bypass valve module permits the positioner to be

isolated for maintenance while operating the valve directly

with the instrument signal. By turning the nylon bypass

valvetothebypassposition(theraisedarrowonthebypass

valvealignedwiththeword“Bypass”onthefacepositioner

bodyindicatesthisposition),thenormalpositioner“output”

pressure to the actuator is blocked and the instrument

signal is applied both to the positioner diaphragm and the

actuator. Thebypassvalvedoesnotblocksupplypressure

to the pilot. Therefore, the supply line should be shut off

before disassembling the positioner.

WARNING: When a valve (because of high pres-

suredrop)uses a supply pressure higher than 20

psig, the 3-15 psig instrument signal may not be

sufficient to operate the valve when the posi-

tioner is bypassed. Moreover, if the positioner

with a high supply pressure is bypassed sud-

denly, the high pressure in the actuator may

damage the diaphragm and/or the control instru-

ment. Therefore, the bypass valve should be

used only if the positioner supply pressure is 20

psig (140 kPa or 1, 4 bar), or at most 35 psig (240

kPa, or 2, 4 bar), or if the controller is capable of

operating the valve directly. When bypassing a

positioner, ensure that the controller output is

equal to supply required to operate valve.

Installation

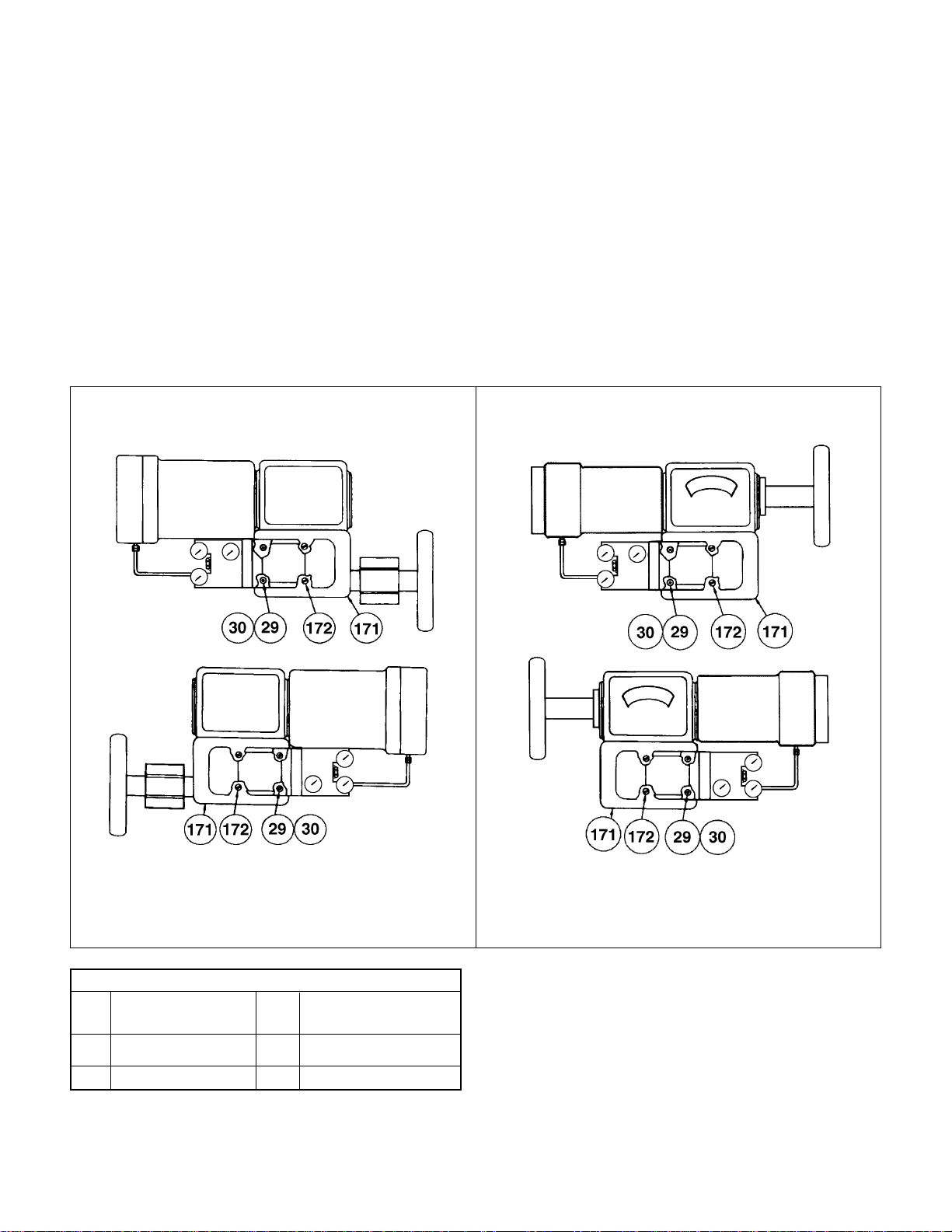

Mounting and Orientation (Figures 2-10)

Thevalveisinstalledinthepipelinetooperateinoneoftwo

ways:

Air to Open Air to Close

Close on air failure Open on air failure

(Reverse Action) (Direct Action)

The choice depends on the desired air failure action. This

subject is dealt with in separate actuator instructions. The

positioner can operate either by direct action (increasing

instrumentsignalproducesanincreaseinoutputpressure)

Figure 1 - Cover Removal

Latch

Bar

Locking

Tabs