5MSFI - F801306

Pumping Elements and Looming

The MulLine SFi kits are pre-calibrated with MSFI-P-B040, blue, pumping elements (0.04cc output per stroke). The 110/220 VAC

pump’s integrally adjustable mer is preset to seng #3 (6min run and 30min delay). The 12/24 VDC pump’s externally adjustable mer

is preset to seng #4 (3min run and 27min delay). A selecon of pumping elements with varying outputs are available to suit almost

any need:

Overview:

The MulLine SFi kits are pre-loomed from the pumping element to the bulkhead connecons on the pump bracket. The push-t

connectors provide an easy installaon of the lines to the bulkhead connectors. The lubricaon line should be Groeneveld-BEKA ø4mm,

semi-rigid, nylon tubing. It is recommended that the tubing is pre-lled with grease to save on the need to prime the system once

installed.

From the pump posion establish the most convenient route for the lubricaon lines. It may be preferred to group the lines into looms

depending on pump locaon and quanty and posioning of the grease points. If grouping the lines into looms, allow sucient length

for connecon to the bulkhead outlet connectors and the bearings, making an allowance for movement on the machinery. In conjunc-

on with the ‘Installaon Record’ sheet (see page 18), t the number idencaon sleeves to the lines at the pump and bearing ends.

The loom should be protected along its length with the conduit/spiral binding/sleeving and/or tape (for part numbers see Accessories on

page 16).

Installaon:

Working from the furthest point from the pump, feed the lubricaon lines through the machine following exisng machine services

where possible. Ensure that the lubricaon lines are posioned to t the bearing ngs. Where a bearing is on a moving part, ensure

that the line is sucient to allow for full movement. To avoid rubbing or fricon with moving parts, grommets or protecve sleeving

should be used. Also, depending on the severity of movement, compression ngs may be preferred at the bearing points.

Connecng the lines:

Cut each lubricaon line to length ensuring a clean, square cut is achieved and connect to the bearing using push t or compression

connectors. Ensure tubing is pushed rmly into connector. Test the assembly by pulling rmly on the line aer installaon.

To connect to bulkhead ngs on the pump bracket follow steps 1-3 as shown above. Remove plug from bulkhead and push the line

rmly into the bulkhead. Again, ensure tubing is pushed rmly into connector. Test the assembly by pulling rmly on the line aer instal-

laon. Using the ‘Installaon Record’ sheet (see page 18) connect the lines to the corresponding numbered pumping elements.

Note: All damaged lubricaon lines should be replaced using genuine spare parts, failure to do so can cause system malfuncons and

major safety issues.

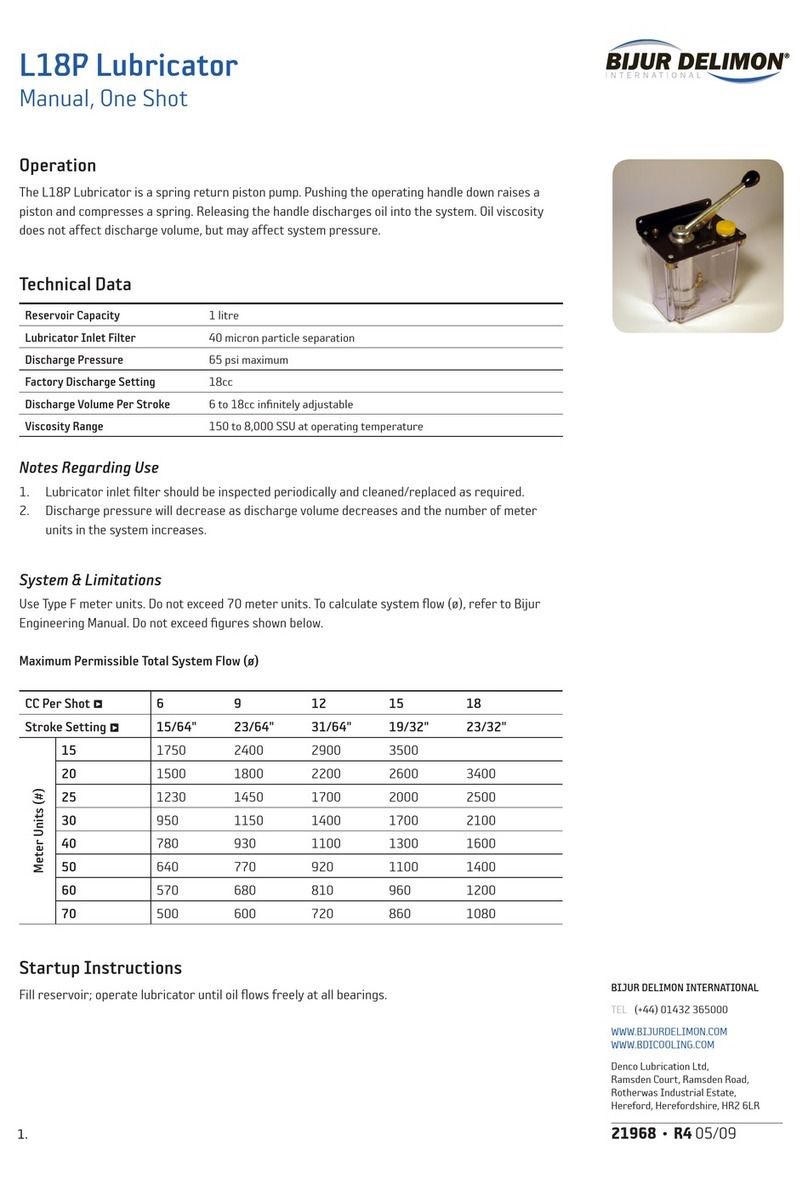

Output pressure

Maximum output pressure from each

pumping element 1740PSI/120 Bar

Standard pump elements for AXL pumps.

Part No. Output/stroke Color Size

MSF-P-R010 0.010 cc Red

Ø4mm

Push-Lock

MSF-P-G015 0.015 cc Green

MSF-P-Y025 0.025 cc Yellow

MSF-P-B040 0.040 cc Blue

MSF-P-G060 0.060 cc Grey

MSF-P-B100 0.10 cc Black

1

REMOVE

2

POSITION LUBRICATION

3

INSERT LUBRICATION

Making the Looms and Connecons