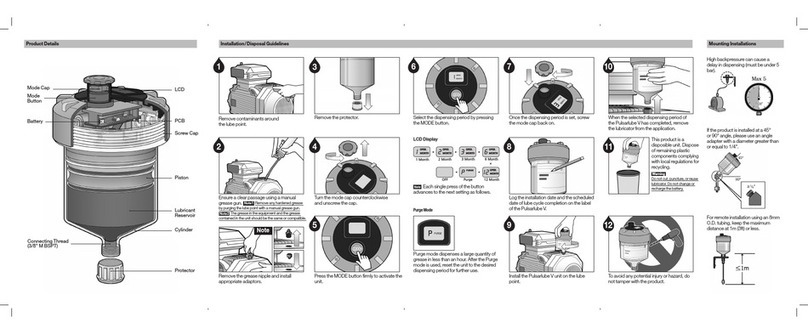

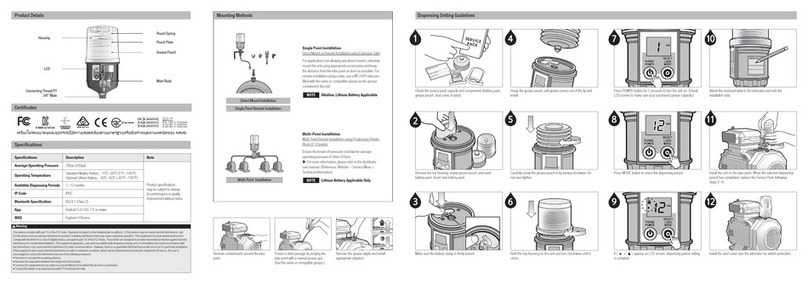

Press to power on press to select

the grease capacity press to set

desired dispensing period.

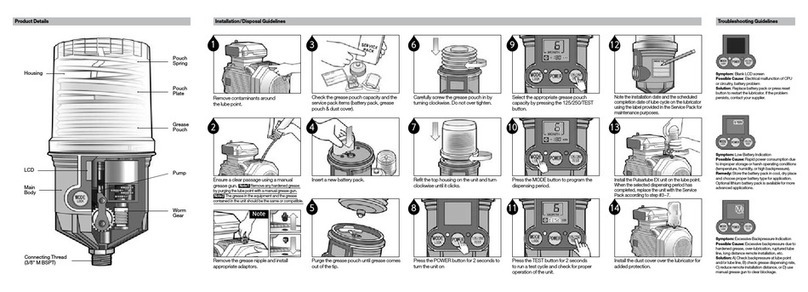

Remove contaminants around the lube

point.

Install the lubricator on the lube point.

After setting the sensor level, set up is

completed if you can see 1) the lock icon 2)

remaining days 3) set dispensing period and

4) grease capacity on the LCD.

Connect the cable of lubricator and the

sensor box cable.

Position the sensor box vertically and align it

to the shaft of the motor. The cap should be

positioned facing downwards.

Installation GuidelinesProduct Details

Insert the battery pack, secure the battery

clip, and purge the grease pouch until

grease comes out of the tip.

Note the installation date and the

completion date of lube cycle on the

label. Install the dust cover over the

lubricator.

Check the grease pouch capacity and

the service pack items (battery pack,

grease pouch, dust cover & label).

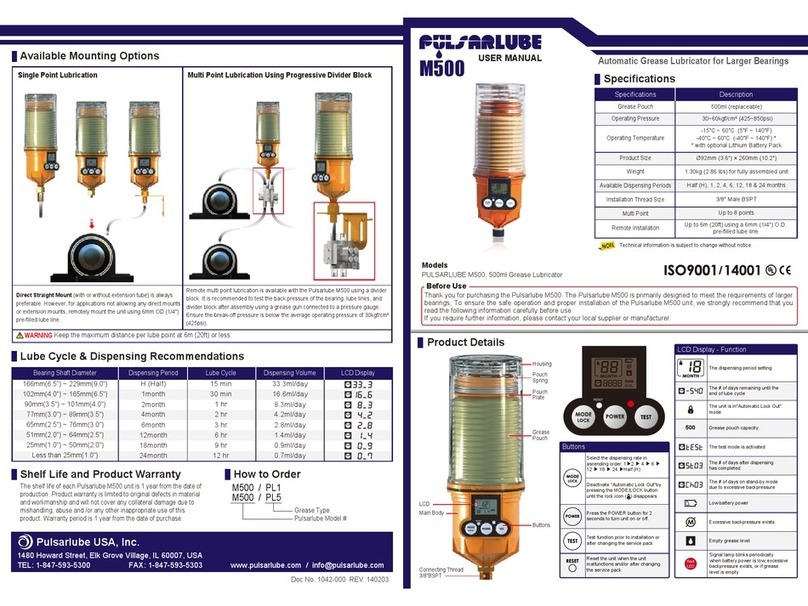

Housing

Pouch Spring

Pouch Plate

Grease Pouch

LCD

Sensor Box

(Vibration Detector)

Main Body

Connecting Thread

(3/8" M BSPT)

1 14

6

7

Install the dust cover over the lubricator for

added protection.

52

2

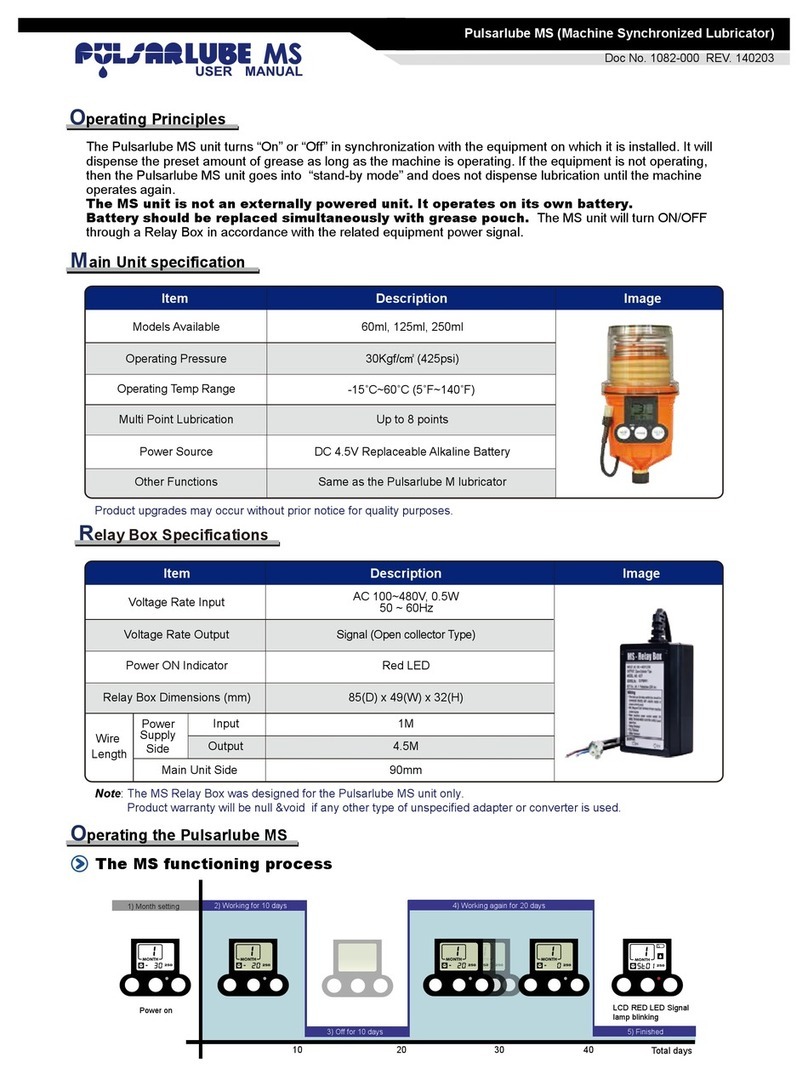

When the equipment is in operation,

the clock icon will be displayed.

When the equipment is in operation,

the clock icon remains off.

When the equipment is not in operation,

only the lock icon will be displayed.

When the equipment is not in operation,

all icons are displayed.

4. Set the dial to the lowest sensitivity until

the clock icon and red LED are displayed.

5. Repeat steps above, as necessary, to

ensure that vibration is correctly being

detected. If you fail to set the correct sensor

level, relocate the sensor box and try again.

How To Replace Service Pack

How To Adjust Sensor Level

LCD Display During Proper Synchronization

LCD Display During Improper Synchronization

Ensure a clear passage by purging the

lube point with a manual grease gun.

(Use the same or compatible grease.)

Hold and press to start Vibration

Detection Mode. Refer to the instructions

"How To Adjust Sensor Level"

3

3

8

9

1. Open the yellow cap of sensor box.

3. Turn the dial to lower and to raise

vibration sensitivity. 0 is the lowest

sensitivity and 10 is the highest sensitivity.

(Factory default setting: 10)

Carefully screw the grease pouch in

without over-tightening and ret the

housing until it clicks.

POWER

POWER

TEST

MODE

MODE

2. Hold and press to start Vibration

Detection Mode. It will last for 60 seconds.

POWER MODE

NOTE

If the unit is not operating in synchronization

properly, adjust and/or relocate the sensor box.

If the problem persists, contact your local distributor

or sales rep.

4

NOTE

The vibration detector checks for

vibration in 1 hour cycle.