BONDIS Easylube 150 Classic User manual

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

Easylube® 150 Classic –Service

Guide

Re-usable single-point automatic lubricator

Step 1. Preparation:

► If you purchased empty grease cup, fill the cup with lubricant as below.

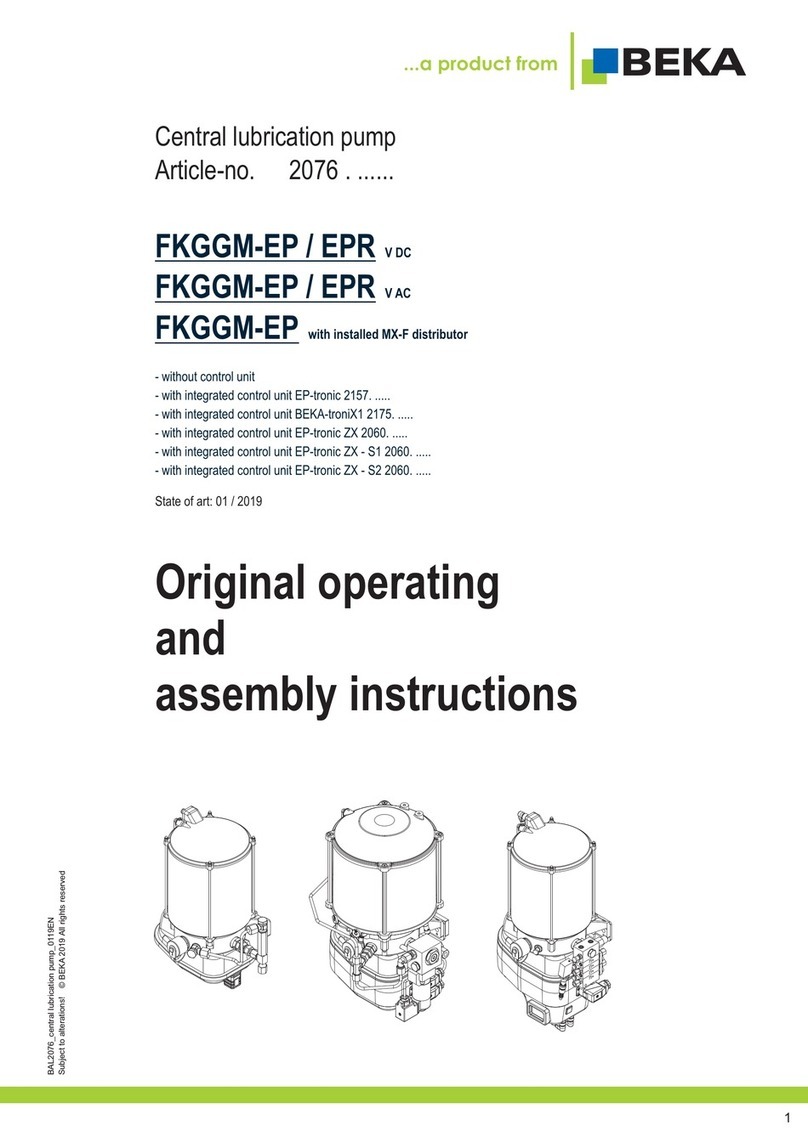

Caution :

If the cup is being filled for the first time, the red piston must be pressed down to bleedair. Fillthe

empty grease cup until the red piston reaches the top and in a level position.

Step 2. Position the press plate:

►Facing the bottom of the body assembly, turn the press late clockwise until it seats.

► Next, rotate the press plate counterclockwise with a ¾ turn.

► Screw the prefilled grease cup into the body assembly securely and make sure the pressplate

touches the red piston in the cup. If done properly, a small amount of grease is supposed to

discharge when the cup is securely screwed in.

Caution :

Falling to engage the press plate and the red piston will disable the piston movement and result

in zero grease output after start-up.

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

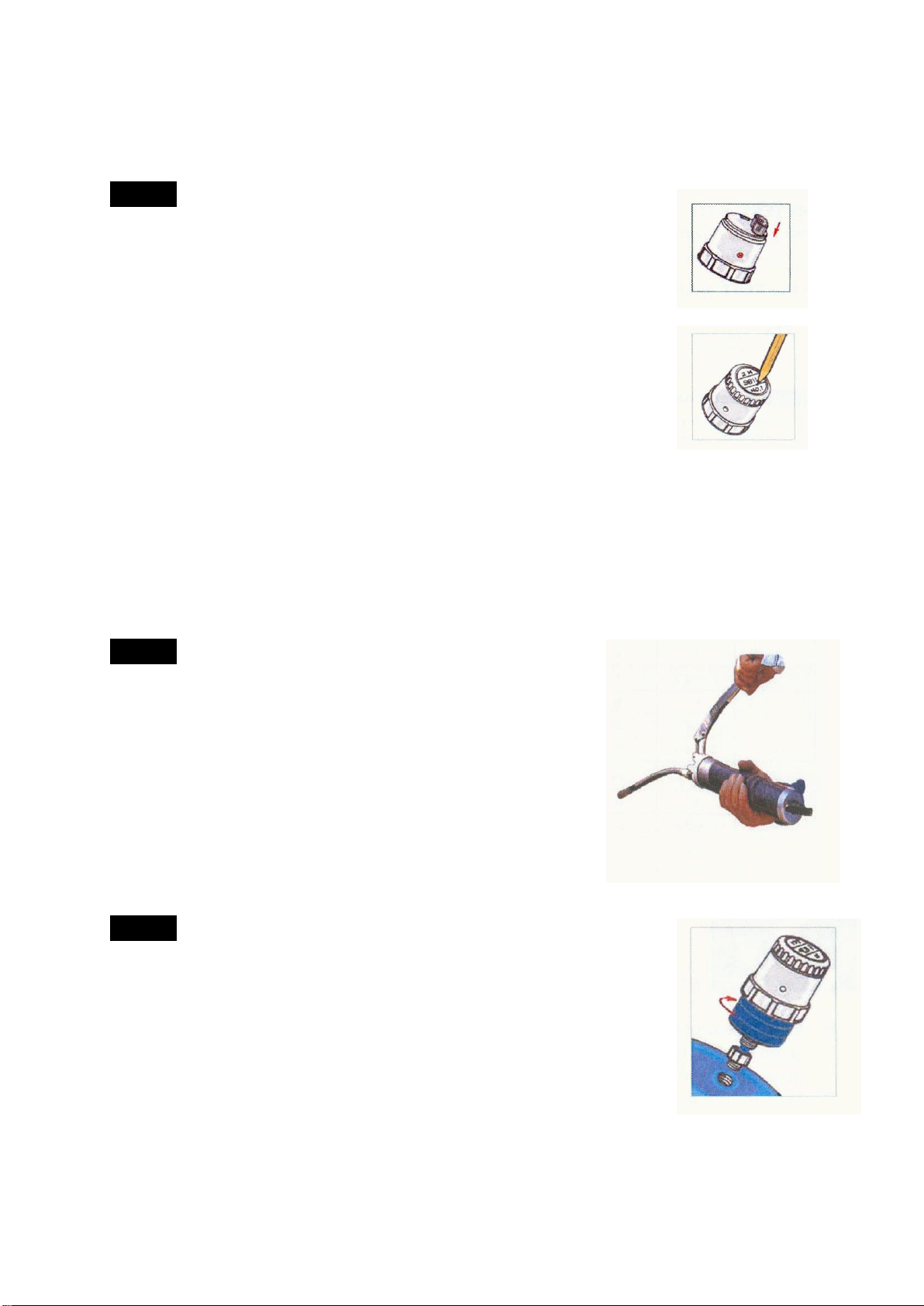

Step 3. Test Easylube before installation:

► The Easylube can be tested by setting all four DIP switches to the ON

position. Use a ball pen or similar tool ( small screwdriver).

► In this test mode the Easylube will cycle 7 to 8 seconds moving the red piston

downward automatically. A small amount of grease should be discharged.

► After the test mode is successfully completed, go to step 4.

Caution:

Whenever the red indicator light is flashing during test mode, remove the

battery and reset the DIP switches, then put the battery back to restart.

Step 4. Set/change the dispense period time:

► Remove the battery from the body assembly.

► Set the levers on the switch to correspond to the time perod required.

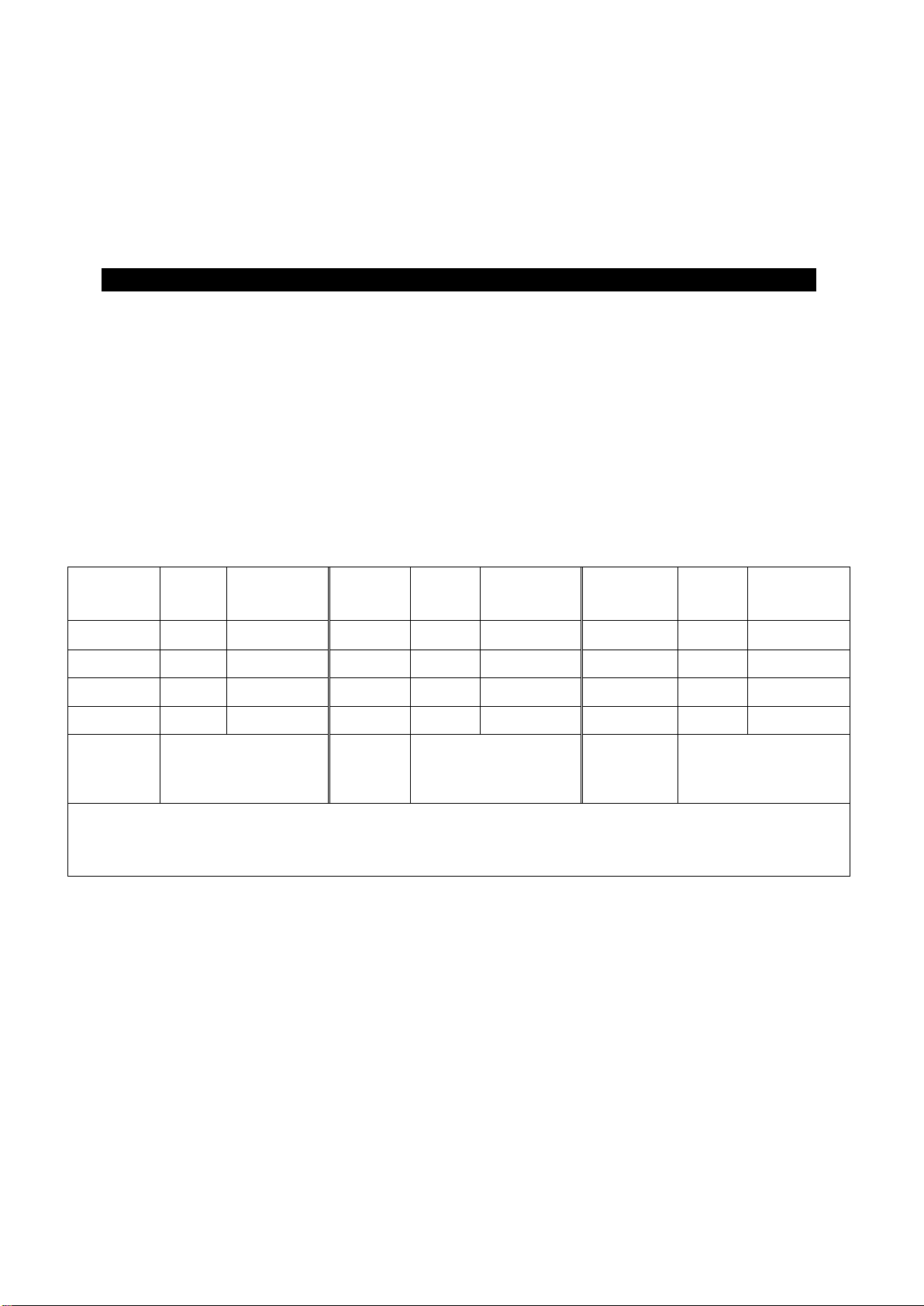

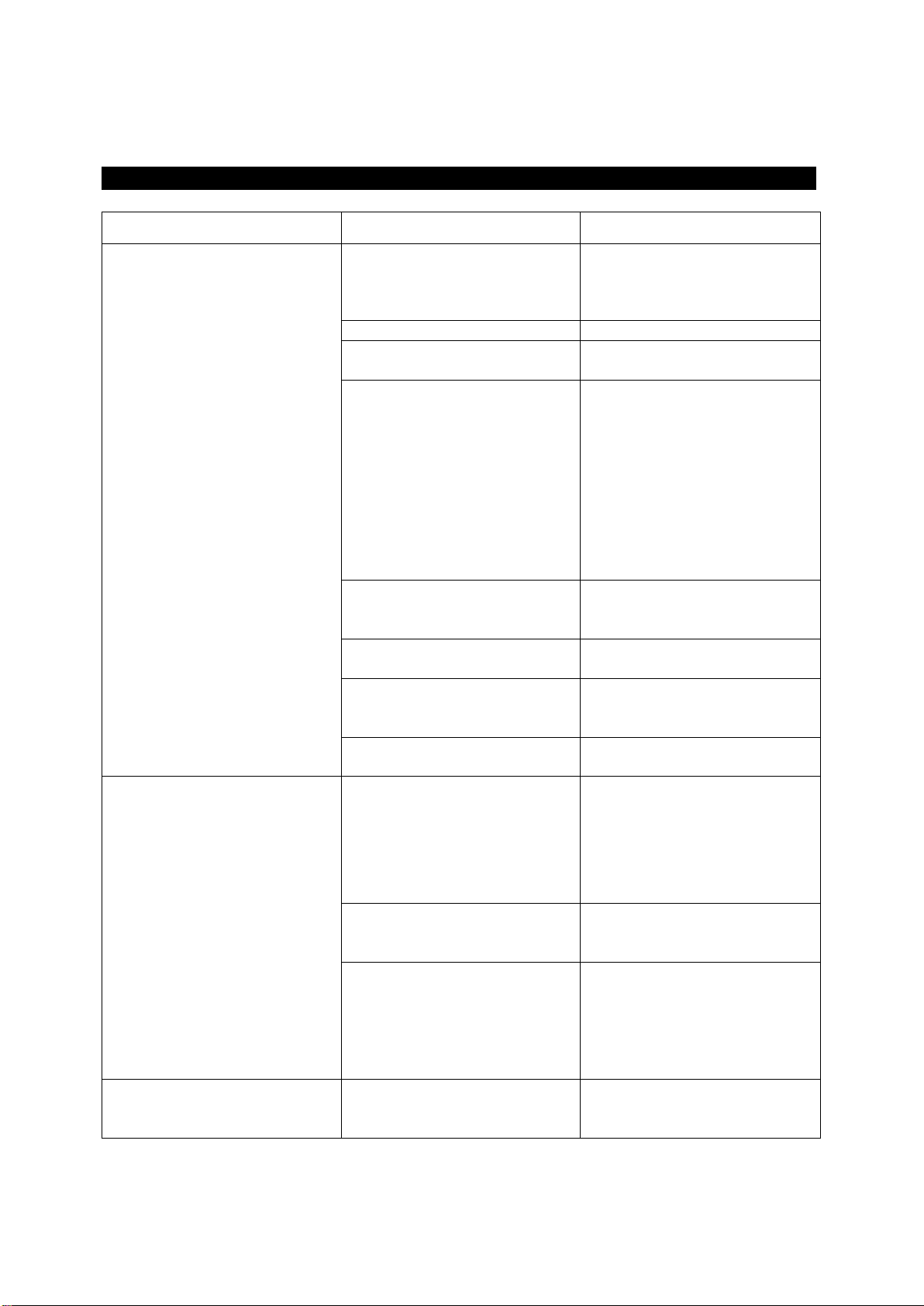

Table 1. DIP-switch setting for dispense period time

Dispense

period

DIP switch

“ON”

Time span

between cycles

Amount/

cycle

Amount/

day

Amount/

week

Amount/

month

Month

Hours

ml

ml

ml

ml

1

1

2

0.417

5

35

150

2

2

4

2.5

17.5

75

3

1+2

6

1.67

11.67

50

4

4

8

1.25

8.75

37.5

5

1+4

10

1.00

7.00

30

6

2+4

12

0.83

5.83

25

7

1+2+4

14

0.71

5.00

21.43

8

8

16

0.63

4.38

18.75

9

1+8

18

0.56

3.89

16.67

10

2+8

20

0.50

3.50

15

11

1+2+8

22

0.45

3.18

13.64

12

4+8

24

0.42

2.92

12.5

The lubricator can be set to any of 12 (represents months) dispensing periods. It will be emptyat

the end of the chosen setting. Each monthlysetting dispenses the same amount oflubricant per

cycle, but at a different frequency.

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

Step 5. Start Easylube:

► Install the battery back into the body assembly to start Easylube.

► The red indicator light on the body illuminates for 5 seconds and then

goes out. This indicates the lubricator has been started correctly.

► Screw the cover onto the body securely.

► Record the following on the cover label :

dispensing period setting

type of lubricant

date of installation

► After the start, Easylube will turn into “sleep” ode and the timer starts to count till each cycle

time is up for the dispensing.

Caution:

Every time the DIP switches are reset, the battery must be removed for approximately 15

seconds to clear the CPU memory.

Step 6. Installation/ preparation:

► Flush the bearing and the pipeline completely with same grease

or compatible with that in the prefilled grease cup.

► The flushing process mustbe done slowly stroke by stroke to

detect any potential blocking in the pipeline or bearing. When a

power stroke is required to push the grease through, this might

indicate a jam or blockage..

►Feed the fresh grease into the bearing until the used grease is

completely purged.

Step 7. Direct mount:

Caution:

If one of the folliwng conditions, please do not direct mount Easylube onto

bearings:

(1) The ambient temperatue is over 60°C.

(2) The bearing pipe thread is 6 mm, 1/16” or less.

(3) Bearings are in difficult to access areas or hazardous environment.

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

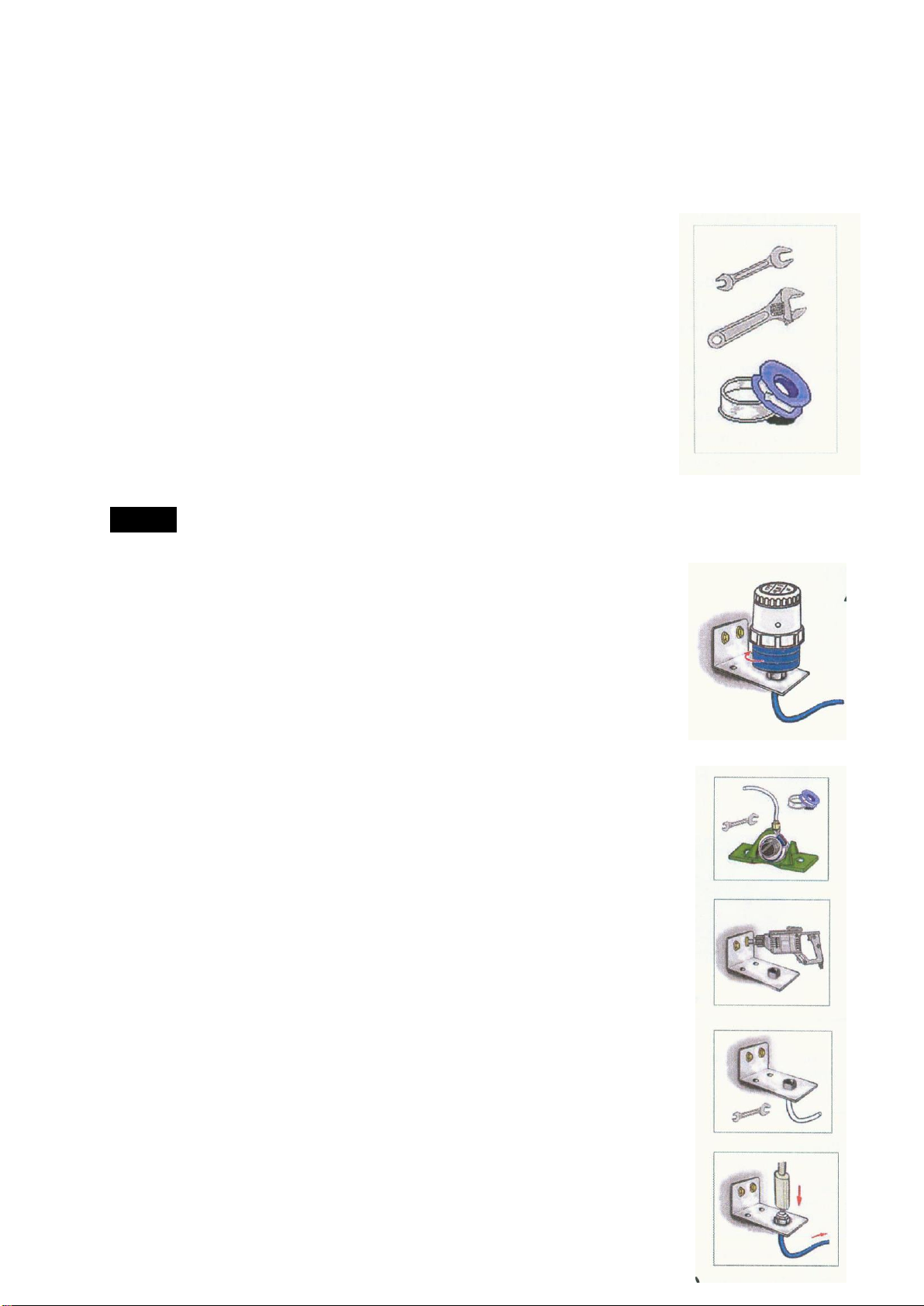

Installation steps:

1. Remove grease nipple from bearing.

2. Select the right size of adapter and accessories required.

3. Tighten seal tape on the outlet thread of the grease cup and

accessories.

4. Mount the adapter into the bearing’s input hole, if necessary.

5. Manually tighten Easylube into the bearing or the adapter.

6. Put the protection casing back to the body.

Step 8. Remote mount:

Caution:

Do not install the lubricator in ambient temperature over 60°C or on any

equipment with system pressure of 75 psi (5.2 bar) orhigher.Always keepthe

number of bends and the length of extension line to a minimum.

Important:

Always install the lubricator at a rigid and stable position.

Use copper piping hardware when the bearing temperature exceeds 50°C.

PU tubing harware can be used at bearing temperature lower than 50°C.

Installation steps:

1. Remove grease nipple from bearing.

2. Select the right size of adapter and accessories required.

3. Tighten seal tape on the outlet thread of the grease cup and

accessories.

4. Mount the adapter into the bearing’s input hole.

5. Install the mounting bracket at a rigid and stable position.

6. Connect the piping or tubing between the bearing and the mounting

bracket.

7. Fill the connecting pipeline and the bearing with grease same or

compatible to the prefilled grease.

8. Manually tighten Easylube into the bearing or the adapter.

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

9. Put the protection casing back onto the body.

The Easylube can be remote mounted up to 4,5 meter from the application, but only if the

grease properties such as viscosity, consistency and operating temperature range are

suitable.

Battery usage

►The battery pack is designed to use 40% of it’s capacity for grease dispensing and 60% for

the red indicator alarm. The alarm function is the most important feature of Easylubeas it will

inform users when lubricaotr fails to feed grease into the bearing.

►Other single point lubricators without alarm function are unable to warnusers when nogrease

grease or only oil ( through separation from soap) is being fed into the bearing.

►Therefore it is importnt to replace the batteryat the end of adispensing period or anytime the

voltage is below 6V/

Table 3 . Lubricator dispense period compared with DIP switch lever positions and battery life

Dispense

period in

months

DIP

switch

“ON”

Battery life

in days *

Dispense

period in

months

DIP

switch

“ON”

Batery life in

days*

Dispense

period in

months

DIP

switch

“ON”

Battery life

in days *

1

1

87

5

1+4

194

9

1+8

300

2

2

114

6

2+4

221

10

2+8

328

3

1 + 2

140

7

1+2+4

245

11

1+2+8

351

4

4

168

8

8

277

12

4+8

382

Back**

1+4+8

of

2+4+8

Test***

All “On”

OFF

All “Off”

Note: Refer to step 3 for location of DIP switch levers.

* The number of days is approximate and is base don a system counterbalance under 45psi(3bar).

** Back is for dispersing pressure inside of the cup.

*** Test is simulated examination of automatic greasing program control.

Caution:

Always dispose of batteries in compliancewith localenvirmentalprotection laws. Donot puncture

or burn the battery pack. Toxic materials may be emitted and cause injury.

BONDIS bvba –Cleydaellaan 16/1 –2630 Aartselaar –BELGIUM

Tel .: +32 3 234 29 18 –Fax: +32 3 233 13 10 –Email: info@bondis.com

ISO 9001:2008 n° 22714 –www.bondis.com

Troubleshooting

Indications

Possible problems

Solution

Red indicator light begins to

flash

Installation error

Follow the instruction step by

step and test the lubricaotr

before start-up

Empty grease cup

Fill grease cup

Battery voltage is below 6V

Test battery voltage with volt

meter.

Pipeline or bearing blockage

Flush the bearing and the

pipeline manually; operate

the grease gun slowly to

detect any jams or

blockages. Make sure used

grease is completely purged

until fresh grease comes out.

Base oil separation from

soap or viscosity variation

Choose the proper grease or

contact grease manufactuer

for information

Back pressure exceeds 75

psi (5.2 bar)

USe test apparatus to

measure back pressure.

Lubricator lines not

completely filled.

Fill the bearing and pipeline

manually with same or

compatible grease.

Lubrication period incorrectly

set up

Shorten the lubrication period

and observe the changes

Lubricator does not dispense

Weak battery

Verify the output voltage of

battery exceeds 6V, which is

the minimum voltage

requirement for operation.

Always start the lubricator

with a new battery.

Press plate is not properly

engaged with the red

piston in the cup

Follow the instruction step by

step and test the lubricator

before start-up.

Ambient temperature too low

for the viscosity, consistency

and operating temperature.

Chose the proper grease.

Consult grease supplier.

Unable to set DIP switch

levers.

Incorrect tool being used.

Move the levers with a ball

point pen or a small

screwdriver.

Doc: E-Easylube-Service guide/2013-07-11

Table of contents

Popular Lubrication System manuals by other brands

Gruetzner

Gruetzner Lubricus LUB-V1 operating instructions

Groeneveld

Groeneveld TriPlus Trailer General manual

perma-tec

perma-tec NOVA 125 operating instructions

Lincoln

Lincoln SKF KFU2 Series Assembly instructions

SKF

SKF GVP-S-034-3D+924 Installation and operation manual

Bijur Delimon

Bijur Delimon SG-A Operating instruction