Dru Metro 150 XT User manual

Other Dru Indoor Fireplace manuals

Dru

Dru Maestro 75XTU RCH User manual

Dru

Dru Global 90 CF User manual

Dru

Dru Diablo Next RCE User manual

Dru

Dru Metro 150XT-41 RCH User manual

Dru

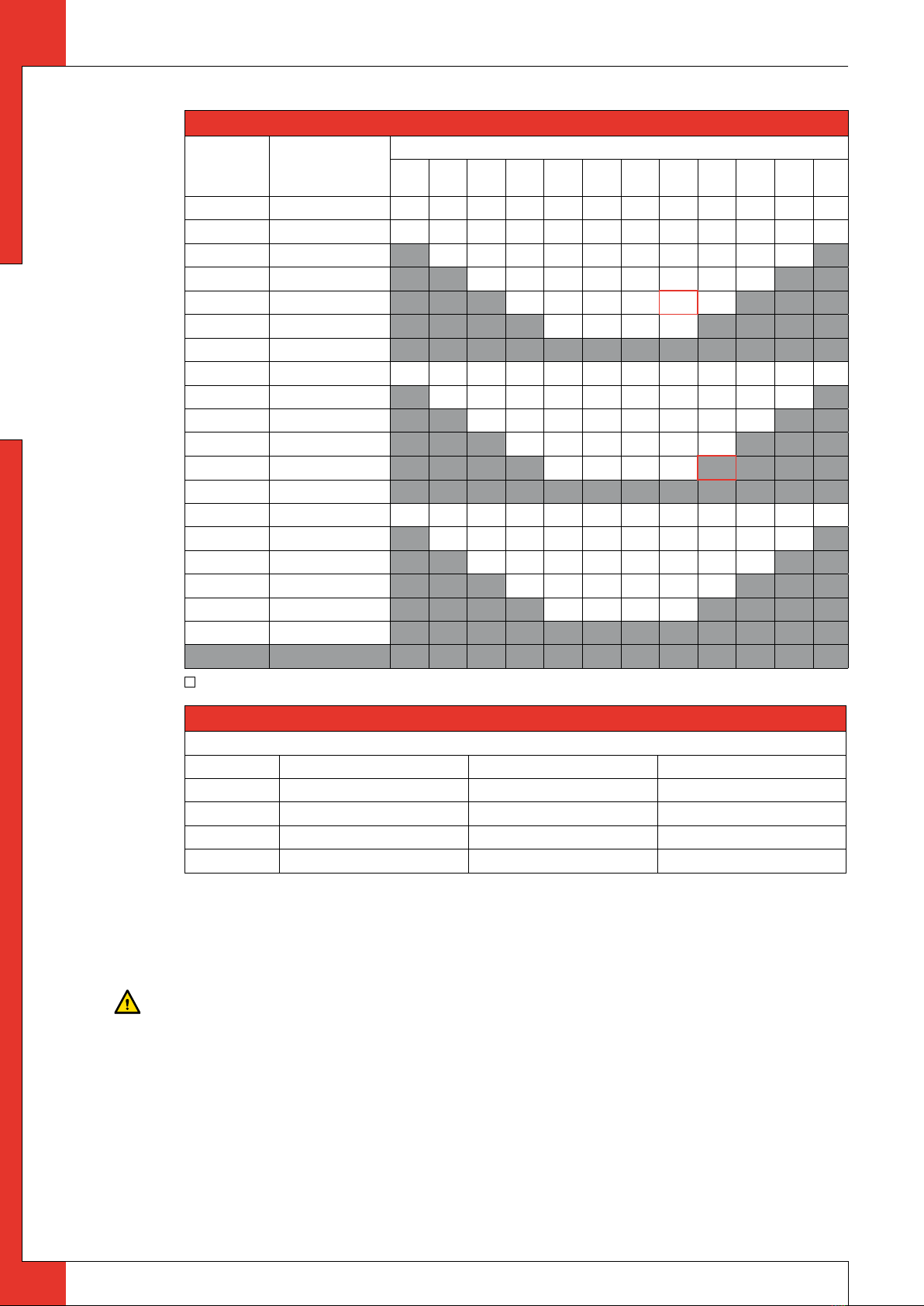

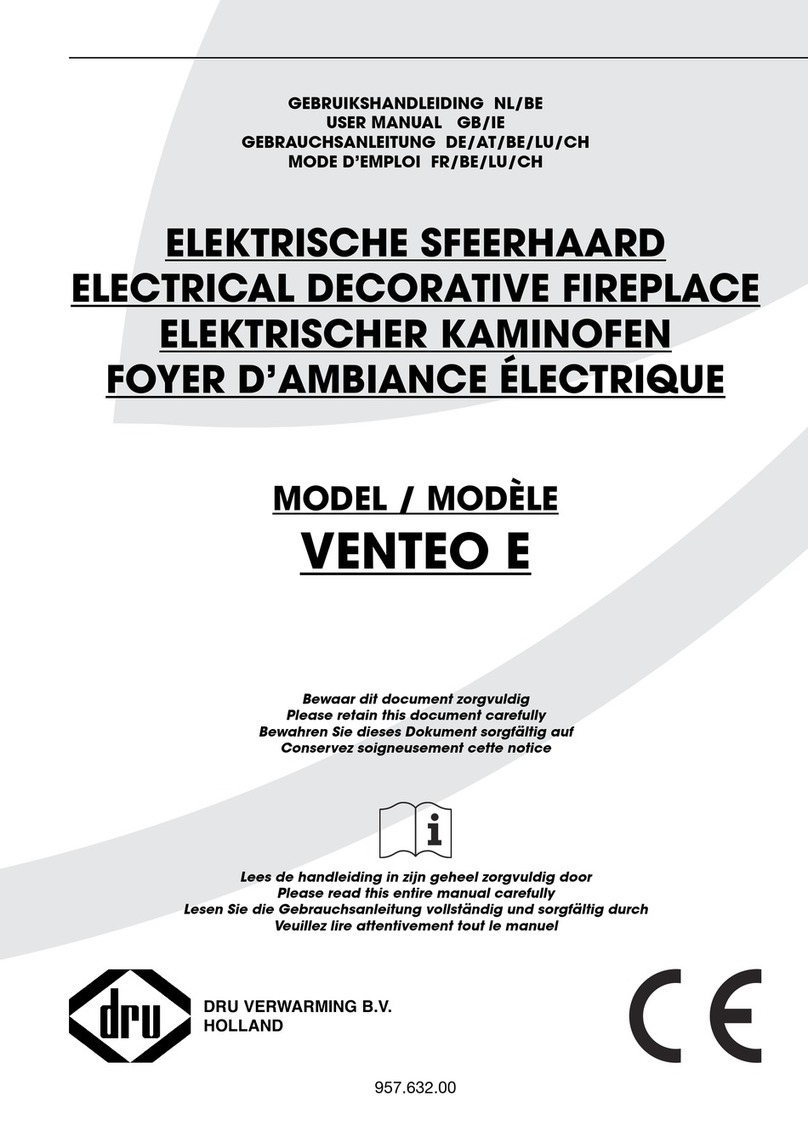

Dru Venteo E User manual

Dru

Dru Cello User guide

Dru

Dru Metro 130 XT User manual

Dru

Dru Virtuo 75 User manual

Dru

Dru Metro 100XT Tunnel 41 RCH User manual

Dru

Dru Spirit User guide

Dru

Dru Saxo SL 80 Guide

Dru

Dru Global Fires 100 BF-03 RCE User manual

Dru

Dru Cosmo RCH User manual

Dru

Dru Metro 100 XT-2 User manual

Dru

Dru Largo Tunnel Guide

Dru

Dru GLOBAL 55 CF User manual

Dru

Dru Maestro 75XTU RCH User manual

Dru

Dru Global 70XT CF-01 RCE User manual

Dru

Dru Global 55XT BF RCE User manual

Dru

Dru Maestro 105/2-01 RCH User manual

Popular Indoor Fireplace manuals by other brands

Brigantia

Brigantia 35-DVRS31N-2 User's installation, operation and maintenance manual

Nordpeis

Nordpeis Bergen Installation and user manual

Superior

Superior BCT2536TMN Installation and operation instructions

Quadra-Fire

Quadra-Fire 5100I-GD-B owner's manual

Renaissance

Renaissance RUMFORD 1000 user manual

Lacunza

Lacunza IV-800 Instruction book

Baxi

Baxi 940 Installer and owner guide

Diamond Fireglass

Diamond Fireglass SS-O22 General assembly, installation, and operation instructions

HearthStone

HearthStone Windsor Bay 8830 Owner's manual and installation guide

Napoleon

Napoleon ASCENT B42 quick start guide

Enviro

Enviro E33GI owner's manual

Smeg

Smeg L30 FABE Installation & user's instructions

KEDDY

KEDDY K700 Installation instructions care and firing instructions

Godin

Godin 3451 manual

Jøtul

Jøtul Jotul GI 535 DV IPI New Harbor Installation and operation instructions

Desa

Desa CCFPDFT Owner's operating & installation manual

Miles Industries

Miles Industries Vogue 1300IRN Installation & operating instructions

Regency Fireplace Products

Regency Fireplace Products Pro Series Owners & installation manual