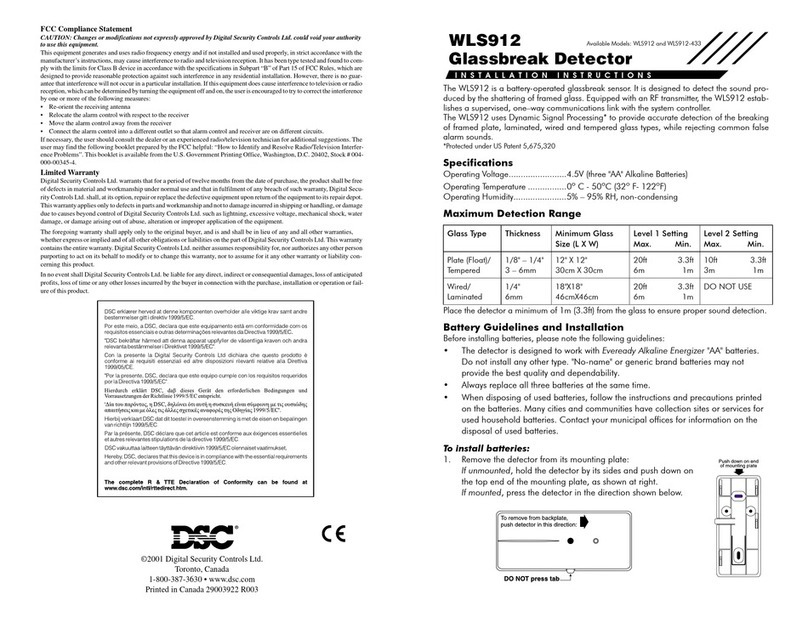

Shock /Glass AdjustmentUseonlyduring testing and setting

SHOCK -foradjustmentofthe

frequencysensitivitywith

potentiometer“SHOCK”

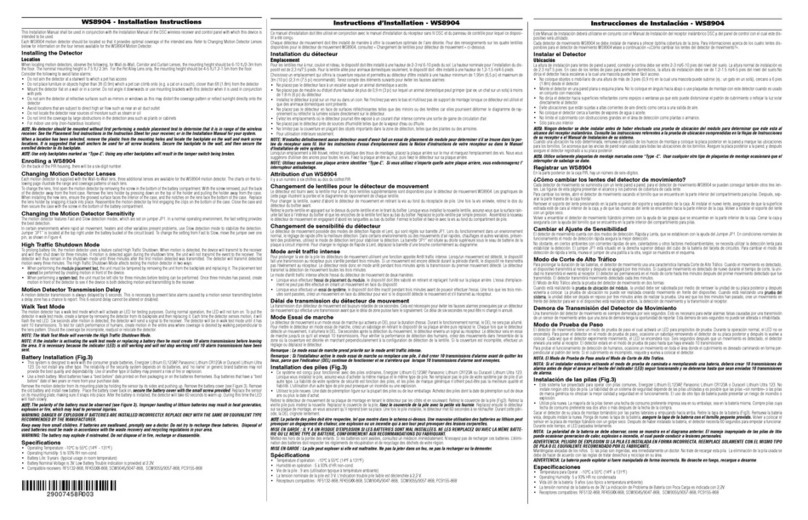

SETTING -UPTHEDETECTOR

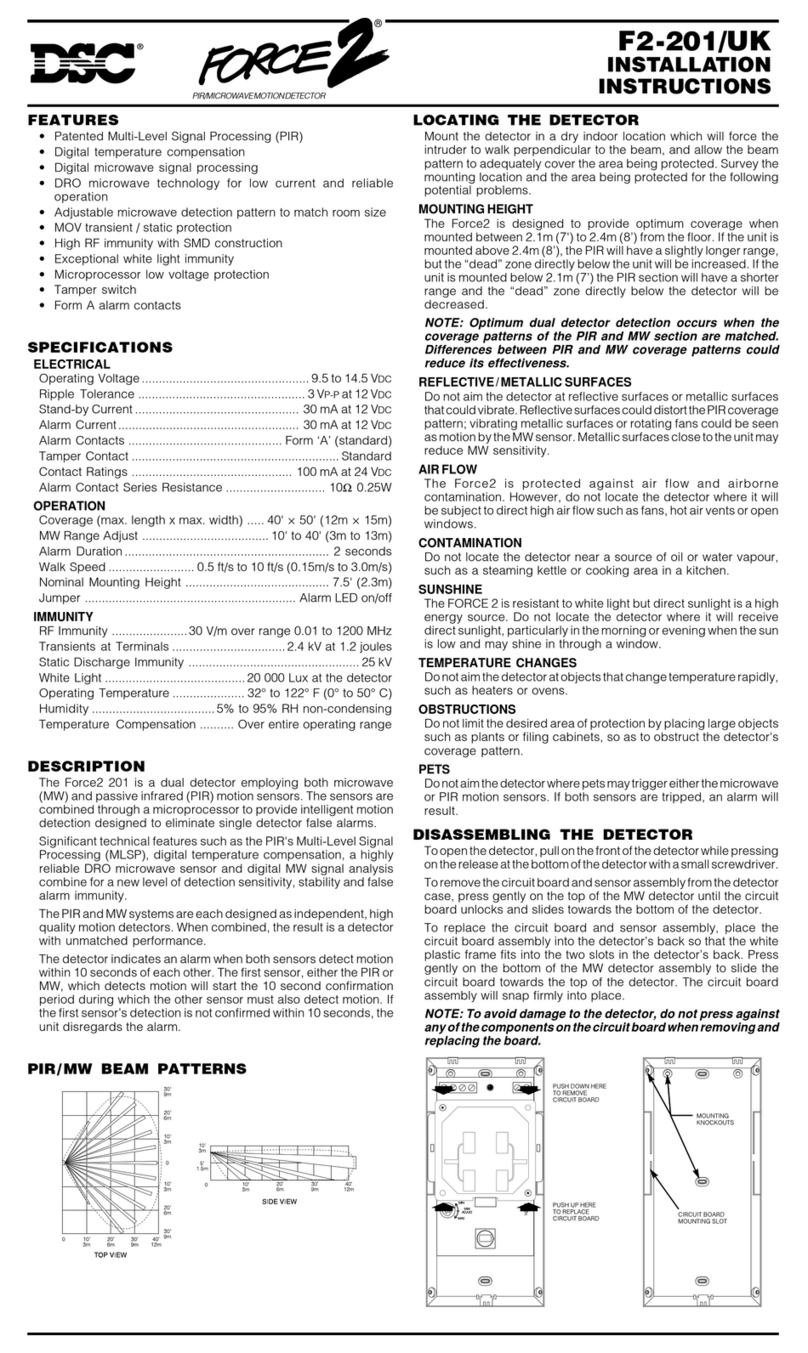

PIRSENSITIVITYADJUSTMENT:Switch3ofDIP-4.Use forSetting ”PULSE”-providessensitivitycontrolofPIRaccording tothe environment.

Position Left -”On”-High sensitivityForstableenvironments.Position Right-”OFF”-LowsensitivityForharshenvironments.

“PIRCAL”POTENTIOMETERADJUSTMENT:According toprotected area range.Usethe potentiometermarked “PIRCAL”toadjustthe detection

sensitivitybetween 15%and 100%according towalktestintheprotected area.(Factorysetting is57%).Rotatethe potentiometerclockwisetoincrease

range,counter-clockwisetodecreaserange.Always walktestand re-adjustifrequired.

LEDINDICATIONOFALARMSIGNAL:Switch1ofDIP-4.Use forSetting “LED”-providescontrolofAlarmsignalLEDindication.

PositionLeft -“On”-LEDenable.PositionRight“OFF”-LEDdisable.

SOUND SENSITIVITYADJUSTMENT:Switch2ofDIP-4.Use forSetting“AUDIO”-providescontrolofsound detection sensitivity.Position Left -

“On”-reducing the sensitivityofsound detection by50%.(Useinsmall room).Position Right“OFF”-Sensitivityofsound detection 100%.

PETIMMUNITYSETTING:Switch4ofDIP-4.Use forSetting “PET”15kg-25kg.Position Left “ON”ImmunitytoPETup to15 kg.

PositionRight“OFF”ImmunitytoPETup to25 kg

TEST PROCEDURES

Waitforone minutewarmup timeafterapplying 12-Vdcpower.Conducttesting withthe protected area cleared ofall people.Makesuretotestthe unit

thoroughlyforproperdetection.

Walktest: 1.Removefrontcover.Set“PULSE”to“ON”position,and set“LED”to“ON”position.2.Replacethe frontcover.3.Startwalking slowly

across the detection area.4.Observethatthe red led lightswhenevermotion isdetected.5.Allow5sec.between eachtestforthe detectortostabilize.

6.Afterthe walktestiscompleted,you can setthe“LED”to“OFF”position.

NOTE:Walktestsshouldbe conducted,atleastonceayear,toconfirmproperoperation and coverage ofthe detector.

ADJUSTMENT

GLASS -foradjustmentof

thehighfrequencysensitivity

withpotentiometer“GLASS”

NORMAL-

forregular

operation

Glass Break adjustment

Toadjustthe glassbreaksensitivity,placethe jumperaccordinglyGLASS TESTmarking.Green (SHOCK)

LEDisconstantlyON.Nowyou canadjustthe sensitivitybyrotating theGLASS CALpotentiometer.Operate

the Sound BreakSimulator*nearthe protected windowand rotatethe potentiometerGLASS CALclock-

wisetoincreasesensitivity,and counter-clock-wisetodecreasesensitivityuntil the Yellowand Red LEDs

areilluminating foreachglassbreaksound.

Note:When the jumperissetforGLASS adjustment, onlythe high frequencysound ofbreaking glass is

detected.*It isrecommended touseGLASS-BREAK SimulatorFG-701 (CROWp/n004001)

ShockAdjustment

Toadjustthe shock setting (increase/decreasesensitivity)placethe jumperaccordinglySHOCKTEST

marking-Yellow(GLASS)LEDisconstantlyON.Nowyou can adjustthesensitivitybyrotatingthepotentiometer

SHOCKCAL.Hitgentlyontheprotectedglassand rotatethepotentiometerclock-wisetoincreasesensitivity,

and counter-clock-wisetodecreasesensitivityuntil the Green and Red LEDsareilluminating foreachhit.

Note:When the jumperissetforSHOCKadjustment, onlythe lowfrequency ofthe shock signalpriorto

glassbreakage isdetected.

SHOCK/GLASS TEST PROCEDURE

FinalTesting

*Makesuretosetjumper“GLASS/SHOCK”inposition NORMAL.When the jumperisinthisposition,the

detectorwill detectbothshockand soundfrequencies.*Toensuremaximumprotectionagainstfalsealarms,

activateanydeviceinthe area,whichmightautomaticallycyclepumps,gene

Warm UpPeriod 60 sec

RFIProtection 30V/m10-1000MHz

EMIProtection 50,000Vofelectricalinterferencefromlighting

VisibleLight

Protection stableagainsthalogen light2.4m(8ft)orreflected light

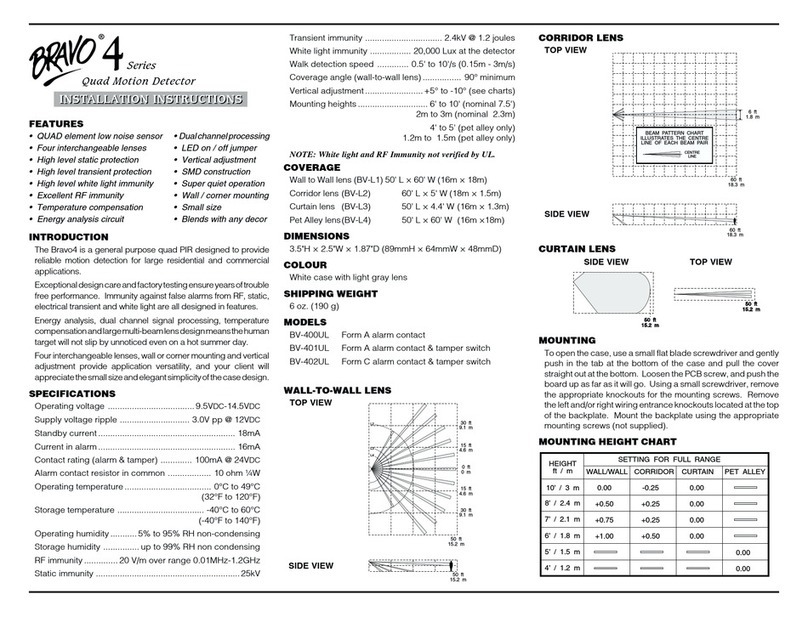

Detection rangeGlass upto10m(900);PIRupto15m(WAlens)

LEDsindicatorYellowLED(GLASS)-glassbreaksignalfortesting&adjustment

GreenLED(SHOCK)-shock signalfortesting &adjustment

RedLED(ALARM) -alarm signal:

Fleshing light-glass&breakdetection orglass &shock &PIR

detection

Constantlight-PIRdetection

Dimensions118mm x62.5mm x41mm (4.65”x2.46”x1.61”)

Weight110 gr.

TECHNICALSPECIFICATION

Detection Method Quad(Fourelement)PIR&electretmicrophone

Detection Speed0.15-3.6m/sec

PowerInput8.2-16 Vdc

CurrentDrawAlarm PIR:16.5mA;Alarm Shock&Glass

22mA;Alarm all:18mA

Standby:16.5mA

BIDirectional

Temp.

Compensation YES

Pulse Count1,AUTO

Alarm Period 2sec

Alarm OutputN.C28Vdc0.1Awith10Ohmseriesprotection

resistors

TamperSwitchN.C28Vdc0.1Awith10 Ohmseriesprotection

resistor-openwhen coverisremove

NORMAL

GLASS

TESTSHOCK

TEST

GLASS

TESTSHOCK

TEST

NORMALNORMAL

GLASS

TESTSHOCK

TEST

BLOCK CONNECTOR

PYROSENSORSWITCH FOR

SETTINGS

FIG 8-PCBLAYOUT

LIMITEDWARRANTY:DigitalSecurityControlsLtd,warrantsthatforaperiod of12 monthsfromthe dateofpurchase,the productshall be free ofdefectsinmaterialsandworkmanshipundernormaluseand thatinfulfillmentofany

breachofsuchwarranty.DigitalSecurityControlsLtdshall,atitsoption,repairorreplacethe defectiveequipmentupon returnsofthe equipmenttoitsrepairdepot. Thiswarrantyappliesonlytodefectsinpartsand workmanshipandnotto

damage incurred inshippingorhandling,ordamage due tocausesbeyond the controlofDigitalSecurityControlsLtd,suchaslightning,excessivevoltage mechanicalshock,waterdamage,ordamage arising outofabuse,alteration or

improperapplication oftheequipment.

Theforegoingwarrantyshall applyonlytothe originalbuyer,and isand shall be inlieu ofanyand all otherwarranties,whetherexpressed orimplied and ofallotherobligationsorliabilitiesonthepartofDigitalSecurityControlsLtd.Digital

SecurityControlsLtdneitherassumesresponsibilityfor,norauthorizesanyotherperson purporting toacton itsbehalftomodifyortochange thiswarranty,nortoassumeforitanyotherwarrantyorliabilityconcerning thisproduct.

InnoeventshallDigitalSecurityControlsLtdbe liableforanydirect,indirectorconsequentialdamages,lossofanticipatedprofits,lossoftimeoranyotherlossesincurredbythebuyerinconnection withthepurchase,installation oroperation

orfailureofthisproduct.

Motion detectorscan onlydetectmotion withinthe designated areasasShownintheirrespectiveinstallationinstructions.Theycannotdiscriminatebetweenintrudersand intended occupants.Motion detectorsdonotprovidevolumetricarea

protection.Theyhavemultiplebeamsofdetection and motion can onlybe detectedinunobstructedareascovered bythesebeams.Theycannotdetectmotion whichoccursbehind walls,ceilings,floor,closed doors,glasspartitions,glass

doorsorwindows.Any

type oftampering whetherintentionalorunintentionalsuchasmasking ,painting,orspraying ofanymaterialon the lenses,mirrors,windowsoranyotherpartofthe detection systemwill impairitsproperoperation.

Passiveinfraredmotion detectorsoperatebysensingchangesintemperature.Howevertheireffectivenesscan be reduced whentheambienttemperaturerisesnearorabovebodytemperatureorifthereareintentionalorunintentionalsources

ofheatinornearthedetectionarea.Someoftheseheatsourcescouldbeheaters,radiators,stoves,barbeques,fireplaces,sunlight, steamvents,lighting and soon.

WARNING:DigitalSecurityControlsLtd,recommendsthattheentiresystembecompletelytestedon aregularbasis.However,despitefrequenttesting,anddueto,butnotlimitedto,criminaltampering orelectricaldisruption,

itispossibleforthisproducttofail toperformasexpected.

Importantinformation:Changes ormodificationsnotexpresslyapprovedbyDigitalSecurityControlsLtdcouldvoidtheuser'sauthoritytooperatethisequipment.

2005 DigitalSecurityControlsLtd

Toronto,Canada

www.dsc.com