15

Taking Measurements

The Micrometer uses focus to measure the distance

between two points at different depths. Subjects on

the same focal plane (depth) will appear in very sharp

focus, while anything above or below will be blurry.

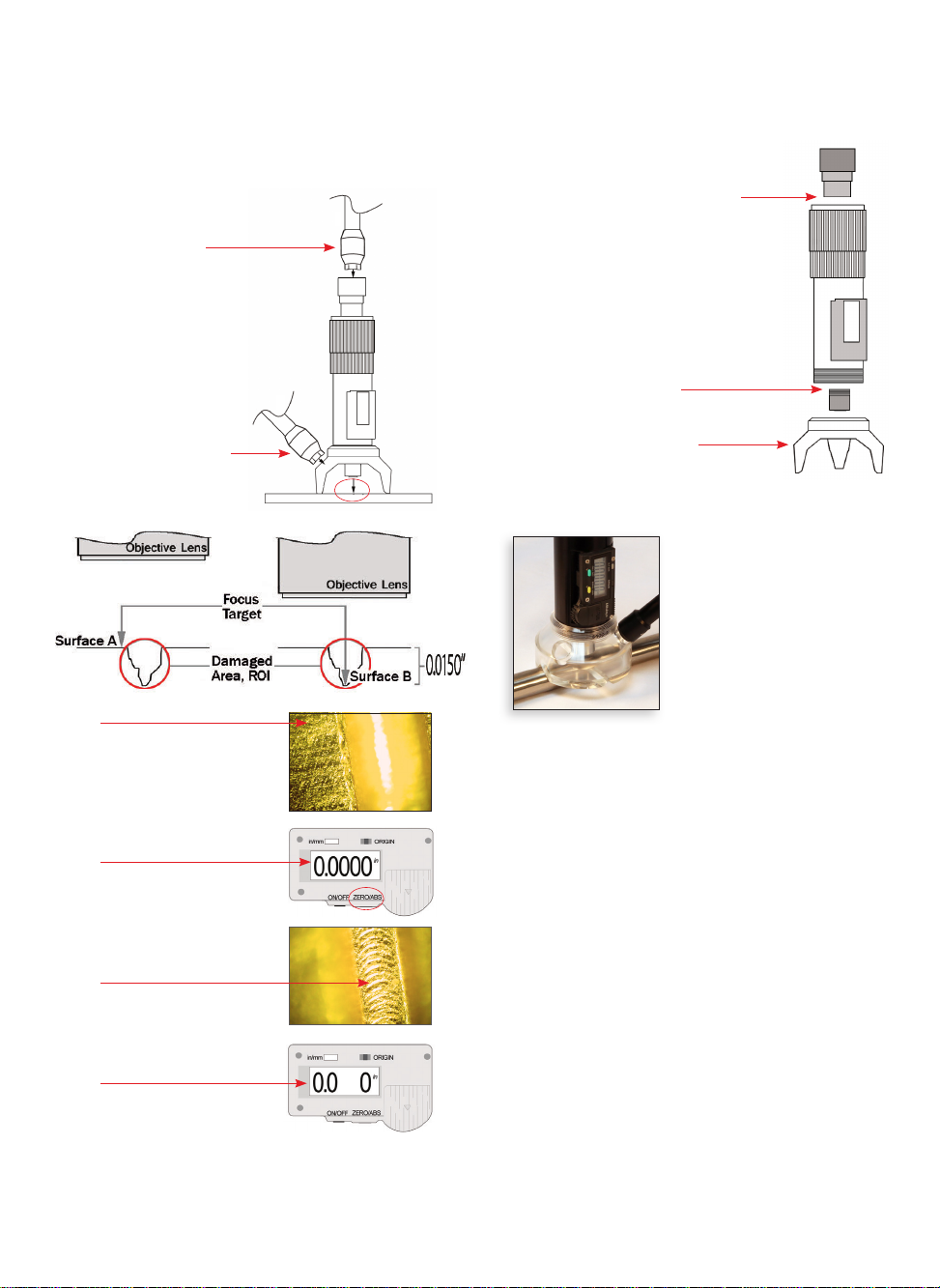

Step 2

Look through the eyepiece

and use the focus adjustment

to bring the surface directly

next to the pit (Surface A)

into focus.

Step 3

Press the “ZERO/ABS”

button to set the starting point

for the measurement. The

display will read “0.0000”.

Step 4

Focus down to nd the the

bottom of damaged area

(Surface B).

Step 5

Record the depth shown on

digital display.

Step 6

For verication, refocus on

the top surface; the display

should show “0.0000” again.

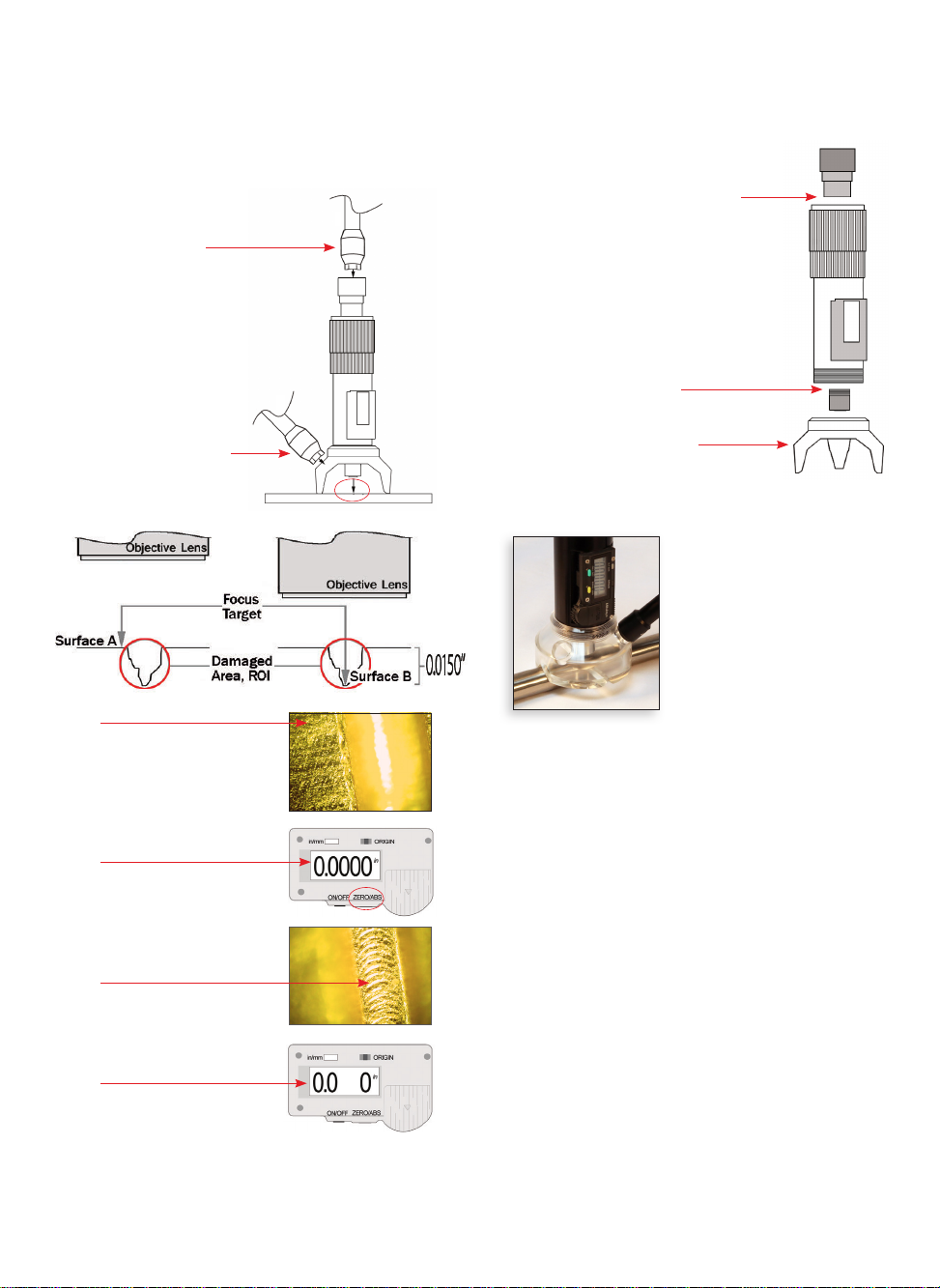

Interchangeable Parts

Use the 3-Leg Base on at surfaces.

Use the 4-Leg Base on curved surfaces.

The Eyepiece, Objective Lens and Base can

be swapped out for different applications.

Use the clear V-Block

Base for small diameters,

outside angles and edges

of at surfaces.

Care should be taken to prevent

dirt or moisture from entering the

tube when swapping eyepieces.

To change the Objective Lens,

turn the focus adjustment

clockwise until the threads of the

objective lens are visible at the

base of the Micrometer. Holding

the Micrometer body rmly, turn

objective lens counter-clockwise

until threads disengage.

The three bases accommodate

dierent types of surfaces:

Useful Tips

The Micrometer does not have prismatic

correction; the view through the eyepiece is

reversed/opposite.

At 100X magnication, the objective lens will be

approx. ¼” above a at surface when in focus.

Lower magnication shows less detail but

provides a wider eld of view. Higher

magnication shows very ne detail but the

eld of view is small.

Use 100X and 200X magnication to inspect

very small features, like scratches, scribe lines,

and corrosion pits.

Use 40X and 80X magnication for wide features

like gouges and bubbles, or to measure overall

thickness of a transparency.

The 10X eyepiece has a reticle for visual width

measurements. Width observations are valid

only at 100X magnication.

Step 1

Shine the ashlight

down through the

eyepiece. A bright spot

will appear below the

objective lens; this is

the center of the eld of

view. Position it directly

over the subject.

Hold the micrometer to

prevent it from moving,

and insert lit ashlight

into base.