Installation and Operation of X-STREAM WASH

6

III. INSTALLATION INSTRUCTIONS

A. QUALIFIED PERSONNEL

These installation instructions are for the use of qualied

installation and service personnel only. Installation

or service by other than qualied personnel may result

in damage to the unit and/or injury to the operator.

Qualied installation personnel are those individuals,

rms, companies or corporations which either in person

or through an agent is engaged in and responsible for:

• The installation of electrical wiring from the electric

meter, main control box or service outlet to the

electrical appliance. Qualied installation personnel

must be familiar with all precautions required and

have complied with all requirements of state and

local authorities having jurisdiction. See: National

Electrical Code, ANSI/NFPA70.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

B. DELIVERY AND INSPECTION

Duke Manufacturing Co. does everything within its

power to ensure you received your unit in good condition.

They are crated on heavy wooden skids and packed to

prevent shipping damage. They have all been carefully

inspected before they were packaged and consigned

to the carrier.

Upon delivery of your Duke unit:

• Look over the shipping container, carefully noting

any exterior damage on the delivery receipt, which

must also be signed by the driver/ delivery person.

• Unpack and check for any damage, which was not

evident on the outside of the shipping container.

• Check for concealed damage. The carrier must be

notied within fteen (15) days of the delivery of

the unit and the crate and all packaging materials

must be retained for inspection.

Duke Manufacturing Co. cannot assume liability for

loss or damage suffered in transit.The carrier assumes

full responsibility for delivery in good order when the

shipment was accepted. However, we are prepared to

assist you in ling your claim.

C. PLACEMENT

• HANDLING – The units are very heavy and may

require the use of moving equipment. Consult with

your local restaurant equipment supplier.

• INSPECTION – Inspect the area where the unit is

being installed. Check for proper clearance with

shut off valves and drain line hook ups.

• LEVELING – The unit is equipped with adjustable

bullet feet. Use a wrench or pliers to adjust up or

down.

• SEALING – Seal the top of the backsplash to the

wall using an NSF approved silicone sealant.

: Equipment is heavy. Heavy

lifting may result in bodily injury. Do not lift

or move without adequate help.

D. PLUMBING REQUIREMENTS

• WATER SUPPLY – Hot and Cold Water should be

supplied by ½” or ¾” water lines, with the ¾” being

the preferred method.

• DRAINS – A 1-1/2” minimum waste connection is

required. If equipped, the scrapping sink should

have a 1-1/2” NPS connection, while the wash,

rinse, and sanitize sinks typically have a 2” NPS

connection.

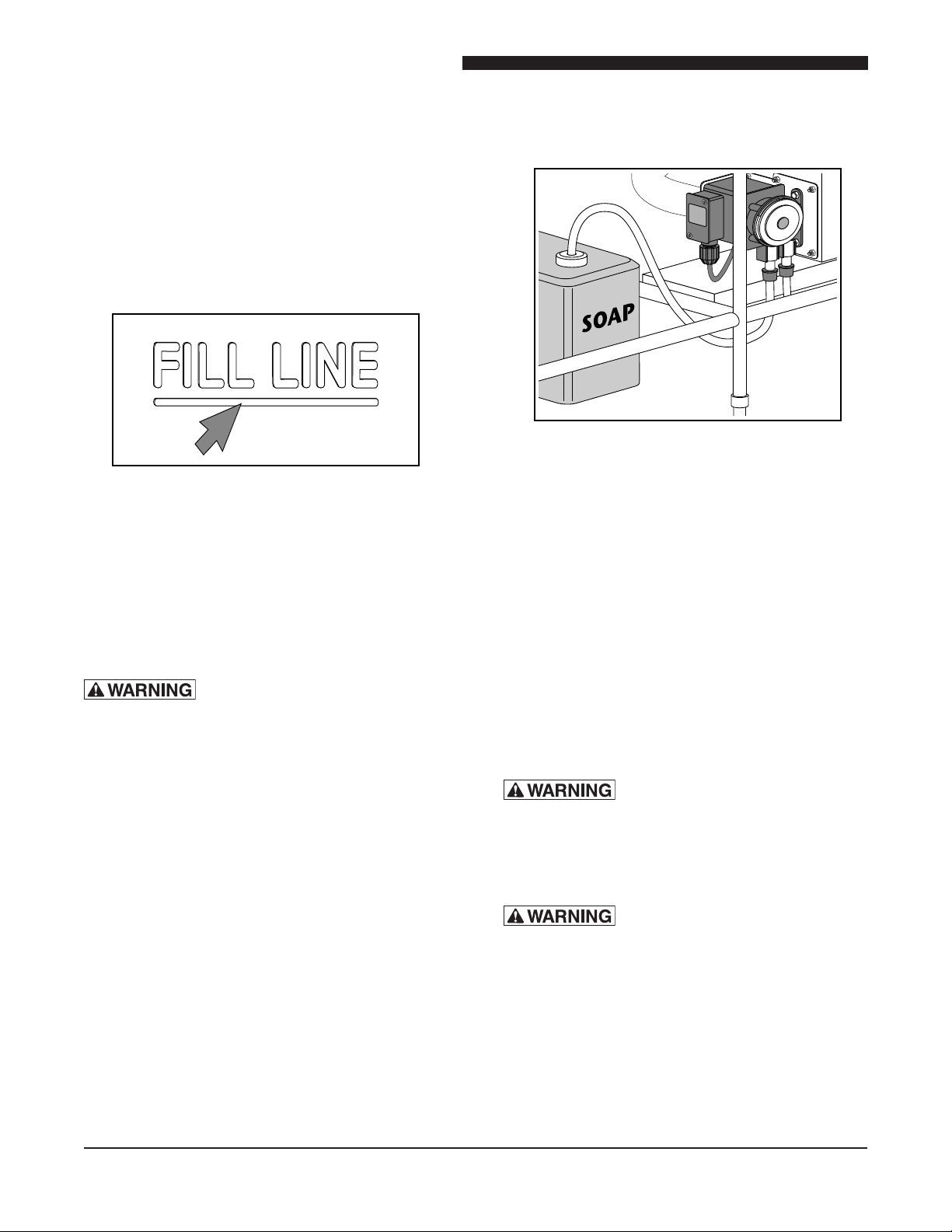

• PUMPS – The wash tank pumps will need to

be piped to a oor drain. This uses a ½” NPT

connection.

Pump

Pipe this connection

to floor drain

Bottom View of Pump Assembly