5.3 BUMP STOP REMOVAL AND FITTING OF UPPER BRACKET

1. Remove the two bump stops (Figure 1 and 2).

2. Drill out the blind rivet (Figure 3) of the LED head light sensor. Use a drill of 5 mm (Not all models will have

this sensor).

3. The chassis bracket assembly has two parts (See Figures 4, 5 and 6). Put the two parts together and offer

them up to the frame left vacant of the bump stop. Now slide the upper of the two chassis brackets inside

the lower of the two until the assembly is loosely attached to the bump stop frame with the holes in

alignment.

4. Offer the upper bracket up to the chassis bracket assembly and attach it using a single M8 x 20mm bolt

and a single serrated washer (Figures 7 and 8).

5.4 ATTACHMENT OF THE LED-LIGHTS SENSOR

1. The sensor can be attached on almost the same position but now to the lib of the upper bracket (Figures 9

and 10) with the M5 x 14, washer and flange nut (Pos. 11, 12 and 13 page 6).

2. The sensor arm remains unchanged.

3. Our upper bracket is designed in the way that the sensor will be in the same position as it was. Still you

have to check the height of the headlights.

4. Correction can be done by shifting the clamp around the shock absorber a bit up or down, till the height

of the headlights is correct again.

5. Tighten the sensor arm bracket and check the height of the headlights again.5.5 Attachment of the Lower

bracket and the Bellows

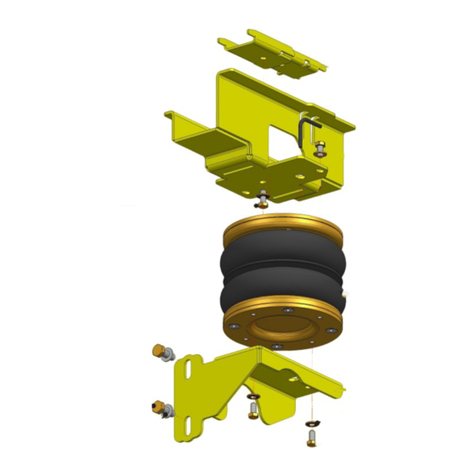

5.5 ATTACHMENT OF THE LOWER BRACKET AND THE BELLOWS

1. Unscrew the two bolts from the bracket that attaches the torsion beam assembly to the axle (Figure11).

2. Reattach the bracket that secures the torsion beam to the axle, thereby also securing the lower bracket to

the axle (Figure 12).

Take care the lower bracket rests flat.

3. See Section 5.7 - “Tube Connection and Disconnection, Cutting and Routing” : Use black tubing for the

left-hand bellow and blue for the right-hand bellow.

4. Feed for the right side the blue (left side is the black hose) tube from the topside trough the biggest hole of

the upper bracket.

5. Manually compress the bellow and connect the tube to the air bellowthen bung the end of the tube to

maintain the compressed state (Figure 13).

6. Shift the air bellow carefully between the brackets and guide the tube (Figure 13).

7. Release the bung from the tube. This allows air into the bellow, which consequently expands upwards

towards the upper bracket

(Figure 14).

8. Attach the bellow to both brackets using two M8 x 16mm bolts and two serrated washers on both sides of

the bellow (Figure 14 and 15). Do not fully tighten at this stage because the bellow may require alignment

once inflated (see Section 5.9 and Figure 16).

9. The distance between the top face of upper plate of the bellow and the bottom face of the lower plate

should now be brought to approximately 14cm. Manoeuvre the bellow such that it is in good vertical

alignment between the upper and lower brackets and tighten the screws.

9 | INSTALLATION MANUAL | AUXILIARY AIR SUSPENSION | VOLKSWAGEN CRAFTER DRW AND 4X4 / MAN TGE DRW AND 4X4 FEB 2021