TABLE OF CONTENTS

PAGE

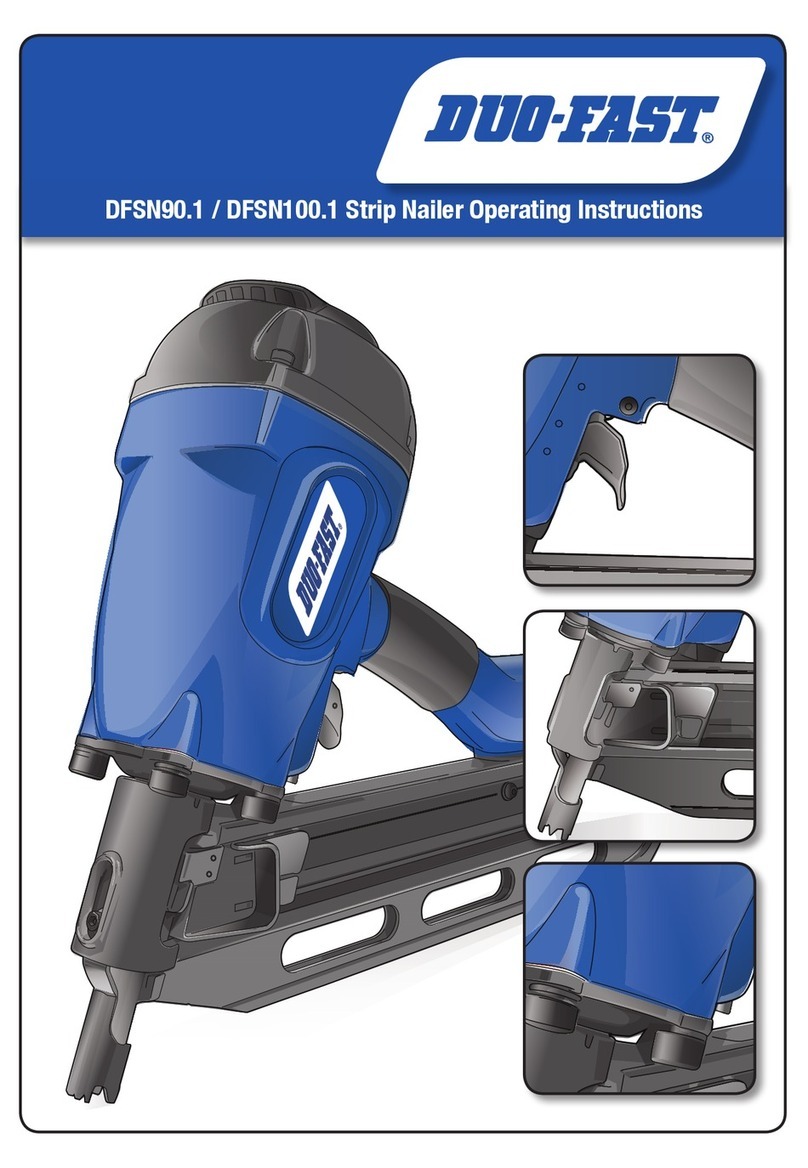

Tool Specification and Features ……………………………….. 1

Safety Instructions ……………………………………………….. 2

Preparations………………………………………………………… 3

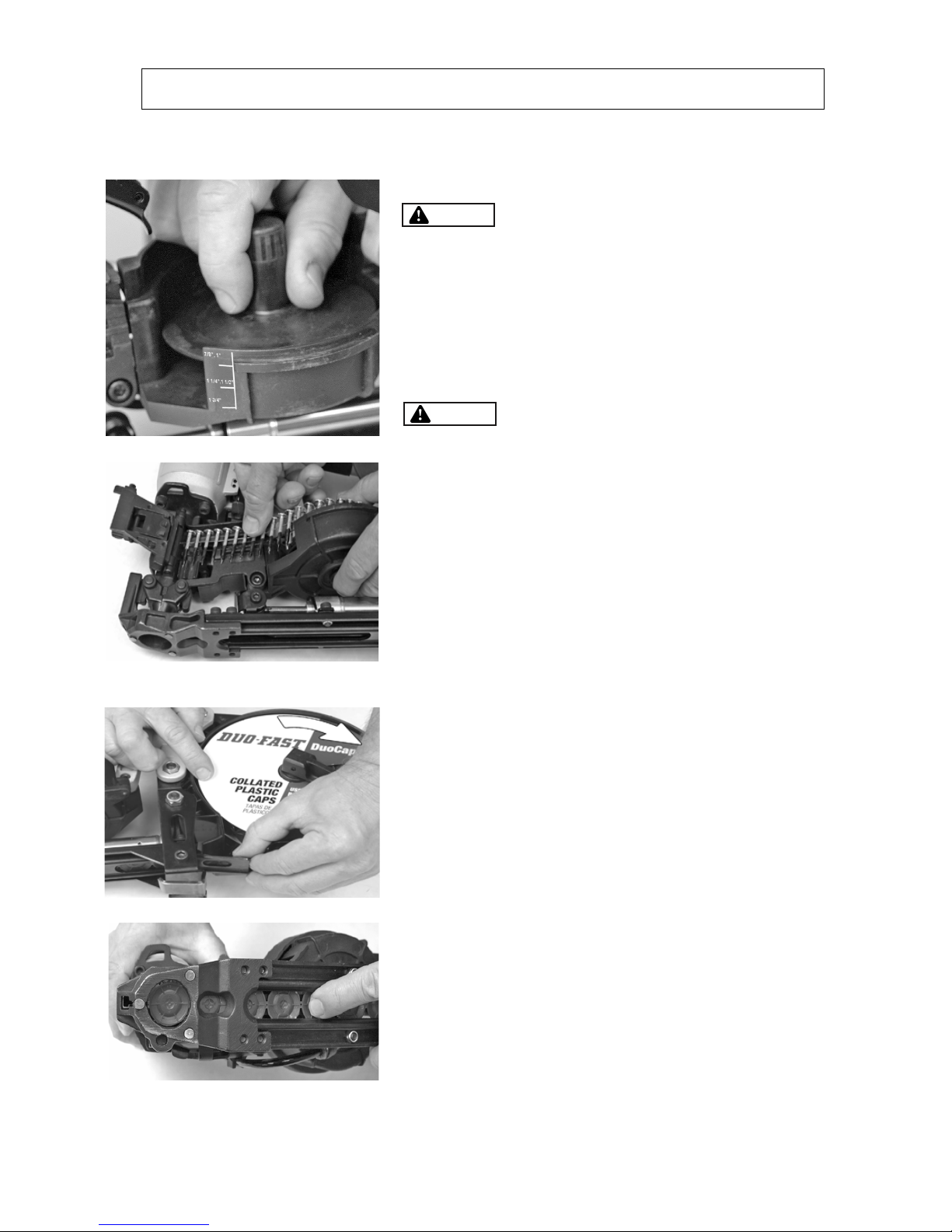

Loading and Operation…………………………………………… 4

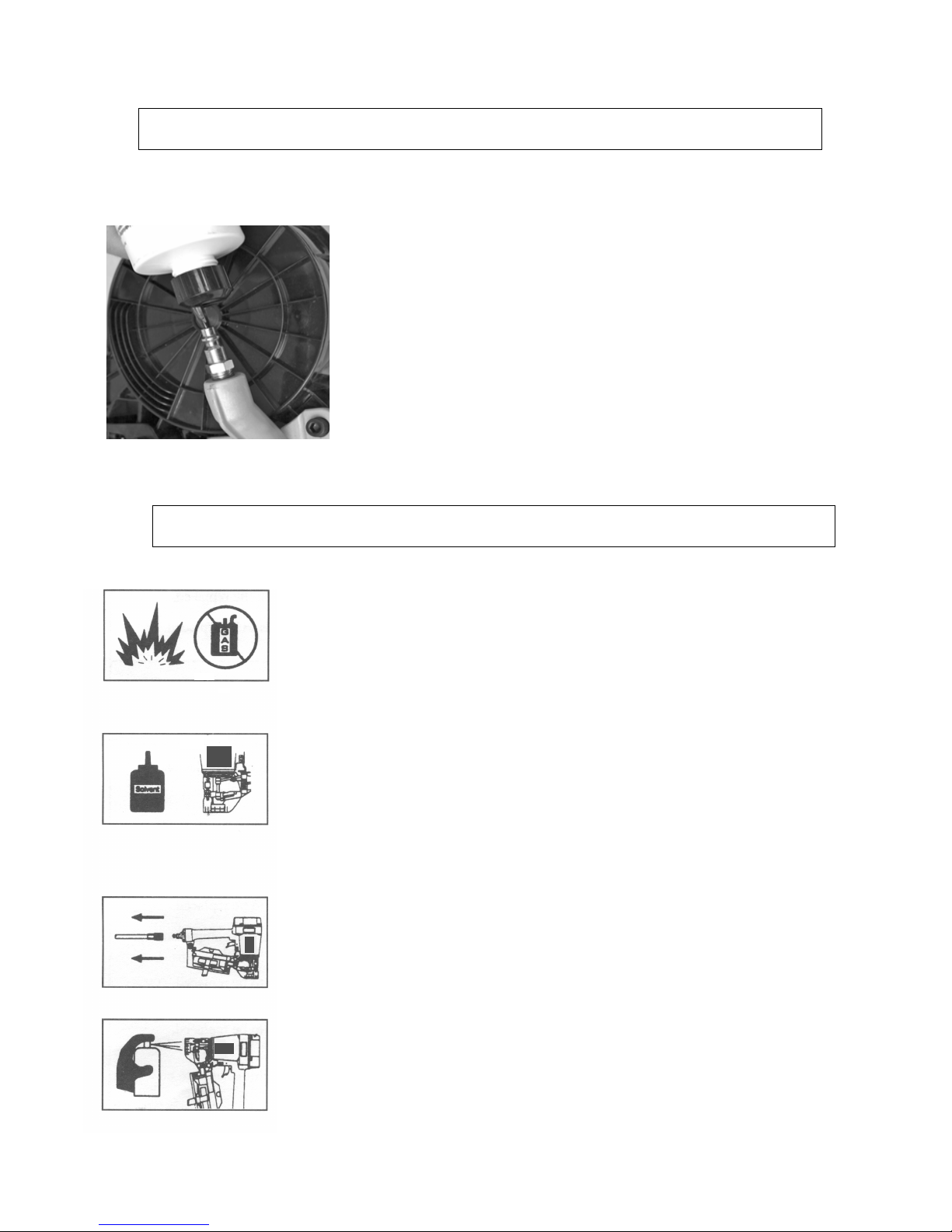

Maintenance ……………………………………………………….. 5

Trouble Shooting …………………………………………………. 6-7

Parts List …………………………………………………………… 8-9

Accessories ………………………………………………………… 10

TOOL WARRANTY AND LIMITATIONS

Duo-Fast

®

warrants that newly purchased power

fastening tools, parts and accessories will be free

from defects in material and workmanship for the

period shown below, after the date of delivery to the

original user.

90-DAY LIMITED WARRANTY

A 90-day warranty will apply to all parts, except

those which are specifically covered by an extended

warranty.

EXTENDED LIMITED WARRANTY FOR ON SITE

CONSTRUCTION APPLICATIONS

assembly castings. A six month warranty will apply

to all magazine parts.

NORMAL WEARING PARTS

The following parts are considered normal wearing

parts and are not under warranty.

• Bumper

• Driver Blades

• ”O” Rings

WARRANTY STATEMENT

Thiswarrantyislimitedtotoolssoldandservicerequested

in the United States. To obtain information on warranty

service in the United States, refer to the Service Center

listing that was provided with your tool.

Duo-Fast's sole liability hereunder will be to replace any part

or accessory which proves to be defective within the specific

time period. Any replacement part or accessory provided in

accordance with this warranty will carry a warranty for the

balance of the period of warranty applicable to the part it

replaces. This warranty does not apply to part replacement

required due to normal wear.

This warranty is void as to any tool which has been subjected

to misuse, abuse, accidental or intentional damage, use with

fasteners,fuel, batteries, or battery chargersnotmeetingDuo-

Fast specification, size, or quality, improperly maintained,

repairedwith other than genuineDuo-Fast

®

replacement parts,

damagedintransitorhandling,orwhich,inDuo-Fast'sopinion,

has been altered or repaired in a way that affects or detracts

from the performance of the tool.

DUO-FAST

®

MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY, FITNESS,

OR OTHERWISE, EXCEPT AS STATED ABOVE, and DUO-

FAST's liability AS STATED ABOVE AND AS ASSUMED

ABOVE is in lieu of all other warranties arising out of, or

in connection with, the use and performance of the tool,

except to the extent other wise provided by applicable law.

DUO-FAST

®

SHALL IN NO EVENT BE LIABLE FOR ANY

DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES,

INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH

MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR

PRODUCTION, SPOILAGE OF MATERIALS, INCREASED

COST OF OPERATION, OR OTHERWISE.

A one year warranty will apply to all housing and cap

Duo-Fast

®

reserves the right to change specifications, equipment, or

designs at any time without notice and without incurring obligation.

An Illinois Tool Works Company

955 National Parkway

Schaumburg, Illinois 60173-5172