6

• If the current range is unknown beforehand, set the function range to the highest

range and then reduce it until the desired range is obtained.

Note: When only figure "1" is displayed, overrange is being indicated and the function

range switch should be set to a higher range.

RESISTANCE MEASUREMENT

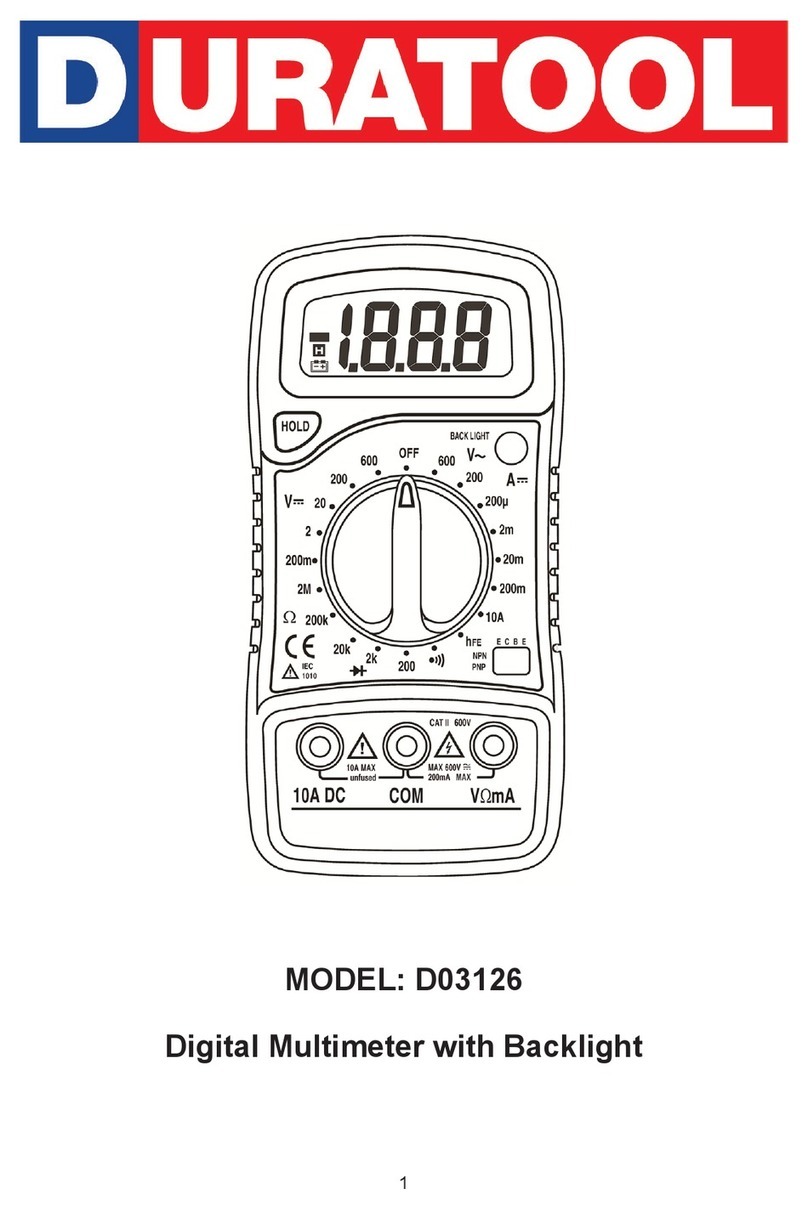

• Connect the black test lead to the "COM" terminal and the red test lead to the "VΩ"

input terminal.

• Set the function range switch to the "Ω" range.

• Connect the test leads across the resistance under measurement and read the

display value. The polarity of the red test lead is positive.

Note: When the input is not connected i.e. at an open circuit, the figure "1" will be

displayed for the overrange condition.

If the resistance value being measured exceeds the maximum value of the range

selected, an overrange indication "1" will be displayed and the function range switch

should be set to a higher range.

TEMPERATURE MEASUREMENT

• Set the function range switch to the "TEMP" position.

• Connect the black plug of the thermocouple to the "COM" and the red plug to the

"mA" input terminal. The polarity of the red test lead is positive.

• Place the working end on, or inside, the object being tested.

• The value of the temperature is shown on the display in "°C".

• The testing temperature is displayed automatically when the thermocouple is put

into the testing terminals.

• The surrounding temperature is shown when the circuit of the sensor is cut off.

• The limit temperature measured by the thermocouple, given together with the

instrument, is 250°C.

DIODE & CONTINUITY TEST

• Set the function range switch to the " " position.

• Connect the black test lead to the "COM" terminal and the red test lead to the "VΩ"

input terminal. The polarity of the red test lead is positive.

• This range has an "Audible Continuity Test" function. The built-in buzzer sounds if

the resistance between two probes in less than 30 ± 20Ω.

• Connect the test leads across the diode and read the display value.

TRANSISTOR hFE TEST (W/MULTIFUNCTION ADAPTOR)

• Set the function range switch to the "hFE" position.

• Set the multi-function adaptor and insert it into the "COM" and "mA" terminal. Be

sure to connect "-" to "COM" and "+" to "mA".

• Ensure that the transistor is "NPN" or "PNP" type.

• Ensure that the transistor is inserted correctly into the E.B.C connector.

• The LCD will show the approximate transistor hFE value.

MEASURING DWELL ANGLE

• Connect the black test lead to the "COM" jack and the red test lead to the "VΩ"

jack.

• Set the rotary switch to the desired "DWELL" range, according to the cylinders of

the motor to be measured.