2

IMPORTANT SAFETY INFORMATION

Please read these instructions carefully before use and retain for future reference.

When using electrical appliances basic safety precautions should always be

followed.

• Check that the voltage indicated on the rating plate corresponds with that of the

local network before connecting the appliance to the mains power supply.

• This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

• This appliance contained no user-serviceable parts. All repairs should only be

carried out by a qualied engineer. Improper repairs may place the user at risk of

harm.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualied persons in order to avoid a hazard.

• Do not leave the soldering station unattended, while it is powered on.

• Never touch the soldering tip or the surrounding metallic parts before the soldering

tip has cooled down completely.

• Turn off the power before connecting or disconnecting the desoldering gun or iron

to the control station.

• Ensure there is sufcient space and ventilation around the appliance to allow the

escape of heat and or fumes.

• Do not use the product near ammable items.

• Turn the power off when this product is not in use.

• The soldering irons must be placed in their holders when not in use.

• Before storage, turn the power off and allow the product to cool down to room

temperature.

• Do not use this product for anything else other than that for which it is designed.

• Children should be supervised to ensure that they do not play with the appliance.

• Do not use this appliance with wet hands.

• Do not expose the soldering station to rain or moisture.

• This appliance must be earthed.

WHAT’S INCLUDED?

• Control Station with desoldering gun holder

• Mains Lead

• Soldering Iron

• Desoldering Gun

• Iron Holder with tray for tip cleaning sponge

• User Manual

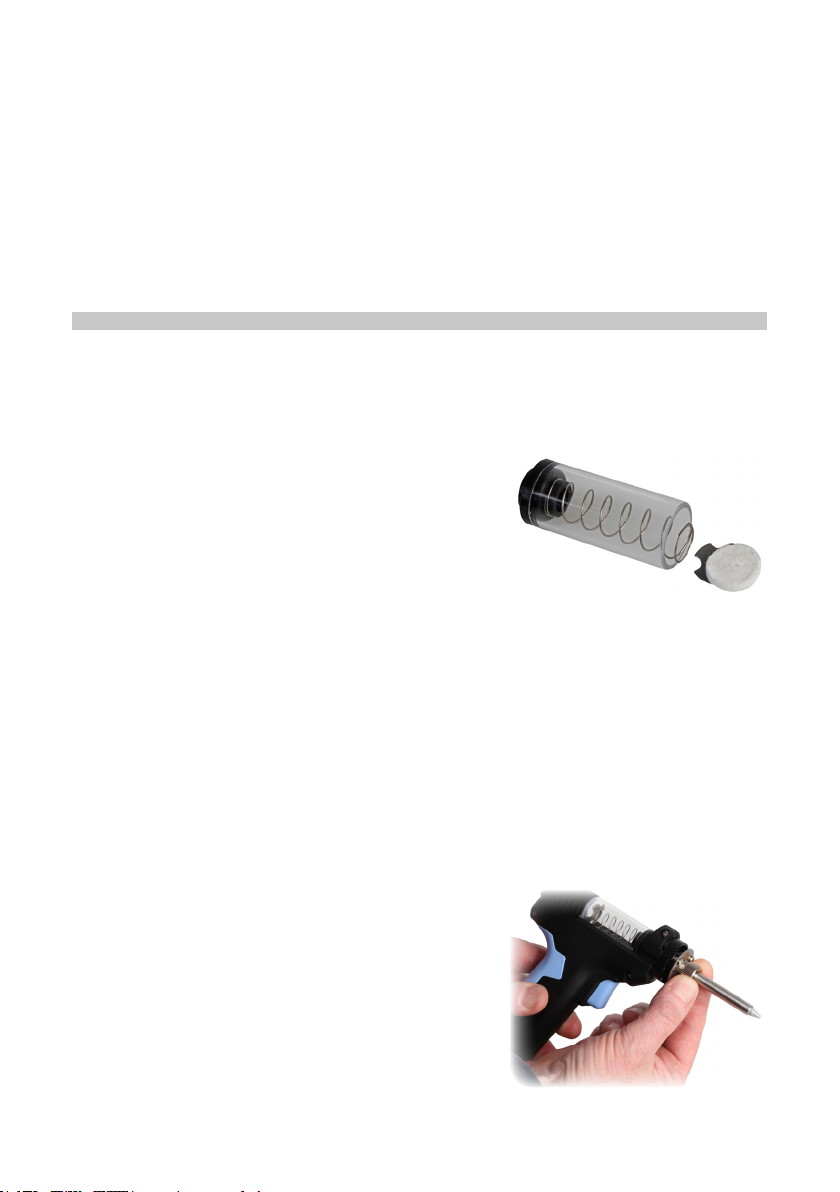

• Desolder tips

• Cleaning wires

• Filter pads