22

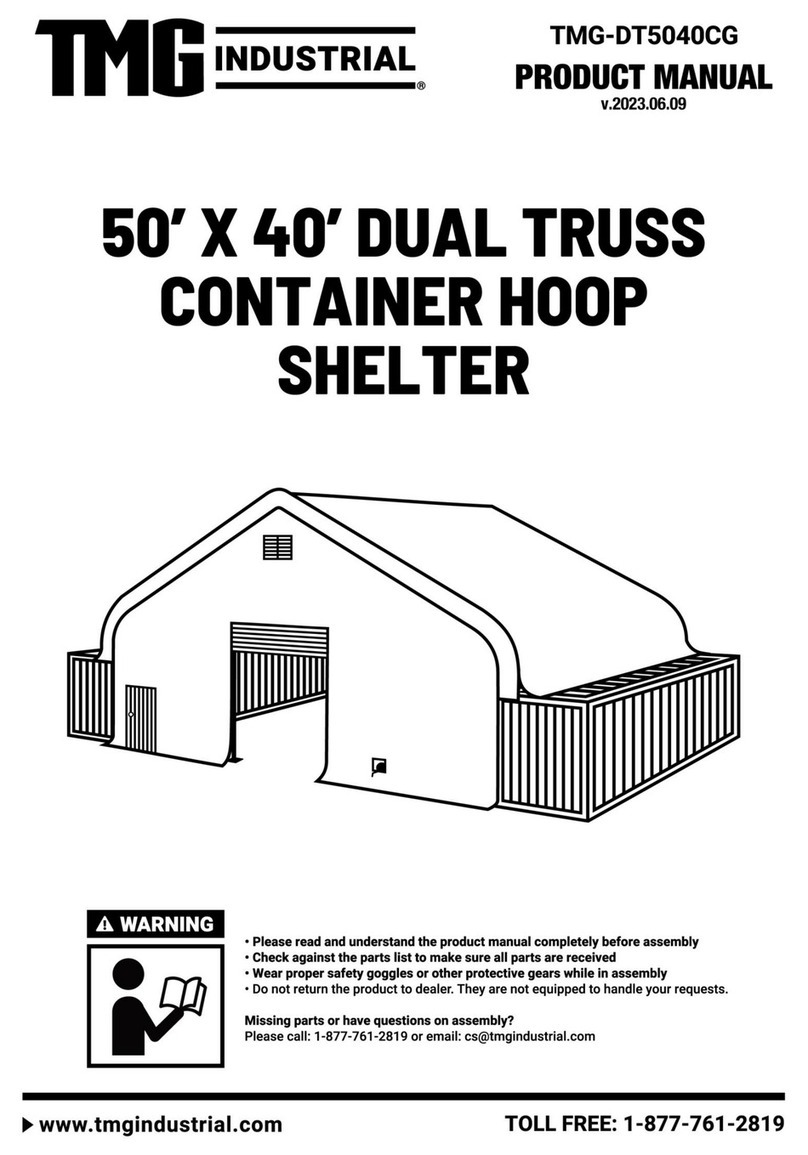

BEFORE YOU BEGIN THE ASSEMBLY PLEASE NOTE

SOME IMPORTANT POINTS

TOOLS REQUIRED

• Drill

• Hex Drive (5/16)

• Hex Drive (3/8)

• Drill Bit 3.5mm

• Drill Bit 10mm

• Square Drive Drill Bit

• Phillips Drill Bit

• Slotted Drill Bit

• Riveter

• Hammer

• Tape Measure

• Ladder

• String Line

• Adjustable Spanner

• Level

• Hand Saw

• Caulking Gun

• Tin Snips (Left & Right Hand)

• Flatle(ForRollerDoor)

• Pipe Wrench (For Roller Door)

• SkillsawandJigsaw(Foroptionaltimberoor)

• MasonryDrilland12mmMasonryBit(forconcreteoor)

BEFORE YOU START

• Read all instructions carefully.

• Identify all parts and check quantities against checklist, before starting.

SAFETY

• Do not attempt to build your shed in high winds.

• Beware of sharp edges.

• Protect your eyes and ears.

• Use electronic tools with care. Use a Safety Trip Switch.

• It is easier and quicker if this shed is erected by two people.

SELECT YOUR SITE

• Your shed must be level. Achieve this by either levelling the ground or by using blocks.

• Ifyourshedistobepositionedonwetordampground,werecommendthatyourshedisraisedupothe

ground slightly.

WARRANTY REQUIREMENTS

The following maintenance process needs to be adhered to, to qualify for the steel warranty of your Duratuf

Guardian shed.

• Wash all surfaces annually using a hose and soft nylon brush.

• Within 2 km of coast – wash every 3 months as above. After a storm, wash the cladding and the gutters as

soon as possible to remove any highly corrosive salt deposits.

• Volcanic Ash Fallout – wash as soon as possible, removing fall out from roof and gutters.

• Do not allow manures, chemicals or other corrosive materials to have direct contact with cladding.

2