During spraying and handling with the application materials

and during cleaning of the equipment follow instructions and

recommendation of manufacturers of particular materials. Use

suitable work protection aids to protect skin, respiratory tract and

eyes (clothes, gloves, respirators protecting masks, resp. breathing

apparatuses, goggles, protection creams etc.).

EQUIPMENT USE AND DESCRIPTION

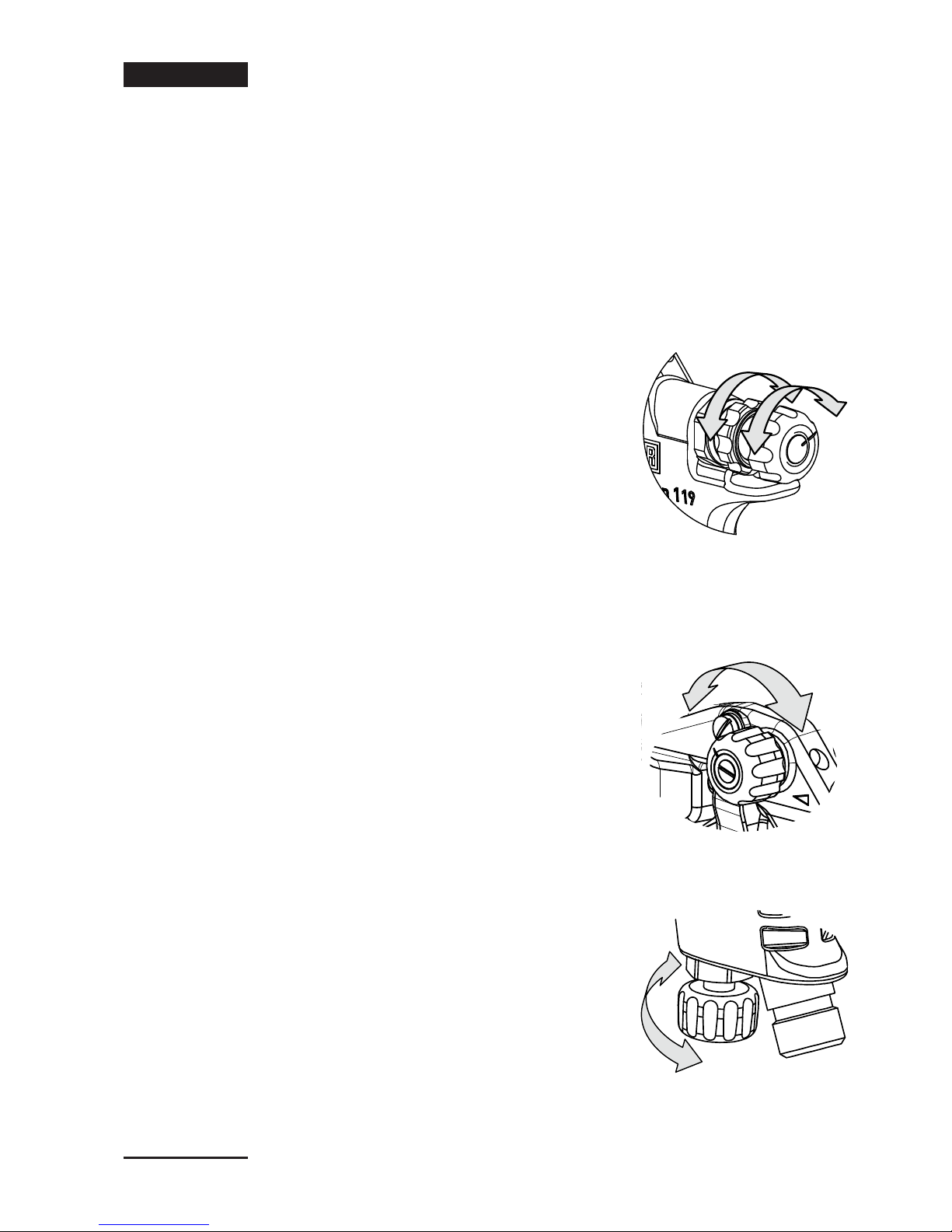

EcoGun 119 air spraying gun is a gun allowing connection of

top vessel (gravity supply of coating material).

Atomising system with decreased pressure of atomising air at the

gun jet mouth, similar to RP system.

The gun features very good grip and balance in hand, as well

as easy less wearisome handling. Assembly threads of connecting

elements are glued with suitable sealing compound (LOCTITE 542).

The spraying gun can handle all types of coating materials,

which are intended to application by spraying, and whose chemical

composition does not disturb the spraying gun components.

Recommended distance of nozzle mouth to the sprayed surface

(spraying distance) depends on side of nozzle assembly and type of

coating material, it ranges from 150 to 190 mm.

Semi-automatic needle seal ensures maximum period

of maintenance-free and reliable operation of the seal.

Mechanical re-tightening of the needle seal enables increased

interval between service repairs. The system joints advantages

of automatic and mechanical design of the needle seal re-

tightening.

This type of the gun can handle following types of the coating

materials:

Solvent-based – synthetic, nitro, acetone, polyurethane, epoxy

and acrylic, primers, llers and nish varnishes

Water-based – acrylic, silicate, silicone and polyurethane

substances

and other application materials of similar properties.

Work environment IE 72 acc. to EN 60721-3-7.