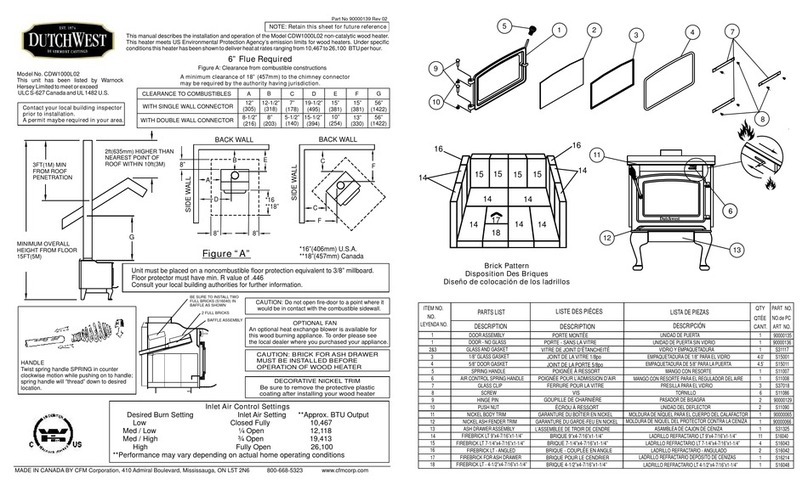

7

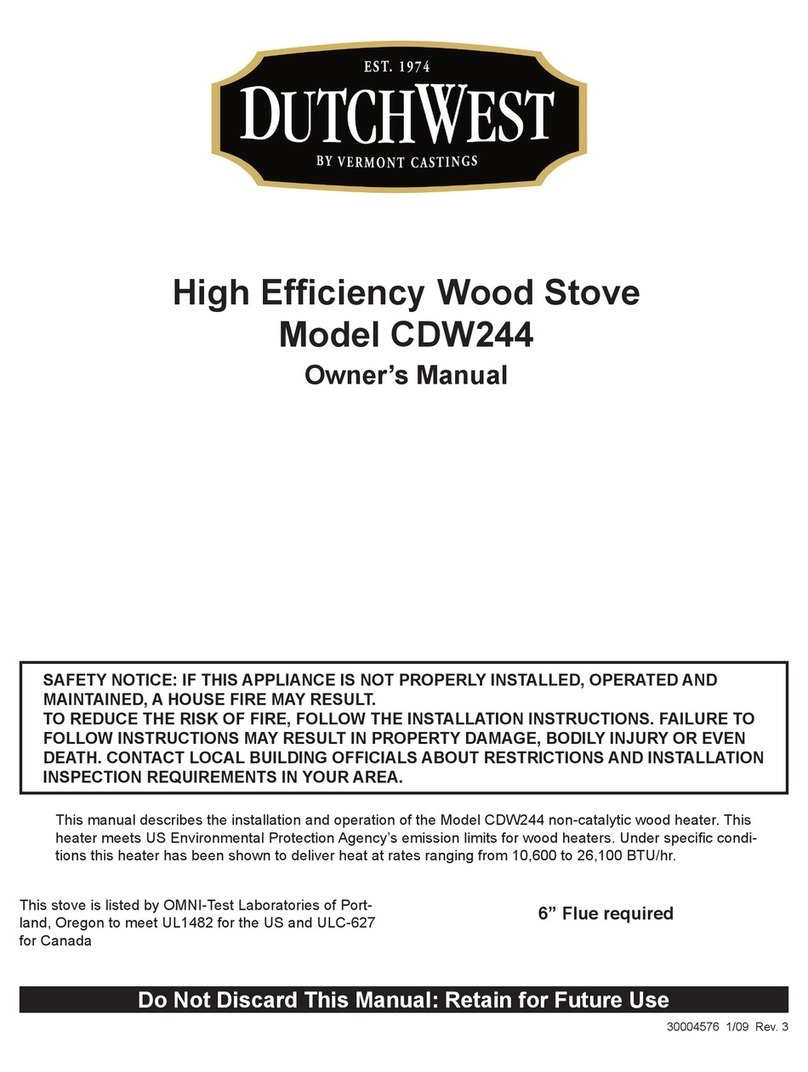

6” (152mm) min dia Stainless steel Flexible liner

CHIMNEY

CONTACT YOUR LOCAL BUILDING AUTHORITY FOR APPROVED METHODS OF

INSTALLATION

a) A chimney connector shall not pass through an attic, roof space, closet, floor, ceiling or

simular concealed space. Where passage through a wall or partition of combustible

construction is desired, the installation shall conform to CAN/CSA-B365 (in Canada). In the

USA, check with local building officials for requirements in your area.

b) It is advisable to have your masonry chimney inspected for deterioration such as cracks

and crumbling mortar before you install your unit.

c) To help ensure a good draft, the top of the chimney should be at least 3 feet (914mm)

above the point of penetration through the roof, and be at least 2 (610mm) feet higher than

any point of the roof within 10 feet (3048mm).

d) Do not use makeshift compromises during installation.

e ) Do not remove bricks or mortar from the fireplace.

CANADA: This fireplace insert must be installed with a continuous chimney liner of

6"(152mm) minimum diameter extending from the flue collar to the top of the chimney. The

chimney liner must conform to the class 3 requirements of CAN/ULC-S635 STANDARD for

lining systems for existing masonry or factory-built chimneys and vents, or CAN/ULC-S640

STANDARD for lining systems for new masonry chimneys.

USA: This fireplace insert must be connected to:

1) A chimney complying with the requirements for type HT chimneys in the Standard for

Chimneys, Factory-built, Residential Type and building Heating Appliance, Ul103, or

2) A code-approved masonry chimney with flue liner.

3) See page 8 for alternate chimney installation.

NOTES:

A stainless steel adapter is

recommended for fastening the

stainless steel flexible liner to the flue

collar.

Male or crimped end of the adapter

must be installed inside the flue collar.

Drill flue collar to permanently fasten

stainless steel adapter using a

minimum of 3 screws.

Fasten stainless steel chimney liner to

the stainless steel adapter using

manufactures instructions.

fire-parts.com