Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use.

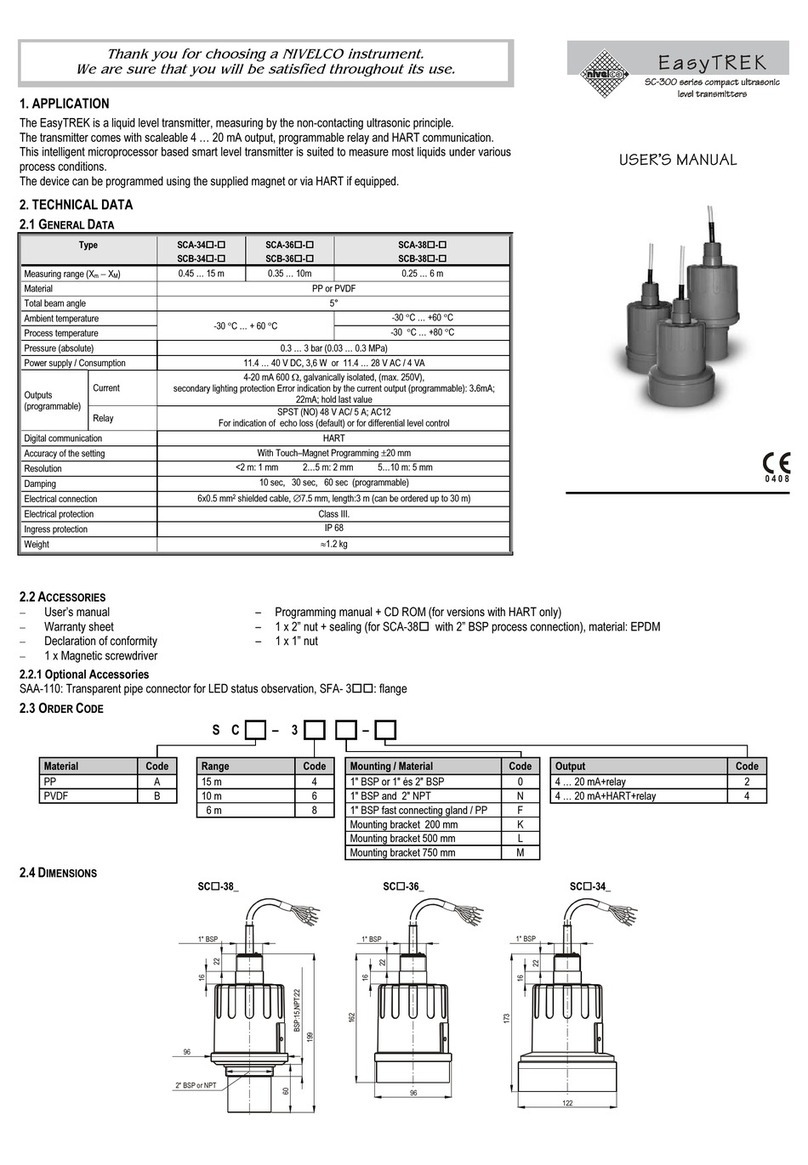

1. APPLICATION

The NIVOPRESS submersible hydrostatic level transmitter is applicable for the continuous level measurement of clean

or chemically faintly contaminated liquids in bored well, open reservoirs and tanks. The NIVOPRESS is easy to install in

already existing tanks and in deep bored well and is especially recommended for controlling of submersible pumps.

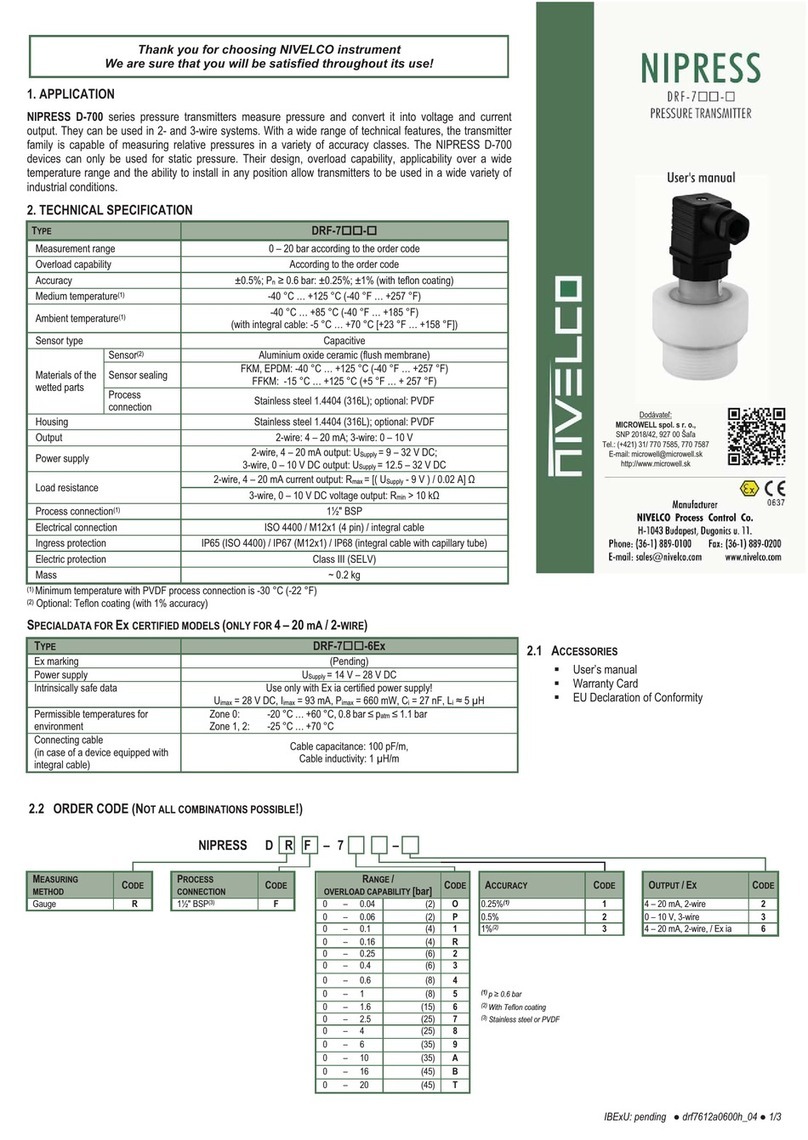

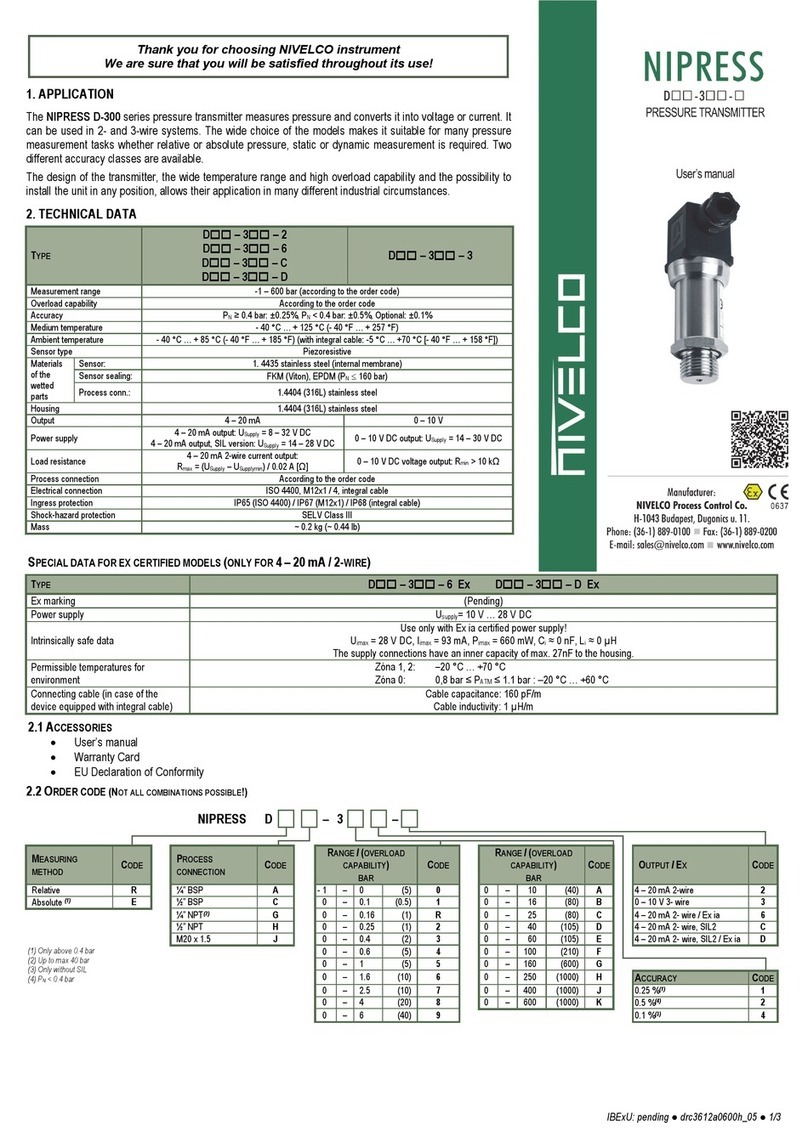

2. TECHNICAL DATA

Type NPK NPH

Ranges 0 …1, 2, 5 etc max 200 m. water head (see order codes)

Overload allowed For models with measuring limit below 20 m w. h. 2 x measuring limit

For models with measuring limit over 20 m w. h. 1.5 x measuring limit

Output 4 … 20 mA 2-wire 0 … 10V 3-wire

Operating voltage 9 to 30 V DC 18 to 30 V DC

Maximum load resistance Rs = (Us - 9 V) / 0.02 A

Us= voltage of the power supply ≥5 kΩ

Current — < 6 mA

Accuracy (FSO) ≤± 0.5 %

Zero drift ≤± 0,1 mA ≤80 mV

Temperature coefficient ≤± 0.1 %/ 10K ≤± 0.2% / 10 K

Operating temperature -10 °C to +60 °C for special request +75 °C

Ingress IP 68

Cable cross secion 0.34 mm2

Cable coating Polyurethane ∅7mm

Cable length up to 300 m according to the order

Probe size ∅22 x 215 mm

Mass probe: 0.2 k g cable: 0.06 kg/m

Wetted parts

Sensor: stainless steel 316L

Probe stainless steel 1.4571

Cable coating: polyurethane

Sealing: VITON

Protecting cap: ABS

Cable mounting plate NAA-103

Applicable With cable length up to150 m

Operating temperature -10 °C to +45 °C

Dimensions 110 x 110 mm

Cable terminal box NAA-101

Dimensions 139 x 119 x 70 mm

Ingress IP 65

Operating temperature –40 °C to +65 °C

Material Plastic

Cable gland ASM16 (∅5 to ∅10mm)

Electric connection Terminal block for cable with max cross section of 2.5 mm2

Cable terminal box with over voltage protection NAA-102 (for 2-wire models only)

Voltage clipping 33 Vpp

Serial resistance 13 ohm ±10 %

Leakage current 10 µA

Other data Same as with NAA101

Over voltage protection unit OVP12/33 and OVP32/33

Electric data Same as with NAA102

OVP12/33 OVP32/33 DIN rail mount

Ingress protection IP 54 IP 20

Dimensions 72 x 42 x19 mm 62 x 65 x 18 mm

2.1 ACCESSORIES Optional (to be ordered)

User’s Manual Cable mounting plate NAA 103

Guarantee sheet Cable terminal box NAA 101

Cable terminal box with OVP12/33 NAA 102

DIN rail mount over voltage protection OVP32/33

2.2 ORDER CODE

NIVOPRESS NP-2-

Output Code Range ** Code Cable length Code Cable length Code

0 … 1 m water head 1 10 m 1 1 m 1two-wire

4 … 20 mA K0 … 2 m water head 2 20 m 2 2 m 2

0 … 5 m water head 3 30 m 3 3 m 3three-wire

0 … 10 V DC H0 … 10 m water head 4 40 m 4 4 m 4

0 … 20 m water head 5 50 m 5 5 m 5

0 … 50 m water head 6 60 m 6 6 m 6

** Different span within the range

on special request. 0 … 100 m w. head 7 70 m 7 7 m 7

0 … 200 m w. head 8 80 m 8 8 m 8

90 m 9

up to 100 m

9 m 9

100 m A 0 m 0

200 m B 10 m 1

300 m C : :

over

100 m

90 m 9

USER’S MANUAL

Manufacturer:

NIVELECO Process Control Co.

H-1043 Budapest, Dugonics u. 11.

Tel: (36-1) 369-7575 Fax: (36-1) 369-8585

2.3 DIMENSIONS in mm

NIVOPRESS NP probe

215

∅

22

protection

cap

St.St.

cartridge

breathing

cable

∅

7

Cable mounting plate NAA103

mounting

plate

breathing cable

Tartó

110

110

15

30

15

∅

10

∅

6,3

7,5

breathing cable

Cable terminal box NAA101/NAA102

139

airing

119

80

ø4,5

Conduit opening Mounting