General Safety Considerations

All users of Dymax fluid dispensing equipment should read and understand the user

guide before assembling and using the equipment.

To learn about the safe handling and use of dispensing fluids, obtain and read the SDS

for each fluid before using it. Dymax includes an SDS with each adhesive sold. SDS for

Dymax products can be requested through the Dymax website.

Specific Safety Considerations

Using Safe Operating Pressures

Pressurizing the components in the dispensing system beyond the maximum

recommended pressure can result in the rupturing of components and serious personal

injury. To minimize the risk of rupturing components and injury, do not exceed the

maximum operating pressure of the components in your fluid dispensing system (see

system specifications on page 13).

Preventing Injection Injury

Discharging fluids or compressed air with a dispensing tip against your skin can cause

very serious injection injury. To minimize the risk of injection injury, do not place the

dispensing tip in contact with your skin.

Product Overview

Description of the Model 400 Dispensing Valve

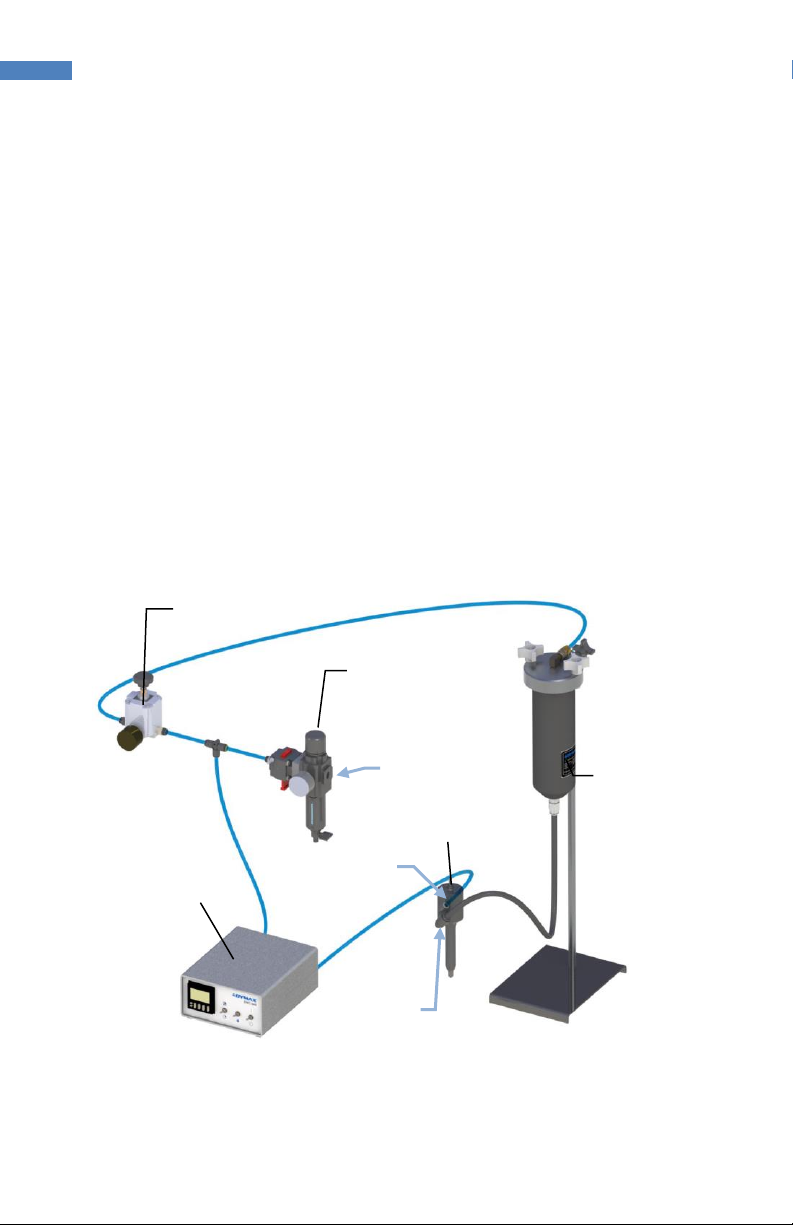

The Model 400 handheld, pneumatic needle valve is designed to deliver precise volumes

of low- to medium-viscosity fluids. Air pressure through the valve retracts the needle

assembly from the seat allowing fluid to flow from the valve fluid inlet to the dispensing

tip. When the air pressure is eliminated, the spring to returns the needle back to its

position, closing the fluid path and ending the dispense cycle. The valve also features a

flow adjustment knob which allows for fine-tuning of the dispense volume, ensuring

precise and consistent deposits. The Model 400 is ideally suited for a wide range of

applications including dispensing cyanoacrylates, inks, and UV light-curable adhesives.