Dynabrade Grinder Series User manual

Other Dynabrade Power Tools manuals

Dynabrade

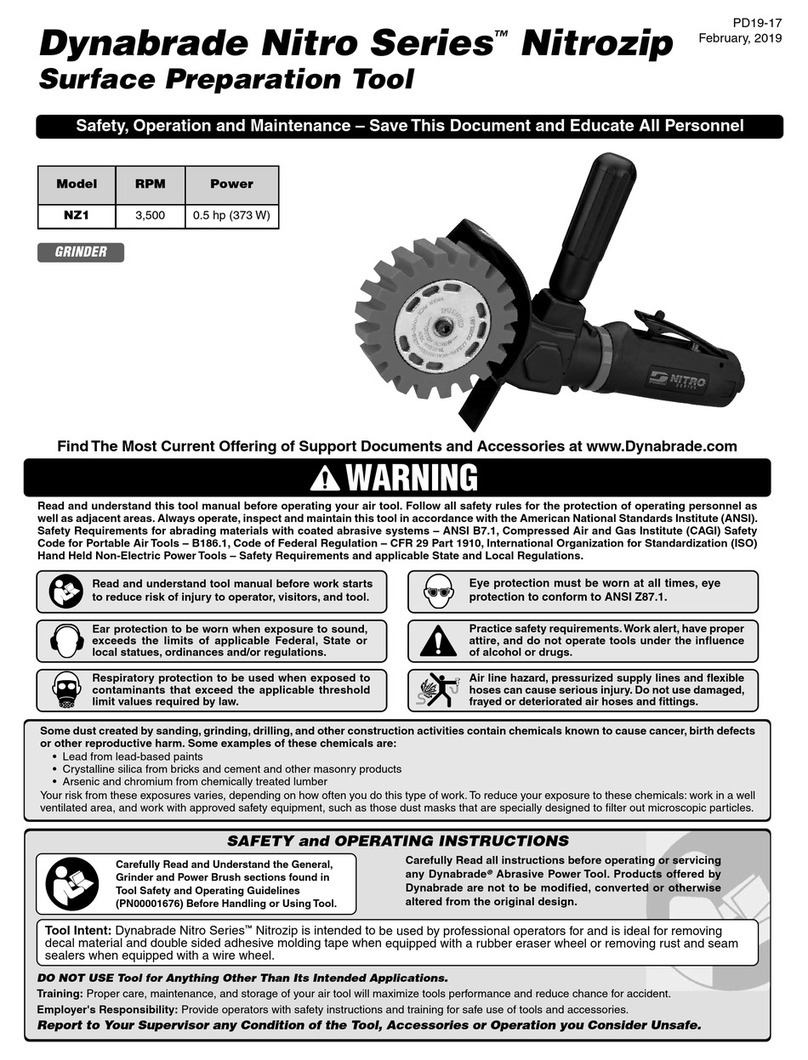

Dynabrade Nitro Series Guide

Dynabrade

Dynabrade Dynastraight 13501 Installation guide

Dynabrade

Dynabrade 13511 Guide

Dynabrade

Dynabrade 40324 User manual

Dynabrade

Dynabrade 51332 Guide

Dynabrade

Dynabrade 52196 Operating instructions

Dynabrade

Dynabrade Nitro Series Guide

Dynabrade

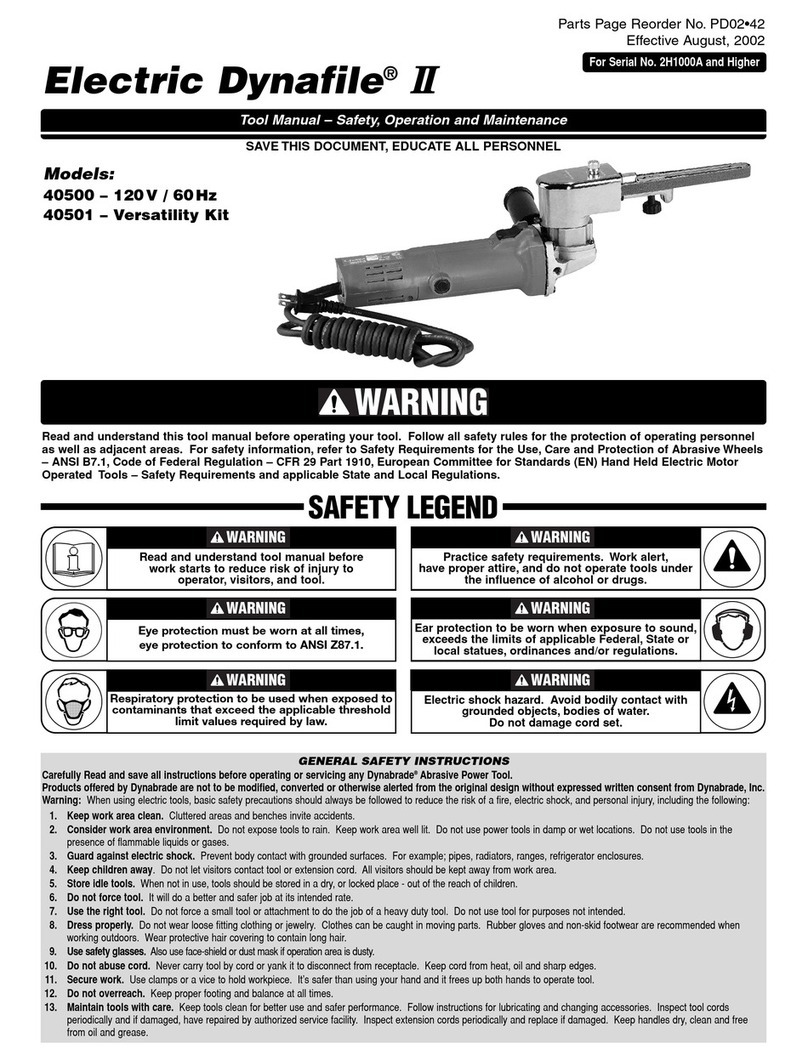

Dynabrade Dynafile II 40500 Guide

Dynabrade

Dynabrade Electric Dynafile II 40501 Guide

Dynabrade

Dynabrade Dynafile 14000 Guide

Dynabrade

Dynabrade 13201 User guide

Dynabrade

Dynabrade Mini-Dynorbital Supreme User manual

Dynabrade

Dynabrade VirtuScaler Webscaler 30200 User manual

Dynabrade

Dynabrade Dynisher 50730 Installation instructions

Dynabrade

Dynabrade 51735 User manual

Dynabrade

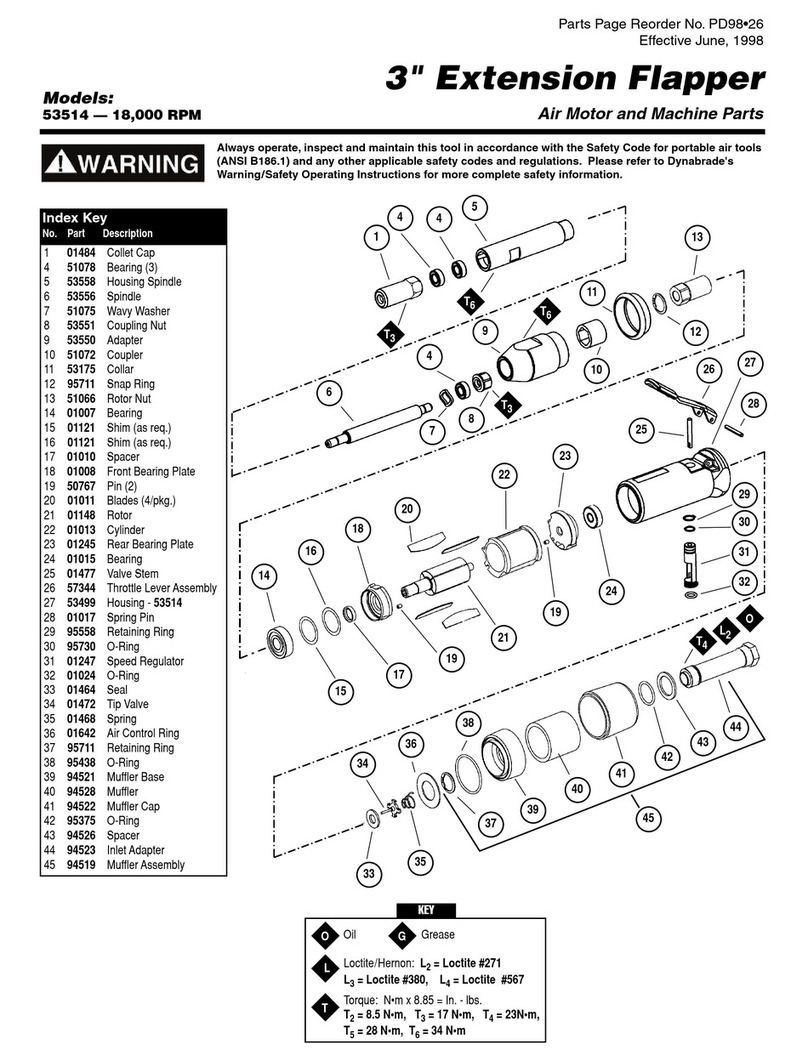

Dynabrade 53514 User manual

Dynabrade

Dynabrade 52050 User manual

Dynabrade

Dynabrade Mini-Dynisher 13300 User guide

Dynabrade

Dynabrade 13400 3 Manual

Dynabrade

Dynabrade 52576 User manual