2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Accessories . . . . . . . . . . . . . . . . . . 3

Setting Up Shop . . . . . . . . . . . . . . . . . . . . . . 4

Required Supplies & Tools . . . . . . . . . . . . . . 4

Optional Accessories . . . . . . . . . . . . . . . . . . 4

Building Notes . . . . . . . . . . . . . . . . . . . . . . . . 5

Common Abbreviations . . . . . . . . . . . . . . . . . 5

Types of Wood . . . . . . . . . . . . . . . . . . . . . . . . 6

Cyanoacrylate Glue. . . . . . . . . . . . . . . . . . . . 6

BuildTheTail Surfaces. . . . . . . . . . . . . . . . . . 6

Build The Fin . . . . . . . . . . . . . . . . . . . . . . . . . 6

Build The Rudder, Stab & Elevator . . . . . . . . 7

Finish The Tail Surfaces . . . . . . . . . . . . . . . . 8

BuildThe Wing . . . . . . . . . . . . . . . . . . . . . . . . 9

Build The Inner Wing Panels . . . . . . . . . . . . . 9

Build The Outer Wing Panels . . . . . . . . . . . 13

Join The Inner Panels . . . . . . . . . . . . . . . . . 15

Join The Outer & Inner Wing Panels . . . . . . 17

Finish The Wing. . . . . . . . . . . . . . . . . . . . . . 18

BuildThe Fuselage. . . . . . . . . . . . . . . . . . . . 19

Prepare The Fuse Sides . . . . . . . . . . . . . . . 19

Join The Fuselage Sides . . . . . . . . . . . . . . . 21

Sheet The Fuse Bottom . . . . . . . . . . . . . . . 22

Finish The Fuselage . . . . . . . . . . . . . . . . . . 22

Install The Servos . . . . . . . . . . . . . . . . . . . . 26

AlignThe Stab & Fin. . . . . . . . . . . . . . . . . . . 26

Align The Stab . . . . . . . . . . . . . . . . . . . . . . . 26

Align The Fin . . . . . . . . . . . . . . . . . . . . . . . . 27

Covering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Prepare For Covering . . . . . . . . . . . . . . . . . 28

Covering Sequence. . . . . . . . . . . . . . . . . . . 28

Covering Tips . . . . . . . . . . . . . . . . . . . . . . . 28

JoinTheTail Surfaces . . . . . . . . . . . . . . . . . 31

Join The Stab, Fin & Fuse . . . . . . . . . . . . . . 31

Hinge The Control Surfaces . . . . . . . . . . . . 32

Fuelproofing . . . . . . . . . . . . . . . . . . . . . . . . . 33

Final Hook-Ups & Checks . . . . . . . . . . . . . . 33

Connect The Servos . . . . . . . . . . . . . . . . . . 33

Mount The Landing Gear . . . . . . . . . . . . . . 35

Finish Radio Installation . . . . . . . . . . . . . . . 35

Mount The Wing . . . . . . . . . . . . . . . . . . . . . 36

Balance Your Model. . . . . . . . . . . . . . . . . . . 36

Set The Control Throws. . . . . . . . . . . . . . . . 37

PreFlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

At Home . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

At The Flying Site . . . . . . . . . . . . . . . . . . . . 38

Engine Safety Precautions . . . . . . . . . . . . . 38

Flying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Find A Safe Place To Fly . . . . . . . . . . . . . . . 38

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Introduction

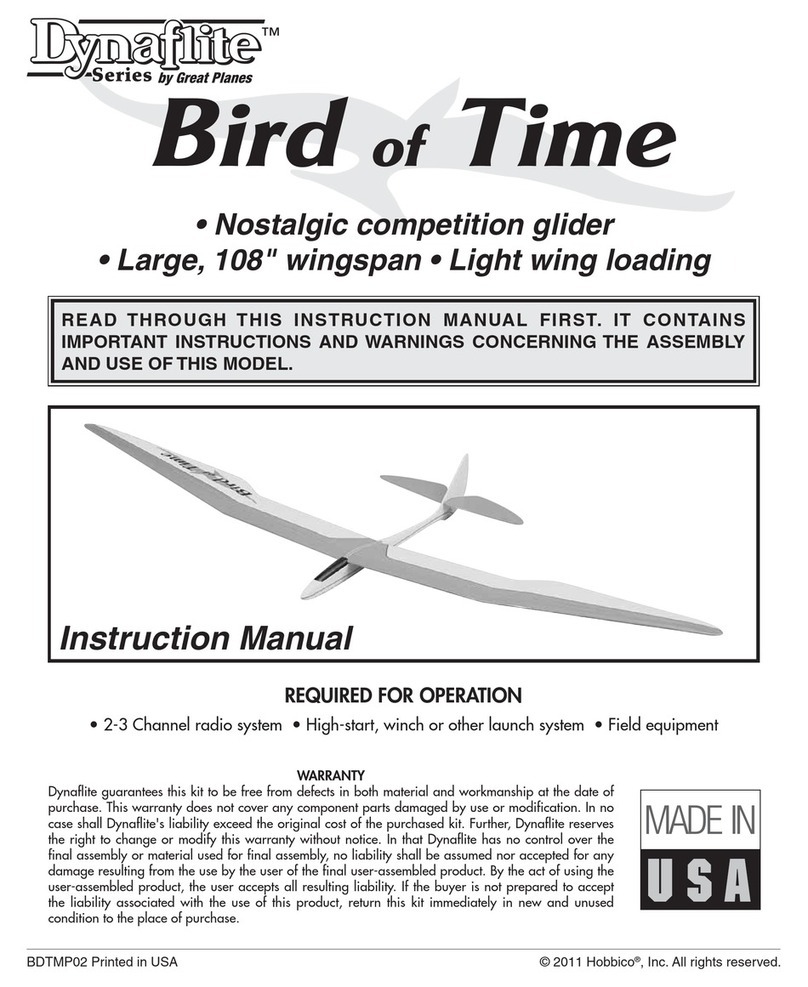

Congratulations and thank you for purchasing

the Dynaflite Butterfly. The Butterfly is a “powered

sailplane” or “motor glider” and is an ideal model for

learning to fly radio controlled models – especially

if you are not able to locate an experienced flight

instructor and must try it on your own. Because

of its large wingspan and light wing loading, the

Butterfly is a gentle model that will give you plenty

of time to think and react. Because of its size and

light weight however, you must reserve first flight

attempts for a calm day – more on that in the “Flying”

section at the end of the manual.The Butterfly does

not require a powerful engine. Any .10 to .15 cu.

in. 2-stroke will do the job – all the engine has to

do is provide a little thrust and the large wing will

do the rest!

The way you fly the Butterfly is to let it climb (it will

do that almost by itself with just a little guidance from

you), then throttle back and fly it around rather like

a sailplane.When you need more altitude just apply

throttle. This doesn’t sound like much action but

don’t worry, if you’re a beginner you’ll be busy. Most

important, you’ll develop the hand-eye coordination

required to fly traditional “40-size” sport/trainers.

Enough said. Please thoroughly read the rest of

the preliminary information, then let’s get started!