Introduction................................................2

Precautions

................................................2

Preparations

..............................................3

Required Accessories..........................................3

Optional

Accessories

..........................................4

Suggested

Supplies

............................................4

Building

Notes

....................................................5

Adhesives

............................................................5

Common Abbreviations......................................6

Types

of

Wood

....................................................6

Inch/Metric Ruler..................................................6

Die-Cut Patterns............................................7& 8

Buildthe Stabilizer

&

Elevators

................9

Buildthe Vertical Fin& Rudder................10

Buildthe

Fuselage

....................................12

Build

the

Bulkheads

..........................................12

Buildthe Wing

..........................................19

Join the Wing

Panels

................................23

Buildthe Ailerons

....................................26

Buildthe Flaps..........................................27

Mount

the Wing

to

the Fuselage

..............28

Finishthe

Fuselage

..................................29

FinalAssembly..........................................33

Finishing

..................................................35

Setthe ControlThrows

............................36

Balance

Your

Model

..................................36

Balance the Model Laterally

....................37

Preflight....................................................37

At

Home

............................................................37

At the Flying Site ..............................................38

Engine Safety Precautions

......................38

AMA

Safety Code (excerpt)

......................39

Flying........................................................39

Find

a

Safe

Place

to

Fly

....................................39

Takeoff................................................................40

Flight..................................................................40

Landing

..............................................................40

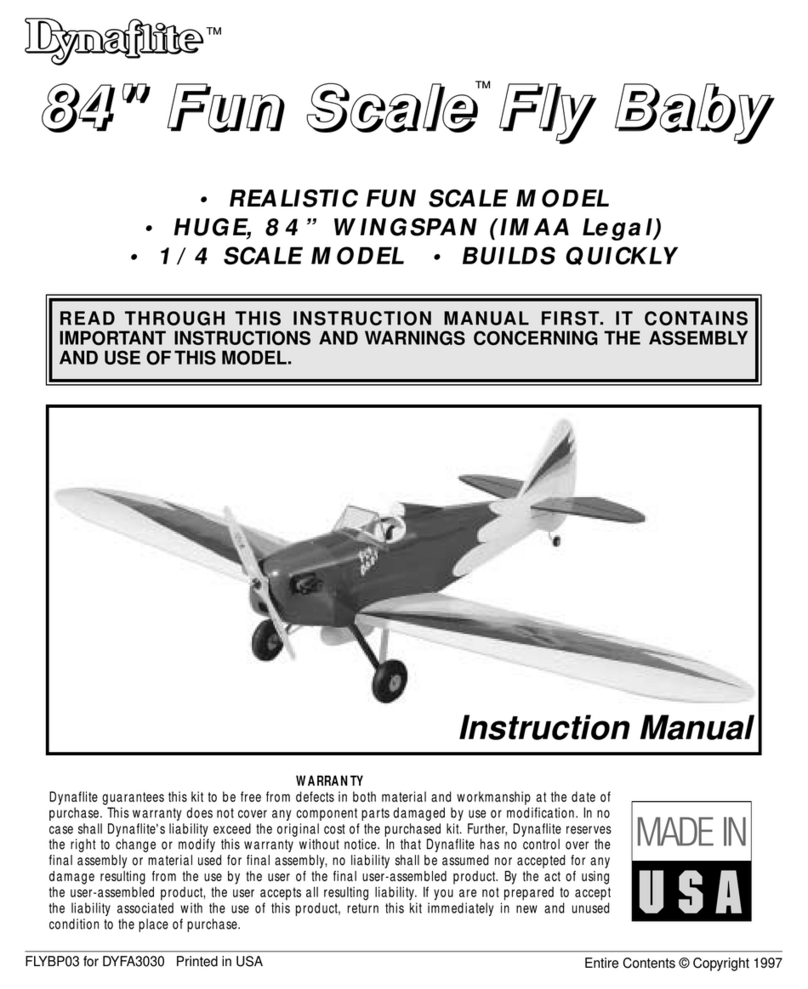

Congratulations on your choice ofthis kitfor

your next project.The Chipmunk isa FunScale®

model of a trueclassicaircraft.Ithas the

presence that only a big model can carry off.

At Dynaflite we take pride inoffering kits that

aresimple and straightforwardto build and

providevalueforyourmodelingdollar.

Because of the size and cost of this model we

assumeyou have builtseveralmodels and have

ageneralworking knowledge of modeling and

its terms. Ifyou HAVE NOTbuilt and flown

several kits, do yourselfa favor- back up and

get some experience before beginning this kit.

1.You must build the plane according to the

plan and instructions. Donot alter or modify

the model, as doing so may result inan unsafe

or unflyable model. Ina few cases the plan

and instructions may differ slightlyfrom

the photos. Inthose instances the plan

and written instructions are correct.

2.You musttake time to build straight, true

and strong.

3.You mustusea proper R/Cradio that isin

first class condition, the correct size of engine

and correct components (fuel tank, wheels,

etc.) throughout your building process.

4.You mustproperly installall R/C and other

componentsso that the model operates

properly on the ground and inthe air.

5.You must test the operation of the model

before every flight to insure that all equipment

isoperatingand you must make certainthatthe

model has remained structurallysound.

6.Ifyou are notalreadyan experienced R/C

pilot,you must fly the model onlywith the

helpofa competent,experienced R/Cpilot.

Remember: Take your time and follow

instructions to end upwith a well-built

modelthat isstraight andtrue.

2