2

TABLE OF CONTENTS

INTRODUCTION .................................................2

PRECAUTIONS...................................................3

PREPARATIONS.................................................3

Required accessories ...................................3

Suggested supplies.......................................4

Building notes ...............................................4

Types of wood ..............................................4

Metric conversions ........................................5

DIE PATTERNS...................................................5

BUILD THE TAIL SECTION ................................6

Build the fin and rudder ................................6

Build the stabilizer.........................................7

Build the elevators ........................................7

BUILD THE WING ...............................................8

Sheet the top of the wing............................11

Finish the wing............................................13

Build the ailerons ........................................14

BUILD THE FUSELAGE ...................................15

Assemble the firewall..................................15

Build the bulkheads and fuselage sides ............18

Assemble the fuselage ...............................19

Mount the wing ...........................................21

Sheet the top of the fuselage......................23

Finish the bottom of the fuselage ...............24

Mount the tail ..............................................26

Make and mount the wing struts.................28

Finish the windshield and cowl ...................29

FINAL ASSEMBLY ...........................................30

Install the radio system ...............................30

Set the control throws .................................30

FINISHING ........................................................31

Finishing the struts......................................31

Balance your model ....................................31

PREFLIGHT ......................................................31

Balance your propellers ..............................31

Charge your batteries .................................32

AT THE FLYING SITE .......................................32

Ground check your model...........................32

Range check your radio..............................32

SAFETY PRECAUTIONS .................................32

FLIGHT..............................................................33

Takeoff ........................................................33

Flying ..........................................................33

Landing .......................................................34

INTRODUCTION

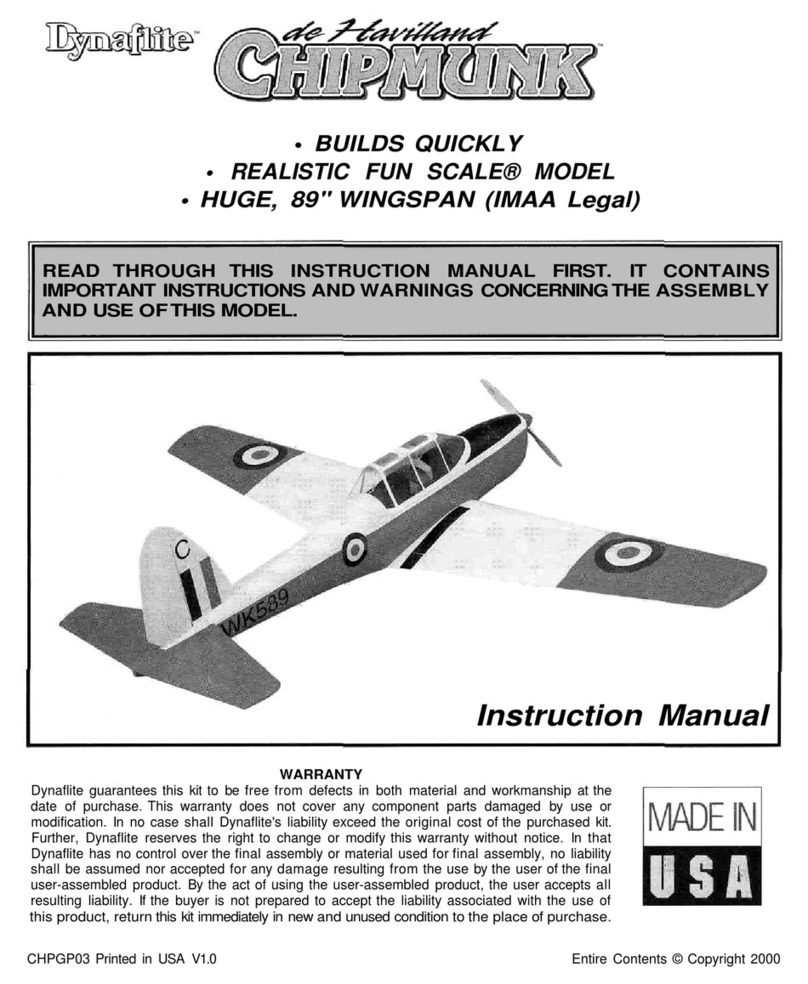

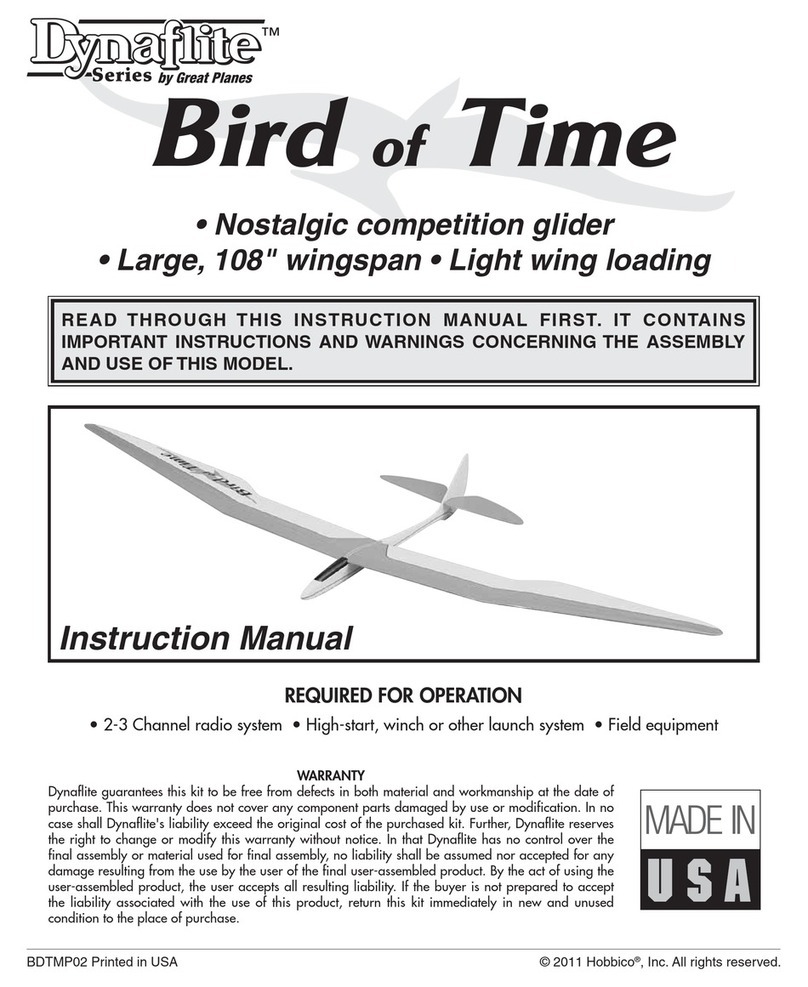

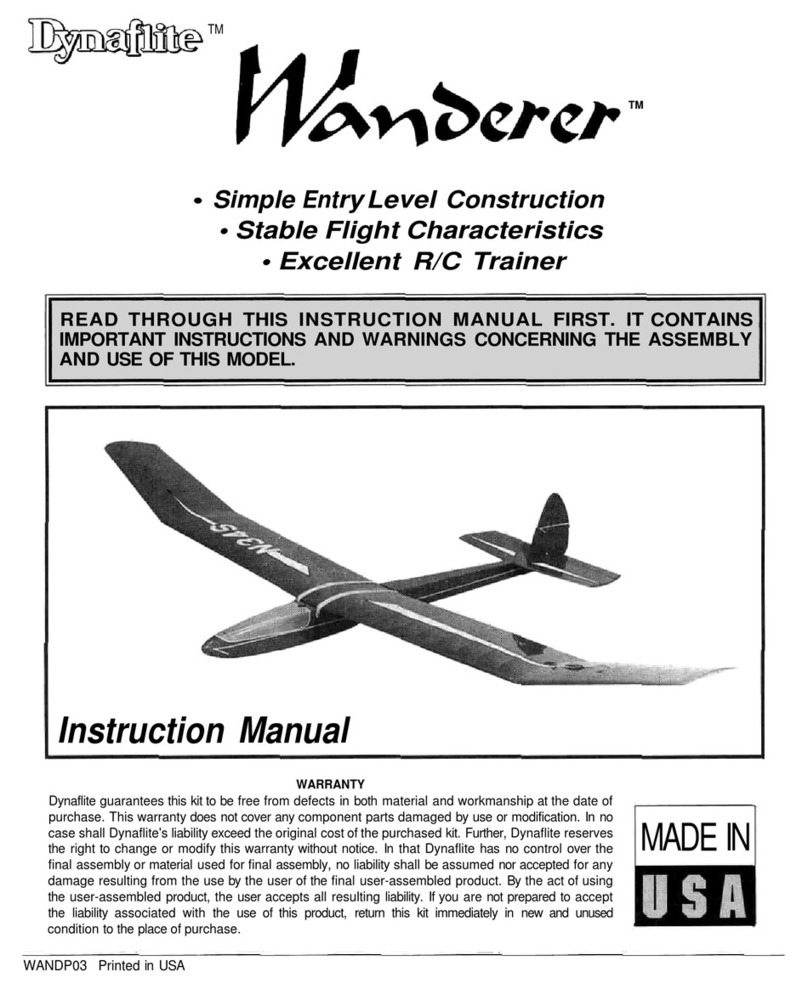

Congratulations on your choice of this kit for your

next project. The Super Decathlon is a Fun Scale®

model of a truly classic aerobatic aircraft. It has the

presence that only a big model can deliver. The

full-scale Super Decathlon is a basic aerobatic

aircraft capable of spins, loops, rolls, immelmanns,

split S’s, hammerheads and basic inverted flight.

Super Decathlons have been the choice for basic

aerobatics in the US for the past twenty-five years.

One of the things that made this plane so popular

was the fact that it was one of the easiest landing

taildraggers ever made. The Dynaflite Super

Decathlon has the great landing habits of the full-

scale plane, with more aerobatic potential.

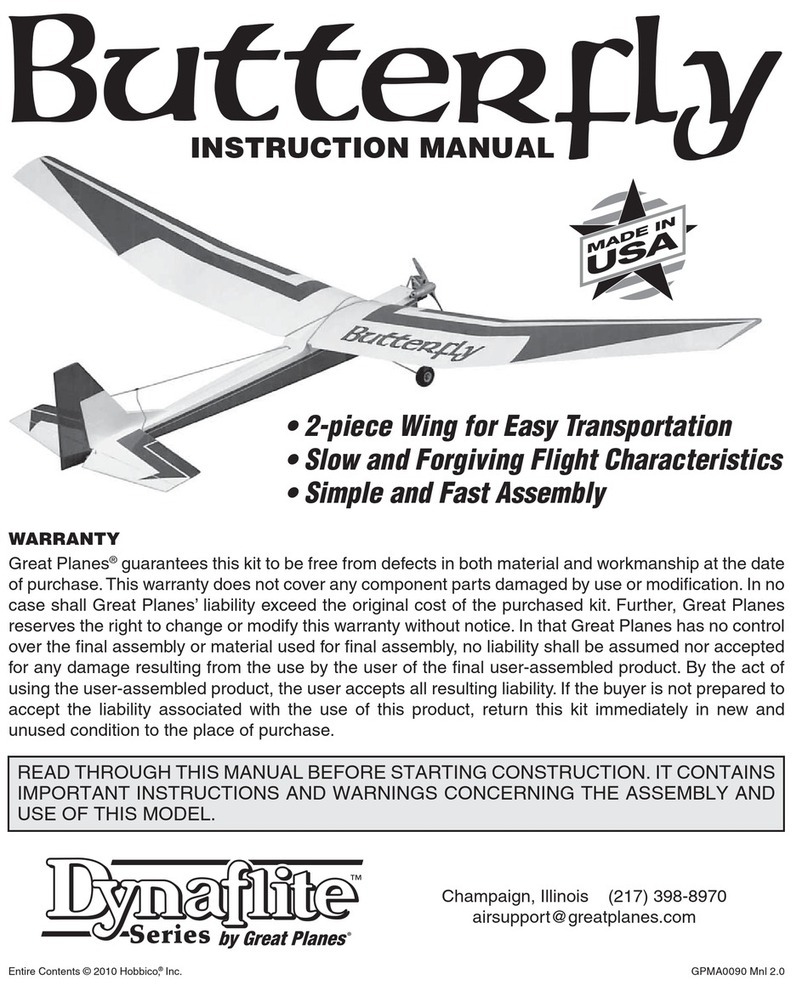

The two-piece wing means transporting this 89"

span model can be done in any vehicle which can

hold the manageable 67" fuselage. The big wing

and strong structure of the Dynaflite Super

Decathlon allows for an engine range from the

1.08 2-stroke all the way up to the 2.1 gas engines.

We do recommend flying wires on the tail if you are

using an engine at the larger end of the

recommended range.

At Dynaflite, we take pride in offering kits that are

simple and straightforward to build and provide

value for your modeling dollar. Because of the size

and cost of this model, we assume you have built

several models and have a general working

knowledge of modeling and its terms. If you HAVE

NOT built and flown several kits, we strongly

recommend you back up and get some experience

before beginning this kit.

YourSuperDecathlonisnotatoy,butasophisticated

working model that functions like a full-size airplane.

Because of its performance, if you do not assemble

and operate the Super Decathlon correctly, you

could possibly injure yourself or spectators and

damage property. To make your R/C modeling

experience totally enjoyable, we recommend that

you get assistance with assembly and your first

flights from an experienced, knowledgeable