Introduction

......................................................2

Precautions.......................................................3

Preparations.....................................................3

Required

Accessories

.......................................3

SuggestedSupplies

.........................................3

Optional

Accessories

.......................................4

BuildingNotes.................................................4

Adhesives

.......................................................4

Common Abbreviations....................................5

Types

of

Wood

................................................5

MetricConversion............................................5

DiePatterns ................................................6&7

Build

the Fuselage ...............................................8

Build

the Wing .....................................................12

BuildtheAilerons ...........................................................16

BuildtheStabilizer

&

Elevators ...........................17

BuildtheVertical

Fin

&

Rudder .........................19

Mount

the

Wing

to

the

Fuselage .........................20

FinalAssembly .................................................22

Finishing..........................................................26

Set TheControlThrows...................................27

Balance

Your

Model.......................................27

Preflight..................................................27

AtHome...............................................................27

At theFlying

Site

...........................................28

Engine

Safety

Precautions................................28

FLYING.............................................................28

Finda

Safe

Place

to

Fly..................................28

Takeoff..........................................................29

Flight.........................................................29

Landing

........................................................29

Terms

&

Definitions

........................................30

Cockpit&WingTipPatterns...........CenterSpread

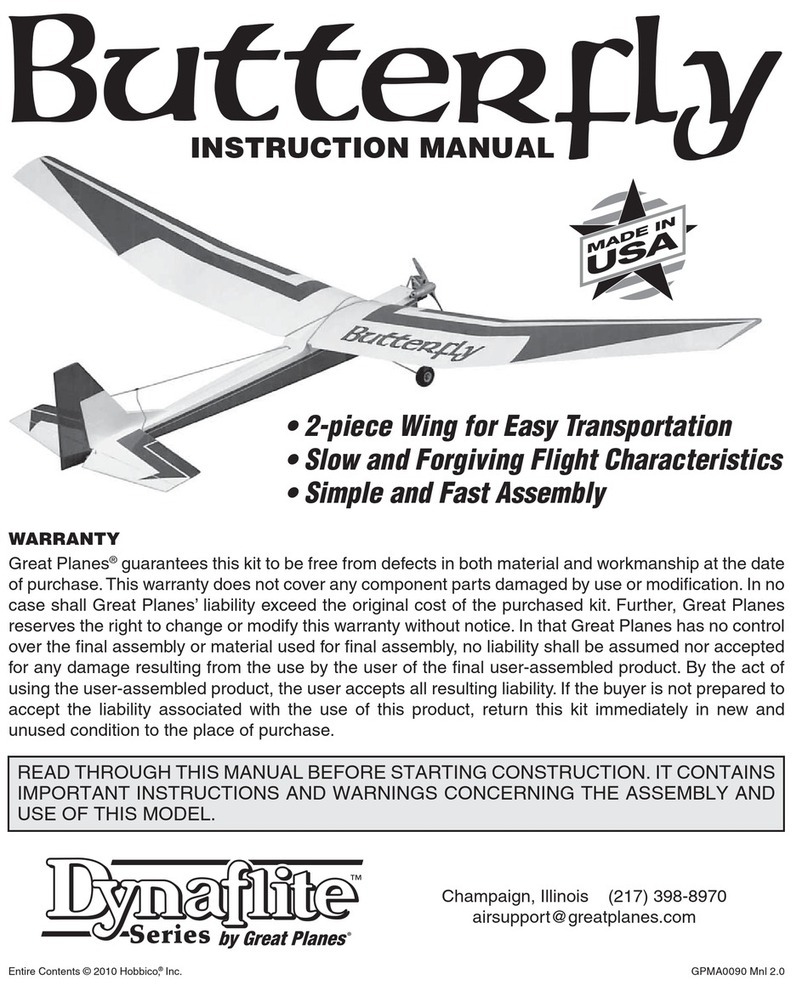

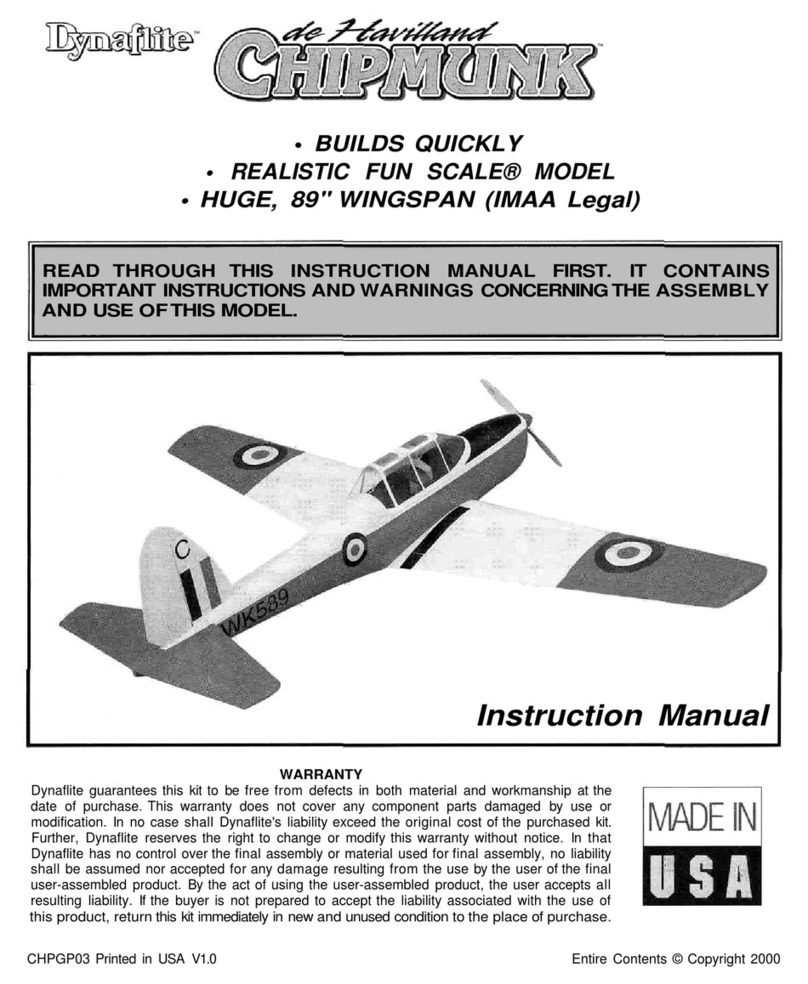

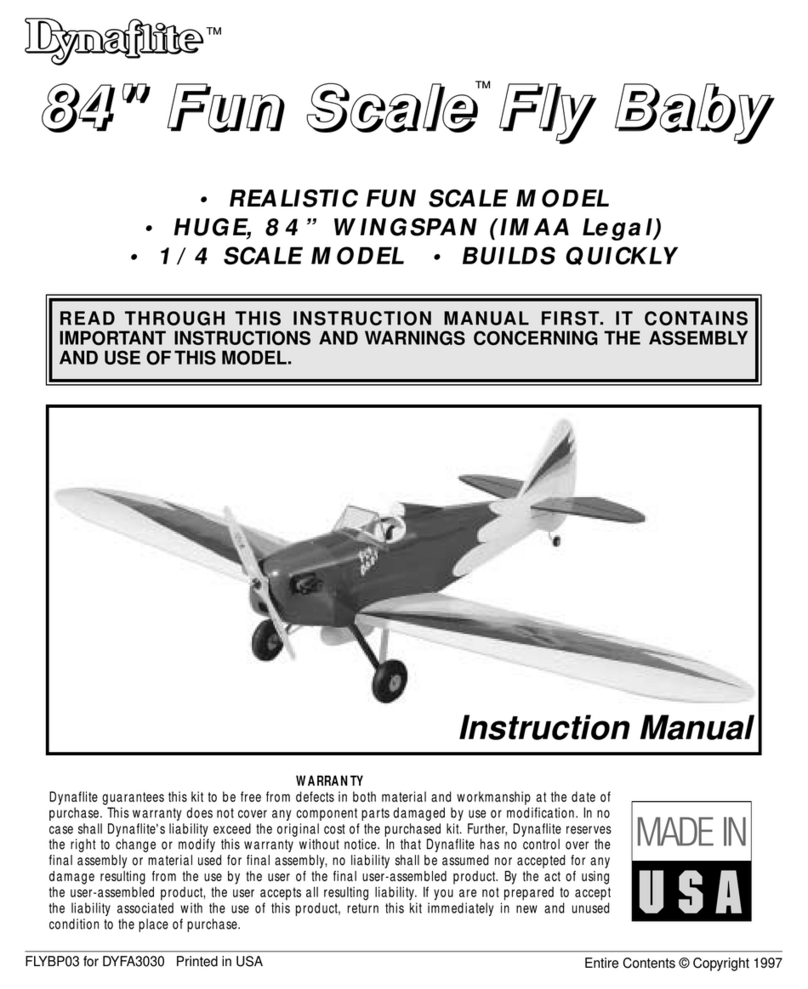

Congratulations onyourchoiceofthis kitfor your

next project.The Fairchild PT-19 isa FunScale®

modelof a true classic aircraft and has thepresence

thatonlya bigmodelcan carry off.

At Dynaflitewe take prideinoffering kitsthat are

simple and straight forward tobuild and provide

value for yourmodelingdollar.Because of the size

and cost of thismodel we assume you have built

severalmodelsandhavea generalworking

knowledgeof modelingand itsterms. Ifyou HAVE

NOTbuiltand flown several kits, doyourself a favor

andgetsomeexperiencebefore beginningthis kit.

Your PT-19 isnota toy,buta sophisticated working

modelthat functionslikea full-size airplane.Because

of its performance,if you do not assembleand

operatethePT-19 correctly,youcouldpossiblyinjure

yourselfor spectatorsanddamageproperty.

Tomake your R/C modeling experience totally

enjoyable,we recommendthatyougetassistance

withassemblyand your firstflightsfroman

experienced,knowledgeablemodeler.You'll learn

faster and avoid risk toyour modelbefore you're

trulyready to solo.Your local hobby shop has

information about flying clubs inyour area whose

membershipincludesqualifiedinstructors.

Youcan also contact thenationalAcademy of Model

Aeronautics (AMA), which has more than 2,300

chartered clubs across thecountry. We recommend

you join the AMA which will provide you with

insurance coverage at AMAclub sites and events.

AMA Membership isrequired at charteredclub

fields where qualified flight instructors are available.

Contact theAMAat theaddress ortoll-free phone

numberbelow.

Academy of ModelAeronautics

5151 East MemorialDrive

Muncie,IN47302

(800)435-9262

Fax(765)741-0057

2